Port plate for plunger pump

A plunger pump and flow plate technology, which is applied in the field of hydraulic plunger pump flow plate, can solve the problems of unfavorable vibration and noise reduction, unfavorable pump vibration and noise reduction, small vortex group pressure, etc., to achieve small vibration and enhanced rigidity , the effect of uniform gradient of pressure and velocity changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

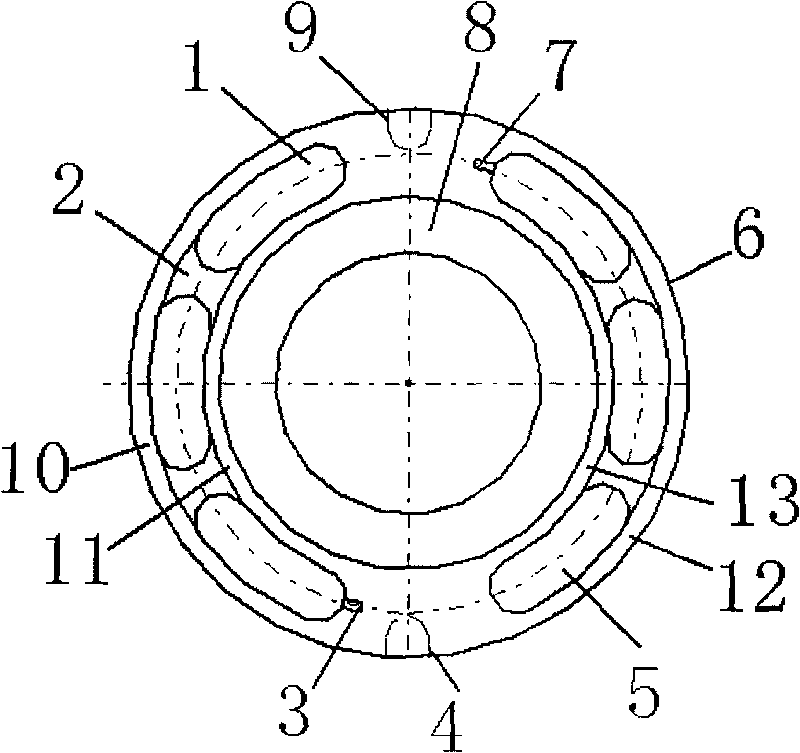

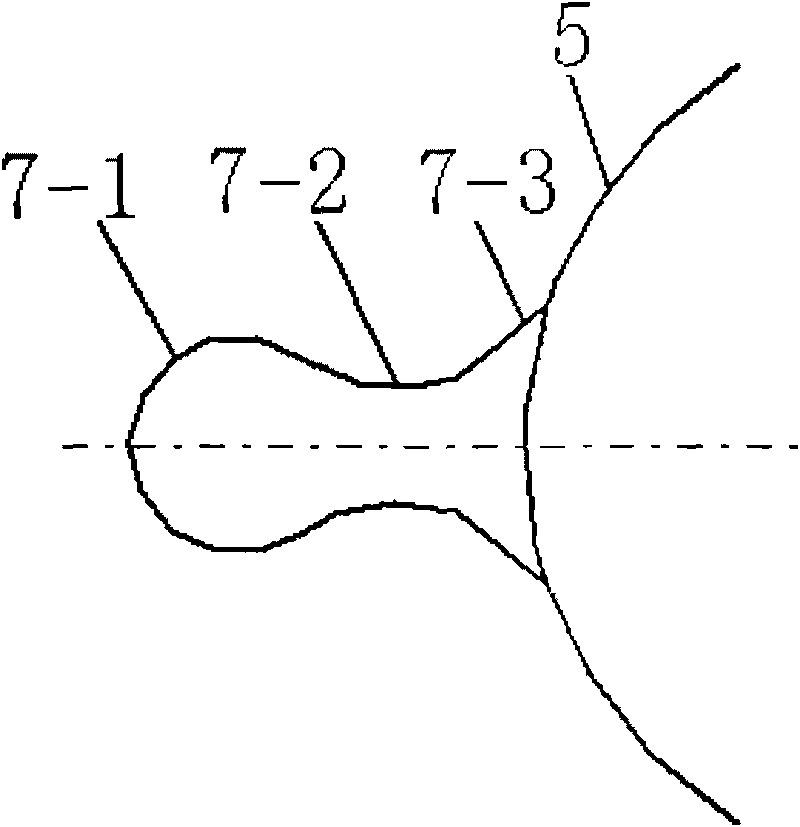

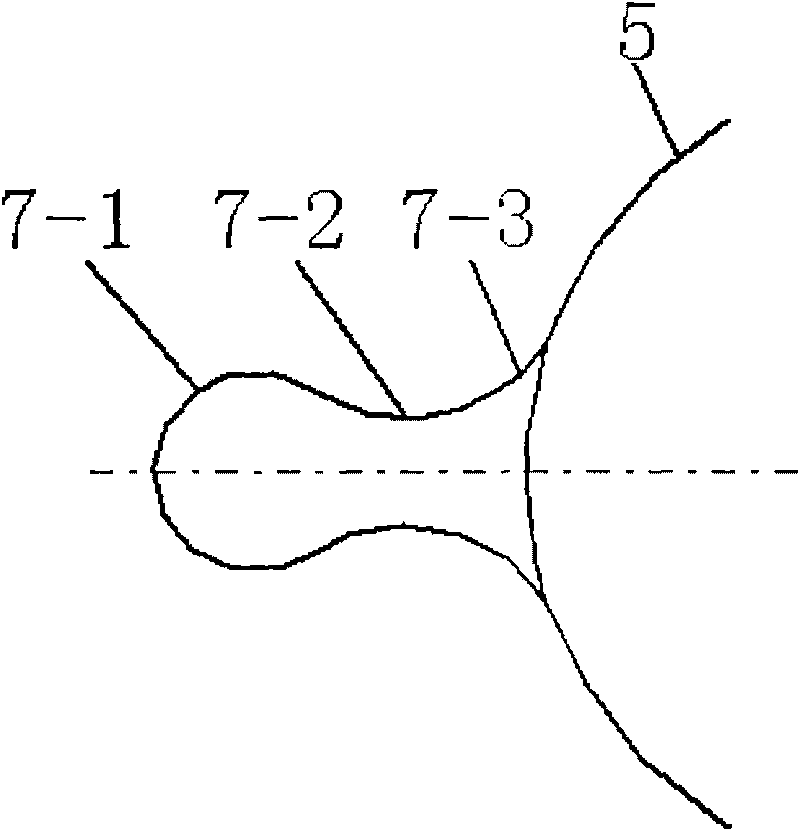

[0021] like figure 1 As shown, in an embodiment of the present invention, the shape of the distribution plate base 6 is circular, and the center of the circular ring is a through hole. The flow groove 8 has a waist-shaped groove 1 in a low-pressure area and a waist-shaped groove 5 in a high-pressure area on the outer ring. The waist-shaped groove 1 in the low-pressure area and the waist-shaped groove 5 in the high-pressure area are isolated from each other and symmetrical with respect to the horizontal axis. The suction port of the plunger pump is connected to the high-pressure area of the outlet of the plunger pump, and the inner and outer parts of the waist-shaped groove 1 in the low-pressure area on the outer ring form an inner sealing zone 11 in the low-pressure area and an outer sealing belt 10 in the low-pressure area; The inner and outer parts of the waist-shaped groove 5 respectively form a sealing belt 13 in the high-pressure area and an outer sealing belt 12 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com