Patents

Literature

79results about How to "Wide range of working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

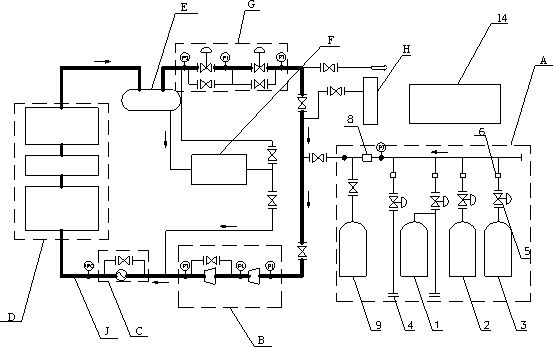

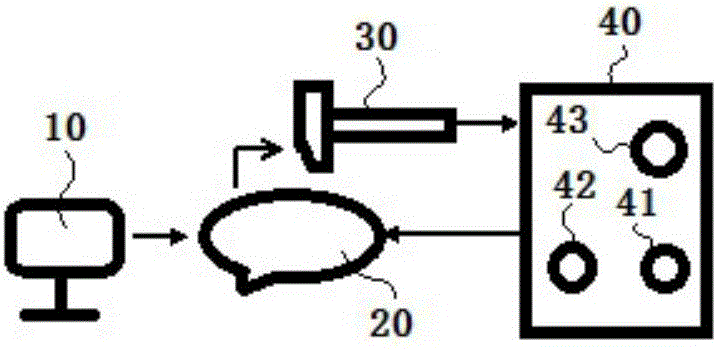

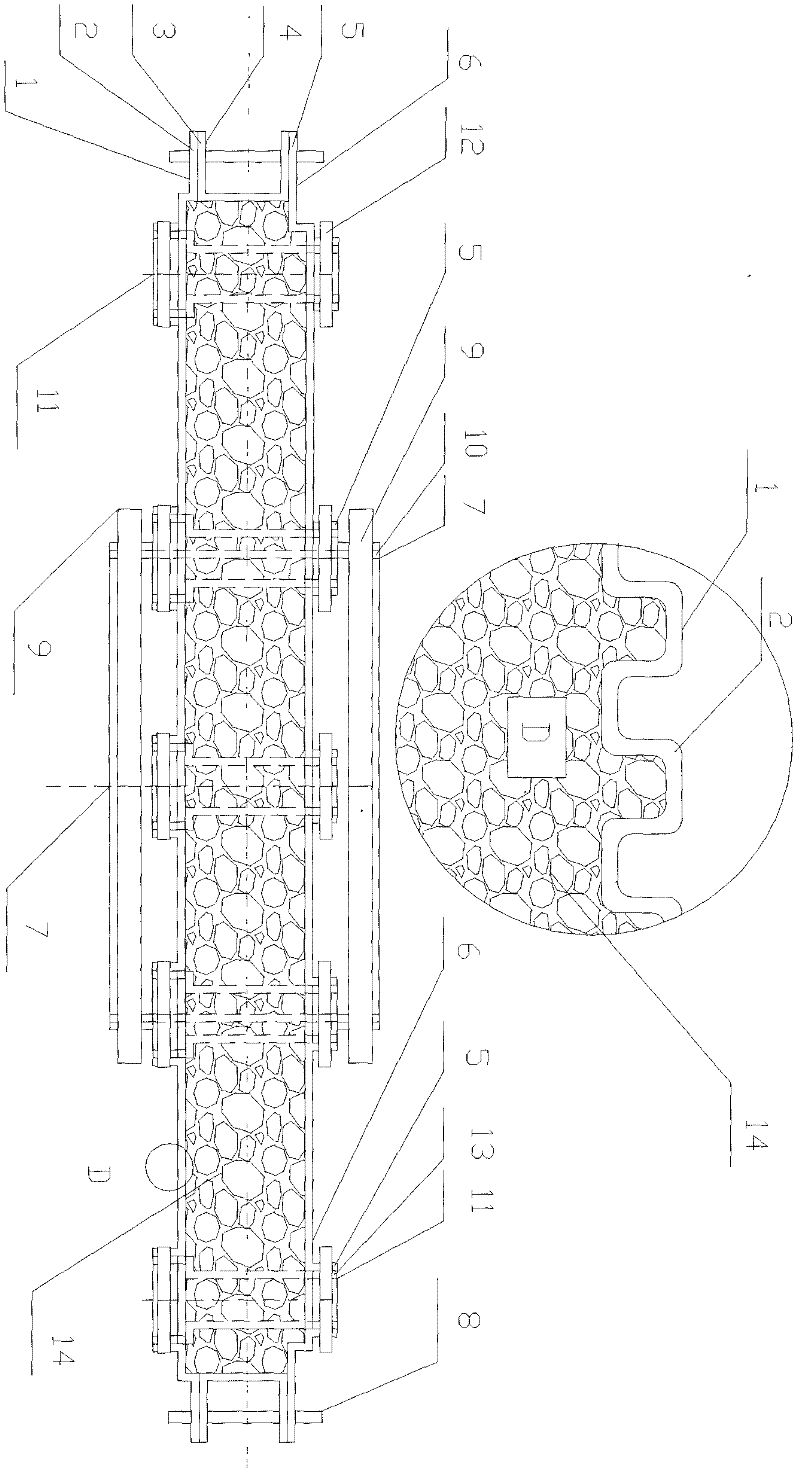

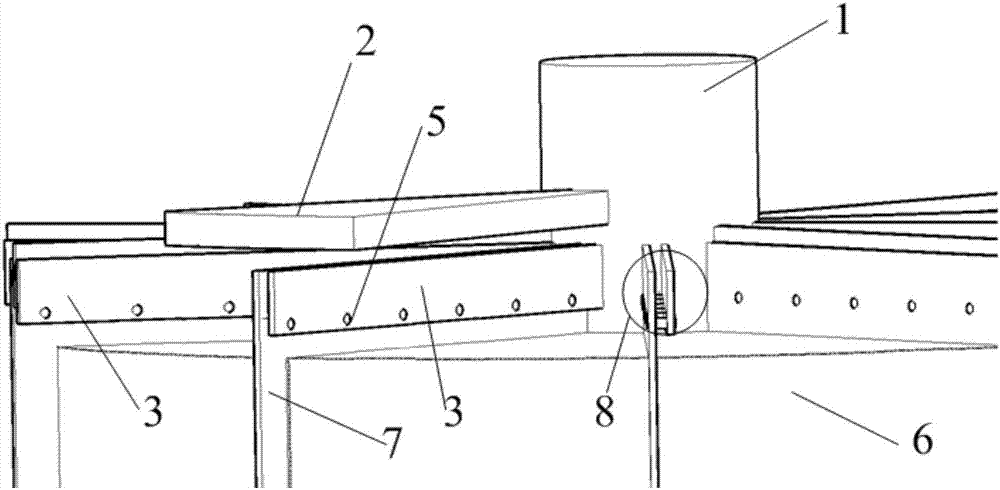

Acid medium transmission pipeline welded joint and parent metal corrosion simulation testing device and method

InactiveCN102305761AIn line with the actual situationWide range of working conditionsWeather/light/corrosion resistanceWashoutStimulation tests

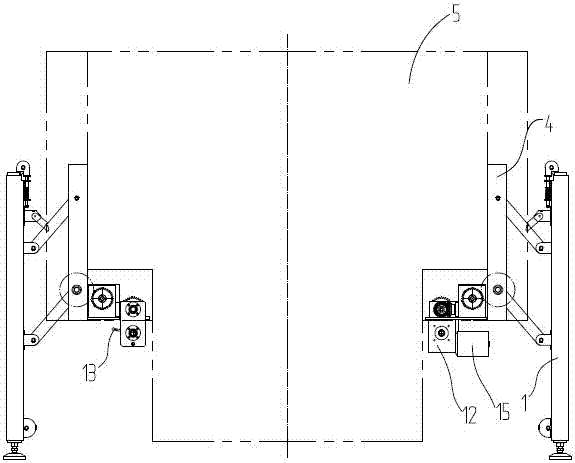

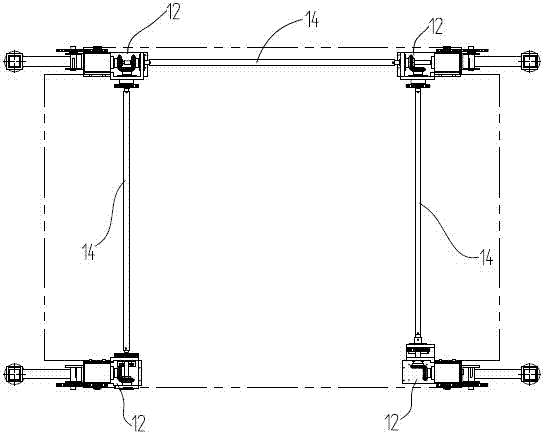

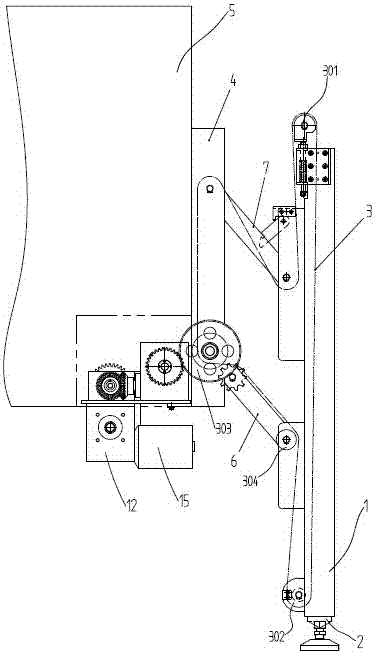

The invention provides a large-scale multifunctional corrosion stimulation test rack taking a test circular road as a main part, which is used for simulating the corrosion condition of high acid natural gas containing H2S, CO2 and Cl on a pipeline parent metal and a welded joint under the pipeline transmission condition. The device and the method provided by the invention can be applied to pipeline parent bodies with different pipe diameters, materials, steel grades and wall thicknesses, or a welded joint corrosion test; and test functions such as test on corrosion of the pipe section parent metal and the welded joint, sulfide stress cracking (SSC), hydrogen induced cracking (HIC), washout, corrosion inhibitor effect, welding process evaluation, corrosion monitoring method comparison, pipeline-corrosion-preventing process optimization and the like are integrated into a whole; and the test functions, such as preference of the corrosion process in the pipeline are integrated into a whole, thus reasonable material selection and safe welding quality are guaranteed, and the corrosion condition of the corresponding corrosion condition on the welded joint and the parent metal is known.

