Broken line inlet type hole plug energy dissipater

A technology of energy dissipation and hole plug, which is applied in sea area engineering, water conservancy engineering, coastline protection, etc. It can solve the problems of large construction work volume, hole plug damage, and low pressure, and achieve good anti-cavitation performance and energy dissipation effect Good, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

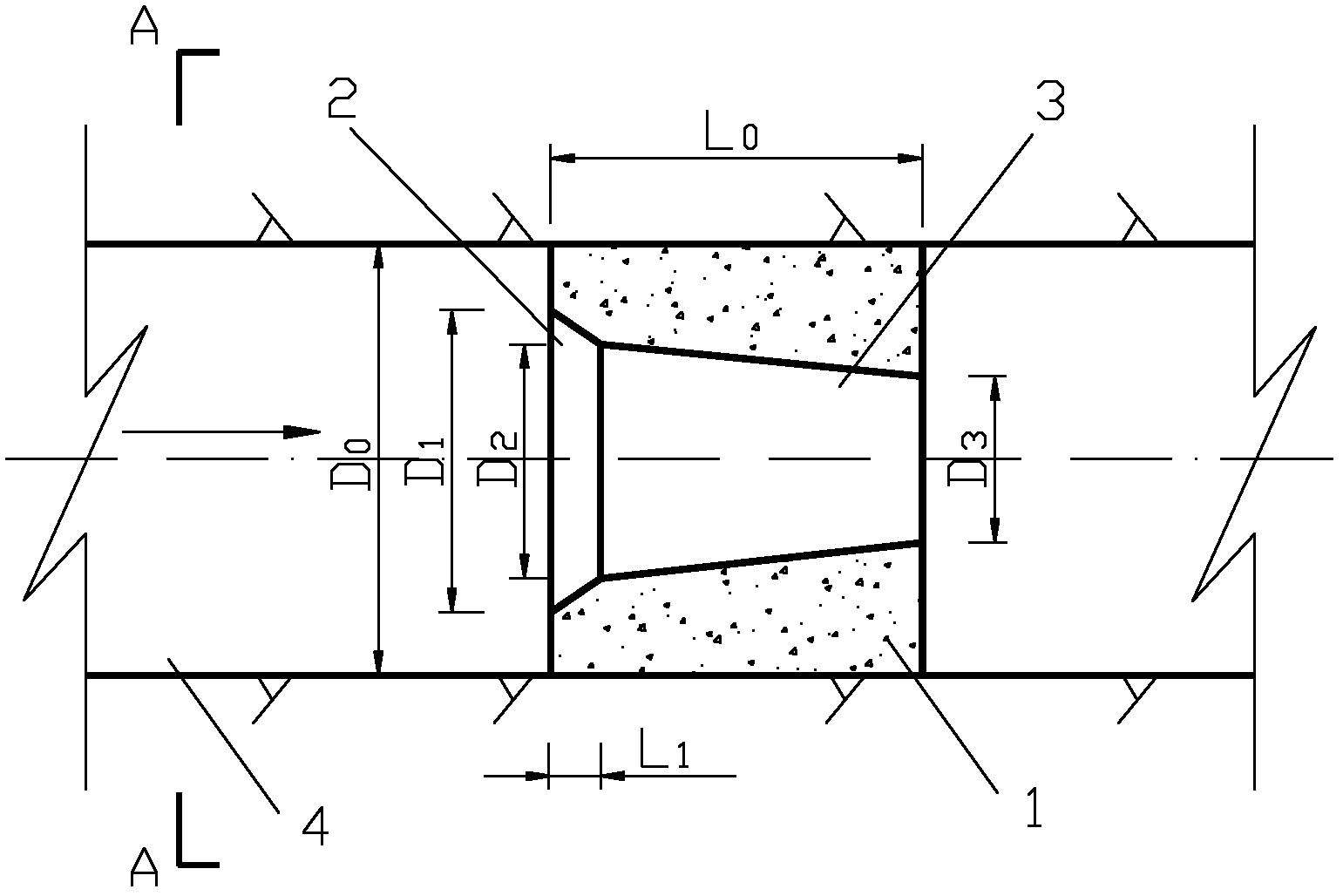

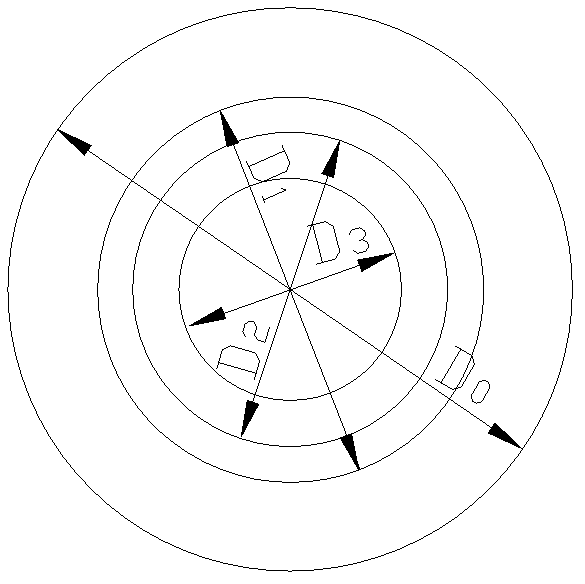

[0021] In this embodiment, the structure of the broken line inlet type hole plug energy dissipator is as follows: figure 1 , figure 2 As shown, it consists of the hole plug base body 1 and the flow holes set in the hole plug body. The flow holes are connected by two constricted truncated conical holes whose front ends are larger than the rear ends and have different tapers. The outlet of the frusto-conical hole 2 is the inlet of the following converging frusto-conical hole 3 .

