Cavitation prevention slurry pump

A slurry pump and anti-cavitation technology, which is applied in the direction of pumps, pump components, non-displacement pumps, etc., can solve problems such as dynamic balance damage, life of flow-passing parts that cannot meet the use requirements, and product competitiveness decline, etc., to achieve easy The effect of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

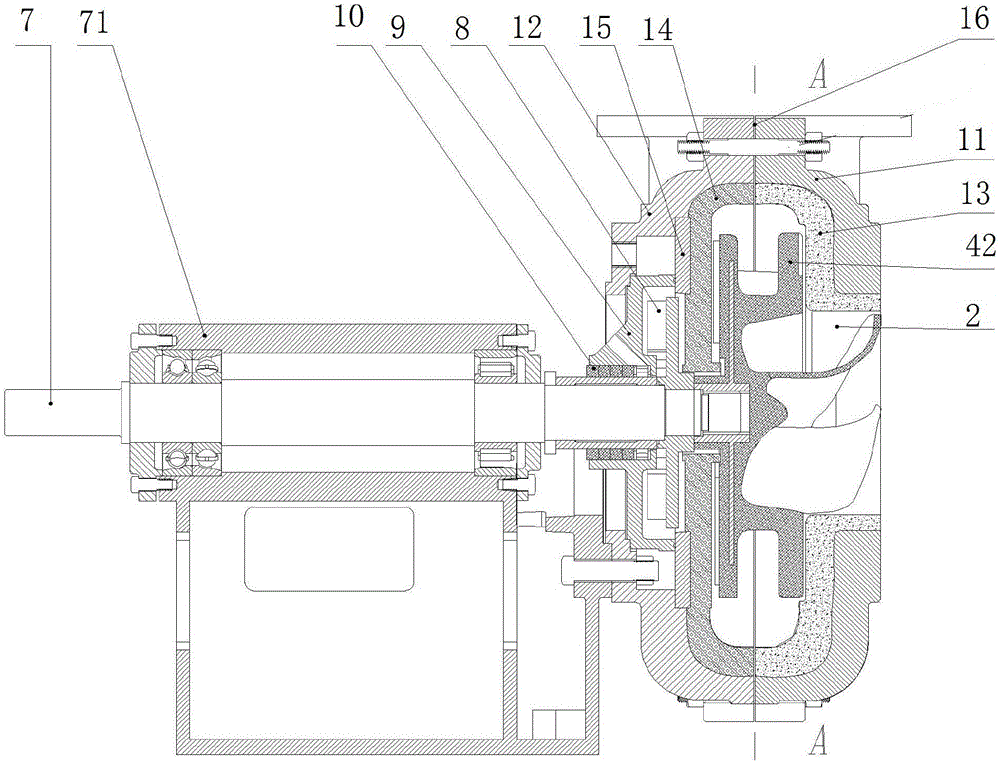

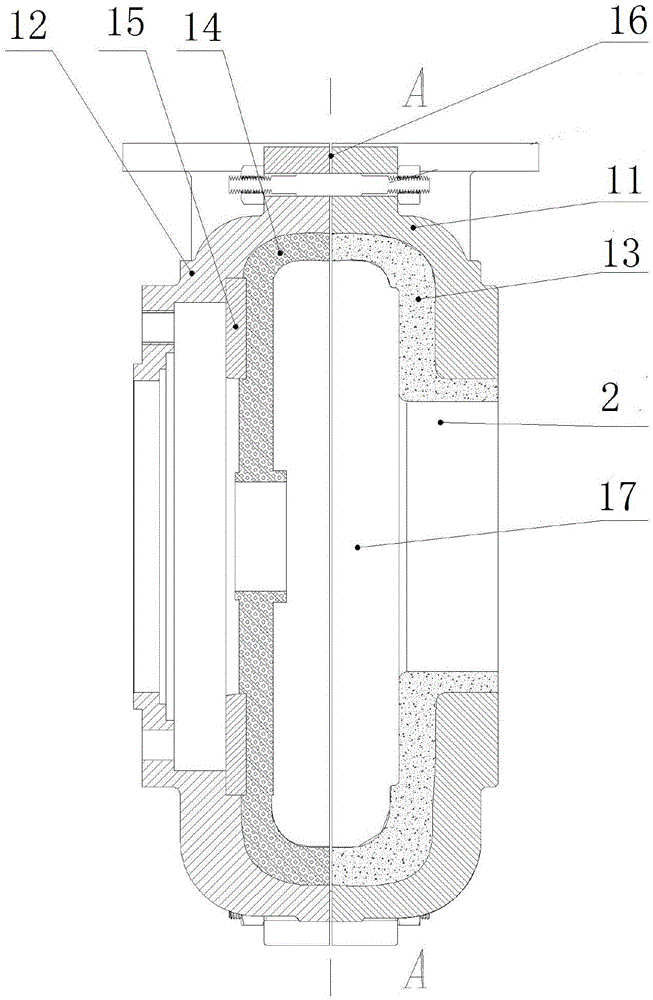

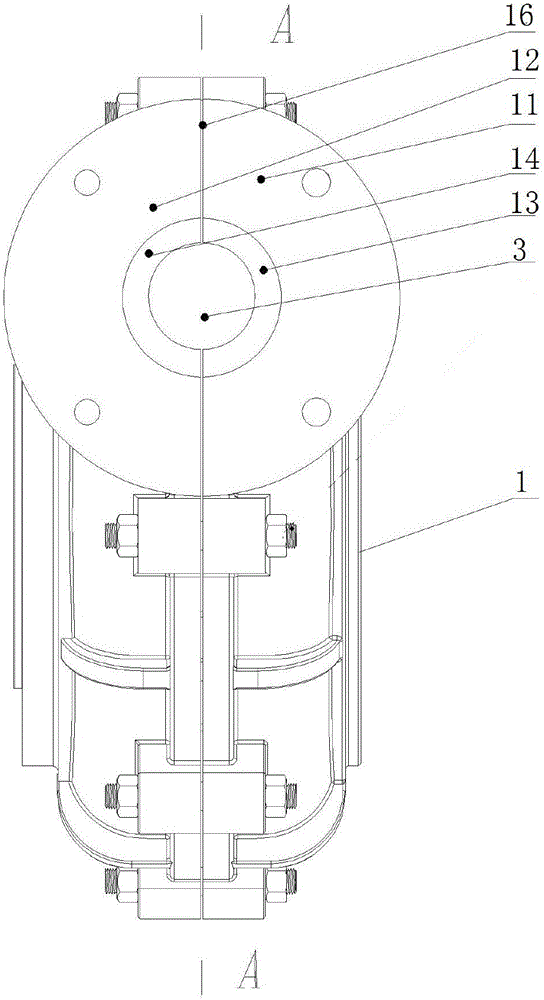

[0037] like Figure 1-6 as well as Figure 11 As shown, an anti-cavitation slurry pump includes a pump body 1, the pump body 1 is provided with a suction port 2 and a discharge port 3, and the pump body 1 is provided with an impeller 4, and the impeller 4 is provided with a centrifugal main blade 5 and an axial flow induction blade 6, the induction blade 6 extends to the position of the suction inlet 2, and the main blade 5 and the induction blade 6 are connected. Preferably, both the induction blade 6 and the main blade 5 are 4 pieces, of course, in the production application, 3 or 5 pieces of the induction blade 6 and the main blade 5 can also be provided respectively according to the production situation.

[0038] In practical applications, the centrifugal main blade 5 and the axial flow induction blade 6 can effectively increase the NPSH of the pump, or reduce the intensity of cavitation.

[0039]In order to further increase the NPSH of the pump, the cross-sectional area...

Embodiment 2

[0049] Such as Figure 7-10 as well as Figure 12 As shown, it is substantially the same as Embodiment 1, the difference is that the impeller 4 is a semi-open impeller, the impeller 4 includes a rear cover 41, the main blade 5 is arranged on the rear cover 41 and It is connected to the induction vane 6 through a smooth transition zone 51 .

[0050] The main blade 5 is a mixed flow blade, and the induced blade 6 is an axial flow blade.

[0051] The diameter of the suction port 2 is 300 mm, the diameter of the discharge port 3 is 150 mm, and the cross-sectional area of the suction port 2 is four times the cross-sectional area of the discharge port 3 .

[0052] The main components of the composite wear-resistant material are 82% (weight) of aluminum oxide and 15% (weight) of vinyl resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com