Double-doped grouting material for repairing pavement and preparation method of double-doped grouting material

A grouting material and pavement technology, which is applied in the field of grouting materials, can solve the problems of poor concrete cohesion, poor high temperature resistance, poor permeability, etc., and achieve good frost resistance, high temperature resistance, and high early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

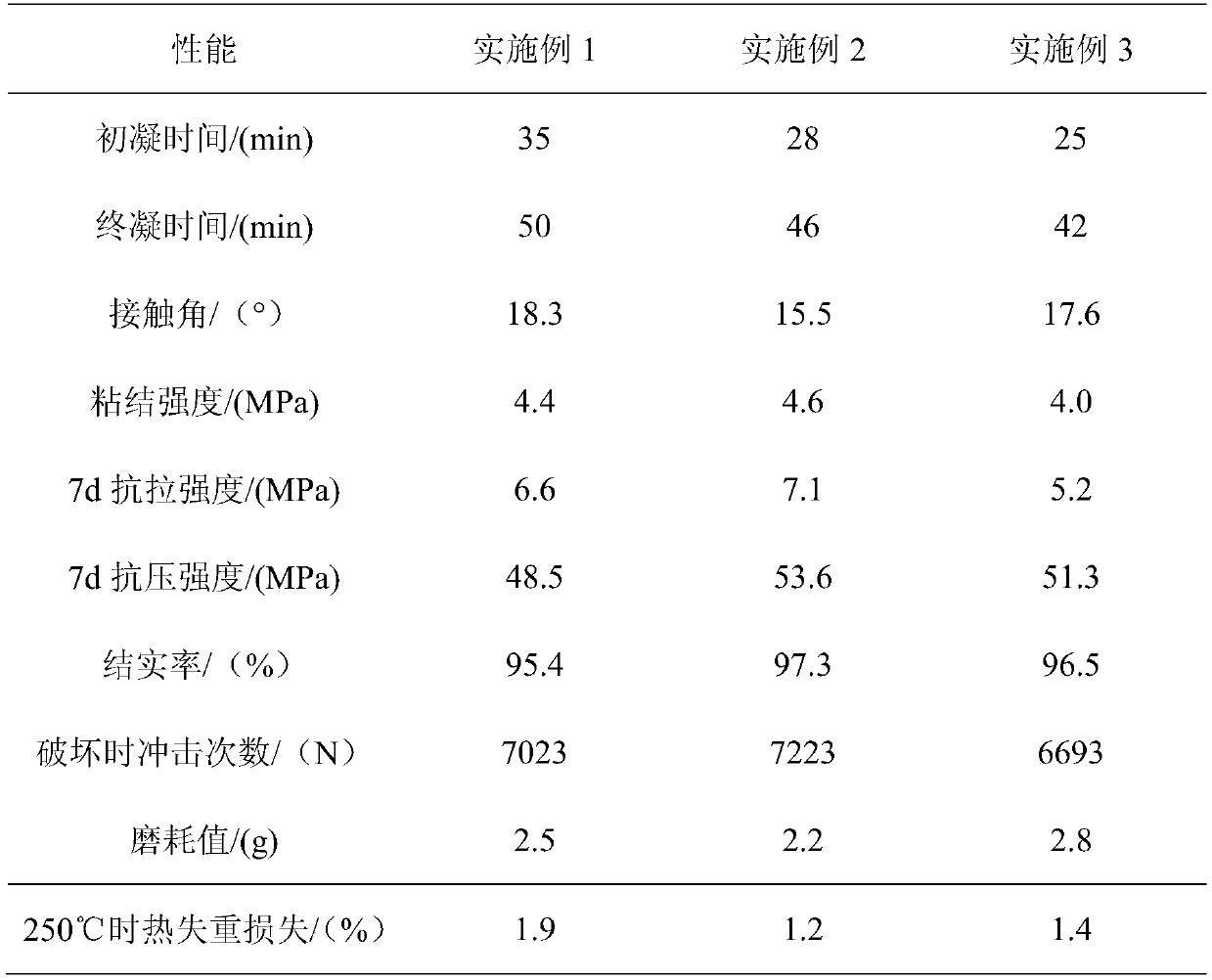

Embodiment 1

[0052] The grouting material for airport pavement repair described in this embodiment is composed of component A and component B.

[0053] The raw materials of component A include in parts by mass: 10 parts of water-based epoxy resin, 5 parts of polyurethane, 0.5 part of antioxidant, 0.1 part of defoaming stabilizer, 2 parts of coupling agent, and 0.3 part of surfactant; the coupling agent is γ -Aminopropyltriethoxysilane, the surfactant is sodium dodecylsulfonate; stir evenly according to the parts by mass to obtain component A.

[0054] The raw materials of component B include: 55 parts of Portland cement, 30 parts of aluminate cement, 5 parts of silica fume, 10 parts of fly ash, 8 parts of barite powder, 3 parts of retarder, waste rubber powder 5 parts, 0.1 part of cement strengthening agent, 0.2 part of water retaining agent; sodium citrate is used as retarder; according to these parts by mass, stir evenly in a mixer with a rotating speed of 400r / min to obtain component B....

Embodiment 2

[0060] The grouting material for airport pavement repair described in this embodiment is composed of component A and component B.

[0061] The raw materials of the component A include by mass parts: 12 parts of water-based epoxy resin, 8 parts of polyurethane, 0.7 part of antioxidant, 0.2 part of defoaming stabilizer, 4 parts of coupling agent, 0.5 part of surfactant; coupling agent It is γ-aminoethylaminopropyltrimethoxysilane, and the surfactant is sodium hexadecylsulfonate; the component A is obtained by stirring evenly in parts by mass.

[0062] The raw materials of the component B include in parts by mass: 65 parts of Portland cement, 20 parts of aluminate cement, 7 parts of silica fume, 15 parts of fly ash, 10 parts of barite powder, 2 parts of retarder, waste 6 parts of rubber powder, 0.2 parts of cement reinforcing agent, 0.1 part of water retaining agent; borax is used as retarder; according to this mass parts, stir evenly in a mixer with a rotating speed of 600r / min ...

Embodiment 3

[0068] The double-mixed grouting material for airport pavement repair described in this embodiment is composed of component A and component B.

[0069] The raw materials of component A include in parts by mass: 15 parts of water-based epoxy resin, 3 parts of polyurethane, 0.8 part of antioxidant, 0.3 part of defoaming stabilizer, 1 part of coupling agent, and 0.4 part of surfactant; the coupling agent is γ -Aminoethylaminopropyltrimethoxysilane, the surfactant is sodium hexadecylsulfonate; stir evenly in parts by mass to obtain component A.

[0070] The raw materials of component B include: 70 parts of Portland cement, 25 parts of aluminate cement, 8 parts of silica fume, 12 parts of fly ash, 12 parts of barite powder, 1 part of retarder, waste rubber powder 3 parts, 0.05 parts of cement strengthening agent, 0.3 parts of water retaining agent; sodium tripolyphosphate is used as retarder; according to this mass parts, stir evenly in a mixer with a rotating speed of 800r / min to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com