Method for optimally designing impellers of bidirectional axial flow pumps

An optimized design, pump impeller technology, applied to the components of the pumping device for elastic fluids, pumps, pump components, etc., can solve the problems of blade vibration and noise, impeller efficiency and cavitation performance decline, etc., to improve the lift. , Improve the reliability of operation, the effect of good anti-cavitation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

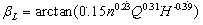

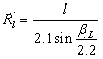

[0032] figure 1 and figure 2 Together determine the impeller shape for this embodiment. figure 1 In order to make the view clear, only the working surface part of the plan view of the impeller is drawn, and the drawing method of the back part is the same. The plan view of the impeller adopts the central symmetry method for hydraulic design, and the blade wrap angle φ (1) Evenly divided along the center line, each horizontal section of the working surface is completely symmetrical along the rotation center, and is evenly divided into five flow surfaces from the hub to the rim side, figure 1 The innermost diameter is the hub diameter d h (2), the innermost diameter is the impeller diameter D (3), which greatly simplifies the drawing process of the two-way axial flow impeller plane hydraulic diagram.

[0033] figure 2 In , the impeller airfoil diagram is improved, and the airfoil working surface becomes a straight line, that is, it coincides with the wing chord, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com