Owner:SOUTHWEST PETROLEUM UNIV

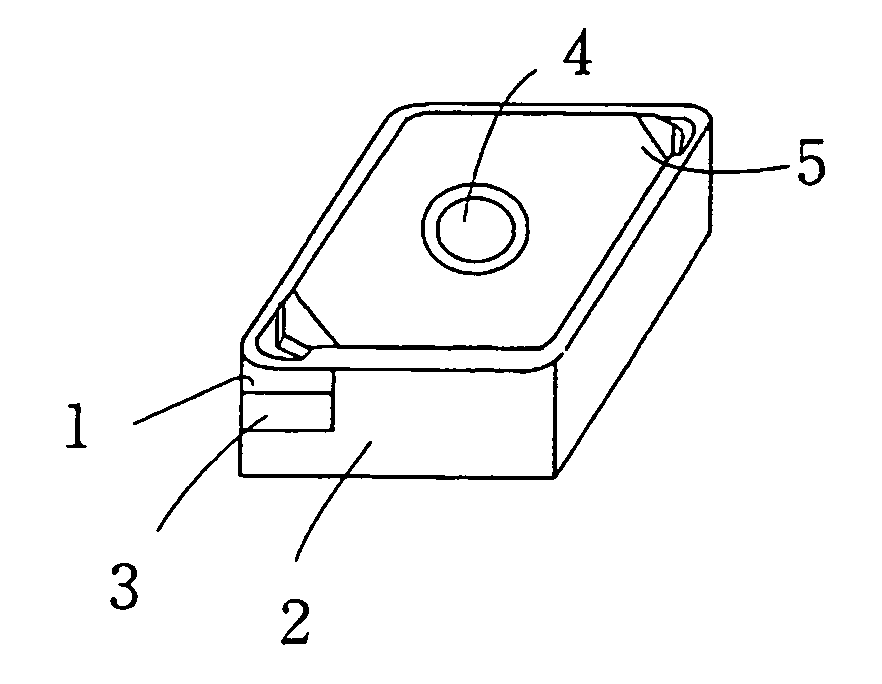

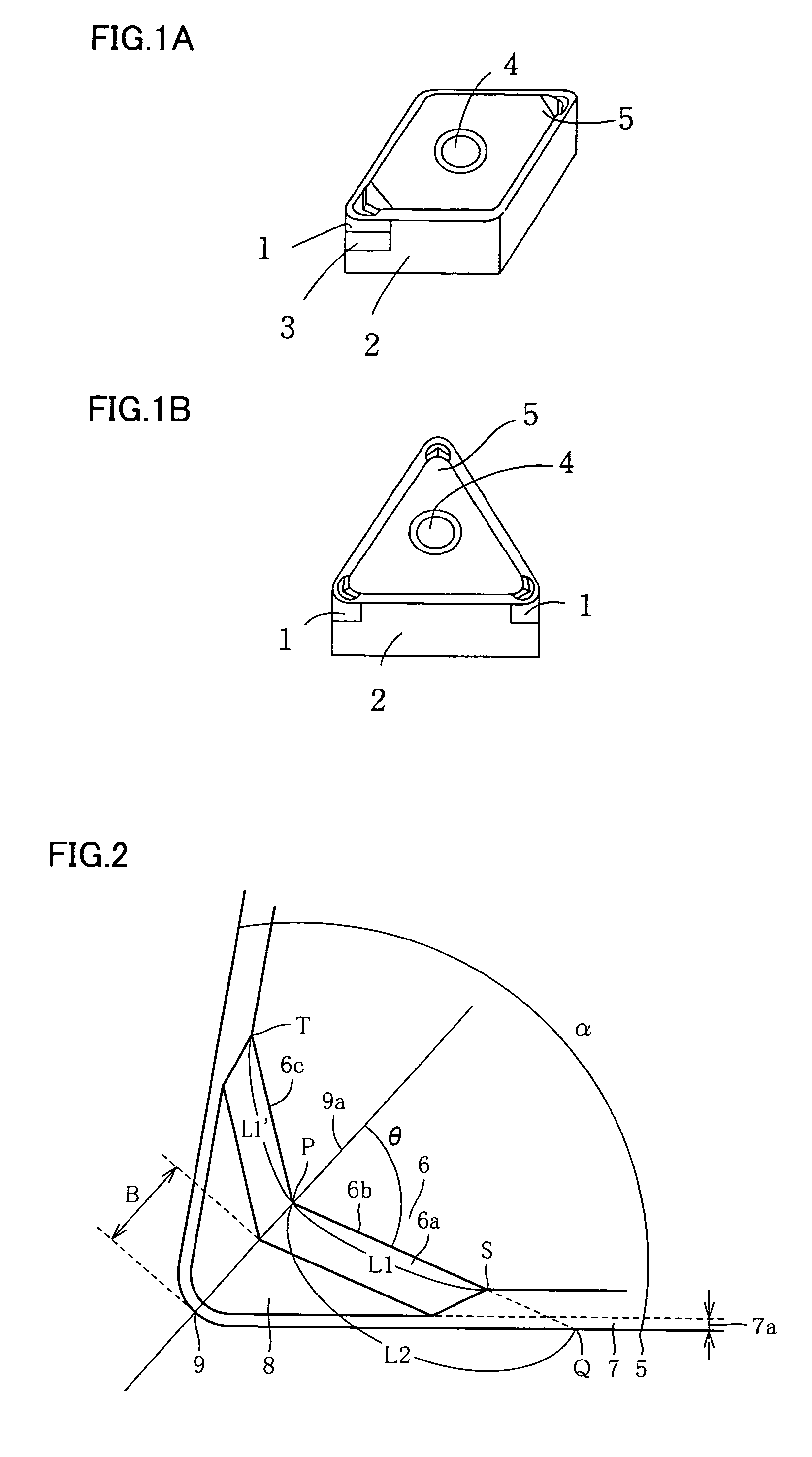

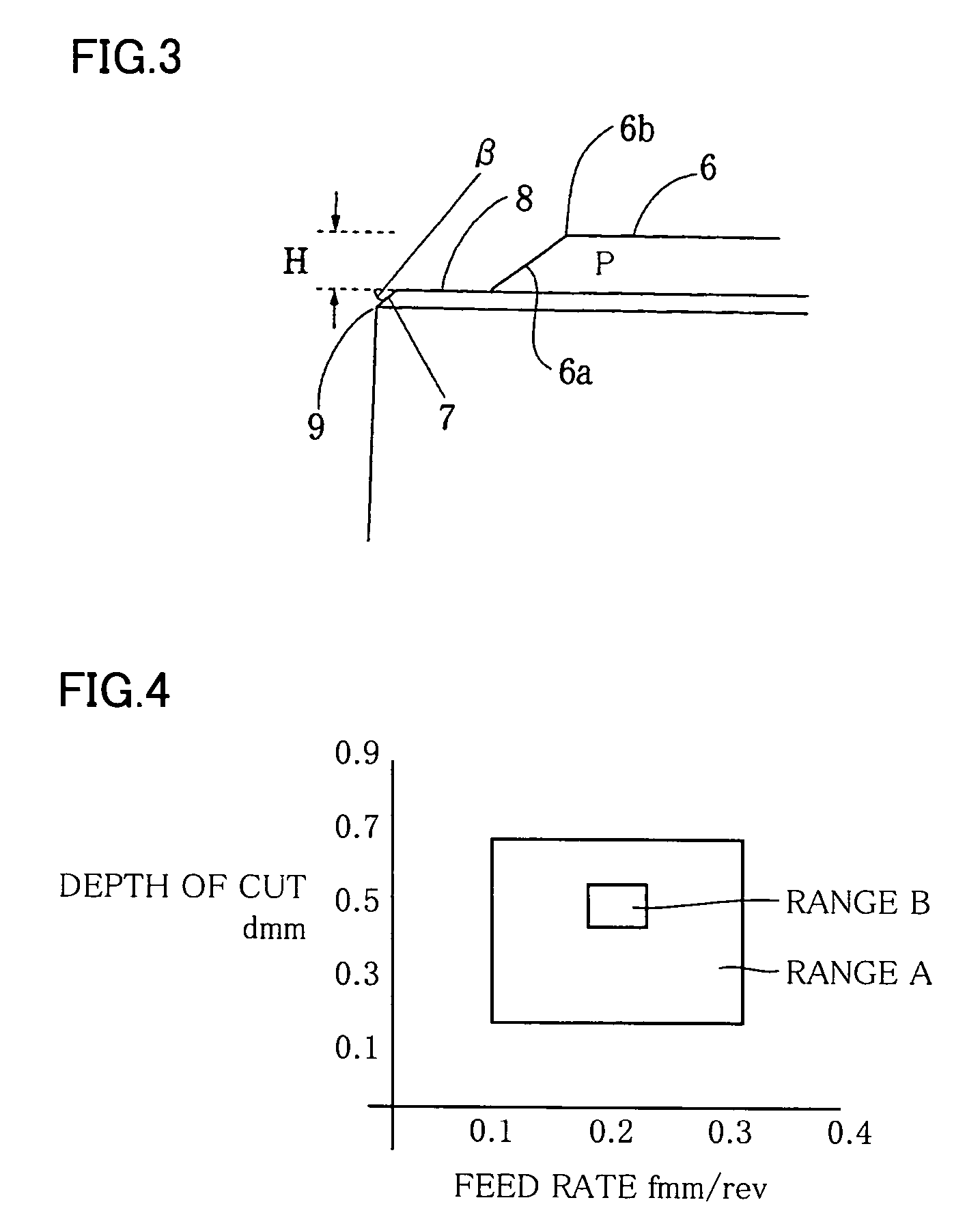

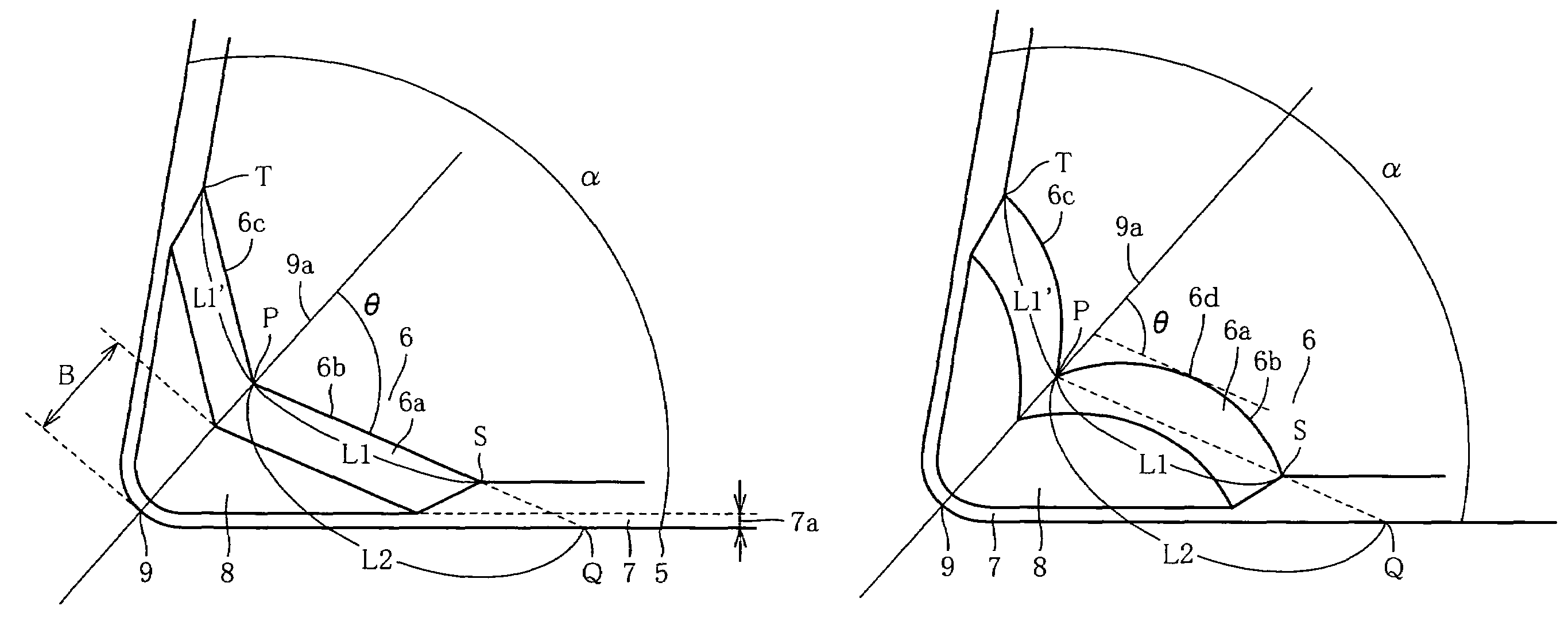

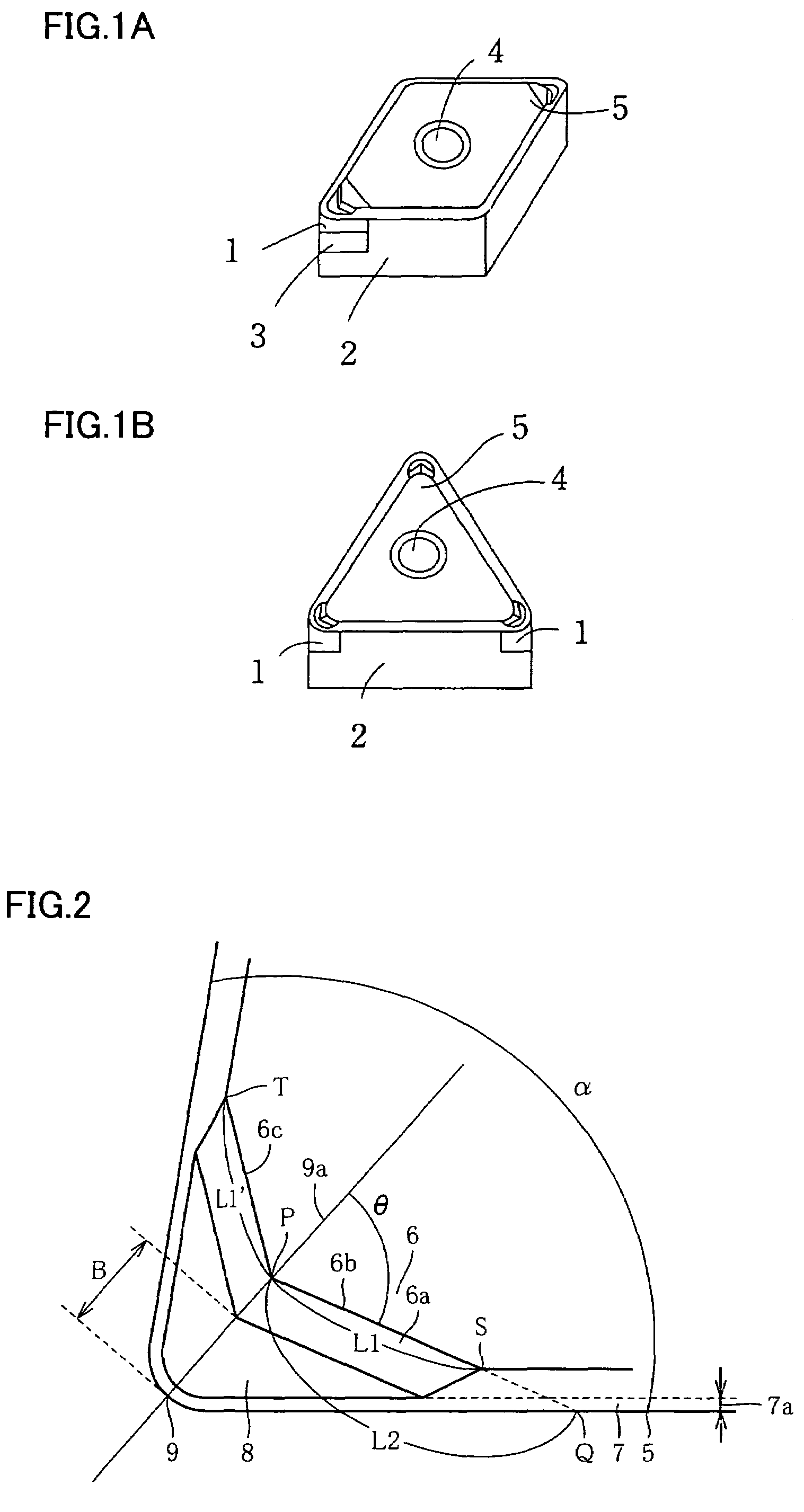

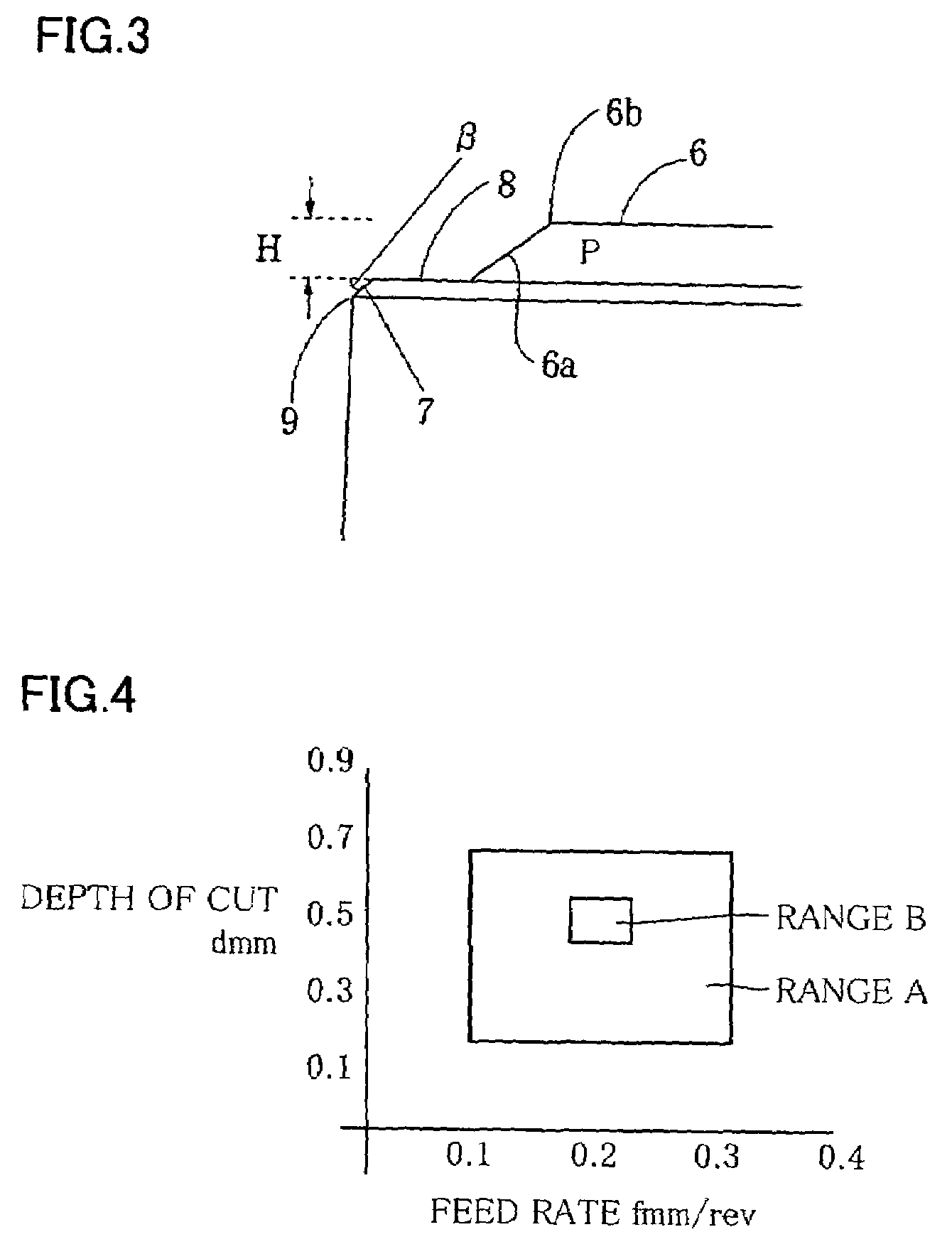

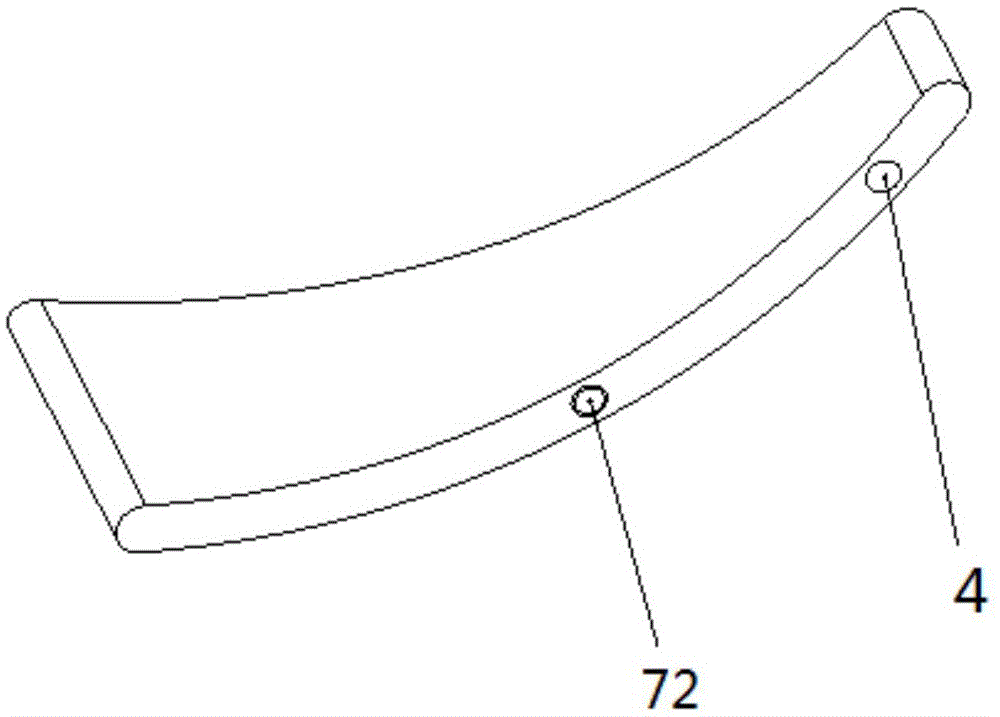

Indexable insert

ActiveUS20070116531A1Improve controllabilityEfficient use ofCutting insertsWorkpiecesBoron nitrideMaterials science

A superhard sintered body containing cubic boron nitride is bonded to an apical angle part of a tool body having a polygonal shape, and an edge and a chip breaker are formed on the superhard sintered body. A chamfer is formed on the intersection between the upper surface and the side surface of the superhard sintered body, the chip breaker has a protrusion, and an angle θ formed by ridges on the apex of the protrusion or a tangential line at a point bisecting the ridges and a bisector for the apical angle and the ratio of the distance between a first intersection between the two ridges on the apex of the protrusion and an extreme point of the first ridge to the distance between a second intersection between a straight line passing through the first intersection and the extreme point and the outer periphery of the tool body and the first intersection are in prescribed ranges.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Catalyst system of catalytic methylester acetate or methylether synthetic acetoanhy dride and use thereof

ActiveCN1778468AImprove stabilityEasy to adjustOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic acid anhydrides preparationIodised saltAcetic anhydride

A catalyst system for synthesizing the acetic anhydride from methyl acetate or bimether by catalytic reaction contains active component (Rh matches) and cocatalyst (alkyl diodine, phosphate and iodine salt). Said catalytic reaction between methyl acetate or bimether, CO and H2 is conducted in acetic acid. Its advantages are high catalytic activity and high stability.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

