Modular industrial equipment facility

a technology for industrial equipment and modular buildings, applied in industrial buildings, special buildings, parkings, etc., can solve the problems of inability to meet the needs of certain applications, inability to meet the needs of industrial equipment, and inability to include adequate backup systems or system redundancies,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

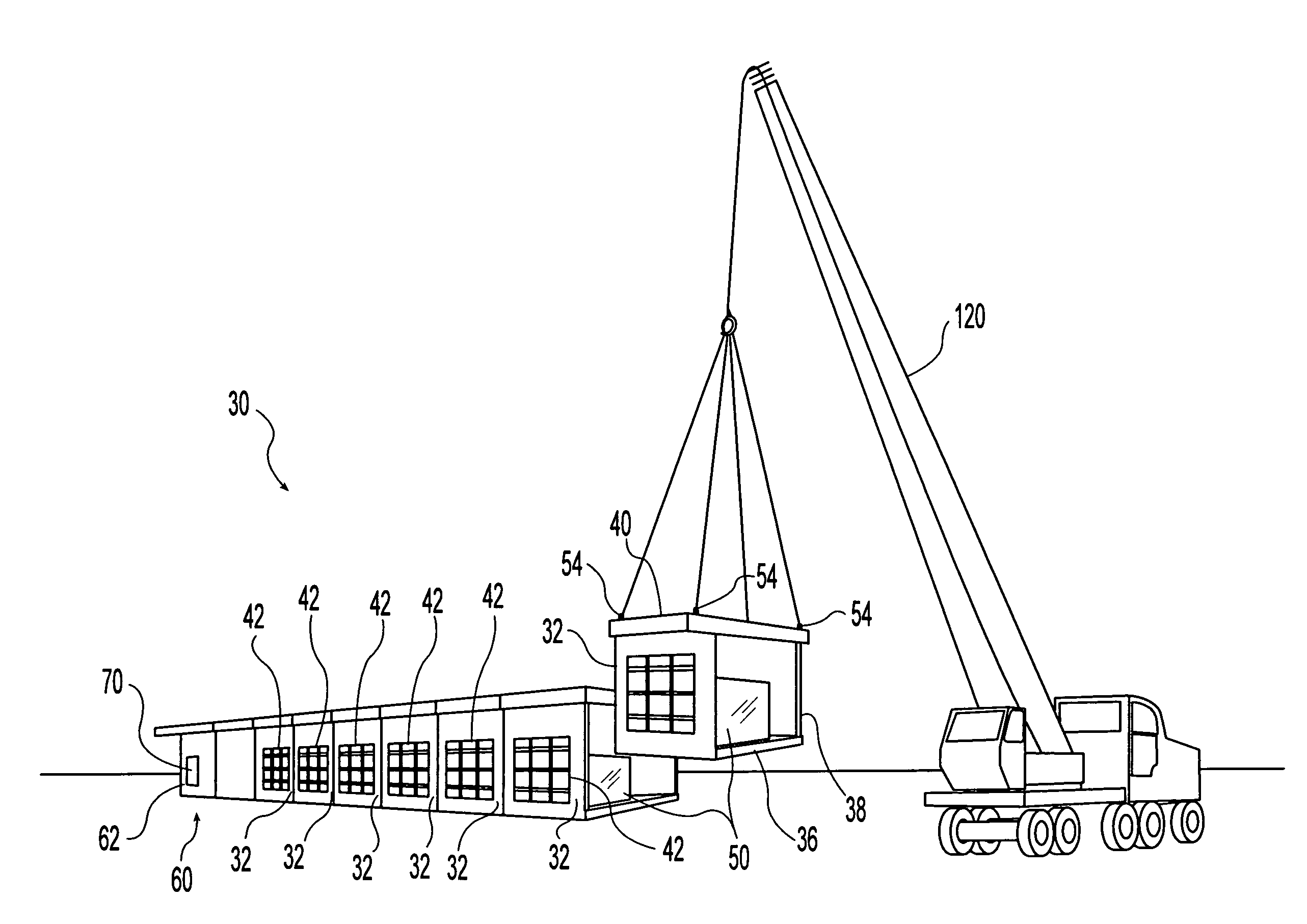

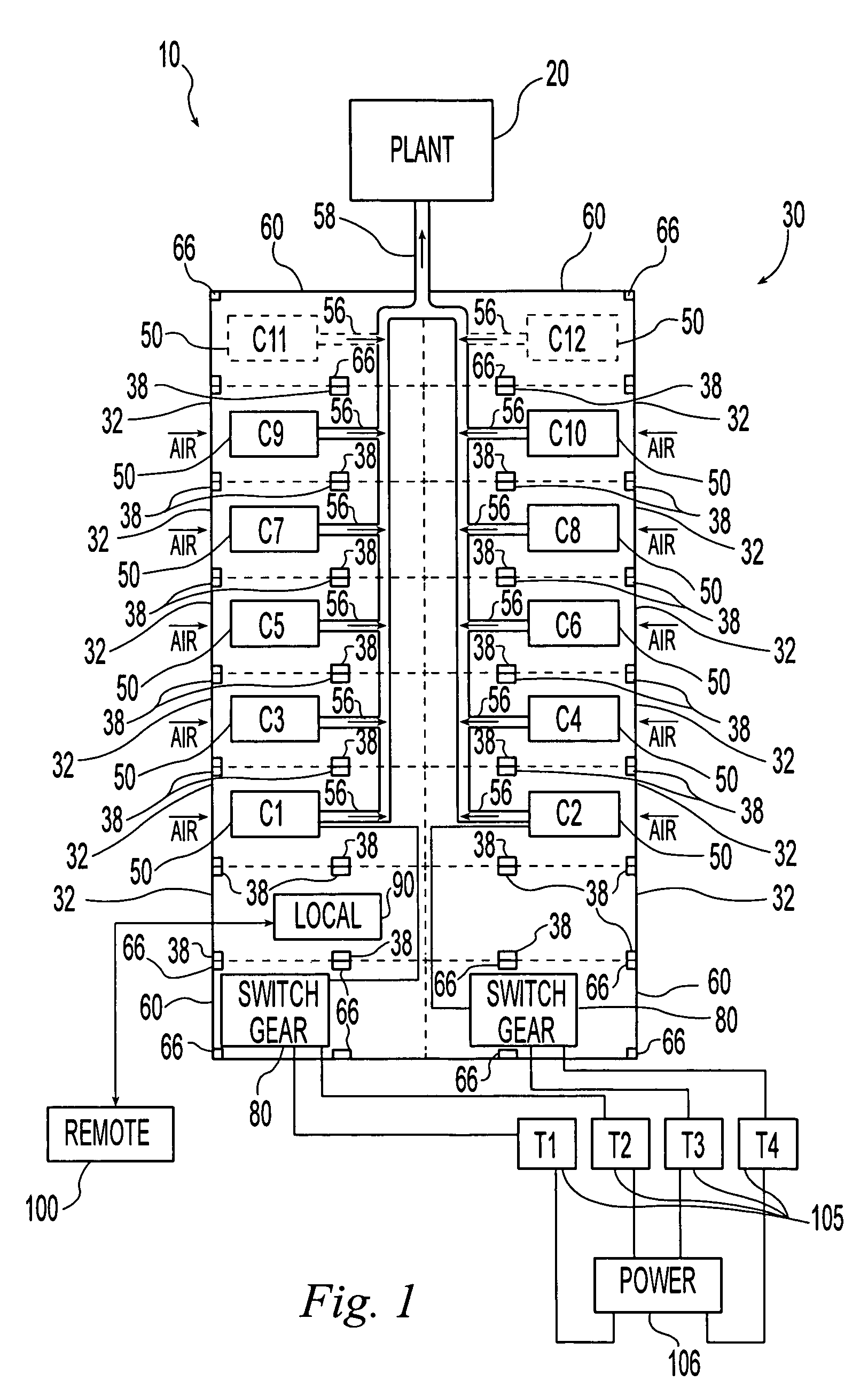

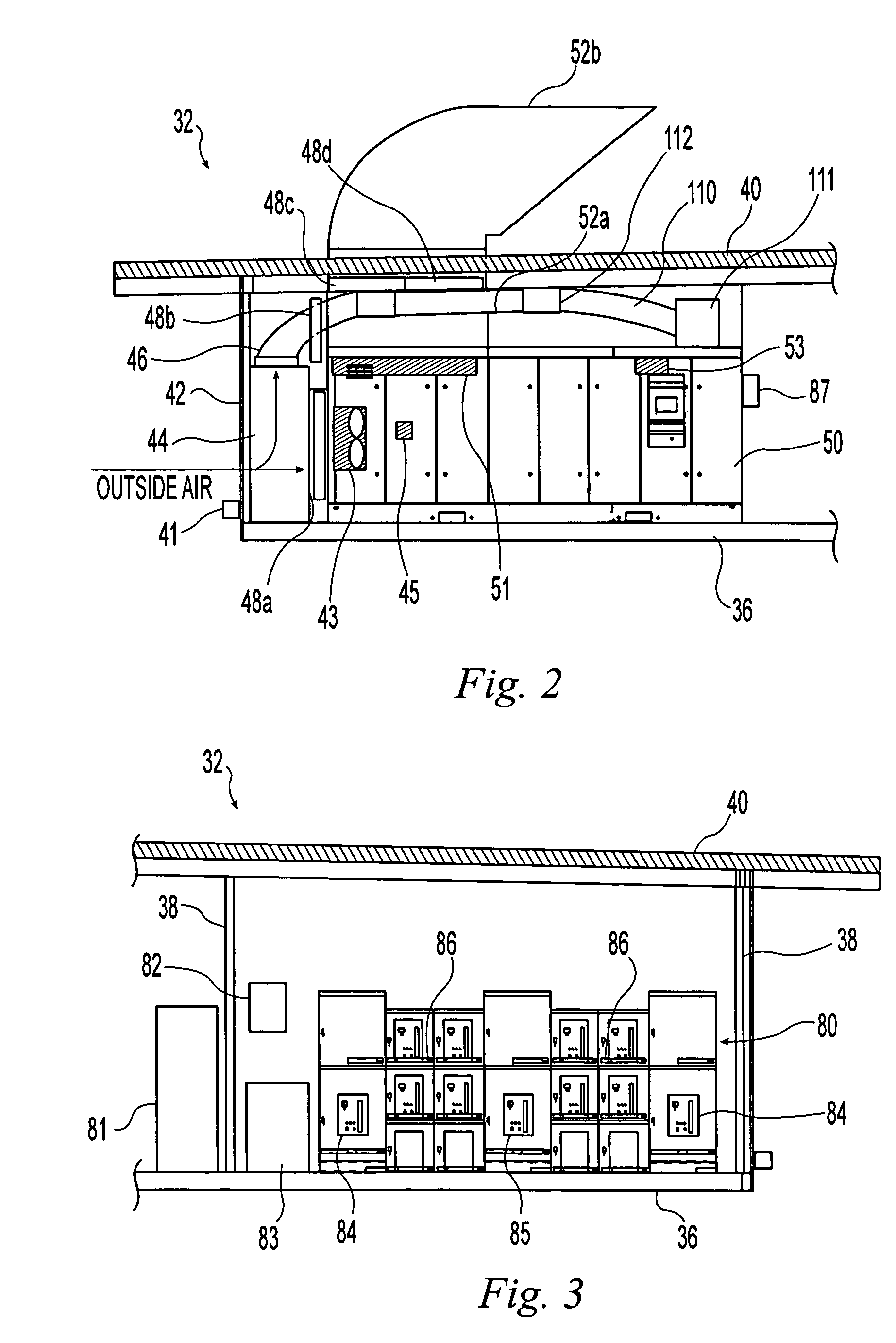

[0017] This invention relates to a reconfigurable modular industrial equipment facility for use with a factory, manufacturing plant or other industrial system or operation. An exemplary embodiment of this facility includes a plurality of pre-fabricated, portable equipment modules that are typically transported to and arranged at a predetermined location. These equipment modules further include: a plurality of internal equipment modules (i.e., for placement on the interior or middle portion of the structure), wherein each internal module is configured to operate independently of or in combination with the other internal modules in the event of a partial system failure; and a plurality of terminal modules (i.e., for placement on the end portions of the structure) for use in combination with the plurality of internal modules. When final construction / assembly of the facility of the present invention is complete, the internal modules and terminal modules form a single, integrated structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com