Forming method of tin alloy electroplating bath liquid and preparation method of soldering tin salient point plating

A technology of electroplating baths and tin alloys, applied in coatings, electrolytic coatings, etc., can solve problems such as void effects, achieve the effects of ensuring deposition, improving reliability and service life, and inhibiting the formation of intermetallic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

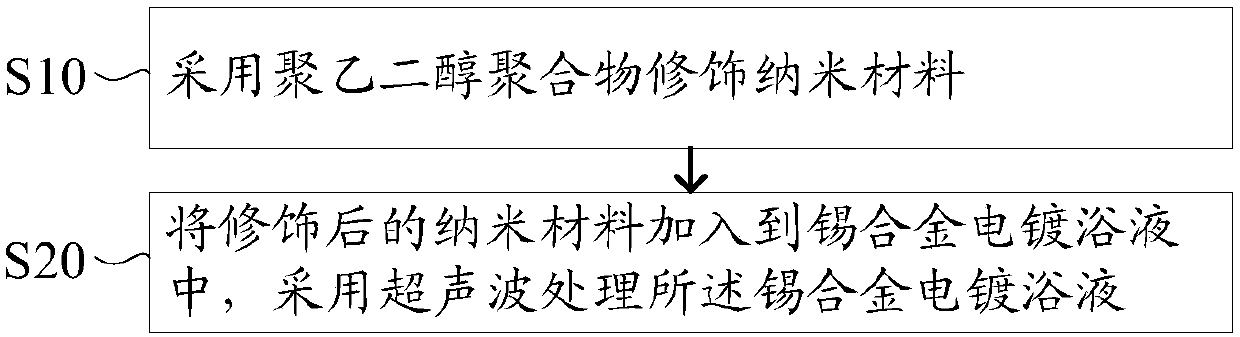

Method used

Image

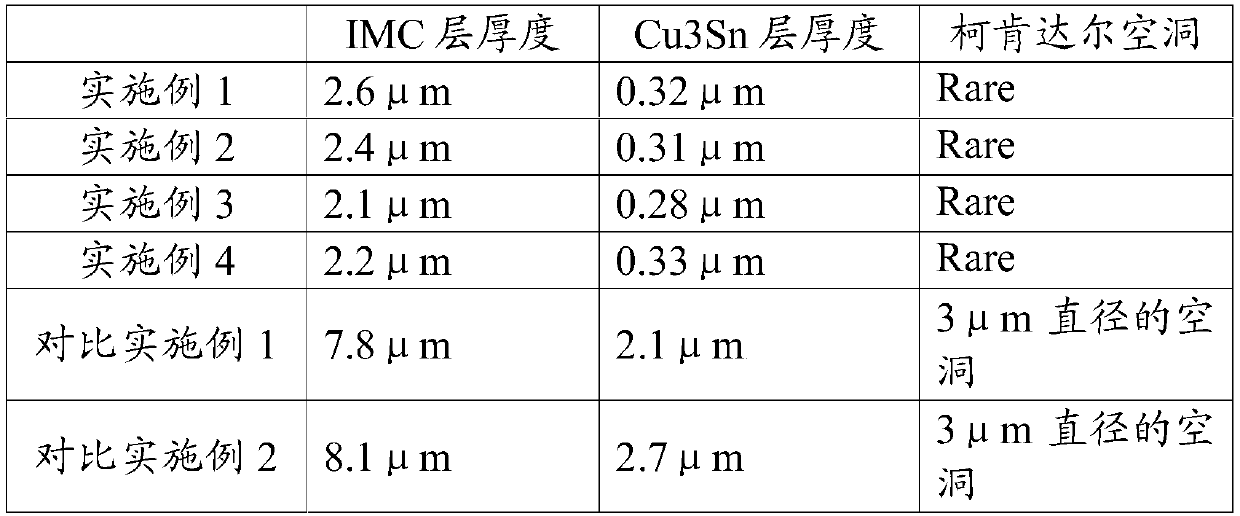

Examples

Embodiment 1

[0027] Step S1: Surface modification (modification) of nano-diamonds (particles) with a particle size of 10nm using mPEG with a molecular weight of 2000, the mixture can be stirred slightly at room temperature for 3 hours, and then use an ultrafiltration centrifuge tube with a molecular weight cut-off (MWCO) of 3000 Centrifuge to remove unmodified mPEG, that is, remove residual or redundant polyethylene glycol polymers to obtain polyethylene glycol polymer modified nano-diamonds (particles), and then add methanesulfonic acid system tin-silver-copper electroplating bath Among them, the tin alloy electroplating bath can be tin-silver-copper electroplating bath, and the specific metal components can be based on product needs;

[0028] Step S2: The tin alloy electroplating bath composition that adopts comprises methanesulfonic acid 120g / L, tin methanesulfonate 20g / L, silver methanesulfonate 0.3g / L, copper methanesulfonate 0.3g / L, The concentration of electroplating additives is 8m...

Embodiment 2

[0034] Step S1: surface-modify single-layer graphene (particles) with a diameter of 0.5 μm to 5 μm and a thickness of 0.8-1.2 nm using mPEG-COOH with a molecular weight of 1000. MWCO) 2000 ultrafiltration centrifuge tube is centrifuged to remove unmodified mPEG-COOH to obtain nano-graphene modified by polyethylene glycol polymer, and then add methanesulfonic acid system tin-silver-copper electroplating bath;

[0035]Step S2: The tin alloy electroplating bath composition that adopts comprises methanesulfonic acid 120g / L, tin methanesulfonate 20g / L, silver methanesulfonate 0.3g / L, copper methanesulfonate 0.3g / L, The concentration of electroplating additives is 8ml / L for the opener, 30ml / L for the silver complexing agent, and 30ml / L for the lightening agent;

[0036] Step S3: Make the concentration of the modified nano-graphene in the formed electroplating bath solution be 0.01wt%;

[0037] Step S4: The prepared composite tin alloy electroplating bath solution is subjected to ul...

Embodiment 3

[0041] Step S1: modify the nano-silver particles with a particle size of 10-20nm to have a diameter of 0.5μm-5μm and a thickness of 5nm-25nm. Materials, the mixture can be stirred slightly at room temperature for 3 hours, and then centrifuged with an ultrafiltration centrifuge tube with a molecular weight cut-off (MWCO) of 3000 to remove unmodified mPEG-COOH to obtain modified nanoparticles modified with polyethylene glycol polymers. The composite material of graphene is then added in the tin-silver-copper electroplating bath of methanesulfonic acid system;

[0042] Step S2: The tin alloy electroplating bath composition that adopts comprises methanesulfonic acid 120g / L, tin methanesulfonate 20g / L, silver methanesulfonate 0.3g / L, copper methanesulfonate 0.3g / L, The concentration of electroplating additives is 8ml / L for the opener, 30ml / L for the silver complexing agent, and 30ml / L for the lightening agent;

[0043] Step S3: Make the concentration of nano-silver modified graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com