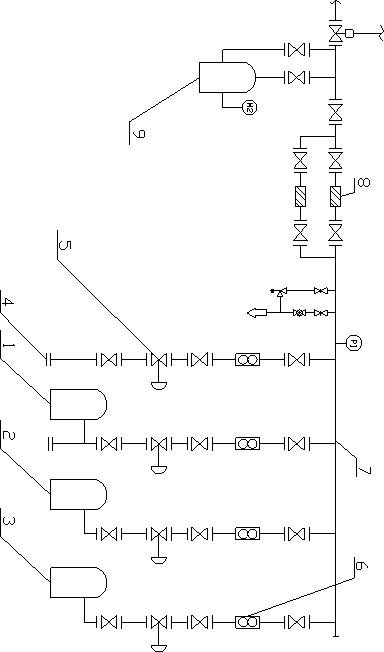

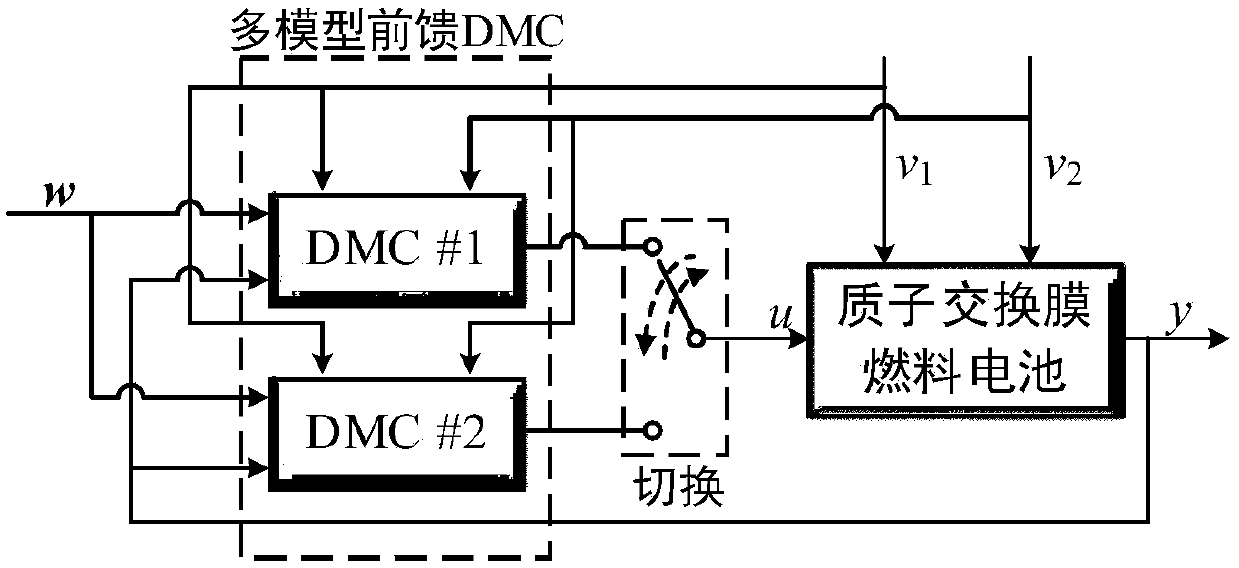

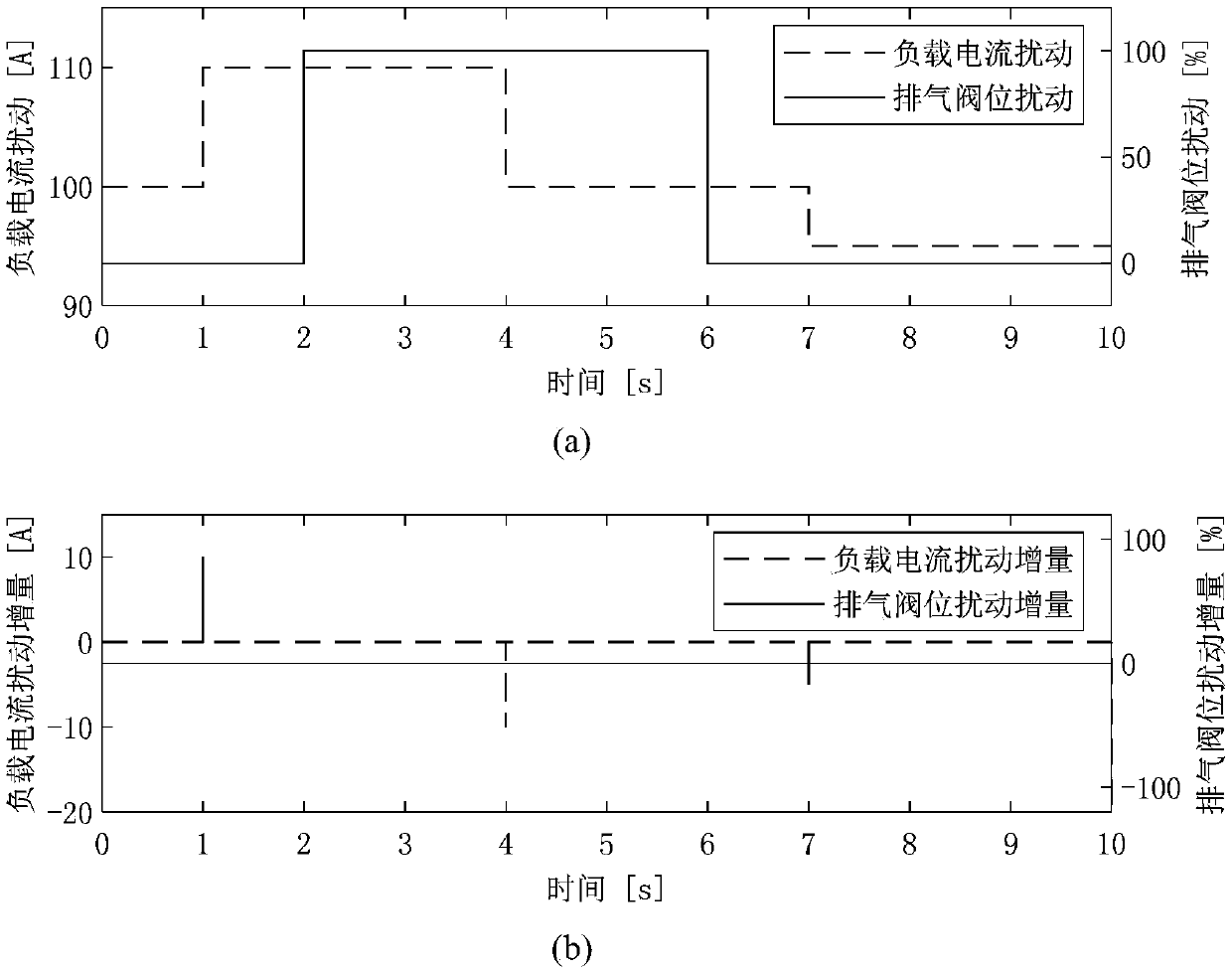

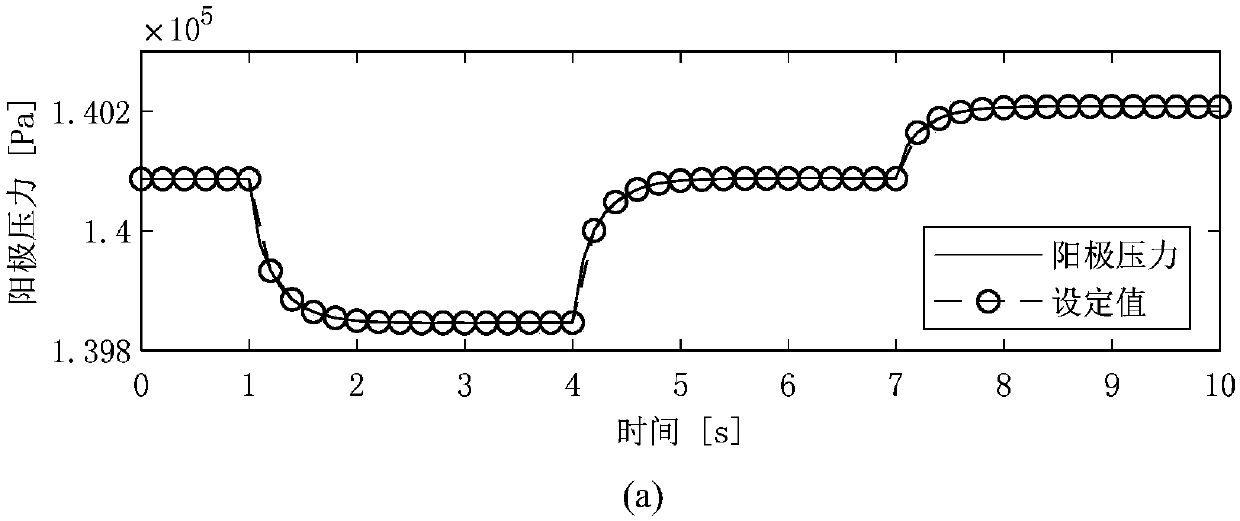

Fuel cell anode pressure dynamic matrix control method based on multi-model feedforward

ActiveCN108681244AGuaranteed optimalityReduce disturbanceAdaptive controlDifferential pressureProton

The invention discloses a fuel cell anode pressure dynamic matrix control method based on multi-model feedforward. A proton exchange membrane fuel cell is regarded as a three-input one-output multivariable object, object input includes a path of controlled quantity and two paths of disturbance quantities, a step response model of an output quantity to the controlled quantity and the disturbance quantities is identified at different steady-state operating condition points, and in control, an identification model for calculating a control increment and a corresponding DMC controller are switchedaccording to the actual operating condition of the fuel cell, thereby ensuring optimality of controlled quantity output. Compared with traditional predictive control, the method provided by the invention is applicable to a wider operating condition range, and disturbance is small during model switching. In addition, the method can also effectively suppress influence of a vent valve position and load current disturbance, control an anode pressure tracking set value, reduce differential pressure stress on the proton exchange membrane, prolong the service life of the proton exchange membrane, and ensure efficient, stable and safe operation of the fuel cell.

Owner:SOUTHEAST UNIV

Indexable insert

ActiveUS7524148B2Improve controllabilityEfficient use ofCutting insertsWorkpiecesBoron nitrideMaterials science

A superhard sintered body containing cubic boron nitride is bonded to an apical angle part of a tool body having a polygonal shape, and an edge and a chip breaker are formed on the superhard sintered body. A chamfer is formed on the intersection between the upper surface and the side surface of the superhard sintered body, the chip breaker has a protrusion, and an angle θ formed by ridges on the apex of the protrusion or a tangential line at a point bisecting the ridges and a bisector for the apical angle and the ratio of the distance between a first intersection between the two ridges on the apex of the protrusion and an extreme point of the first ridge to the distance between a second intersection between a straight line passing through the first intersection and the extreme point and the outer periphery of the tool body and the first intersection are in prescribed ranges.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

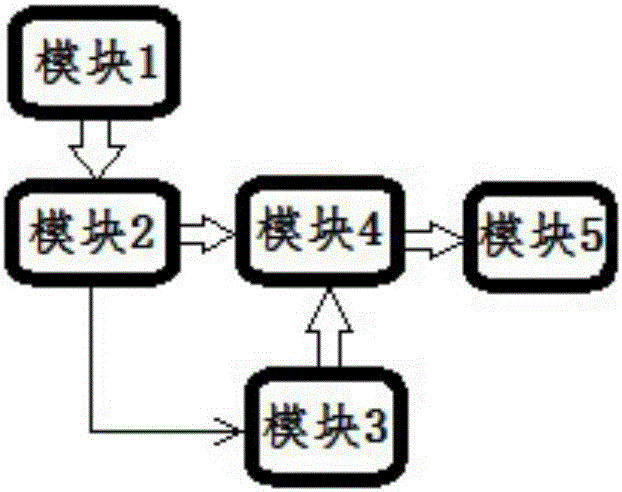

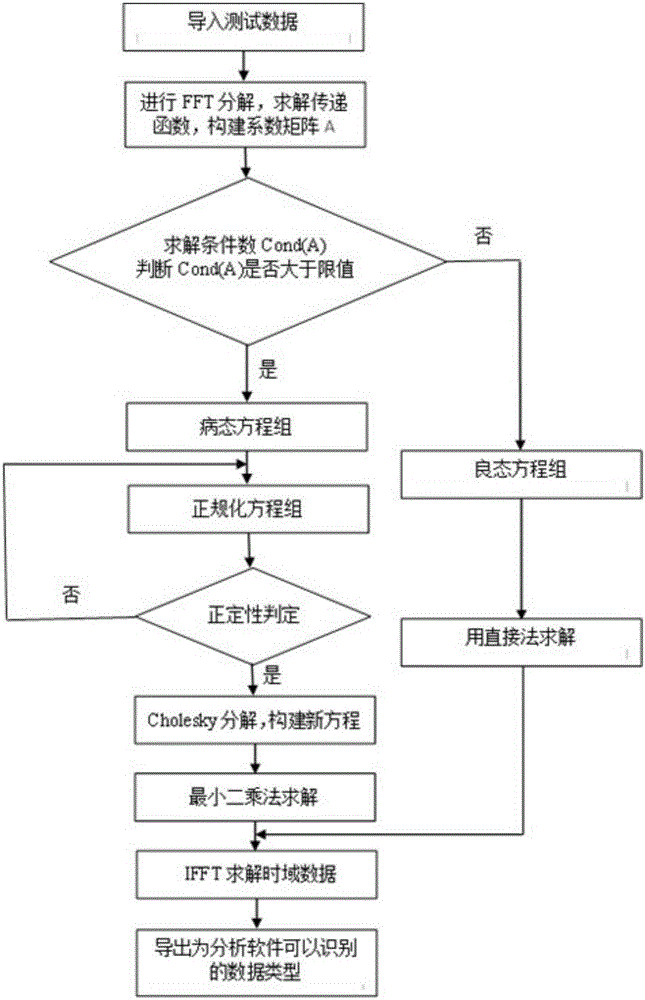

Method and system for identifying noise source in high speed train

InactiveCN107179201AReduce mistakesReduce calculation errorsRailway vehicle testingSound sourcesCrosstalk

A method for identifying a noise source in a high speed train is characterized in that each of a plurality of possible vibration exciting points is equipped with at least one measuring point sensor; a backup sensor is arranged at the same measuring point position in a different direction, or a plurality of sensors simultaneously acquiring signals are mounted at the same measuring point; before the test, an exciting hammer is used for knocking on each measuring point of an input signal, and the output response of all the other measuring points is tested at the same time so as to constitute a real transfer relation of the measuring points before mutual crosstalk; strongly coupled crosstalk data of an input channel are strongly decoupled through actual output signals of the measuring points; real exciting signals of the measuring points after the decoupling are used for the identification and analysis of a sound source in the train; and the exciting measuring points are ranked with respect to influence factors of response points to determine the main noise source of the noise in the train. According to the invention, the false frequency can be eliminated to accurately determine a noise source outside the train and a vibration source so as to facilitate the effective control and reduction of the noise in the high speed train.

Owner:CHINA RAILWAYS CORPORATION +1

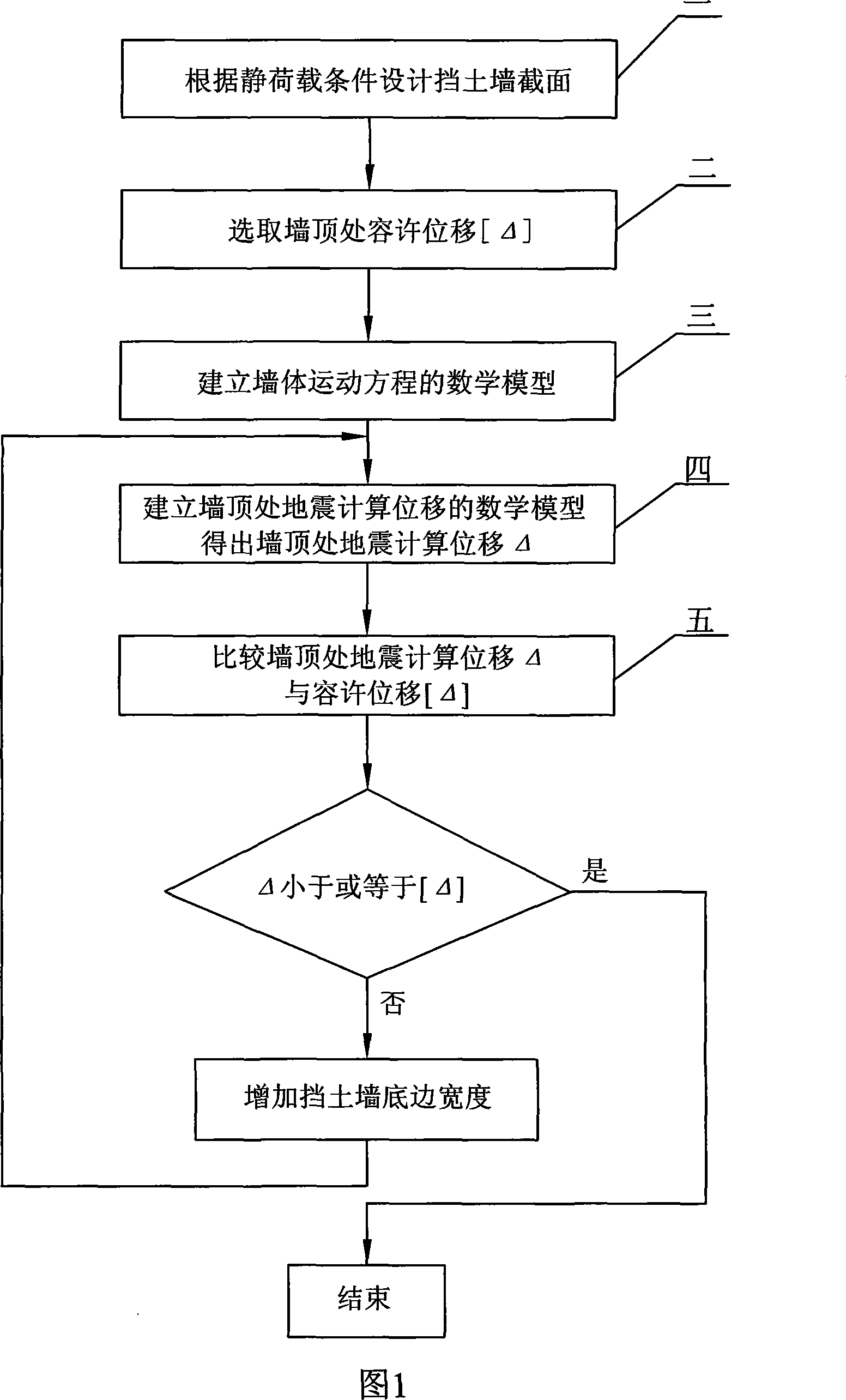

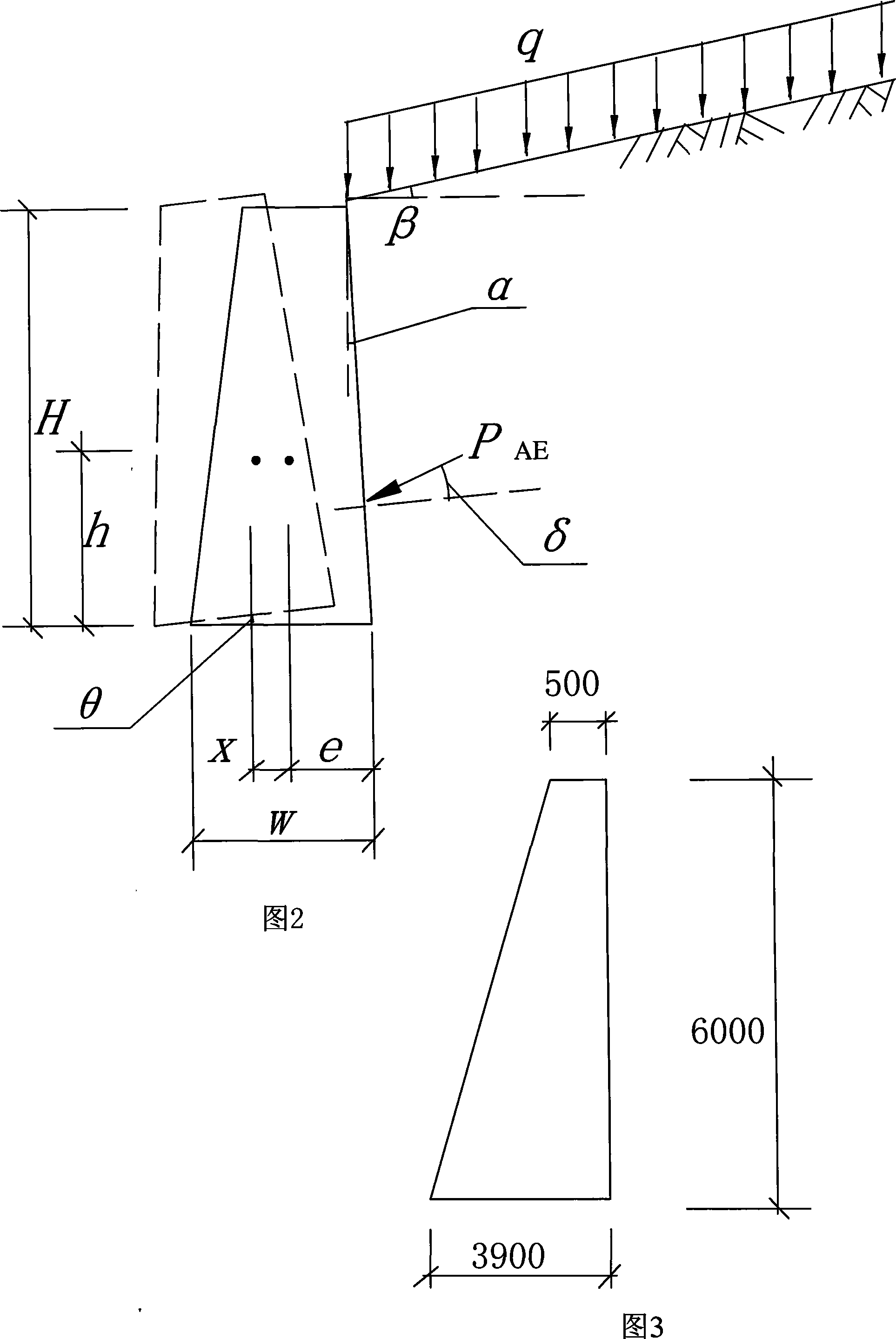

Gravity bulkhead design method based on earthquake displacement

InactiveCN101211381AWide range of working conditionsSmall amount of calculationArtificial islandsUnderwater structuresEquations of motionSeismic displacement

A weight-type retaining wall design method based on earthquake displacement relates to a retaining wall design method. The invention resolves the following problems in prior retaining wall aseismatic design methods: Not considering of the slide displacement or the rotary displacement of wall bodies; or only considering the slide displacement, but not of the rotary displacement of wall bodies, so that design allowance displacement of retaining walls is by far different from actual displacement; as well as two big displacement or insufficient estimation on the displacement, so as to influence utilization functions of retaining walls. Main steps of the invention are as follows: Design the section of a retaining wall and take the allowable displacement at the wall top, so as to establish the mathematical module for the wall body motion equation; establish the mathematical module of the earthquake calculate displacement at the wall top; compare the earthquake calculate displacement delta at the wall top against the allowable displacement [DELTA]. The invention overcomes the shortcomings in prior design methods that only considering of horizontal slide displacement of wall bodies, but not of the insufficiency of cohesion force on backfilled soil; the motion equation considers of the coupling movement between the slide displacement and rotation for the wall bodies, so that the method is suitable for more expansible working conditions and more closes to engineering facts.

