Hydraulic pressure servo valve

A servo valve and water pressure technology, which is applied in the direction of servo motor components, fluid pressure actuators, circuit components, etc., can solve the problems of not many hydraulic servo valves, no practical effect of servo valves, and poor control characteristics of servo valves. Achieve the effects of suppressing cavitation, small zero drift, and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

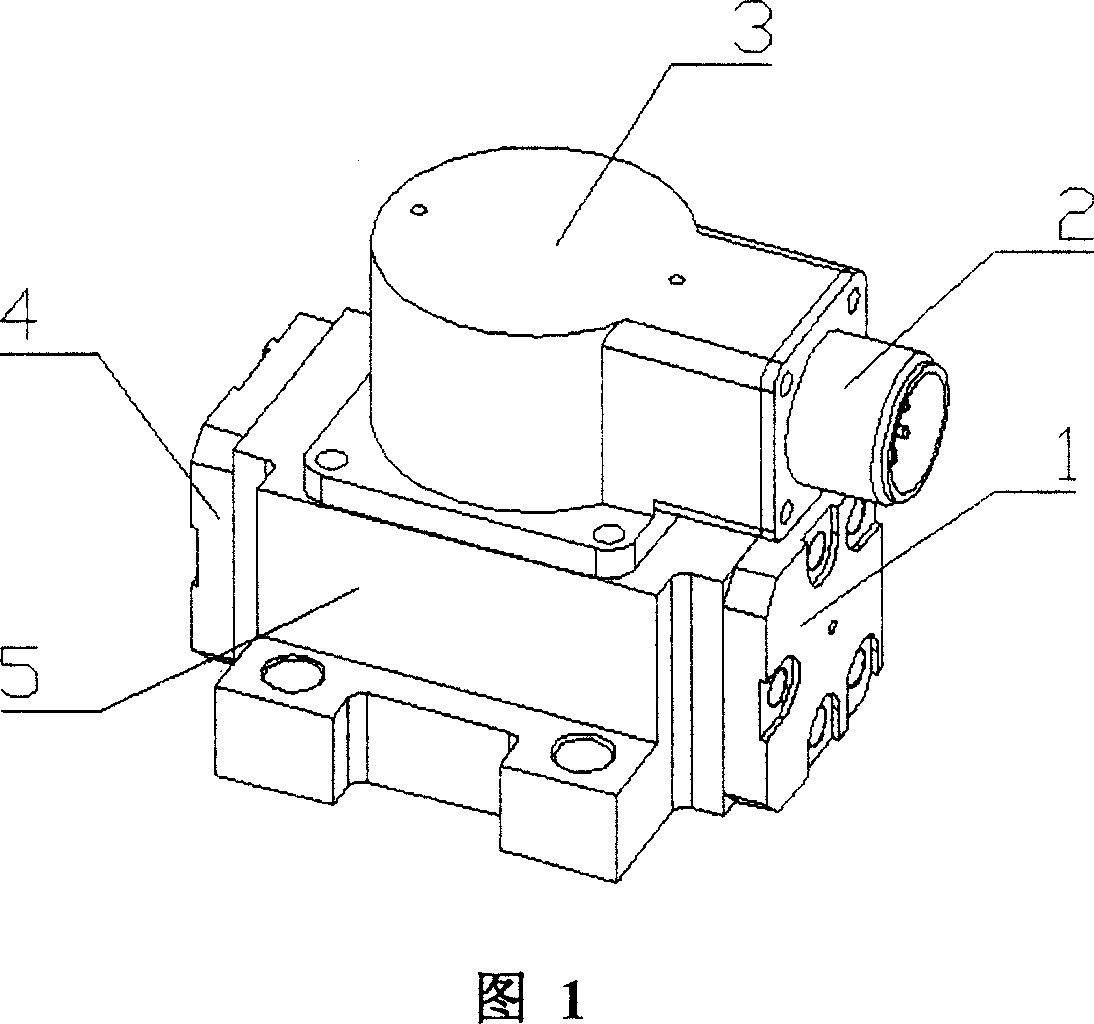

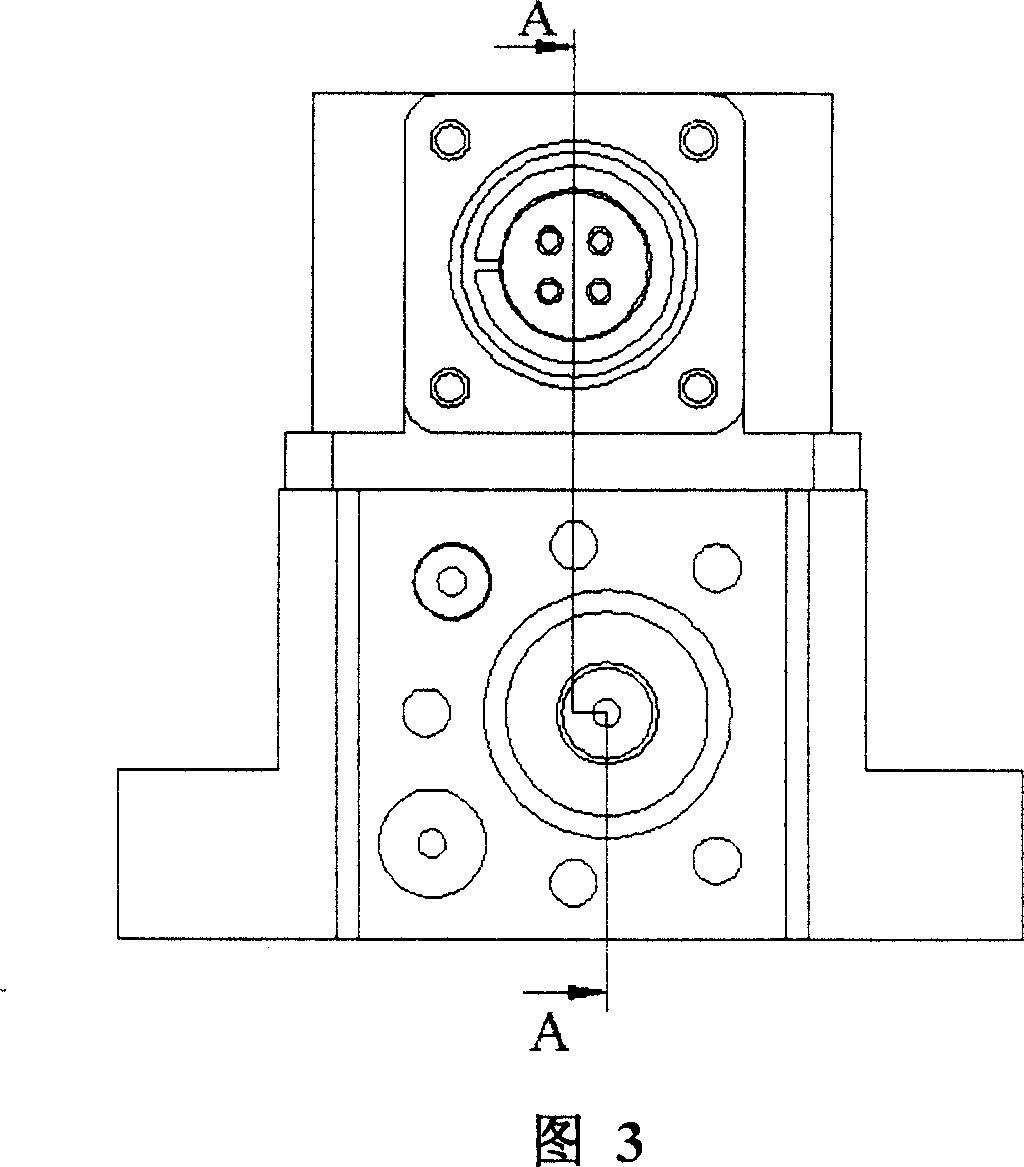

[0030] The present invention is composed of a permanent magnet torque motor, a pre-amplification part and a slide valve power part, and Fig. 1 shows a power line connector 2, a coil casing 3 of the permanent magnet torque motor, and a front end cover 1 and a rear end cover of the slide valve power part 4. Valve body 5.