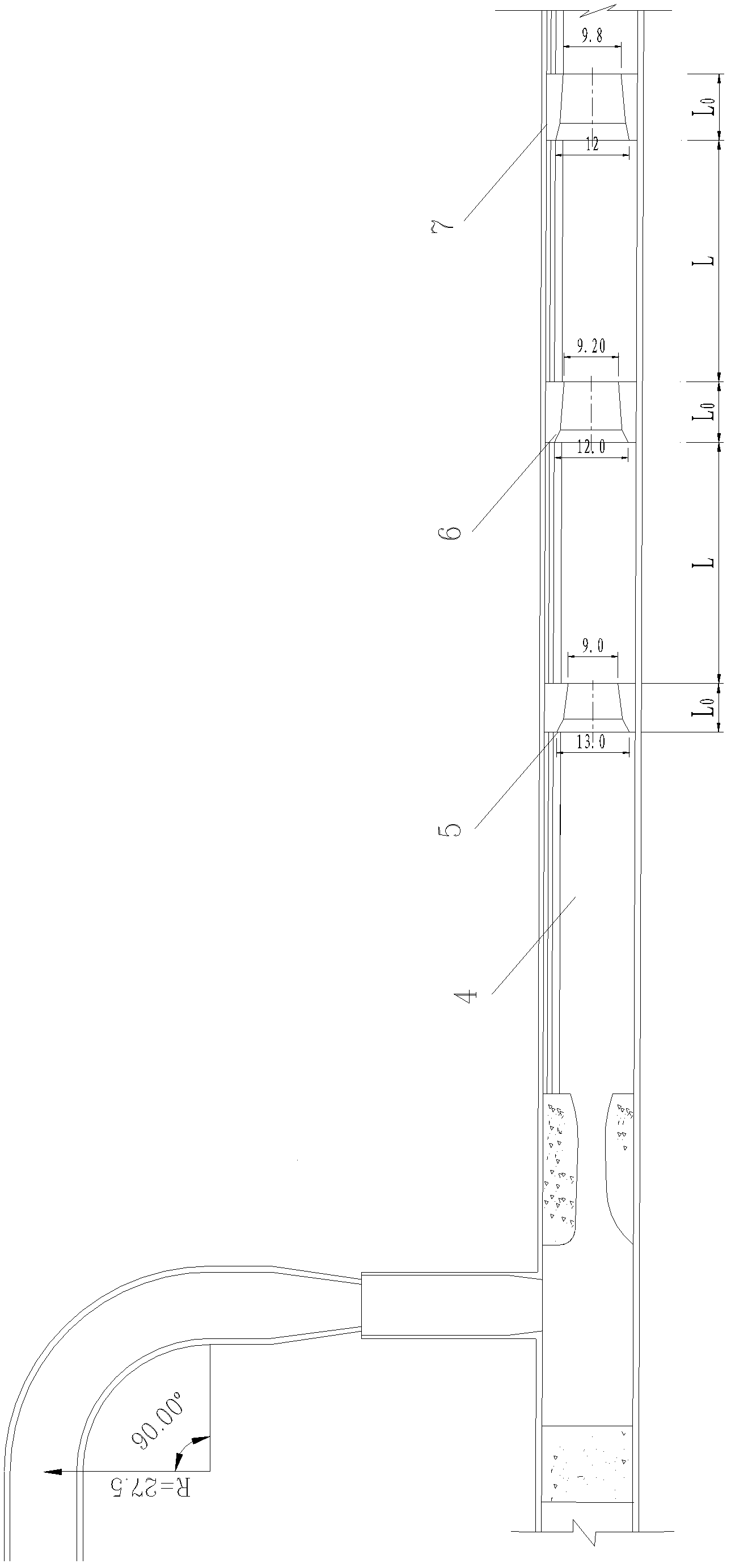

[0022] The folding line inlet type hole plug energy dissipator described in this embodiment is used for the hole diameter D 0 = 15m spillway tunnel energy dissipation, the relevant dimensions are as follows: the total length L of the hole plug 0 =0.73D 0 = 11m, the length L of the front constricted frustoconical hole 1 =0.27L 0 = 3m, the inlet diameter D of the front constricted frustoconical hole 1 =0.87D 0 = 13m, the outlet diameter D of the front constricted frustoconical hole 2 = Inlet dia...

Embodiment 2

[0025] In this embodiment, the structure of the broken line inlet type hole plug energy dissipator is as follows: figure 1 , figure 2 As shown, it consists of the hole plug base body 1 and the flow holes set in the hole plug body. The flow holes are connected by two constricted truncated conical holes whose front ends are larger than the rear ends and have different tapers. The outlet of the frusto-conical hole 2 is the inlet of the following converging frusto-conical hole 3 .

[0026] The folding line inlet type hole plug energy dissipator described in this embodiment is used for the hole diameter D 0 = 15m spillway tunnel energy dissipation, the relevant dimensions are as follows: the total length L of the hole plug 0 =0.666D 0 = 10m, the length L of the preceding constricted frustoconical hole 1 =0.25L 0 = 2.5m, the inlet diameter D of the front constricted frustoconical hole 1 =0.8D 0 = 12m, the outlet diameter D of the front constricted frustoconical hole 2 = Inl...

Embodiment 3

[0029] In this embodiment, the structure of the broken line inlet type hole plug energy dissipator is as follows: figure 1 , figure 2 As shown, it consists of the hole plug base body 1 and the flow holes set in the hole plug body. The flow holes are connected by two constricted truncated conical holes whose front ends are larger than the rear ends and have different tapers. The outlet of the frusto-conical hole 2 is the inlet of the following converging frusto-conical hole 3 .

[0030] The folding line inlet type hole plug energy dissipator described in this embodiment is used for the hole diameter D 0 = 15m spillway tunnel energy dissipation, the relevant dimensions are as follows: the total length L of the hole plug 0 =0.73D 0 = 11m, the length L of the front constricted frustoconical hole 1 =0.18L 0 = 2m, the inlet diameter D of the front constricted frustoconical hole 1 =0.8D 0 = 12m, the outlet diameter D of the front constricted frustoconical hole 2 = Inlet diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inlet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com