Air turbine pump with pre-pressing pump

A technology of air turbine and pre-pressure pump, which is applied to components, pumps, and pump devices of elastic fluid pumping devices, and can solve problems such as complex system structure, working system efficiency, and use, and save driving motors or The structure of the air turbine system, the effect of low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

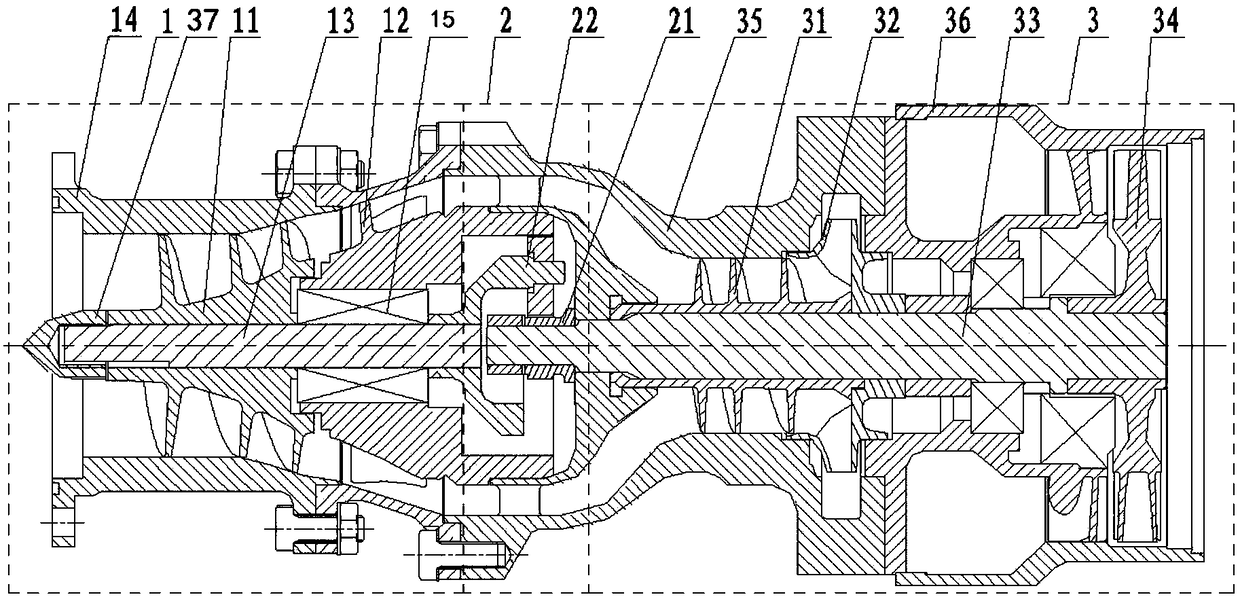

[0021] Such as figure 1 As shown, the present invention provides an air turbopump with high anti-cavitation performance and wide working range, which can be used in fuel supply systems with strict requirements on anti-cavitation performance, especially in the field of aerospace propulsion. 1. The reducer 2 is composed of the main pump 3, and the pre-pressure pump 1 and the main pump 3 are respectively installed on both sides of the reducer 2.

[0022] The pre-compression pump 1 includes a front housing 14, a pre-compression impeller 11, a guide vane 12 and a pre-compression pump shaft 13, the pre-compression impeller 11 is installed on the pre-compression pump shaft 13, and is arranged in the front housing 14, the guide vane 12 It is arranged on the rear side of the pre-compression impeller 11 and installed on the pre-compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com