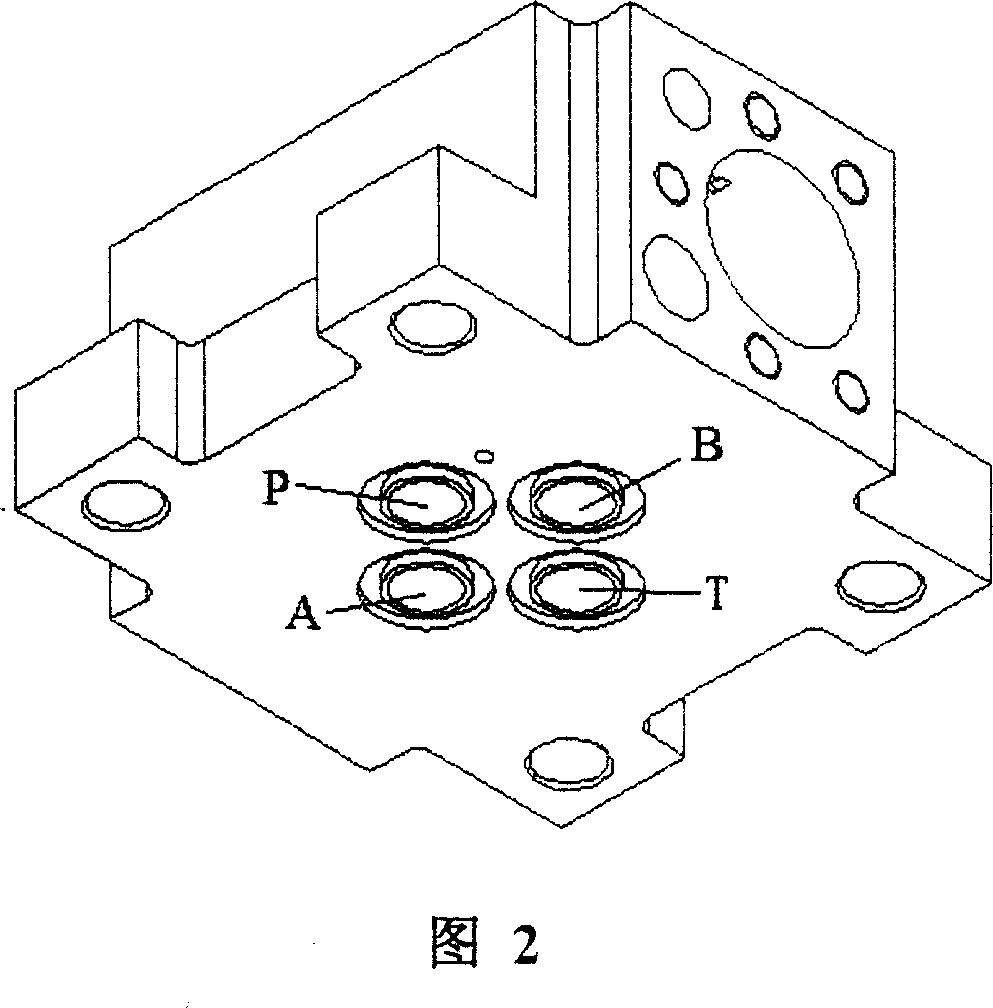

[0031] Fig. 2 is a perspective view of the valve body 5, the bottom surface of the valve body 5 is provided with an input port P, an output port T, a left control port A and a right control port B.

[0032] As shown in Figure 4, Figure 7, Figure 8, and Figure 10, the valve body 5 forms an interference fit with the valve sleeve 9, the valve sleeve 9 forms a sliding fit with the valve core 11, and the two ends of the valve core communicate with the outside world through the valve core stopper 10. Sealing, the spool stopper 10 is fixed with the front end cover 1 and the rear end cover 4 by screws, and a valve body fixing damping hole 42 is opened on the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com