Grate tooth sealing structure

A technology of grate tooth and tooth cavity, which is applied in the field of grate tooth sealing structure, to achieve the effect of increasing energy dissipation, reducing fluid leakage and avoiding large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the implementation purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments of the present application will be described in more detail below with reference to the accompanying drawings in the embodiments of the present application.

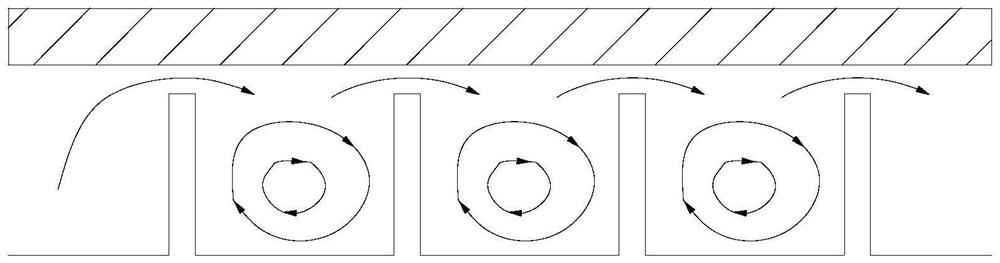

[0031] Under normal circumstances, the gap control of the grate seal structure is difficult. The reason is that vibration, deformation, wear, yaw and other reasons make it difficult to maintain the grate seal gap at a small value. The gap between the receivers will not be too small, and when the gap is large, it will cause a large amount of cold air leakage.

[0032] In order to overcome the above problems, the present application proposes a grate sealing structure that can reduce gas leakage in the sealing flow path and no longer pursue a small sealing gap.

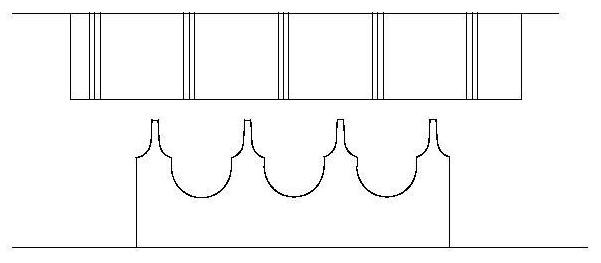

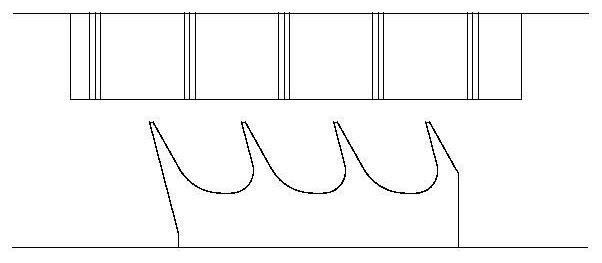

[0033] like image 3 and Figure 4 As shown, the grate sealing structure provided by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com