Induction wheel high in cavitation resisting performance

A technology of inducer and cavitation, applied in the parts of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problem of reducing system efficiency, increasing system structure size and weight, and system complexity. To solve problems such as chemical change, to achieve the effect of wide range of working conditions, less influence, and no increase in axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] The invention provides an inducer with high anti-cavitation performance, which can improve the anti-cavitation performance of the inducer itself without adding other complicated devices such as pre-boost pumps and driving sources. The system is simple and compact, and will have a large Advantage.

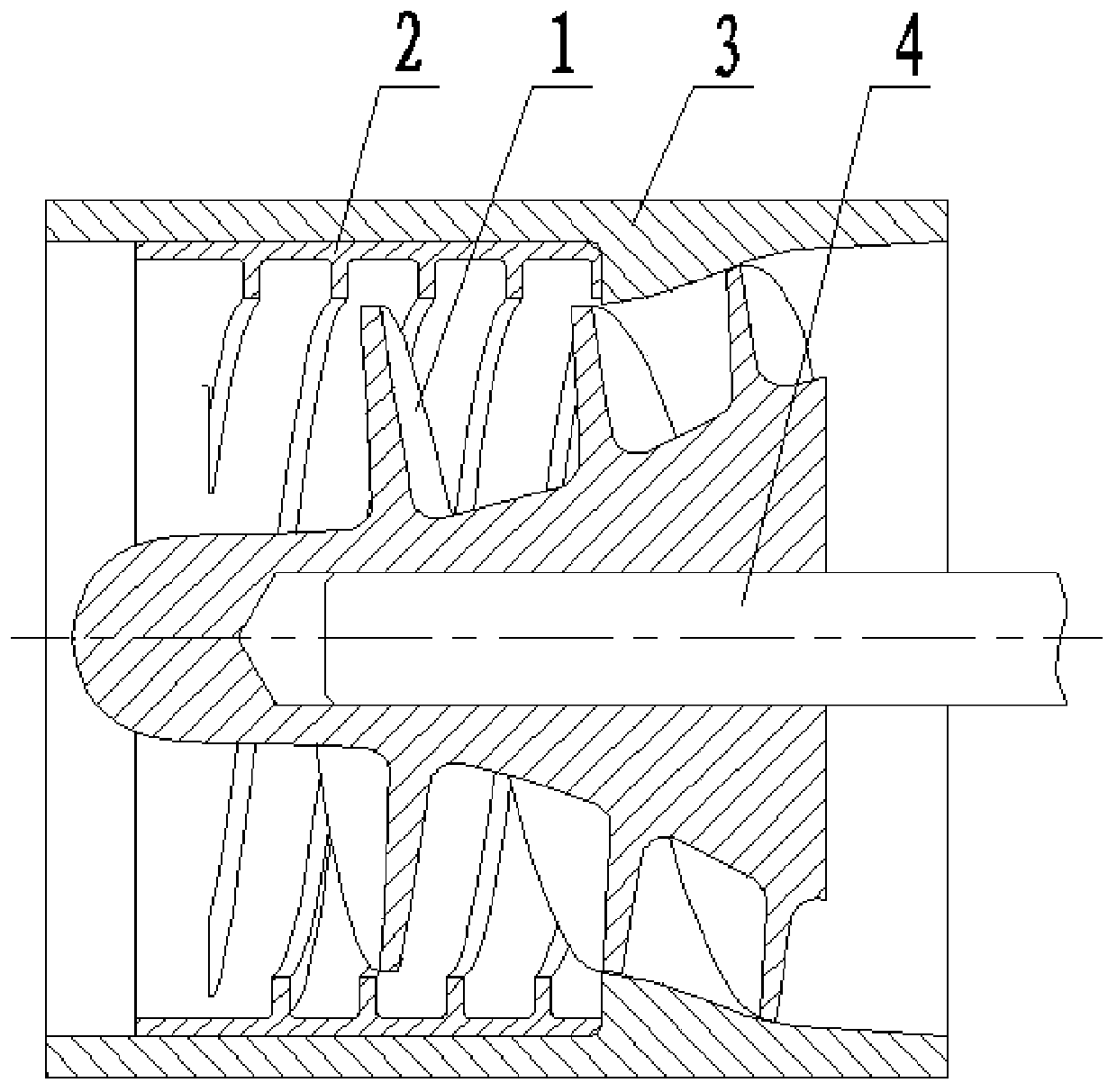

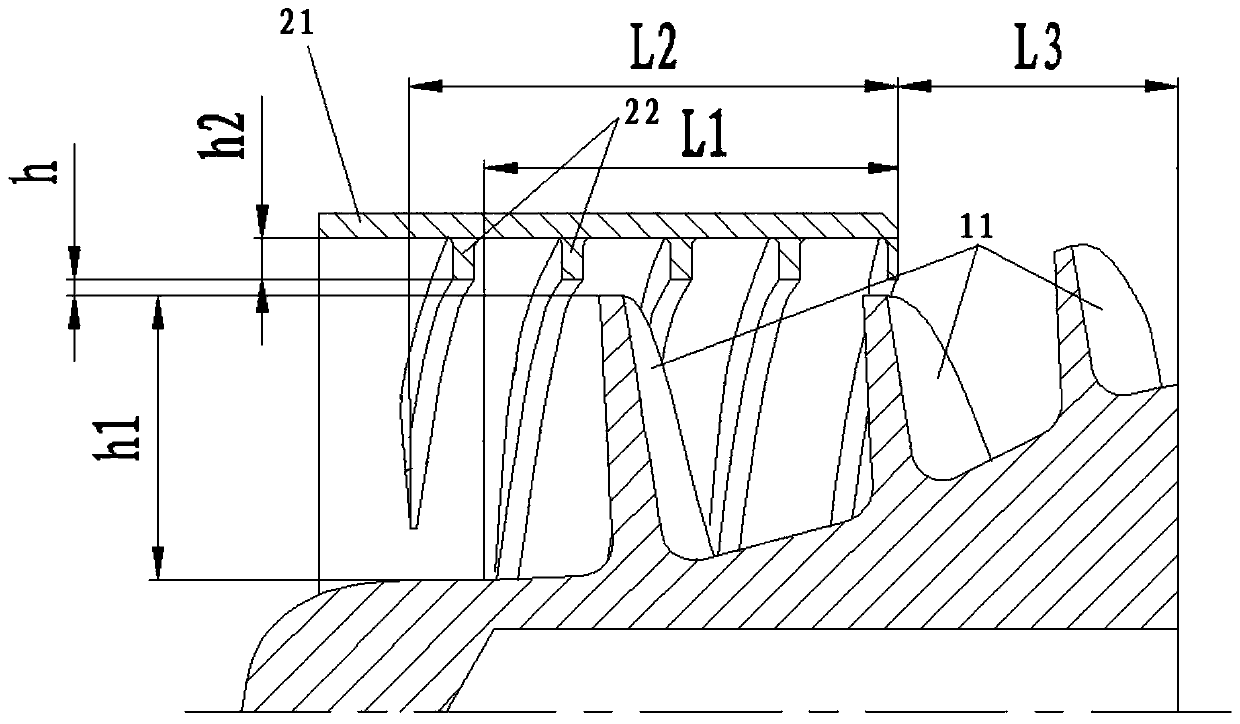

[0024] like figure 1 Shown is the overall cross-sectional view of the inducer. It can be seen from the figure that an inducer with high cavitation resistance includes an impeller 1, a stationary blade grid 2, a casing 3 and a drive shaft 4; wherein, the casing 3 is a hollow cylindrical structure; The stationary cascade 2 is an annular structure; the stationary cascade 2 is attached to the inner wall of the housing 3; the drive shaft 4 is a rod-shaped structure placed axially and horizontally inside the housing 3; and the drive shaft 4 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com