Environment-friendly engine

An environment-friendly engine technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of environment-friendly engine vibration, increase the burden of arrangement, shorten the reaction distance, etc., to achieve efficient power improvement and easy installation , the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

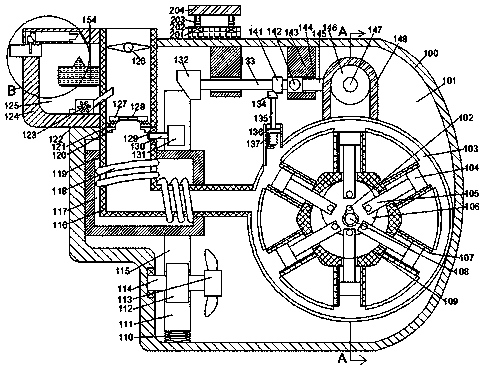

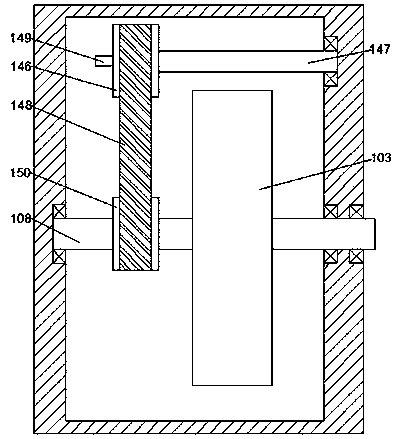

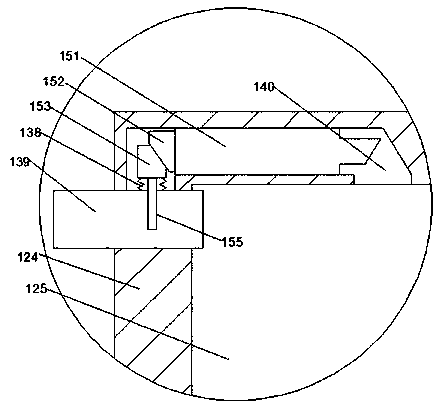

[0016] Such as Figure 1-Figure 3 As shown, the environment-friendly engine of the present invention includes a fuselage 100 and a first cavity 101 arranged in the fuselage 100, the inner wall of the right end of the first cavity 101 is fixedly connected with a circular cylinder 103, and the circular cylinder 103 The inner circumference of the cylinder 103 is provided with equidistantly distributed piston chambers 107, the piston chamber 107 is slidably connected with a piston 108, and the near center end of the piston 108 is fixedly connected with a piston push rod 105, and the piston push rod 105, The circular cylinder 103 is provided with an internal tooth chamber 109 located at the center of the circle, and the internal tooth chamber 109 is rotatably connected with an output shaft 108 extending forward and backward. 103 rear end of the first sprocket 150, the output shaft 108 is sleeved with a disc 106, the disc 106 is fixedly connected with a first fixed tip 102 located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com