Owner:HARBIN INST OF TECH

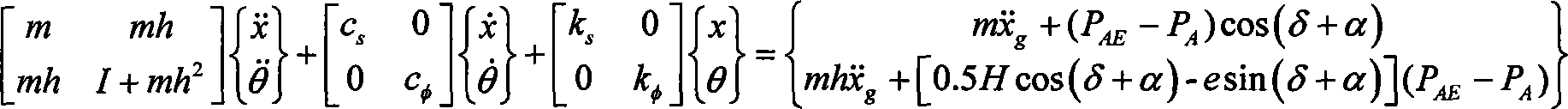

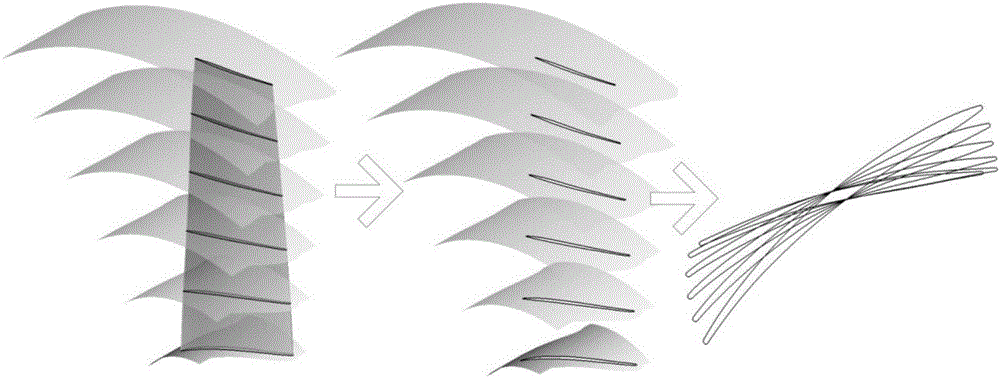

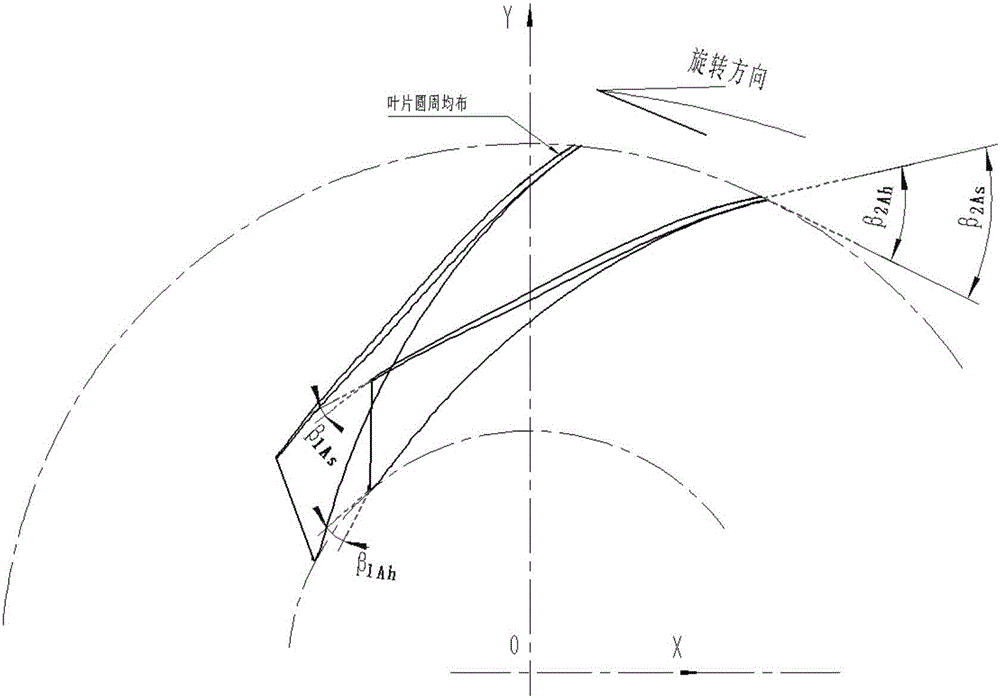

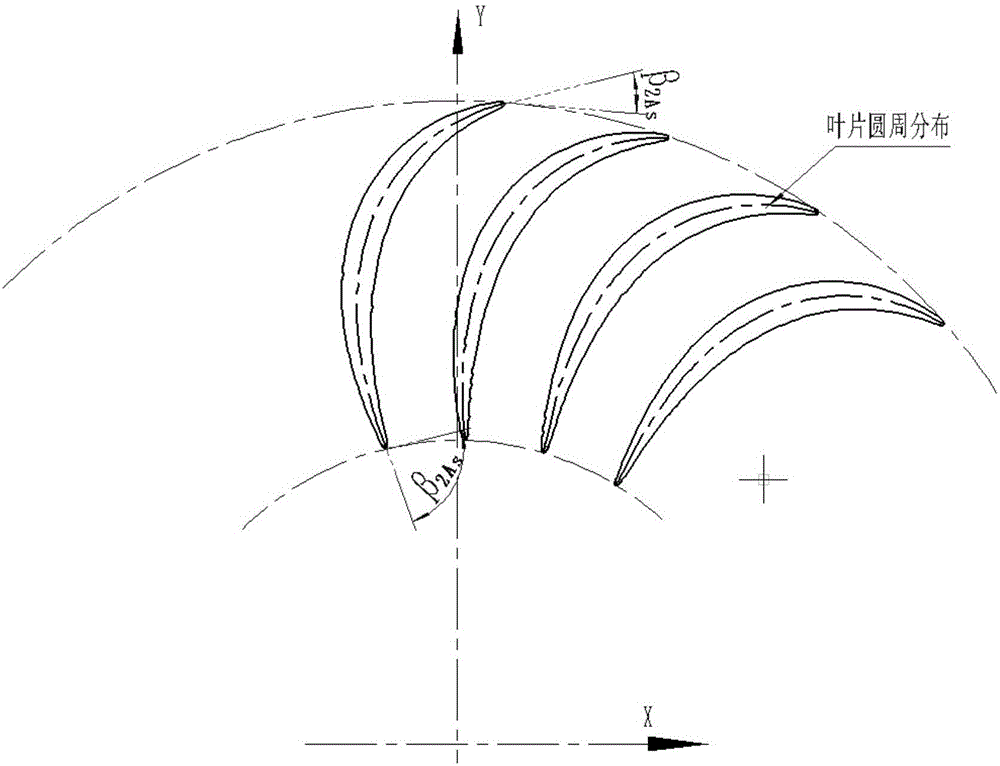

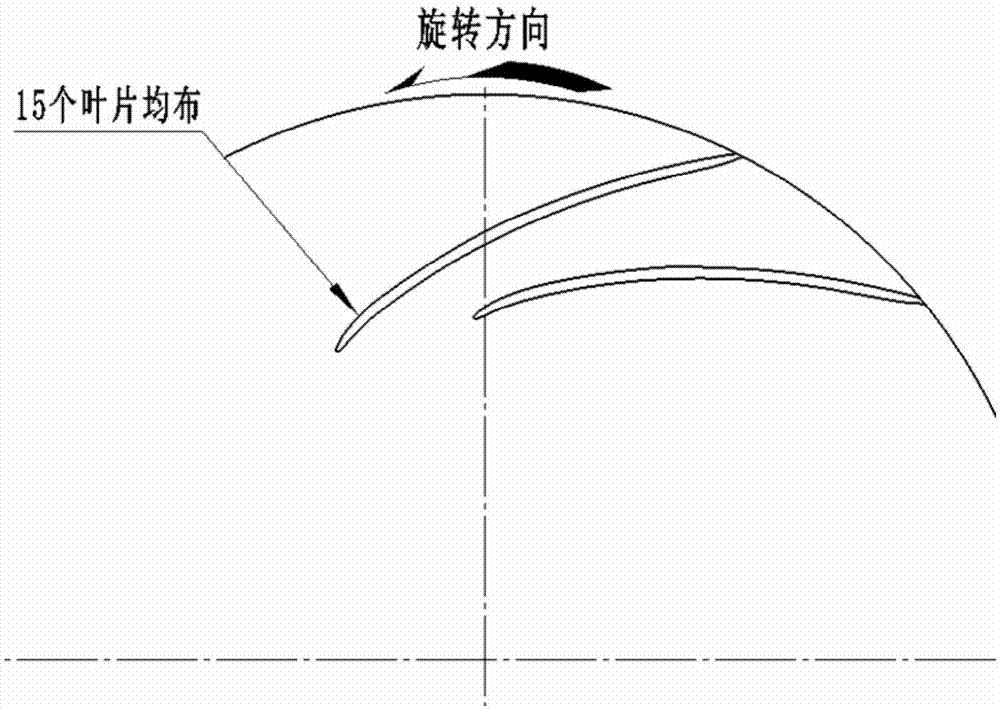

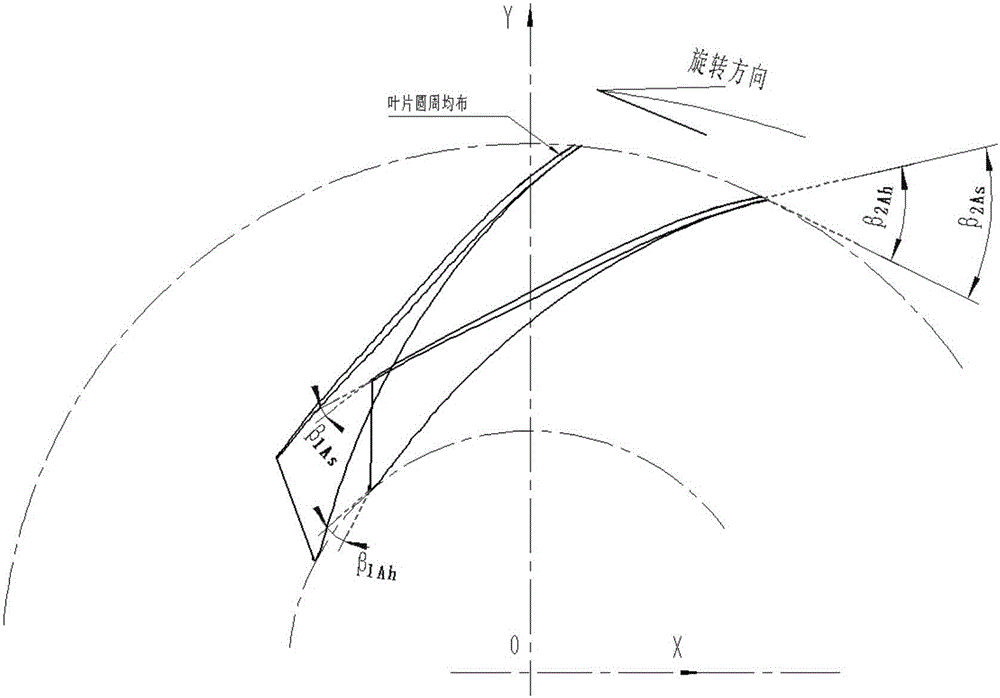

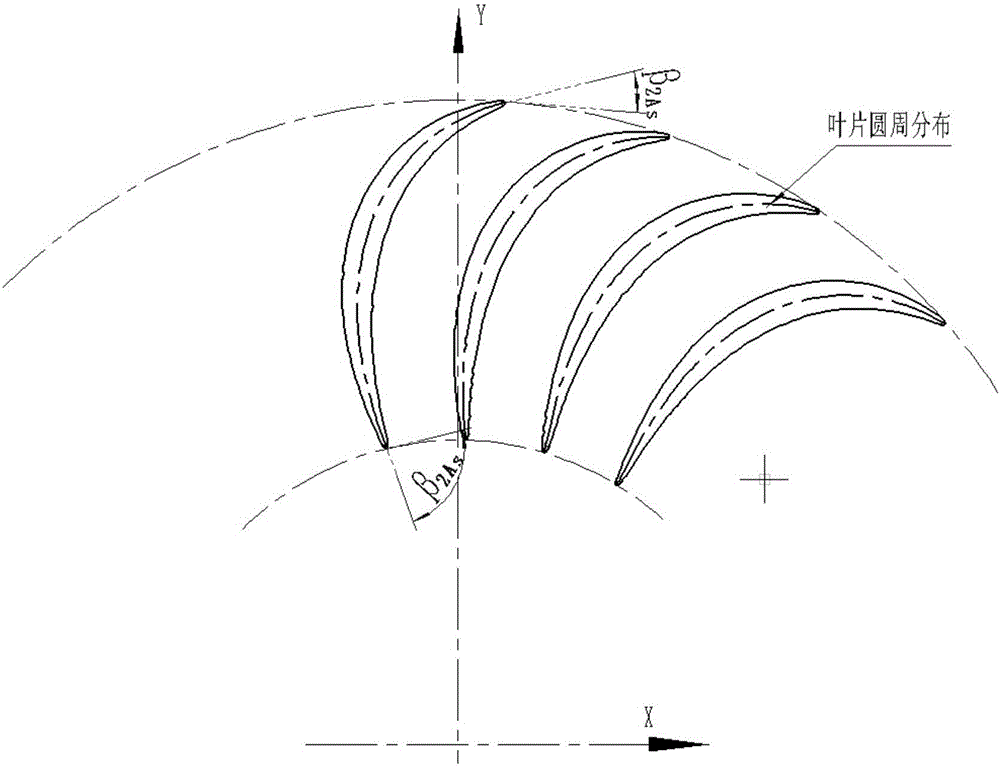

Axial flow blade form

ActiveCN106151105AImprove efficiencySolve the problem of low impeller efficiencyPump componentsPumpsPressure curveLength variation

The invention discloses an axial flow blade form. The surface of the axial flow blade form comprises a suction curved surface, a pressure curved surface, an upper curved surface and a lower curved surface, wherein the side surfaces of two cylinders cover the upper curved surface and the lower curved surface, the radii of the cylinders corresponding to the upper curved surface and the lower curved surface are separately marked as R2 and R1, and R2 is larger than R1; the side surfaces of a series of coaxial cylinders of which the radii r changing from R1 to R2 are crossed with the axial flow blade form, forming a series of crossed surfaces, and then, the series of crossed surfaces are spread along the plane so as to obtain a series of spread cross sections; and a blade inlet angle varies with the variation of the ratio value of a height ratio, and both the angle variation of the blade inlet angle and the length variation of a chord meet a cubic spline curve relationship. By improving key shape parameters (for example, the blade inlet mounting angle, the blade outlet mounting angle, the specific variation form of the chord with blade height and the like), the problem that the efficiency of the axial flow blade is low can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

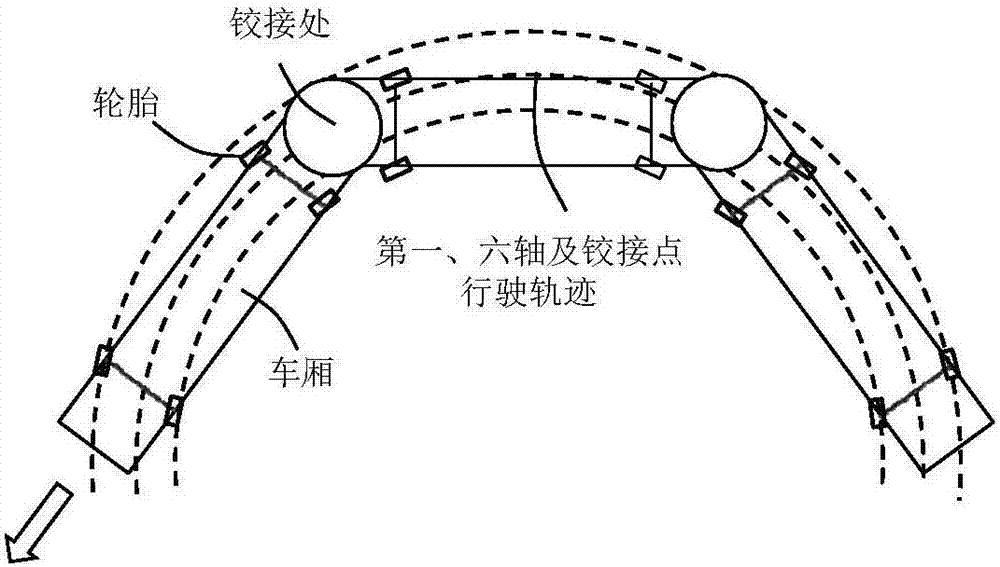

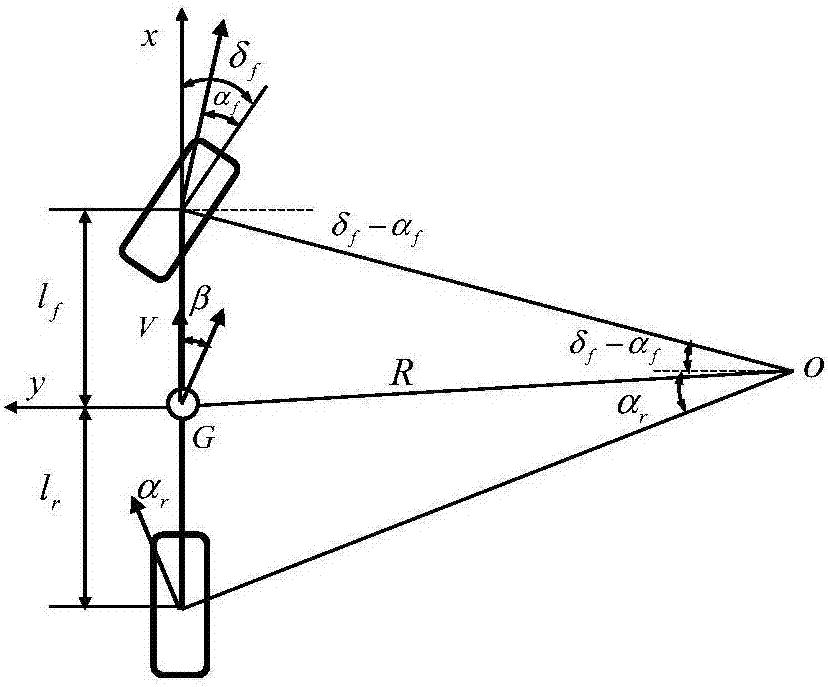

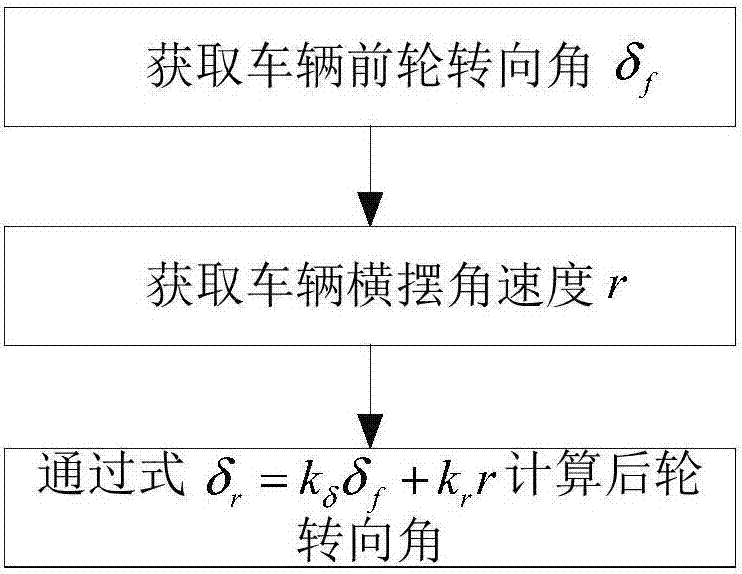

Multi-axle steering control method for improving vehicle handling stability

InactiveCN107963124AImprove stabilityAccelerated lateral responseSteering linkagesAutomatic steering controlSteering angleLow speed

The invention discloses a multi-axle steering control method for improving vehicle handling stability. The multi-axle steering control method comprises the steps that the first carriage front wheel steering angle delta f and the vehicle transverse swaying angular speed r are obtained; and through the direct ratio values of the vehicle front wheel steering angle delta f and the vehicle transverse swaying angular speed r, the rear wheel steering angle delta r is calculated, and steering of rear wheels is controlled. The multi-axle steering control method has the advantages that the multi-axle steering characteristic is achieved, the first-section vehicle mass center side slip angle is kept to be zero, the stability of a vehicle can be effectively improved, the lateral response speed of the vehicle can be effectively increased, and the track following ability under the low-speed situation can be ensured.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

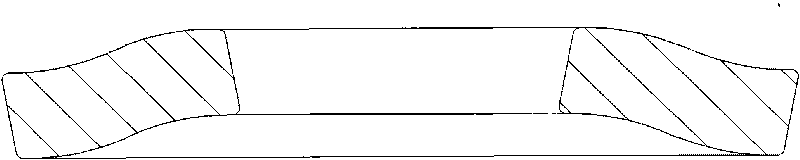

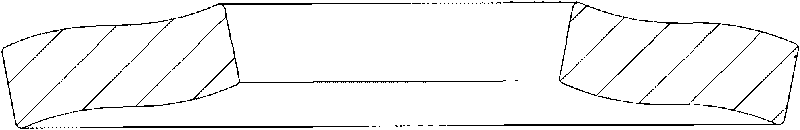

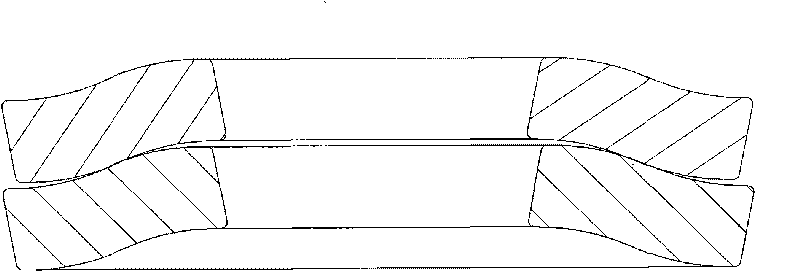

Waveform movable pressing pretightening butterfly spring

The invention relates to a waveform movable pressing pretightening butterfly spring, which is arranged statically on a joint of a bolt and a fastened piece and is static relative to a contact component. The waveform movable pressing pretightening butterfly spring is characterized in that: the waveform movable pressing pretightening butterfly spring is a butterfly gasket; an inner hole and an excircle of the waveform movable pressing pretightening butterfly spring which has uniform thickness have a shape of cone; upper and lower reverse surfaces are both waveform surfaces; each surface is at least provided with more than one complete waveform; each waveform has resilience capacity; the waveforms of the upper and lower reverse surfaces are staggered sequentially to be arrayed uniformly from the inner hole to the periphery or from the outer diameter to the inner hole; and a plurality of waveform movable pressing pretightening butterfly springs can be combined in a folding or overlapping mode.

