Bearing type precise ball cambered surface envelope worm wheel spoke

A technology of worm gears and bearings, applied in gear transmissions, portable lifting devices, belts/chains/gears, etc., can solve the problems of easy wear and unsuitability of heavy-duty meshing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

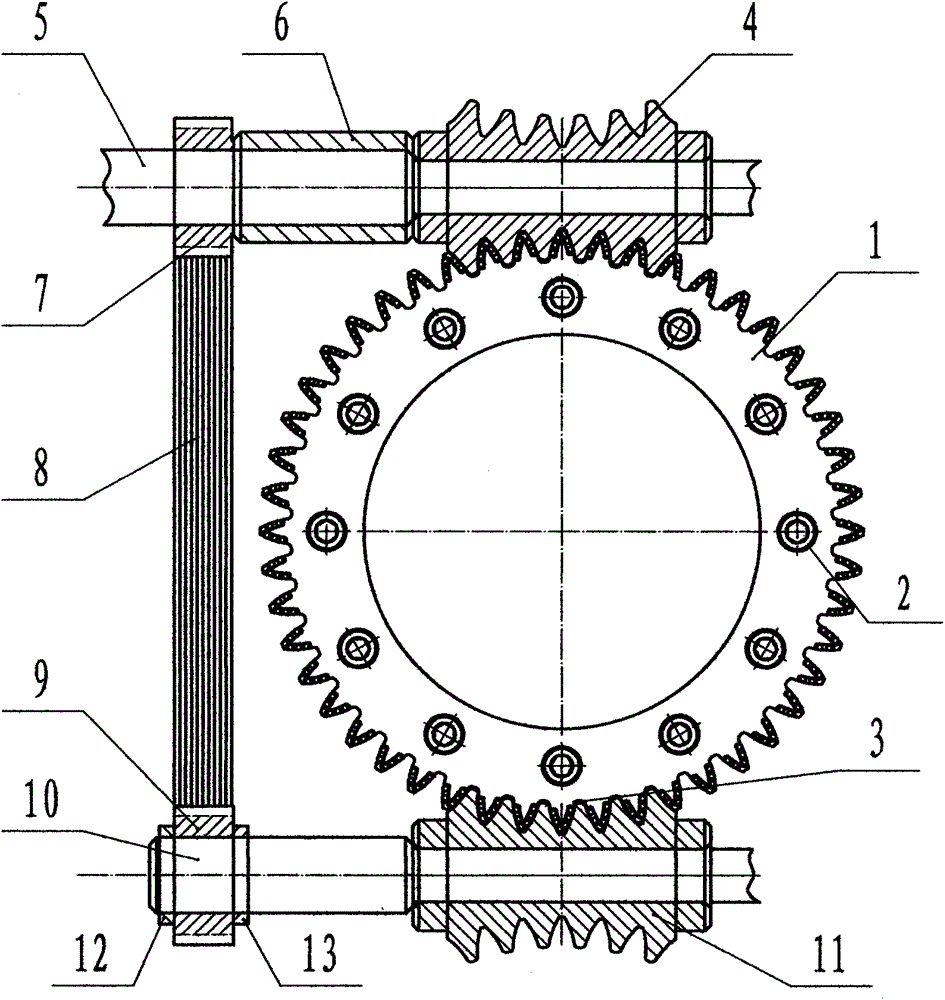

[0007] 1. Combine figure 1 Implementation: The bearing-type worm gear 1 is tightly positioned through the uniformly distributed screw holes 2 on the circumference of the worm gear and the required workbench set screws, and the bearing-type worm gear 1 is meshed with the arc-enveloping worm 4 and 11 without backlash 3 to ensure the transmission accuracy. The power shaft 5 passes through the adjustment sleeve and is bonded with the arc-enveloping worm 4, and the two worms of the arc-enveloping worm 4 and 11 are supported by the required housing. The synchronous pulley 7 is installed on the power shaft 5 and the power is transmitted to The synchronous pulley 9 on the shaft 10 ensures synchronous rotation through the adjustment mechanism to drive the arc surface enveloping worm 11, circular locking rings 12, 13 to adjust and lock the pulley 9 on the shaft 10;

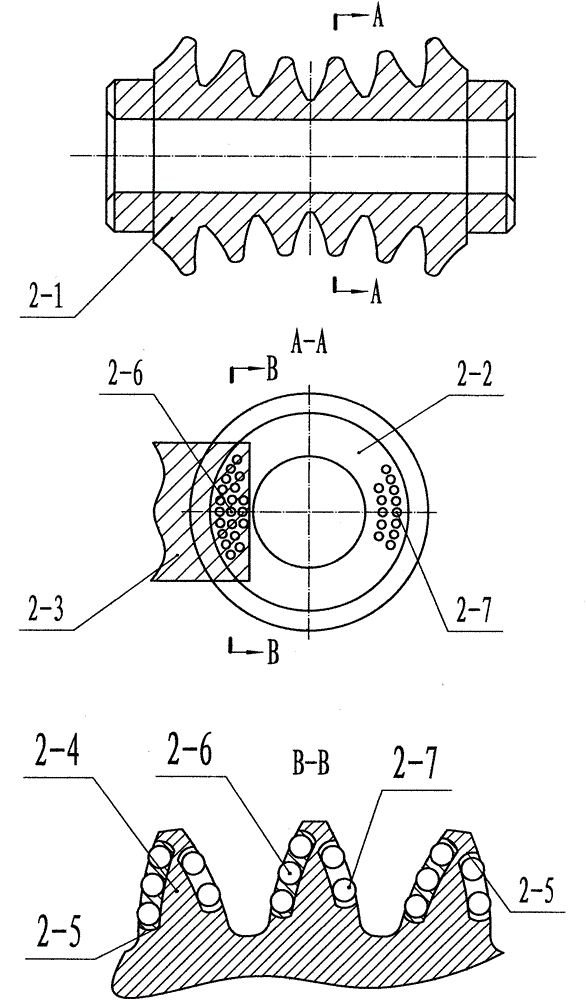

[0008] 2. Combine figure 2 Implementation: Replace expensive copper with steel for the worm gear without affecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com