Planar valve capable of achieving natural ventilation of door lintel and reducing opening and closing force

A technology of opening and closing force and lintel, applied in climate change adaptation, ship lifting device, ship lock, etc., can solve problems affecting the safe operation of ship locks, increase valve opening and closing force, length of opening and closing rod, etc., and achieve energy saving and reduction Small opening and closing force, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

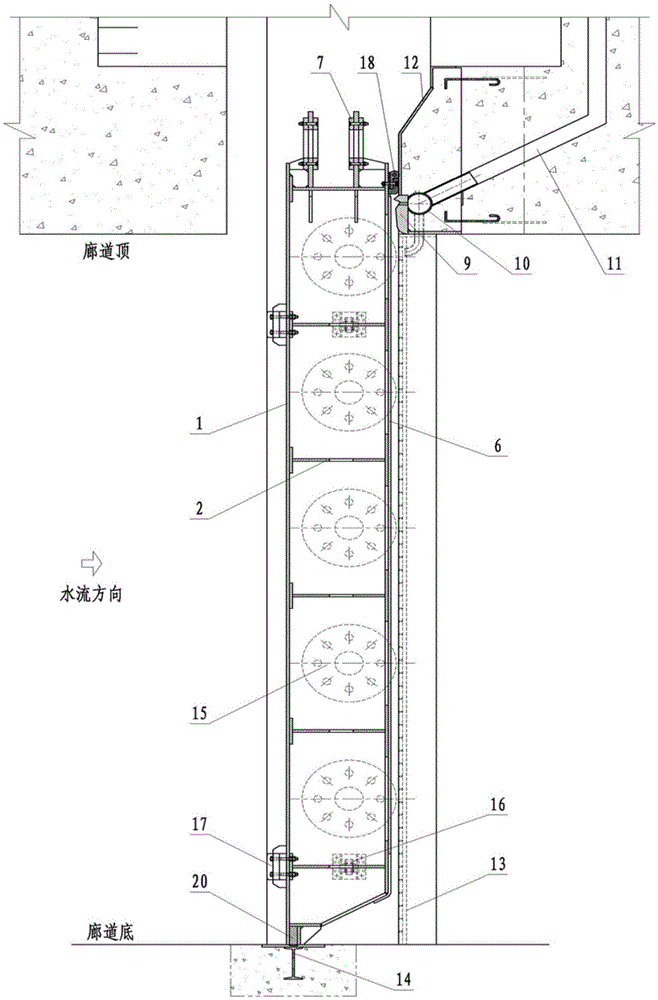

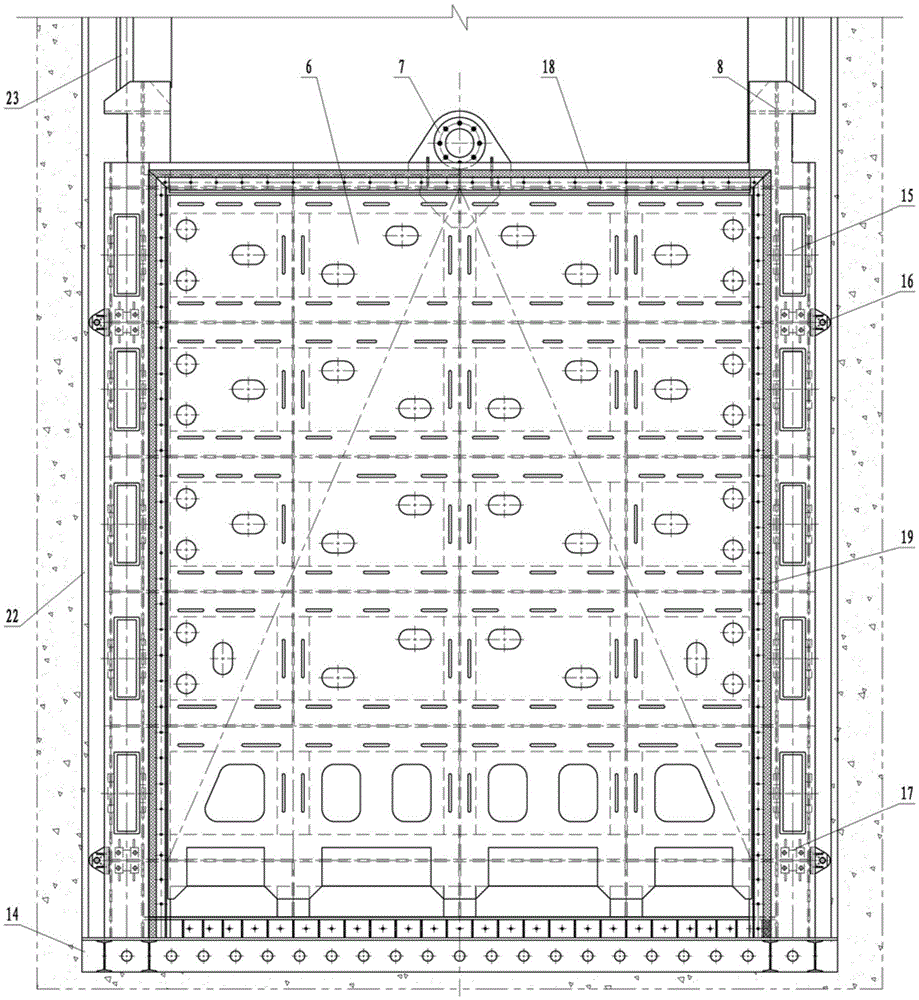

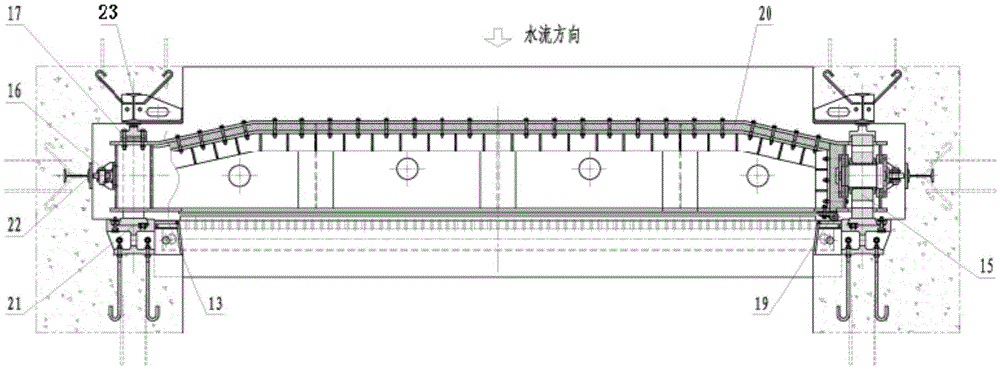

[0023] figure 1 It is a schematic diagram of a vertical cross-sectional structure of a valve according to an embodiment of the present invention, figure 2 It is a schematic diagram of the back structure of the valve according to an embodiment of the present invention, image 3 It is a schematic view of the structure of the valve looking up from the bottom according to an embodiment of the present invention, Figure 7 It is a large sample diagram of the door body and ventilation device described in an embodiment of the present invention.

[0024] Such as Figure 1-Figure 3 Shown: a planar valve that can make the door lintel ventilate naturally and reduce the opening and closing force, including the door body structure, door lintel and embedded system, water stop system, support and limit system and track system. The door body structure includes Panel 1, main girder 2, diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com