Owner:超化公司

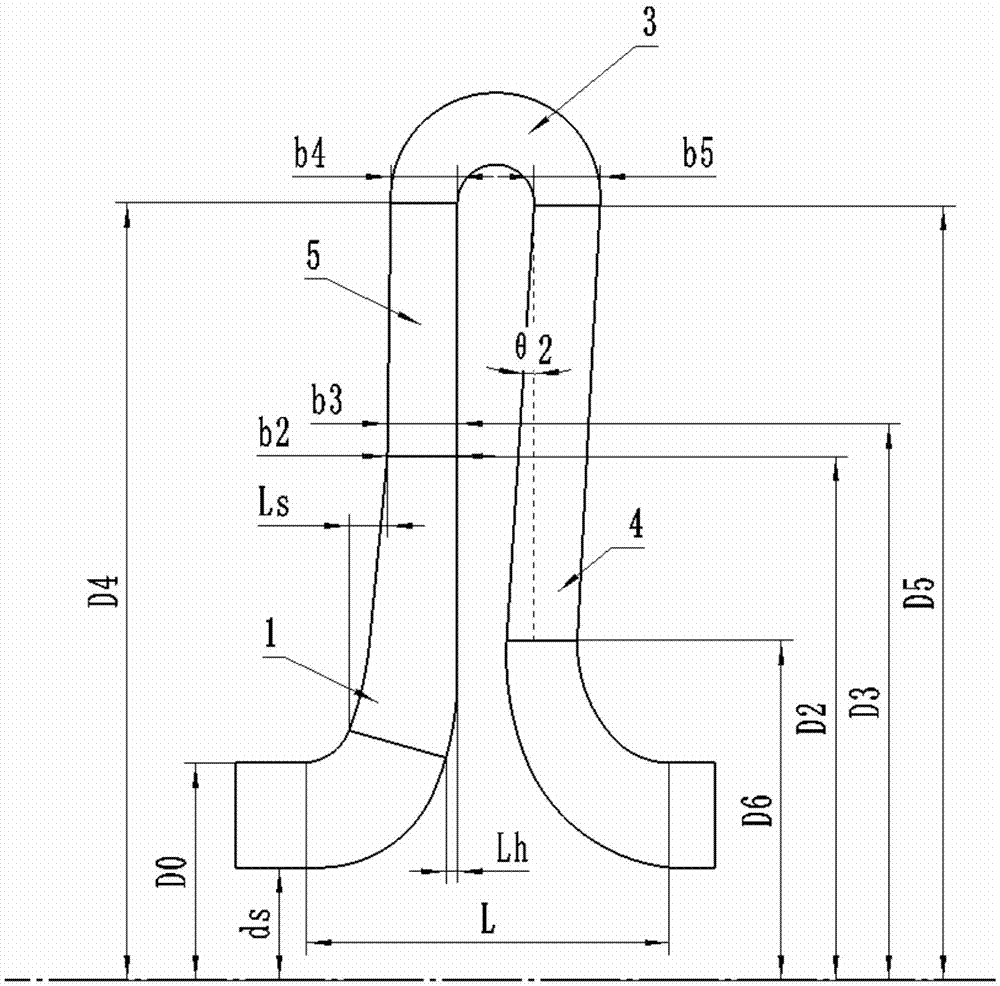

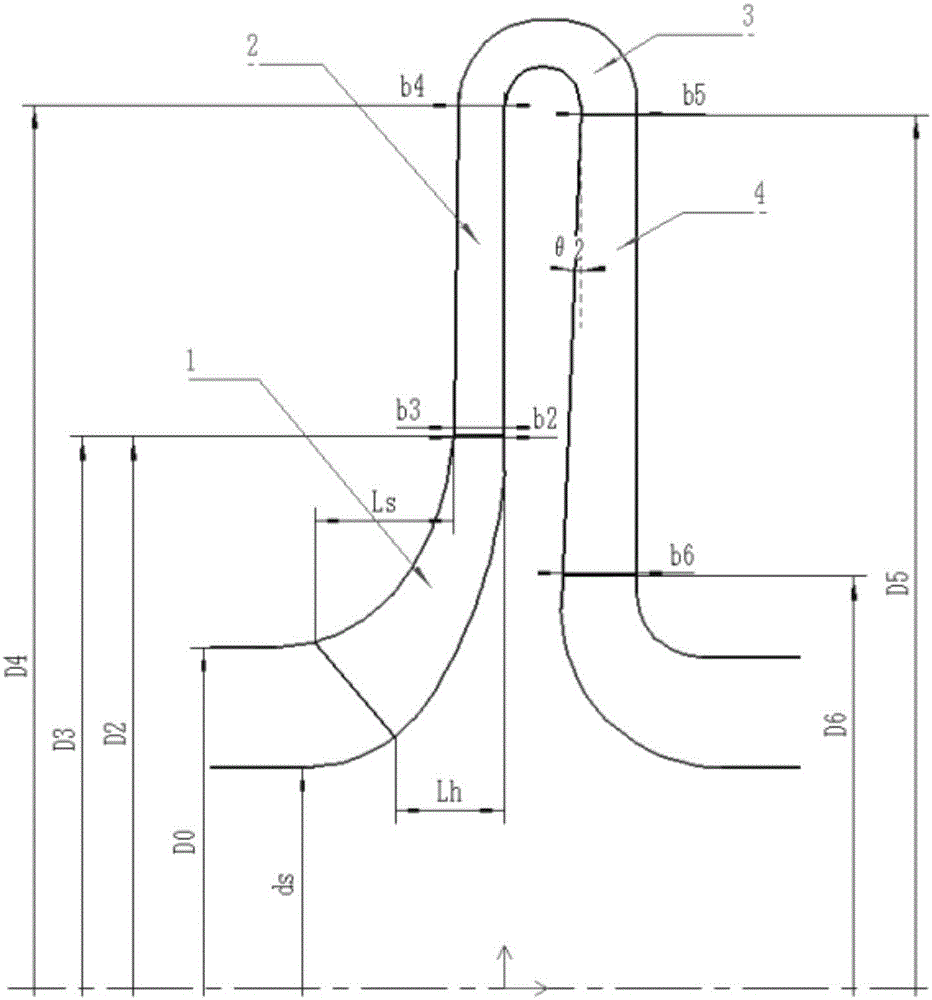

Pipeline compressor model stage with flow coefficient of 0.0495 and impeller design method

InactiveCN106762811AHigh head coefficientWheel hub ratioPump componentsDesign optimisation/simulationImpellerEngineering

Owner:SHENYANG TURBO MASCH CORP +1

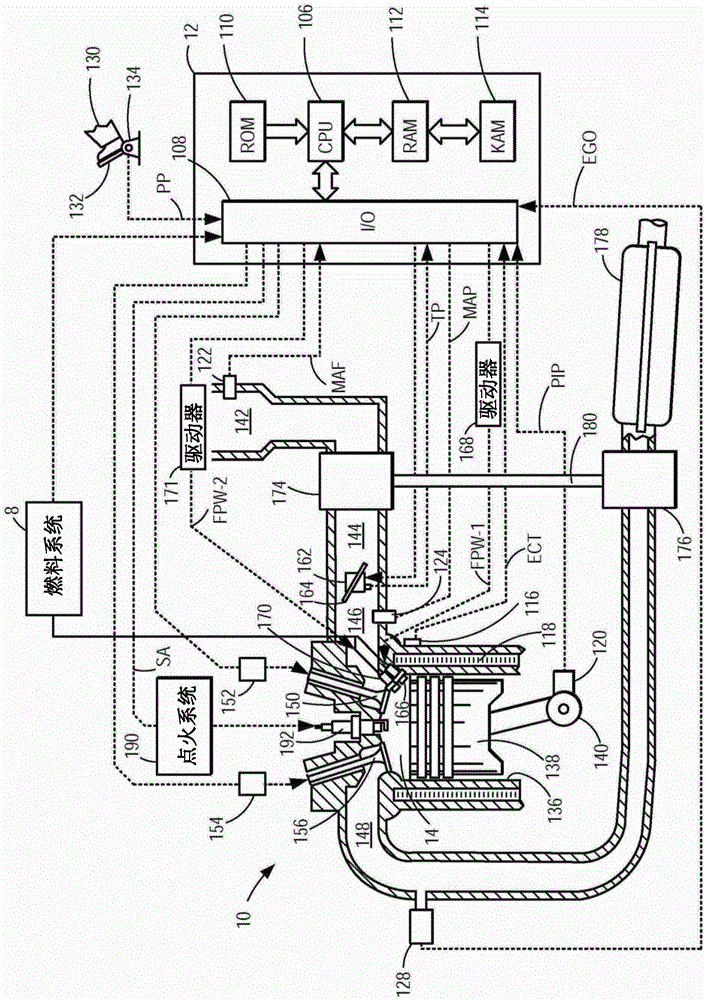

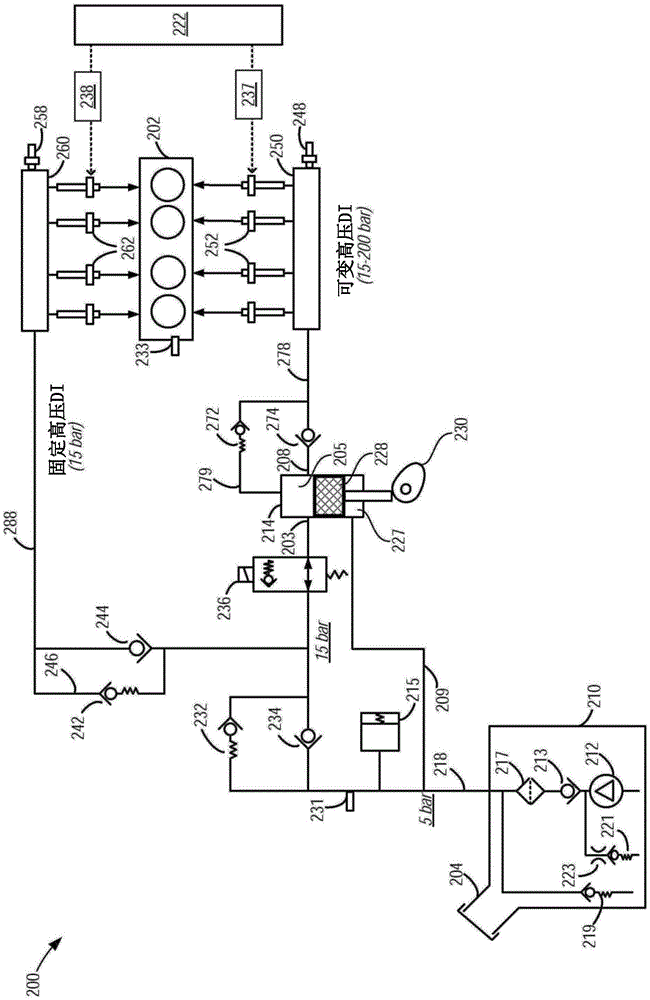

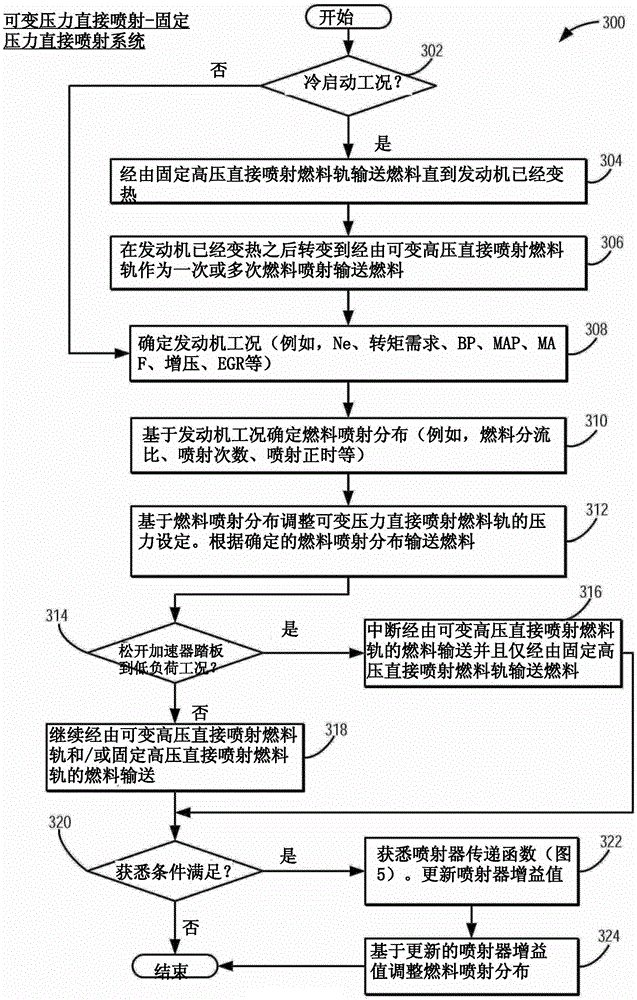

Methods and systems for fixed and variable pressure fuel injection

ActiveCN105697175APrecision injectionImprove injection efficiencyElectrical controlInternal combustion piston enginesRail pressureSystem configuration

Methods and systems are provided for operating a high pressure injection pump to provide each of high fixed fuel pressure at a first direct injection fuel rail and high variable fuel pressure at a second direct injection fuel rail. The direct injection fuel rail pressure can be raised above a pressure provided with a lift pump via a fuel system configuration that includes various check valves, pressure relief valves, and a spill valve positioned between an inlet of the high pressure injection pump and the port injection fuel rail. Fixed and variable high pressure direct injection may be advantageously used to provide learn the ballistic region of each direct injector.

Owner:FORD GLOBAL TECH LLC

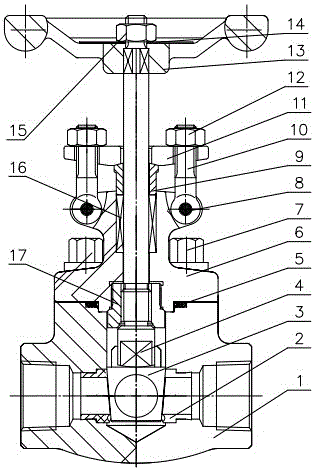

Hard sealing lifting type brake plug valve and control method thereof

ActiveCN105065701AReduce frictionExtended service lifeOperating means/releasing devices for valvesSlide valveEngineeringHigh pressure

The invention relates to a hard sealing lifting type brake plug valve and a control method thereof. The hard sealing lifting type brake plug valve comprises a valve body, a valve seat, a valve plug, a valve rod, a gasket, a valve deck, studs, pins, a packing bushing, swing bolts, a packing pressing plate, swing bolts, a hand wheel, a hand wheel gasket, a nut, packing and a valve rod nut. The valve body and the valve deck are connected through the studs. The valve deck and the packing pressing plate are connected through the swing bolts. The valve rod is connected with the valve plug through a head flat-square part. A full-bore partial-rotation structure is adopted, the flow coefficient is large, and the opening and closing space is small. The metal-sealing, fireproof, anti-static and blowout prevention valve rod structure is adopted, and the hard sealing lifting type brake plug valve is suitable for high-temperature-resistant, high-pressure-resistant and strong-corrosion-resistant working conditions and is wide in application range. The packing structure can be replaced on line, and online maintenance is convenient. During operation, a sealing pair is disengaged, friction between opening and closing torque and the sealing pair is reduced, and the service life of the valve is prolonged.

Owner:浙江福瑞科流控机械有限公司

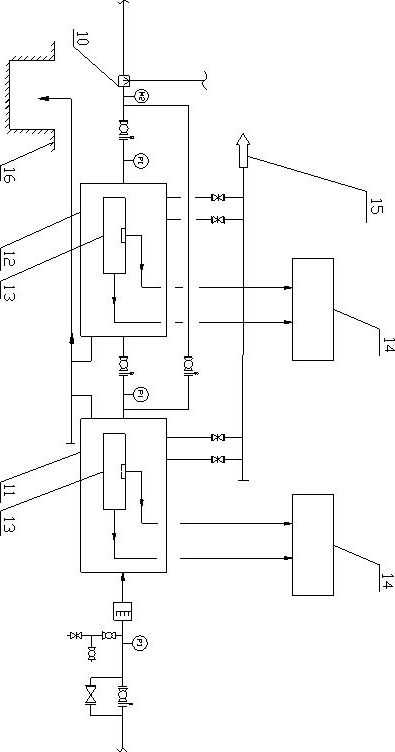

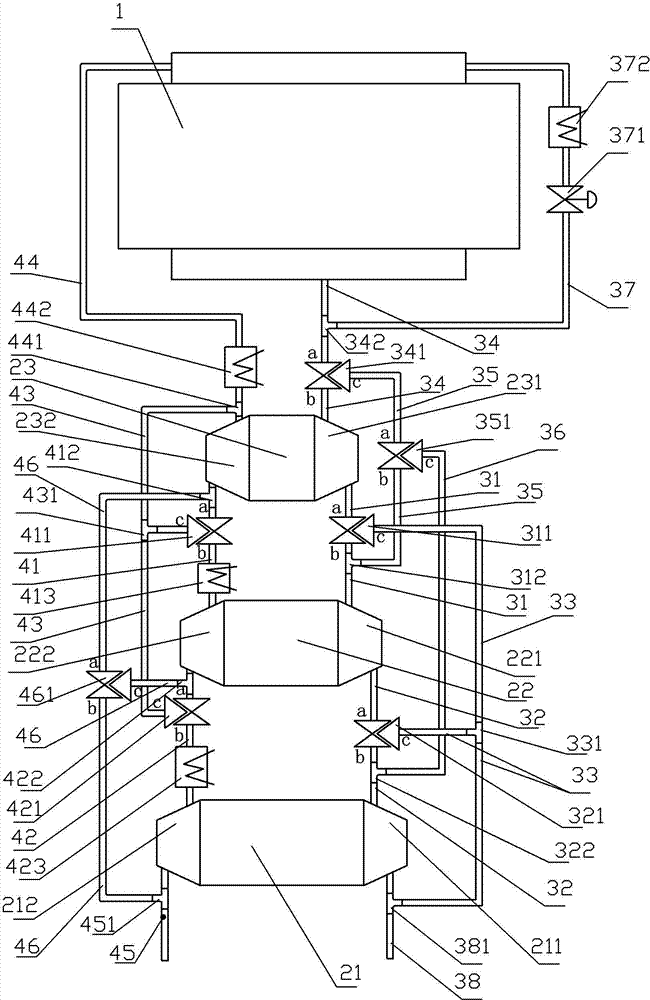

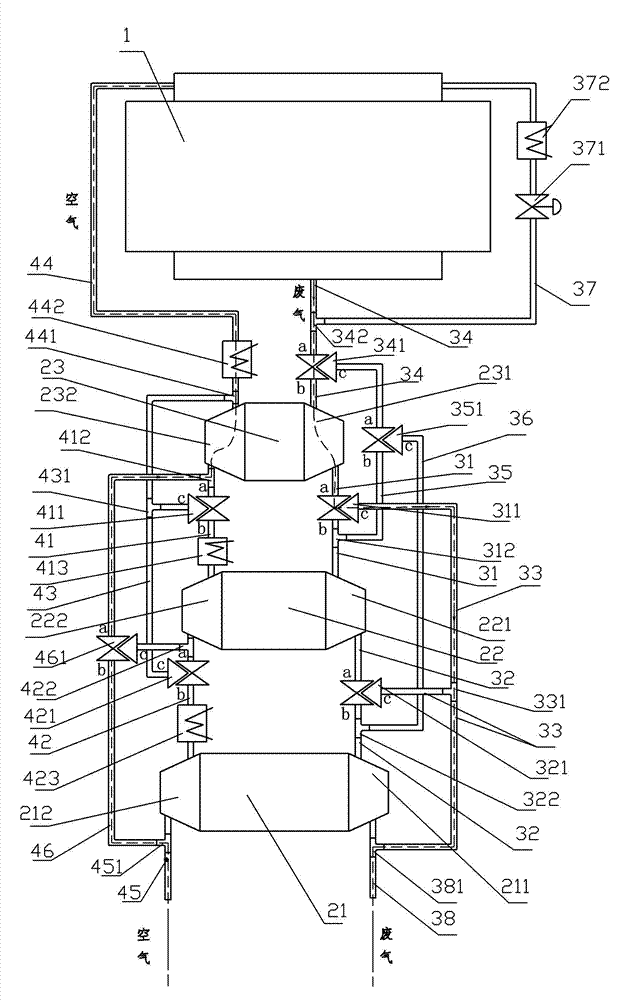

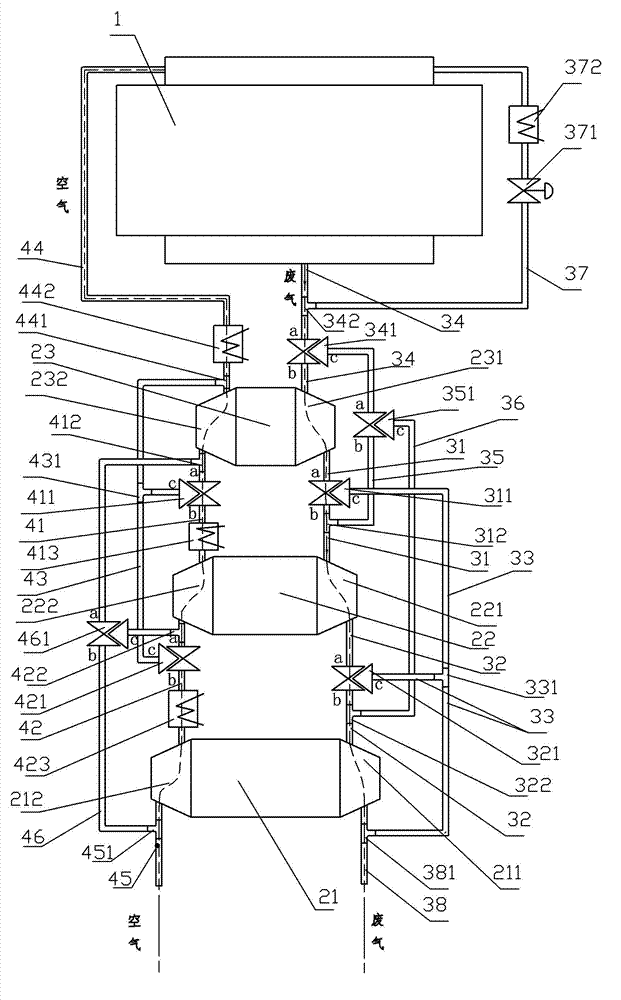

Level-variable turbocharging system and engine with same

ActiveCN103615308AImprove machine efficiencyGood acceleration and responsivenessInternal combustion piston enginesTurbochargerEngineering

