Large submersible electric pump

A submersible electric pump, a large-scale technology, applied in the direction of pumps, pump devices, electromechanical devices, etc., can solve the problems of increasing diffusion loss, reducing air gap, crowding flow channels, etc., to improve anti-cavitation performance, increase power factor, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The primary task of the invention is to effectively control and reduce the temperature rise of the motor and the rotating parts of the supporting bearings during the working process.

[0019] The structure of the motor part is firstly described in detail below:

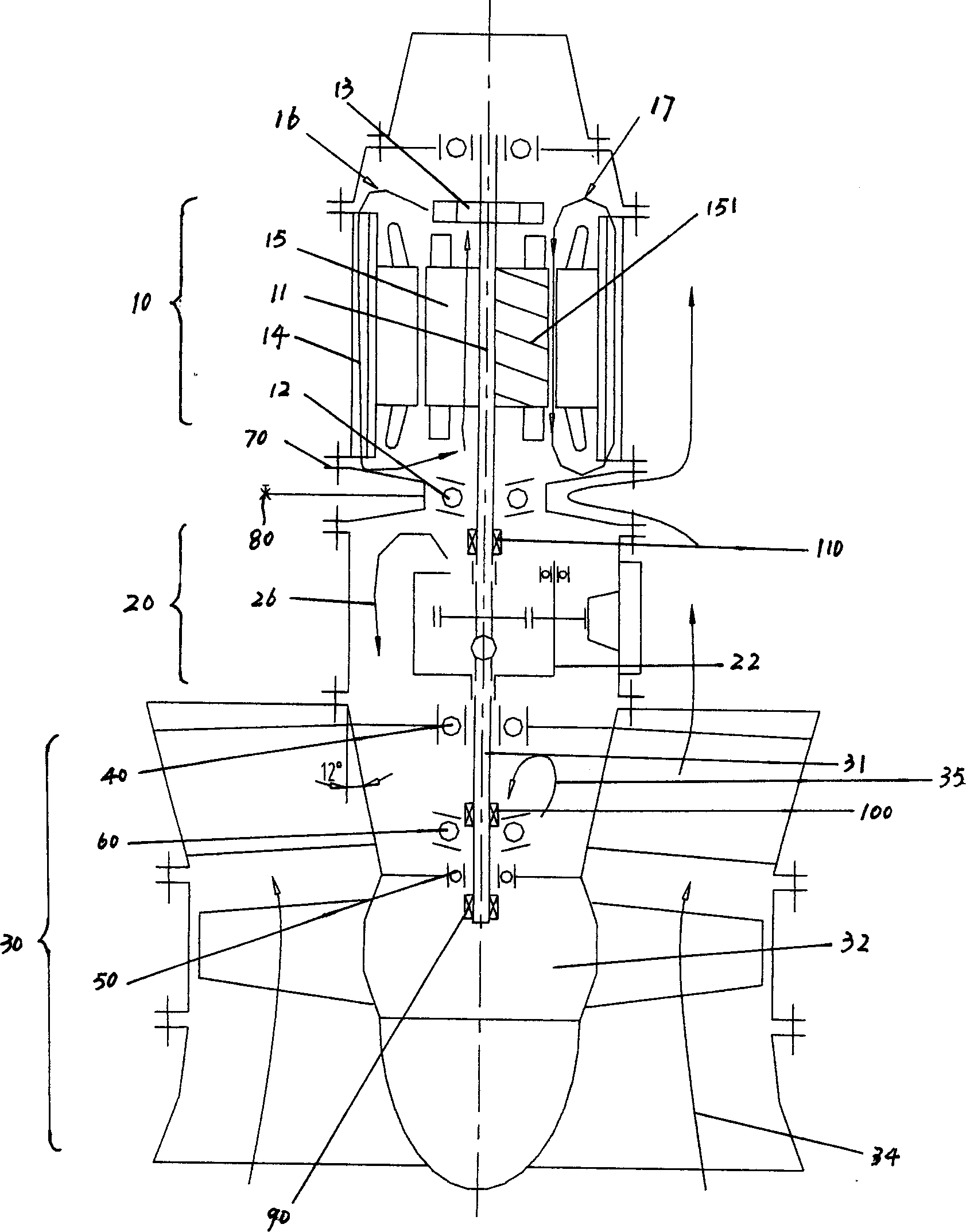

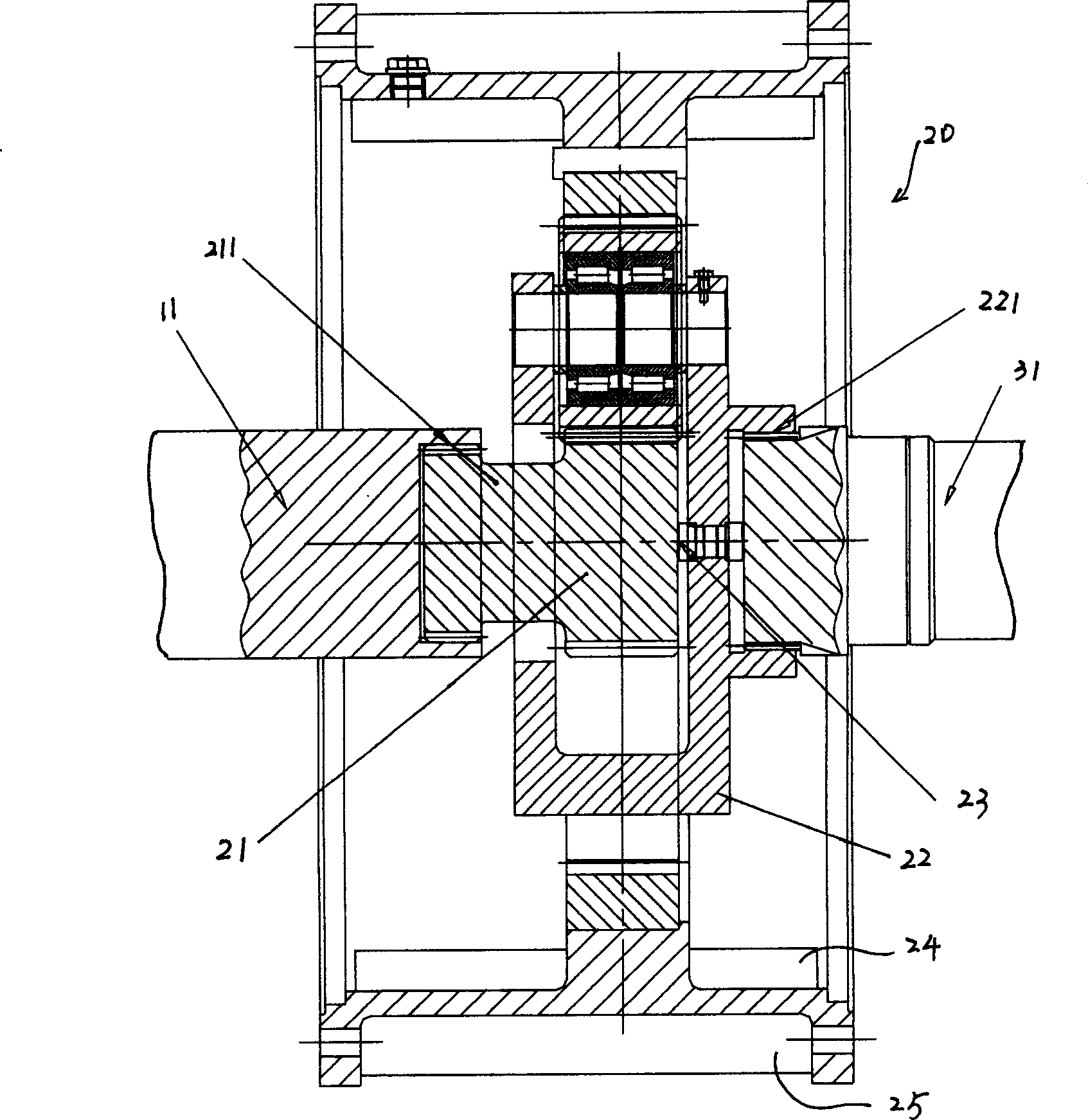

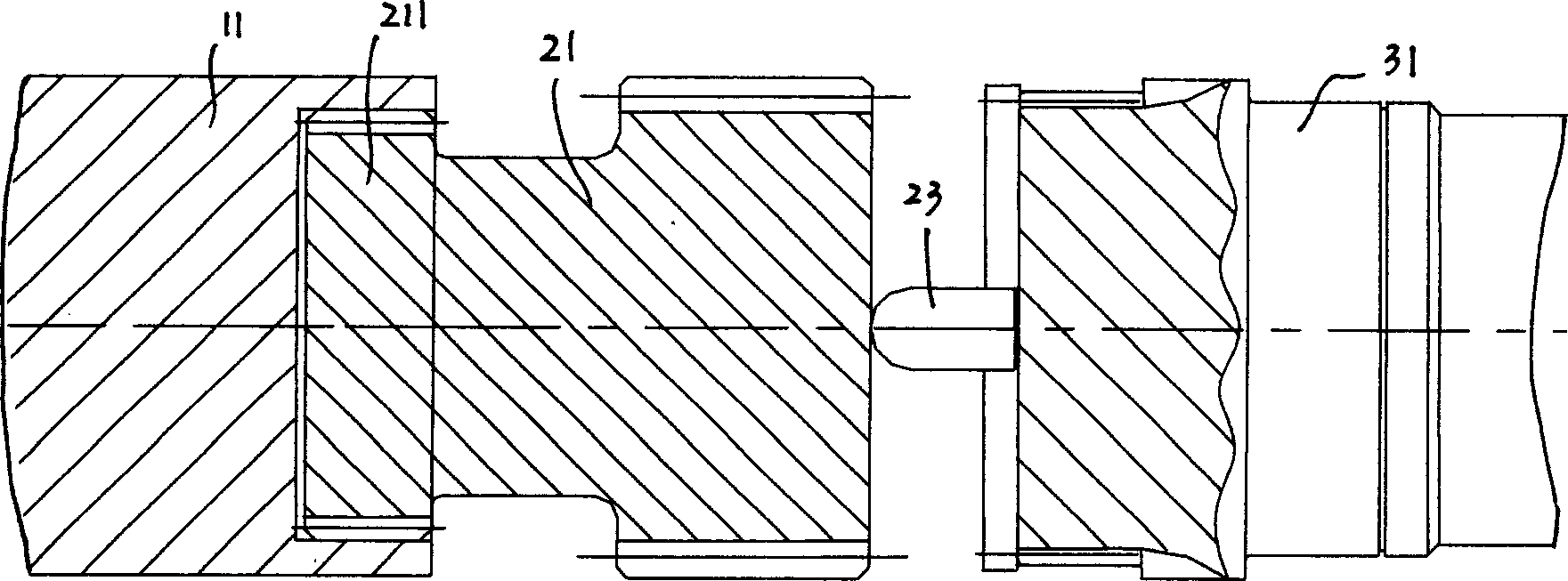

[0020] see figure 1 , the inside of the motor 10 is provided with a centrifugal fan 13 to adopt an air cooling cycle formed by forced air cooling, such as figure 1 The direction indicated by the arrow 16 in the figure forms an air-water cooling system with the water cooler 14 provided on the casing of the motor 10, which can effectively reduce the temperature rise of the stator; a spiral groove 151 is arranged on the surface of the rotor 15, and the A groove 151 with a large pitch is formed on the surface of 15, and its function is similar to that of a spiral fan. The pitch of the groove 151 is 0.1 to 0.2 times the diameter of the motor rotor 15. In order to increase its ventilation capacity, a rectangular thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com