An engine with a level-variable turbocharging system comprises an engine body (1) and the level-variable turbocharging system, wherein the engine body (1) comprises an engine mechanical assembly and an engine electric control unit; the level-variable turbocharging system comprises a large turbocharger (21), a middle turbocharger (22) and a small turbocharger (23) which are different in flow, each of the turbochargers comprises a turbine and an air compressor which form a network with an air pipe through a tee joint (312), a tee joint (322), a tee joint (331), a tee joint (342), a tee joint (381), a tee joint (412), a tee joint (422), a tee joint (441), a tee joint (451), a three-way valve (311), a three-way valve (321), a three-way valve (341), a three-way valve (351), a three-way valve (411), a three-way valve (421) and a three-way valve (461), and connected with the engine body (1).

Owner:HUNAN TYEN MACHINERY

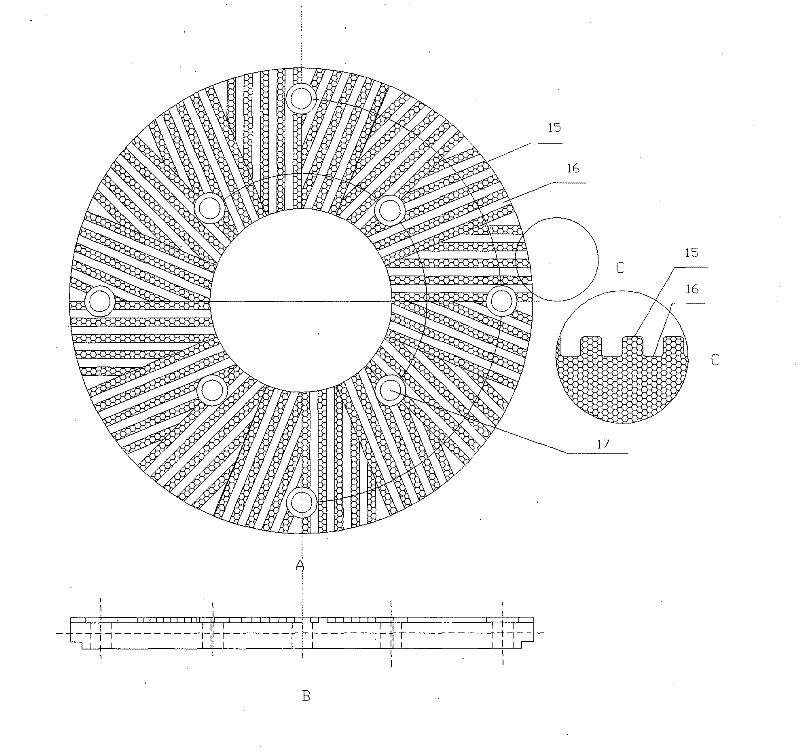

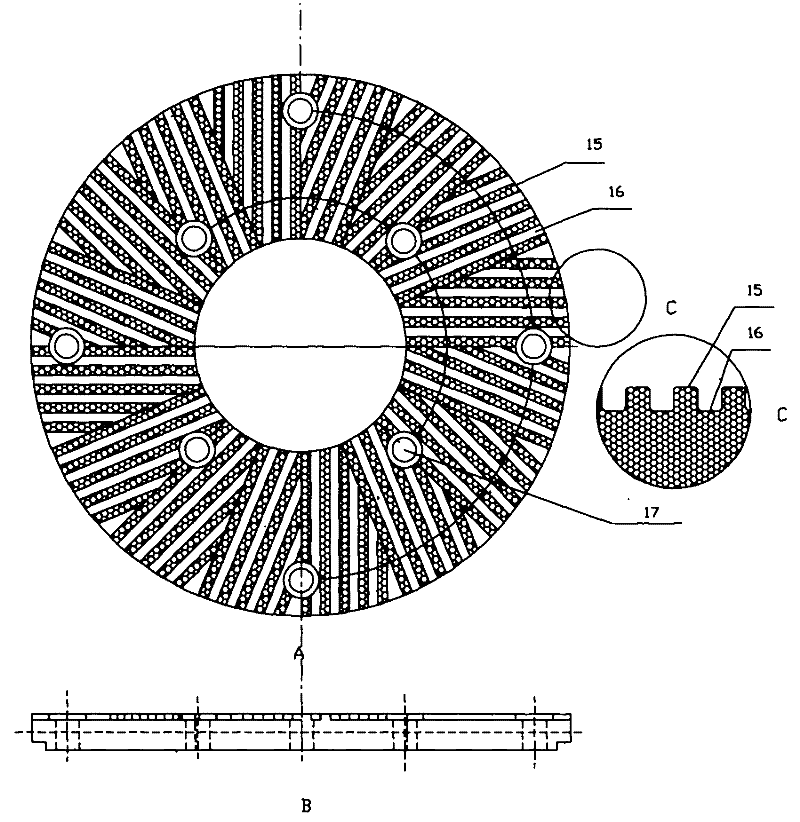

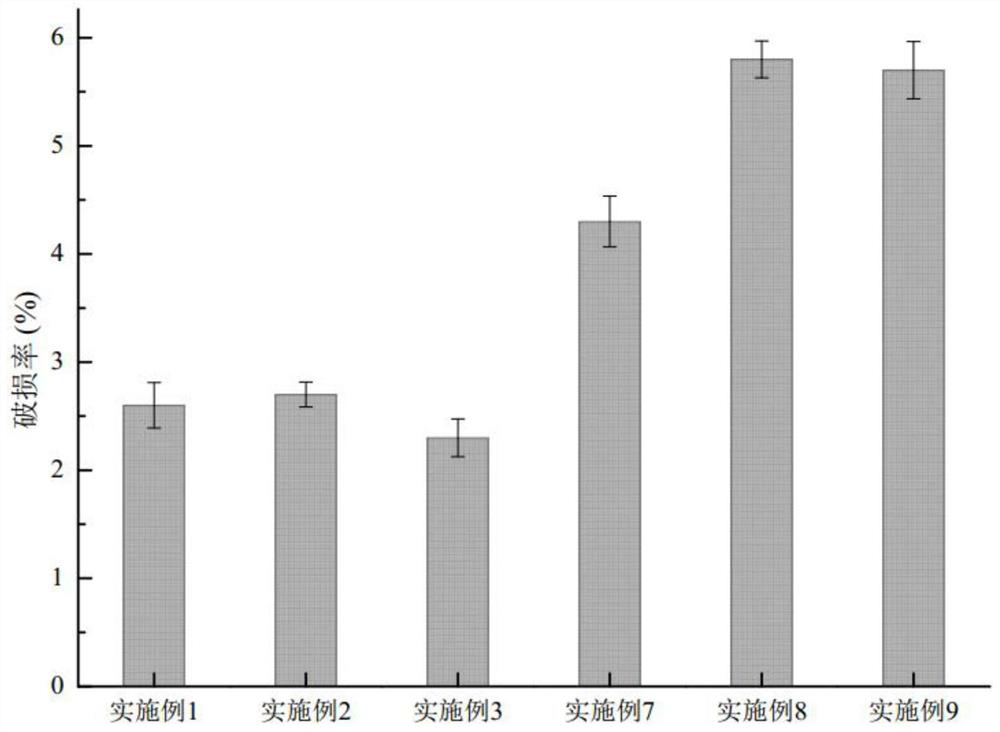

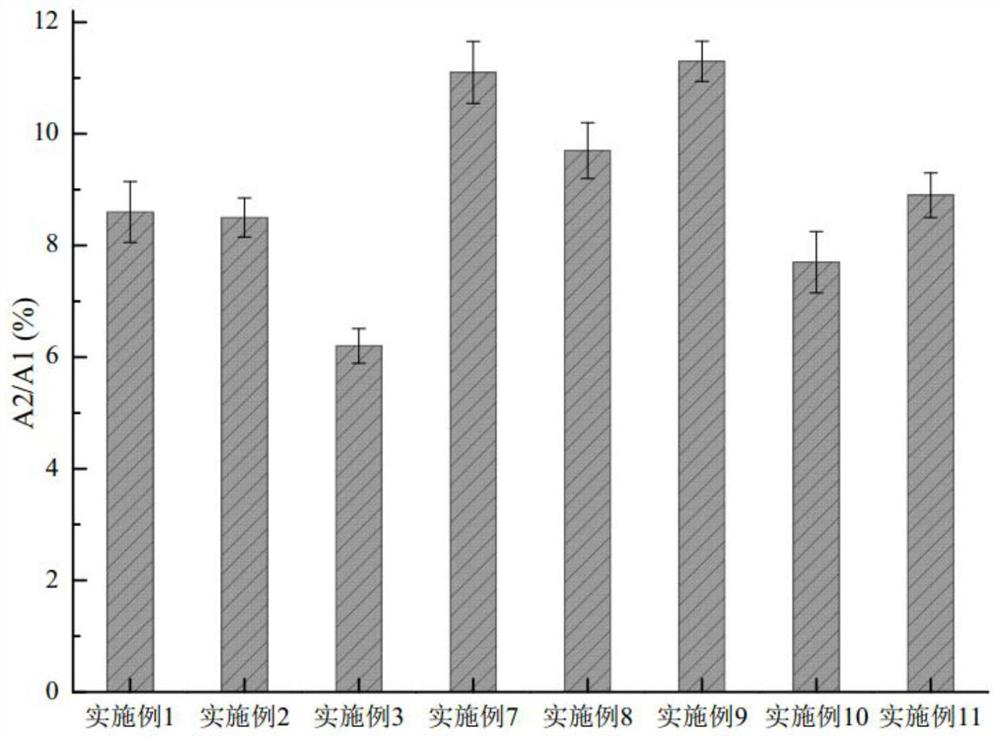

Silicon carbide ceramic millstone and preparation method

InactiveCN102350727AHomogeneous microstructureHigh strengthCeramic shaping apparatusGranularityToughness

The invention provides a silicon carbide ceramic millstone and a preparation method. The silicon carbide ceramic millstone is characterized by comprising a ceramic circular ring (A) with a certain wall thickness, grooves formed by alternate bulges (15) and sags (16) are distributed on one surface of the ceramic circular ring (A), and eight through-holes (17) with the same specification are alternately and evenly distributed along the inner side and the outer side of the ceramic circular ring. The preparation method comprises the steps of raw material preparation, pressing, firing and processing, and is characterized in that phenolic resin is evenly mixed with silicon carbide powder with the granularity of 0.1 to 3mum at the ratio of 1:3 to 5; after a mixture is solidified at a temperature of 40 DEG C to 100 DEG C, granulated powder (14) with the granularity of 50 to 200mu m is prepared and is then evenly loaded into a special mould; under the pressure of 50 to 300MPa, isostatic pressing is conducted and the pressure is maintained for 10 to 30 minutes; then the granulated powder is demoulded and a green body of the silicon carbide ceramic millstone is manufactured; and after the firing and cold working, the silicon carbide ceramic millstone is manufactured. The silicon carbide ceramic millstone has the advantages of high strength, high toughness, excellent wear-resisting property and long service life, and is suitable for industrialized large scale production.

Owner:SHANDONG UNIV OF TECH

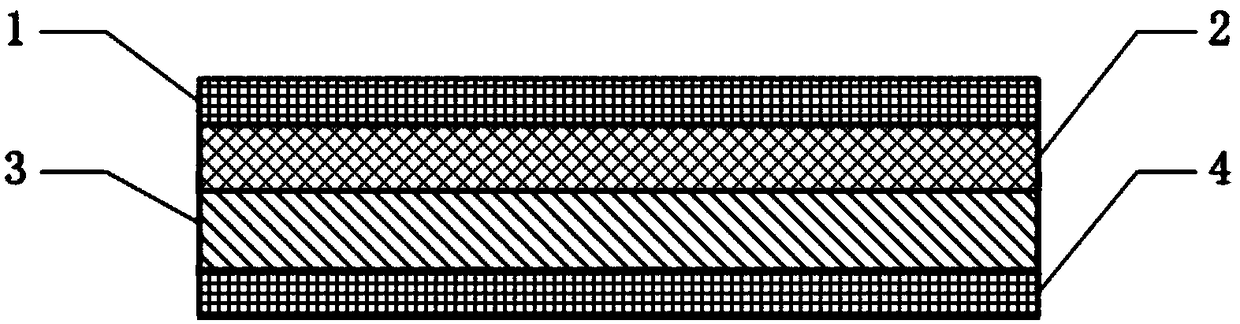

Composite filter material and preparation method thereof

PendingCN109501408AImprove filtering effectExcellent temperature and corrosion resistanceFibre treatmentSynthetic resin layered productsFiberGlass fiber

The invention provides a composite filter material and a preparation method thereof. The composite filter material provided by the invention comprises a first PTFE impregnating layer, a chemical fibernet layer, a glass fiber expanded fabric layer and a second PTFE impregnating layer which are sequentially contacted, wherein the chemical fiber net layer is combined with the glass fiber expanded fabric layer to realize a synergistic effect as well as excellent filtering performance, temperature resistance and strength performance; meanwhile, the PTFE impregnating layers are compounded on two sides of a combination body so as to facilitate the collection of fine dust and further improve the dust removal efficiency. Therefore, the integral composite material has excellent filtering performance, temperature and corrosion resistance, broad use conditions and long service life.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

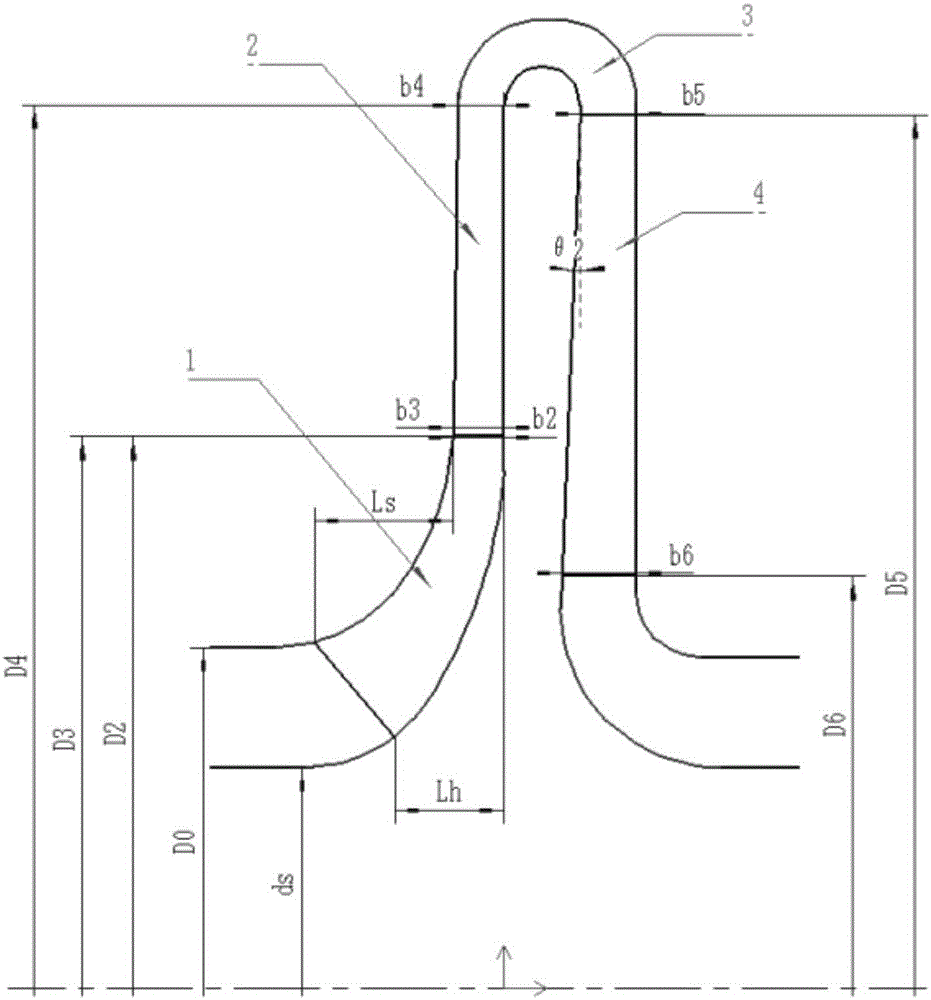

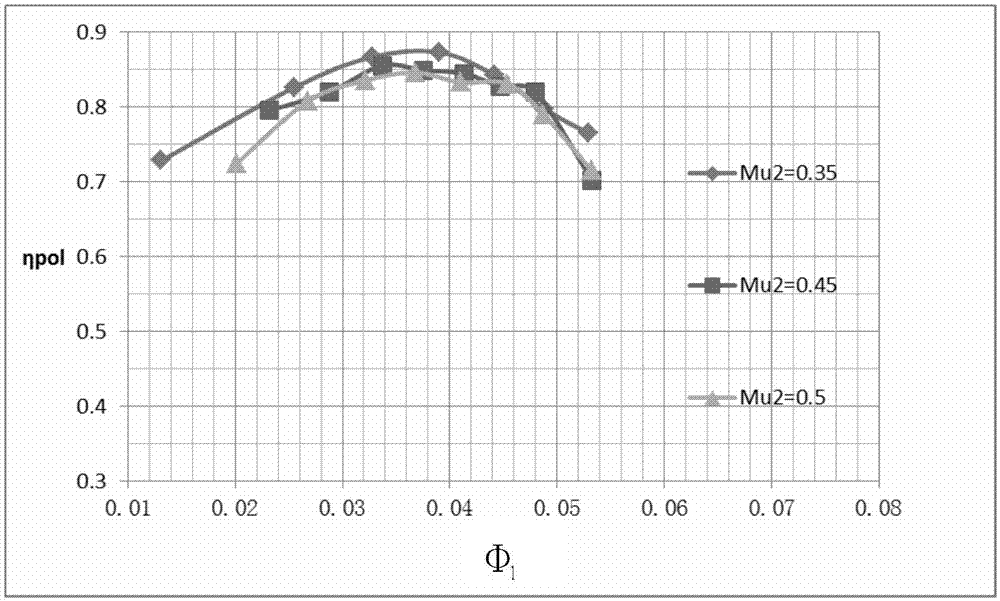

Model stage special for pipeline compressor

InactiveCN106870447AHigh variable efficiencyHigh head coefficientPump componentsPumpsCentrifugal compressorStreamflow

The invention belongs to a centrifugal compressor model stage, and particularly relates to a model stage special for a pipeline compressor. The model stage is suitable for modeling design of a pipeline compressor product. The model stage comprises an impeller, a vaneless diffuser, a curve and a backflow device; the impeller is located at the inlet position of the model stage, the vaneless diffuser is arranged at an outlet of the impeller, the backflow device is located at the outlet position of the model stage, and the vaneless diffuser is communicated with the backflow device through the bend; and the design machine mach number Mu2 of the model stage is 0.35 to 0.5, the flow coefficient phi1 is equal to 0.023 to 0.053, the energy head coefficient tau is equal to 0.47 to 0.71, the design condition point polytropic efficiency etapol under each mach number is equal to 0.846 to 0.873, the hub ratio ds / D2 of the model stage is equal to 0.4, and the ratio L / D2 of the span to the diameter is 0.292. The model stage is high in efficiency, high in energy head coefficient, large in hub ratio and small in span; by means of the model stage, the pipeline compressor can have the higher running efficiency and wider working condition scope; and meanwhile, the rotor working rotating speed can be decreased, the bearing span is shortened, and the rotor stability is improved.

Owner:SHENYANG BLOWER WORKS GROUP CORP

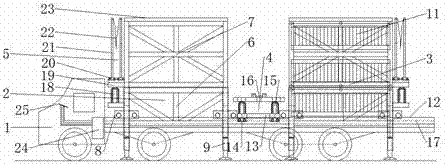

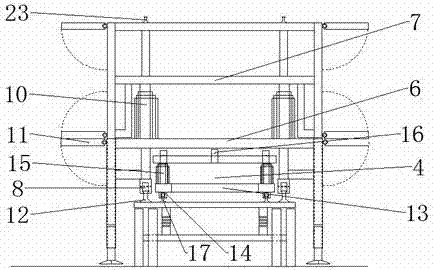

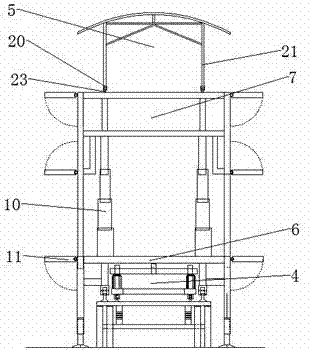

Movable-type hydraulic work protective platform in tunnel

PendingCN107882582AMove quicklyEasy to maintainUnderground transportProps/chocksCivil engineeringArchitectural engineering

The invention relates to the technical field of civil engineering, in particular to a movable-type hydraulic work protective platform applied into a tunnel. The movable-type hydraulic work protectiveplatform comprises a flat transporting trolley, a wheeltrack-type hydraulic lifting rack part mounted on a trolley body, a wheeltrack-type hydraulic lifting arching mounting trolley part and a wheeltrack-type hydraulic lifting telescopic protective rack part. The wheeltrack-type hydraulic lifting rack part comprises a wheeltrack-type hydraulic lifting rack which comprises a rack upper part and a rack lower part. The rack lower part is provided with a rack travelling device and supporting legs for supporting the hydraulic lifting rack, and the rack upper part is provided with a lifting device and a foldable working platform. The wheeltrack-type hydraulic lifting arching mounting trolley part comprises a mounting trolley mounted on the trolley working platform. The wheeltrack-type hydrauliclifting telescopic protective rack part comprises a wheeltrack-type hydraulic lifting telescopic protective rack, a protective rack lifting device and a protective rack lifting platform. The movable-type hydraulic work protective platform has the technical advantage that the safety degree of centralized operation is high.

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 17 BUREAU GRP

Homogeneous rhodium catalytic system of oxo-acetic anhydride and its use

InactiveCN1939586AImprove stabilityEasy to adjustOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsIodised saltAcetic anhydride

A Ru catalyst system with high activity and stability for preparing oxo acetoanhydride from methyl acetate by catalytic homogenizing reaction features that the phosphate additive is used in it besides the alkyl iodine and the iodate of alkali metal are used as its cocatalyst.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Liquid mechanical seal internally provided with axial floating tray sleeve

PendingCN110030383ARealize dynamic observationAvoid safety accidentsEngine sealsEngineeringMechanical engineering

Owner:ENVIRONMENTAL GASKET COMPANY

Worm type lifting mechanism and system

ActiveCN106957035AReduced torque requirementsSmooth liftToothed gearingsLifting devicesDrive wheelEmergency rescue

The invention discloses a square cabin lifting device and relates to a worm type lifting mechanism. The worm type lifting mechanism comprises a drive wheel and a drive device which are arranged in cooperation with a transmission chain. A worm gear reducer is assembled between the drive wheel and the drive device. When the drive device drives the drive wheel to rotate, a square bin support ascends and descends under the drive of the transmission chain. A worm type lifting system comprises four worm type lifting mechanisms arranged at the four corners of a square bin in a supported manner. The lifting mechanism provides large rotation torque for conversion of the worm gear reducer and lower the requirement for torque of the drive device; in addition, the square cabin can ascend and descend stably and is safely and rapidly operated due to the self-locking performance of a worm wheel and a worm, and the use requirement for actions such as fast field emergency rescue is met; and in addition, transmission rods are sequentially connected with the lifting system composed of the worm type lifting mechanisms, synchronous ascending and descending of four supporting points of the square cabin are ensured, one person is enough for one-point operation, labor force is saved, and the lifting efficiency is improved.

Owner:SICHUAN JOINER MACHINERY & AUTOMATIC EQUIP

Hydrate gel type filter element and preparation method thereof

InactiveCN109351055AReduce chromaReduce turbidityFiltration separationGel preparationNon oxide ceramicsFiltration

The invention relates to a hydrate gel type filter element and a preparation method thereof. The hydrate gel type filter element comprises hydrogel for barrier filtration and a support for supportingthe hydrogel. The hydrogel is metal hydroxide gel, and the support is prepared from metal oxide and nonoxide ceramic materials. The hydrate gel type filter element prepared according to the method isextensively applicable to the field of water purification and capable of effectively removing bacteria and viruses in water and has excellent improving effects on water turbidity and color and excellent removal effects on total organic carbon and the like.

Owner:WUHAN UNIV +1

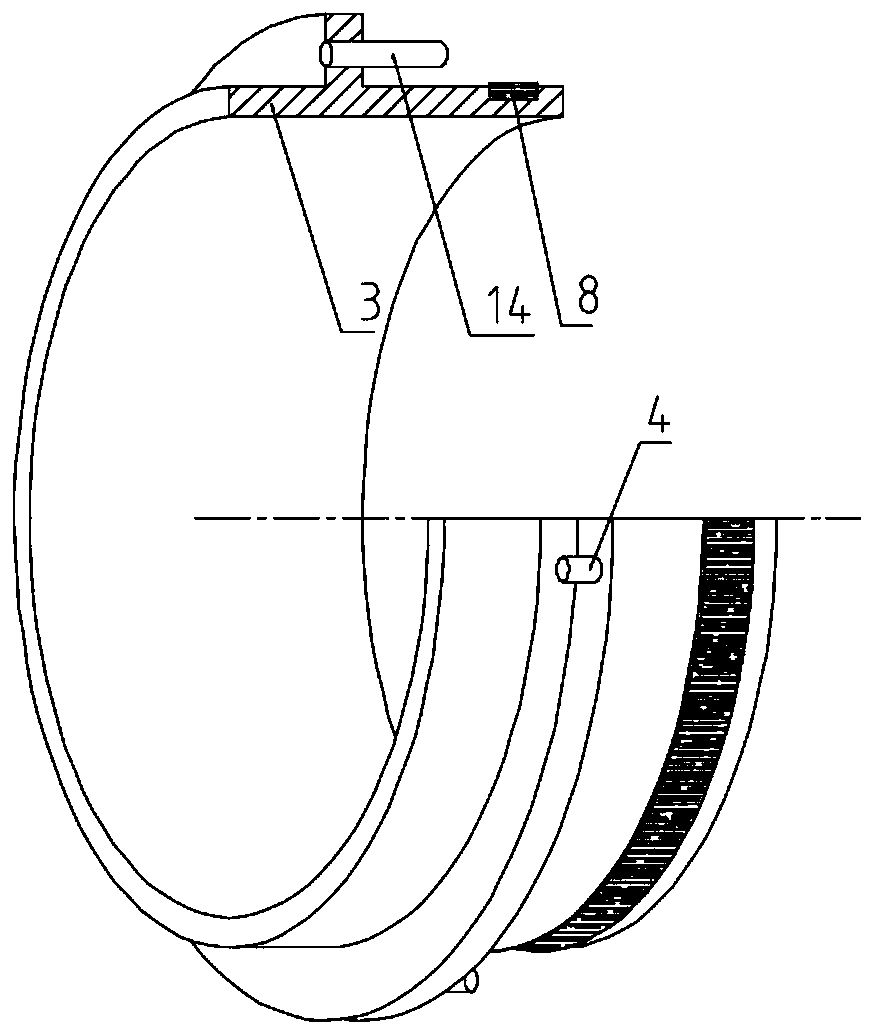

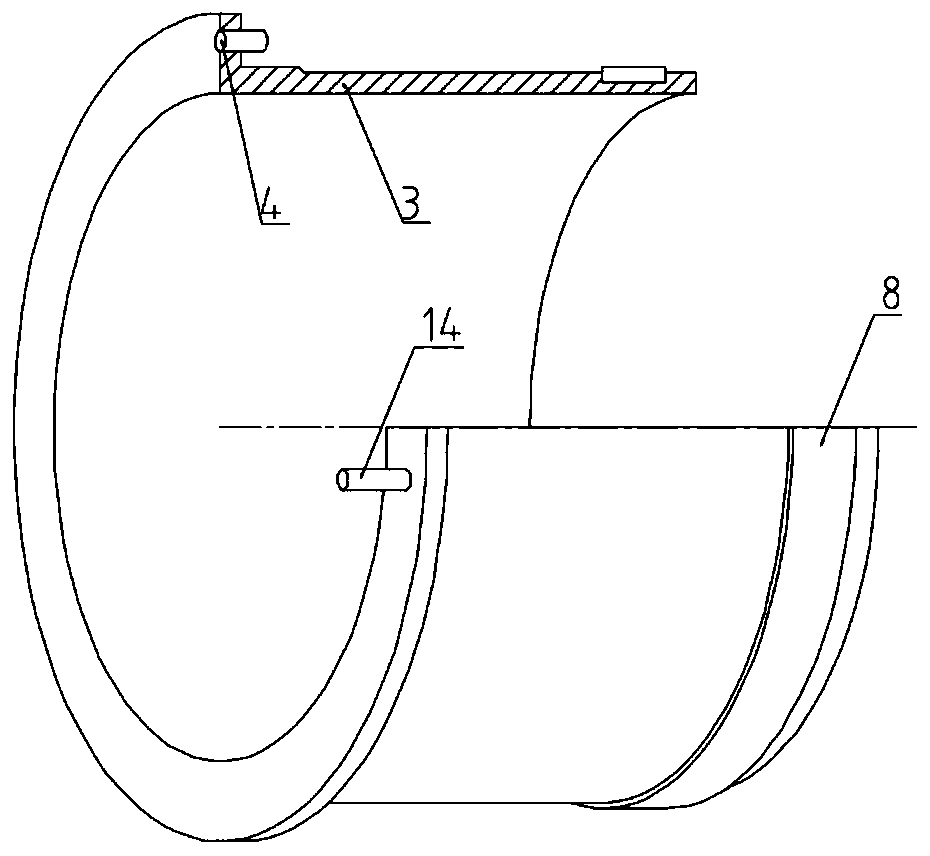

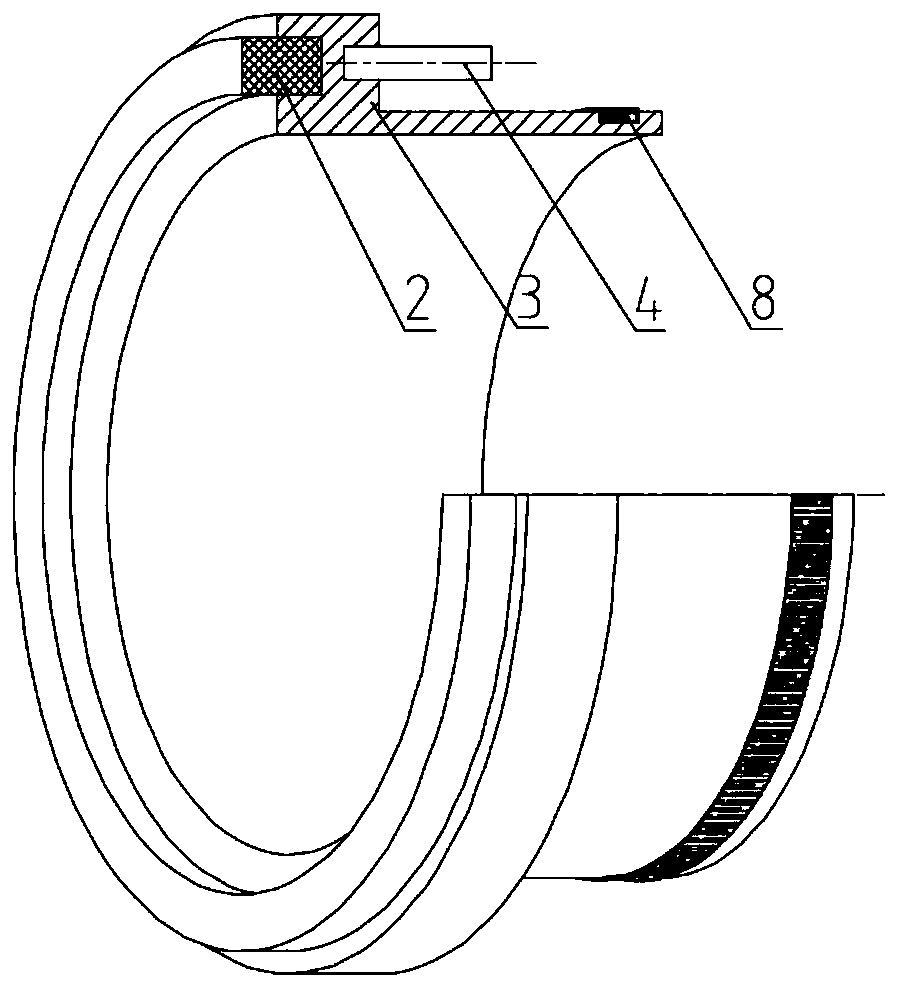

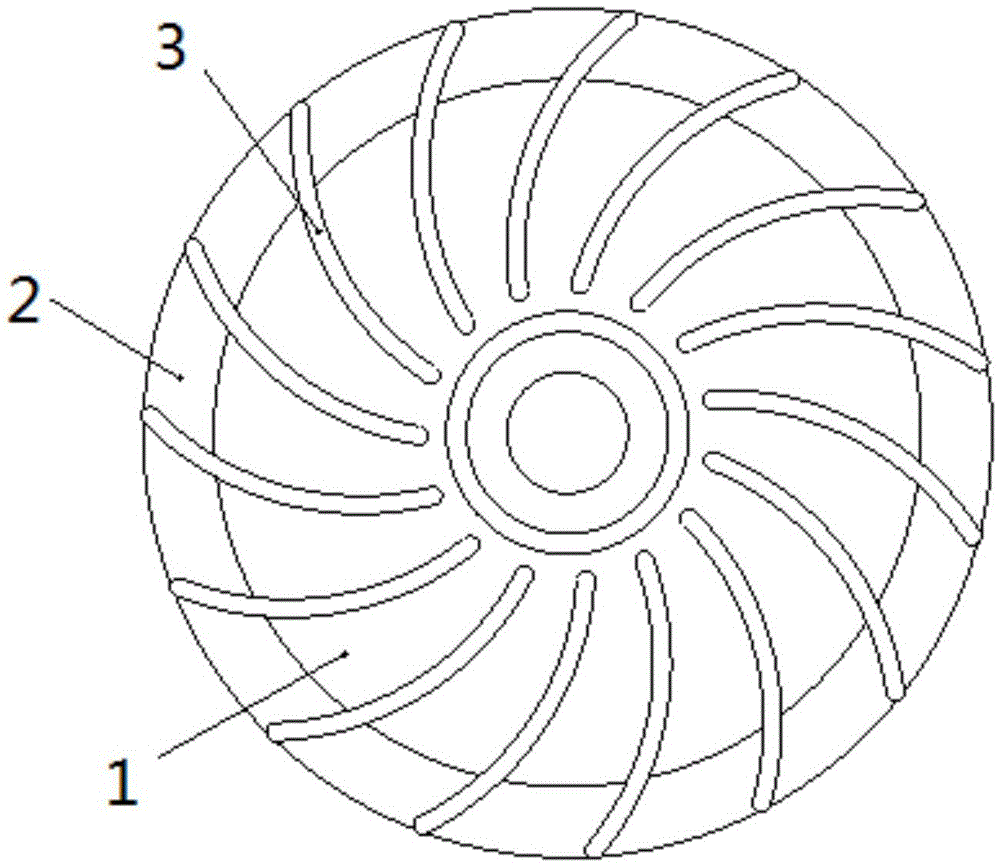

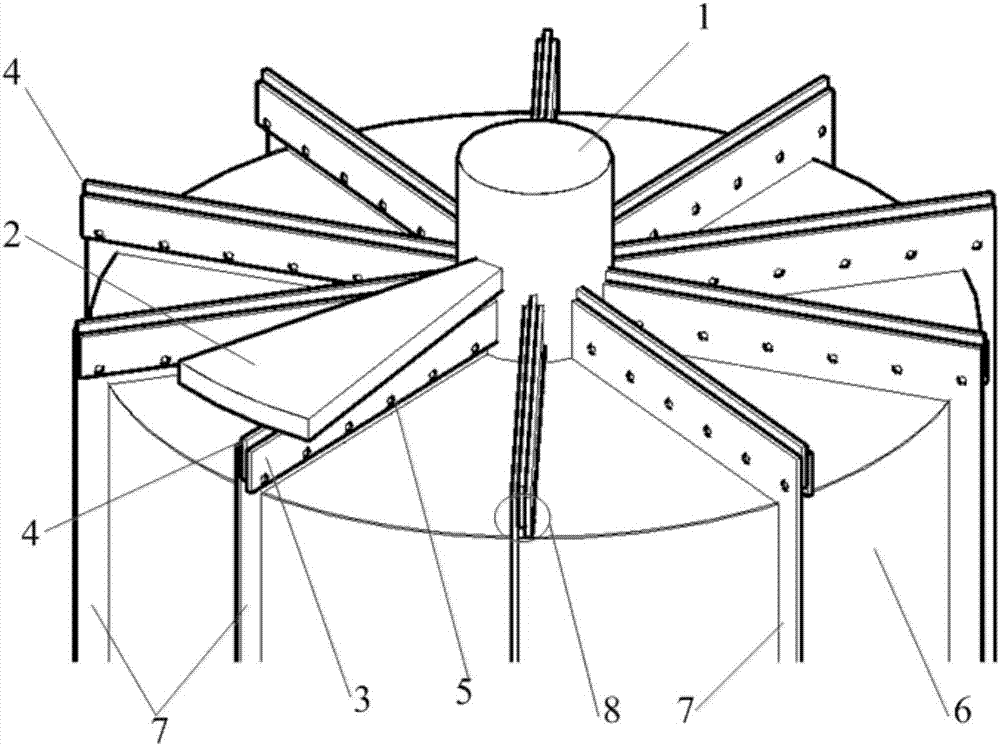

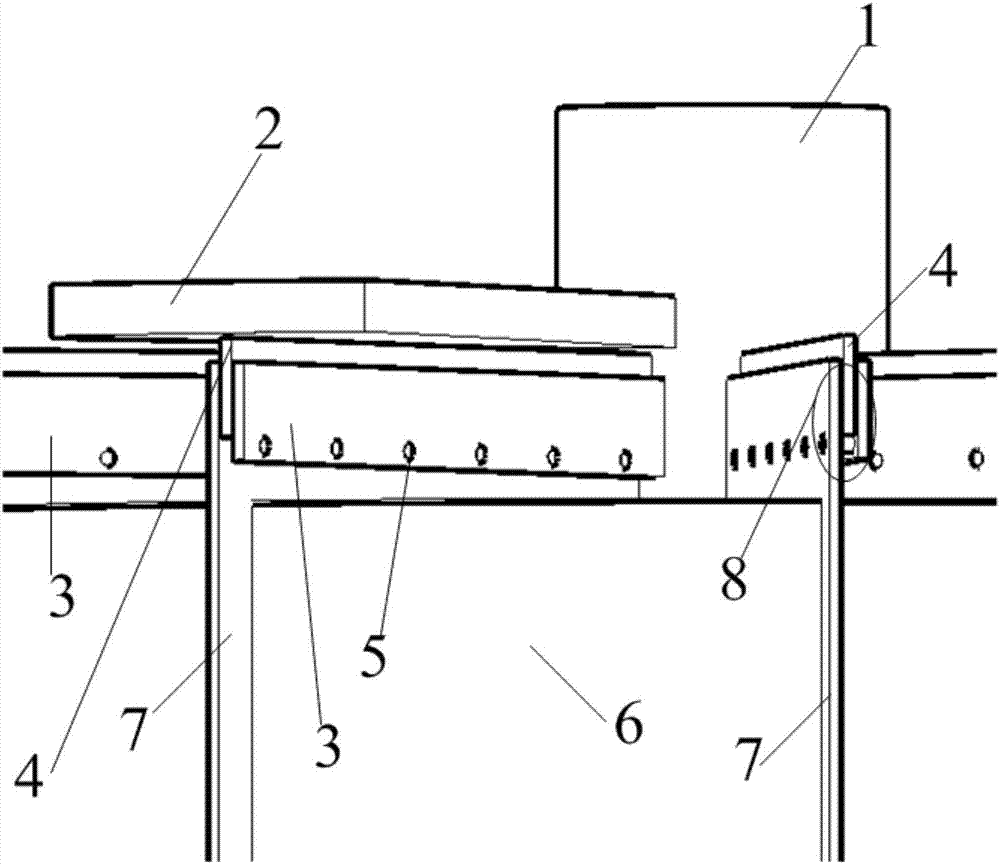

Blade-adjustable semi-open impeller

ActiveCN105650027AImprove versatilityWide range of working conditionsPump componentsPumpsImpellerWorking range

The invention provides a blade-adjustable semi-open impeller which comprises an impeller disc, an adjusting ring and blades. An annular boss is arranged on the front of the impeller disc, and the adjusting ring can be mounted on the boss in a sleeving manner. When a positioning pin hole A is formed in each blade, a corresponding long round hole B is formed in the adjusting ring, a long round groove A corresponding to each long round hole B and crossed with the same in extending direction is formed in the impeller disc, a positioning pin A is arranged in each positioning pin hole A, and one end of each positioning pin A is fixed in the corresponding positioning pin hole A while the other end of the same penetrates the corresponding long round hole B to be inserted into the corresponding long round groove A. The blade-adjustable semi-open impeller has a blade detachable function, and the blade can rotate to change angle in a plane of the impeller disc when not being detached completely to realize wider working range and improve efficiency of a fan.

Owner:ESURGING TIANJIN TECH CO LTD

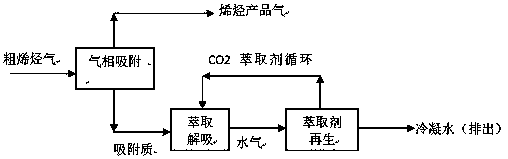

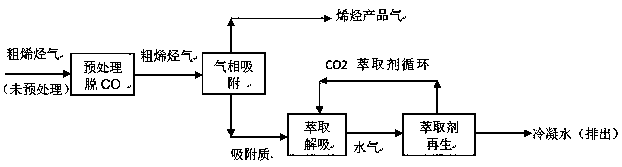

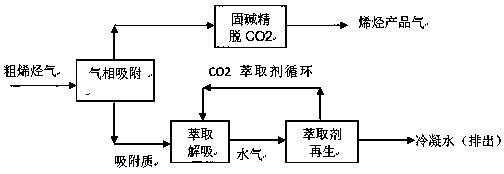

Purification method for deep dehydration and impurity removal of olefin by full-temperature range adsorptive extraction

InactiveCN107774083ASolve the difficulty of desorptionBig roomEthylene productionHydrocarbon oils refiningChemistryAfter treatment

The invention discloses a purification method for deep dehydration and impurity removal of olefin by full-temperature range adsorptive extraction. The purification method is characterized in that crude olefin feed gas (liquid) enters a gas / liquid phase adsorption process, an extraction and desorption process and an extracting agent regeneration process sequentially, moisture and trace impurity components are absorbed by an absorbing agent, and an olefin product with a purity of more than or equal to 99.9-99.99 percent (v / v) flows out from the top of an adsorption tower; after the adsorption process is completed, an extracting agent is introduced into the adsorption tower for the extraction and desorption process to dissolve out the moisture and the trace impurity components. Extraction anddesorption gas enters the extracting agent regeneration process, and the extracting agent is recovered and recycled after treatment. The purification method disclosed by the invention has the benefits that by adopting an adsorption-extraction and desorption process and in combination with an adsorption mechanism and an extraction and desorption dissolving mechanism, the whole operation process ismore stable and safer, the energy consumption is low, the product purity is high, the equipment investment cost is low, the purity of the olefin product is more than or equal to 99.9-99.99 percent, and the yield is more than or equal to 99 percent.

Owner:SICHUAN TECHAIRS

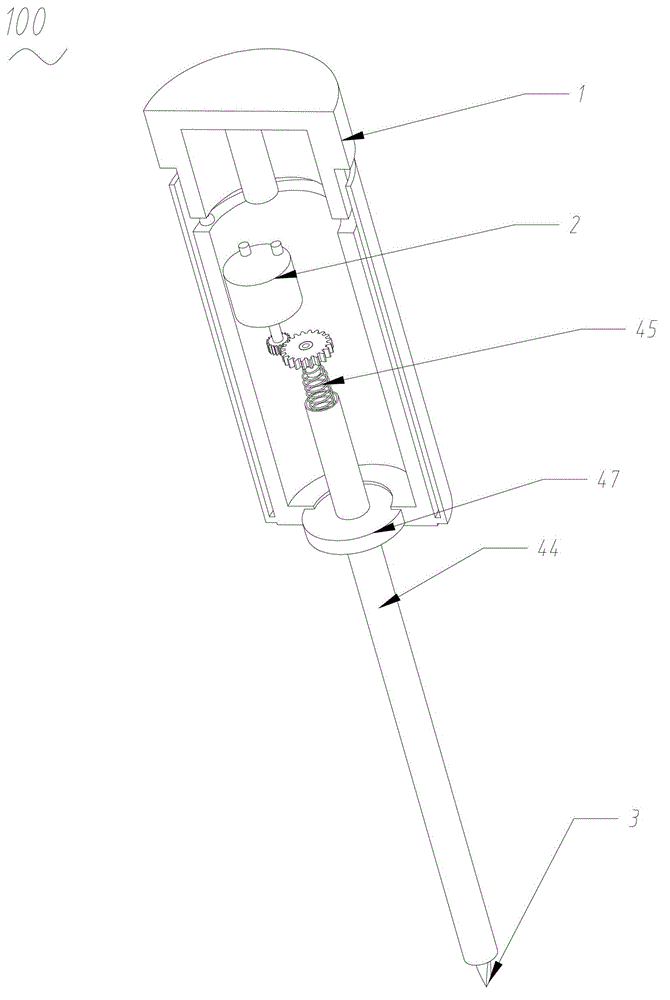

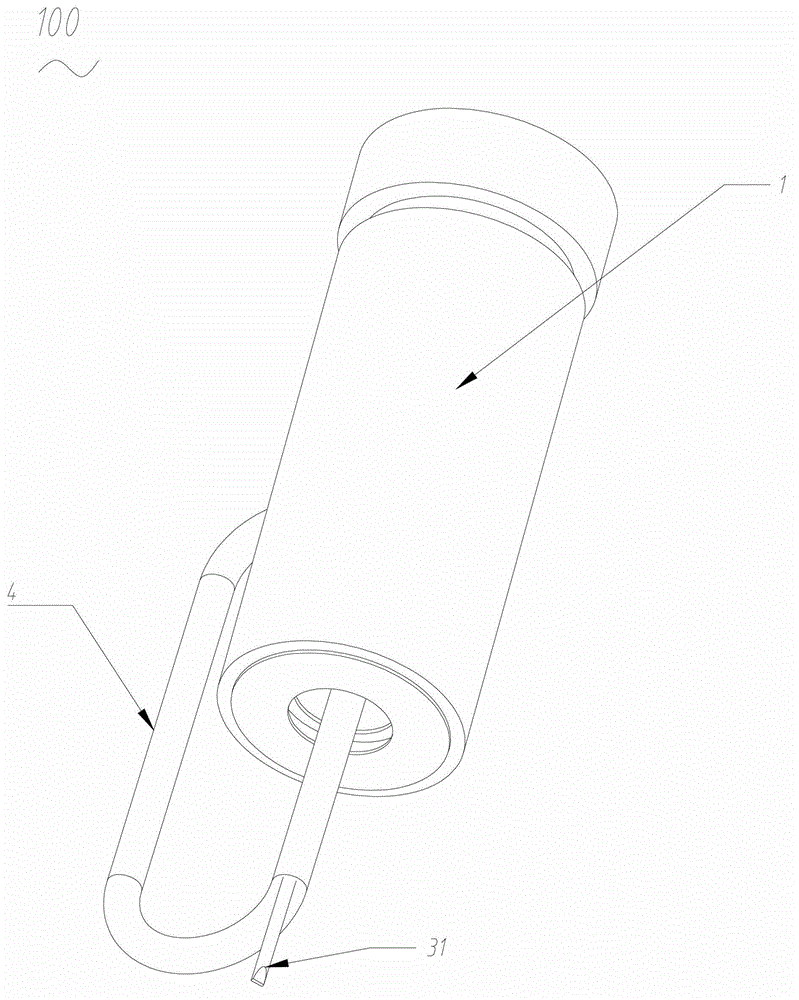

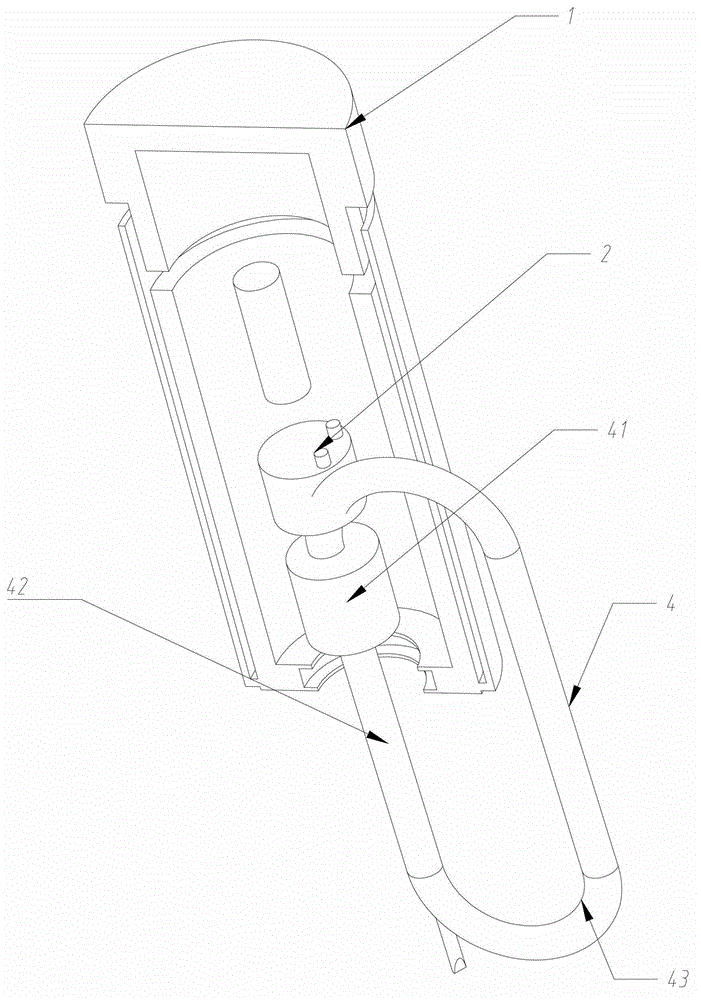

Electric tool

InactiveCN102941556AWide range of working conditionsPortable power-driven toolsPower driven toolsElectric machineEngineering

The invention provides an electric tool which comprises a shell, a motor arranged in the shell and an output shaft and is provided with a flexible conduction system, wherein the flexible conduction system is driven by the motor, is connected with the output shaft and can be used for transmitting the torque of the motor to the output shaft. Since the flexible conduction system is flexible, the electric tool can be operated under a narrow environment.

Owner:苏州安必瑟斯机电技术有限公司

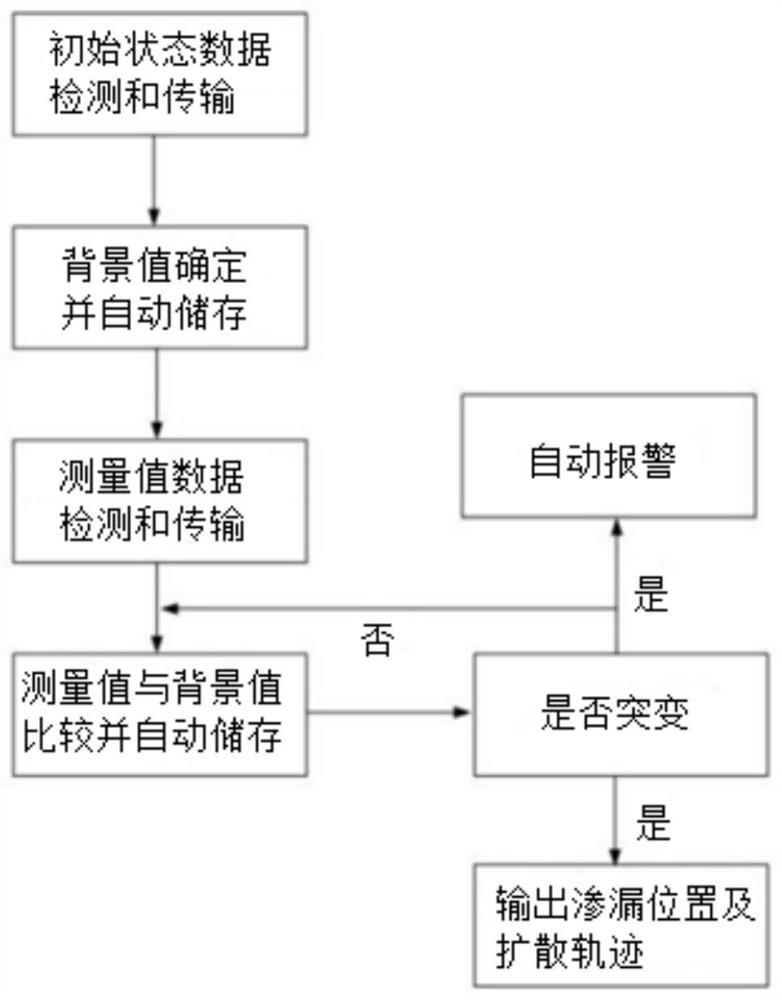

Oil product leakage monitoring technology adopting radioactive tracer

InactiveCN112177600AReduce churnEasy to recycleConstructionsEvaporationRadioactive tracerIsotopic tracer

The invention provides an oil product leakage monitoring technology adopting a radioactive tracer, and relates to the technical field of oil product permeation detection. A preparation method of the radioactive tracer comprises the following steps of: loading an isotope tracer on a porous carrier in an acid solution; providing a precipitant solution, wherein the precipitant can react with the isotope tracer to form an insoluble substance; and providing a hydrophobic solvent, performing surface hydrophobic treatment on the porous carrier loaded with the insoluble substance by the hydrophobic solvent, and drying to obtain the radioactive tracer. The monitoring technology comprises the following steps: acquiring initial state data by using a detection module; transmitting the initial state data to a server side for automatic storage, and determining a background value; measuring measured signal values at various moments, and transmitting the measured signal values to the server side for automatic storage; and comparing the measured signal values at various moments with the background value, transmitting an alarm signal to an alarm module by the server side when result data changes suddenly, and outputting information of a leakage position and an oil substance diffusion track in an area.

Owner:ZHEJIANG OCEAN UNIV

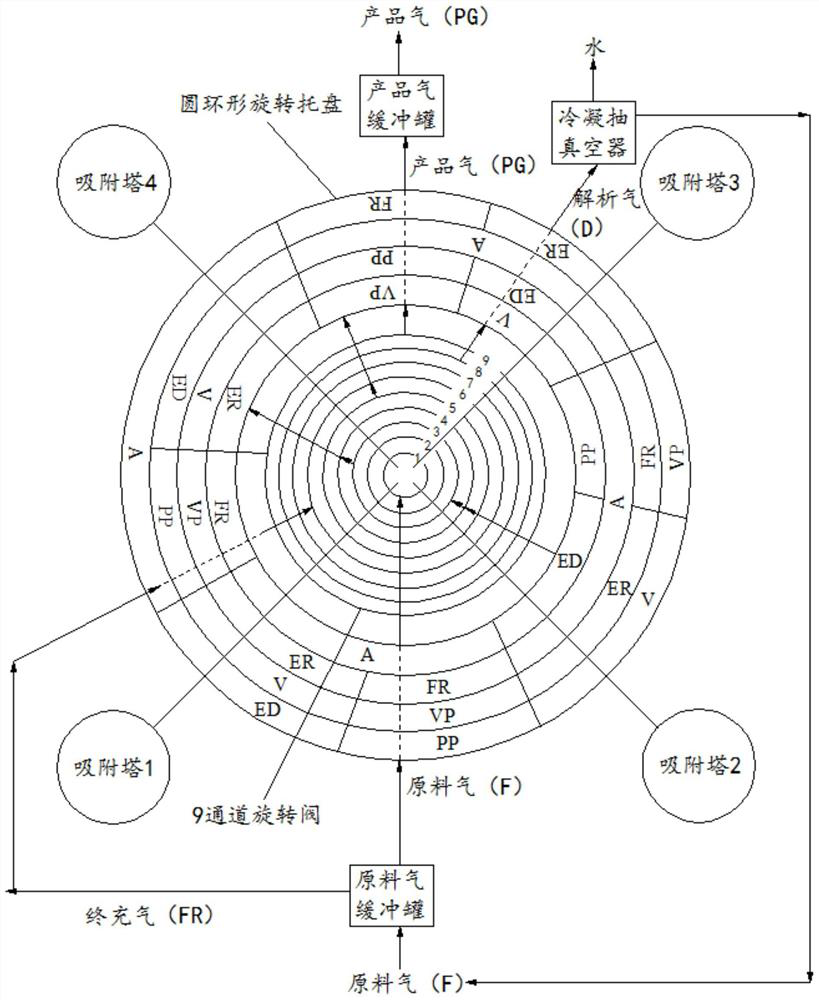

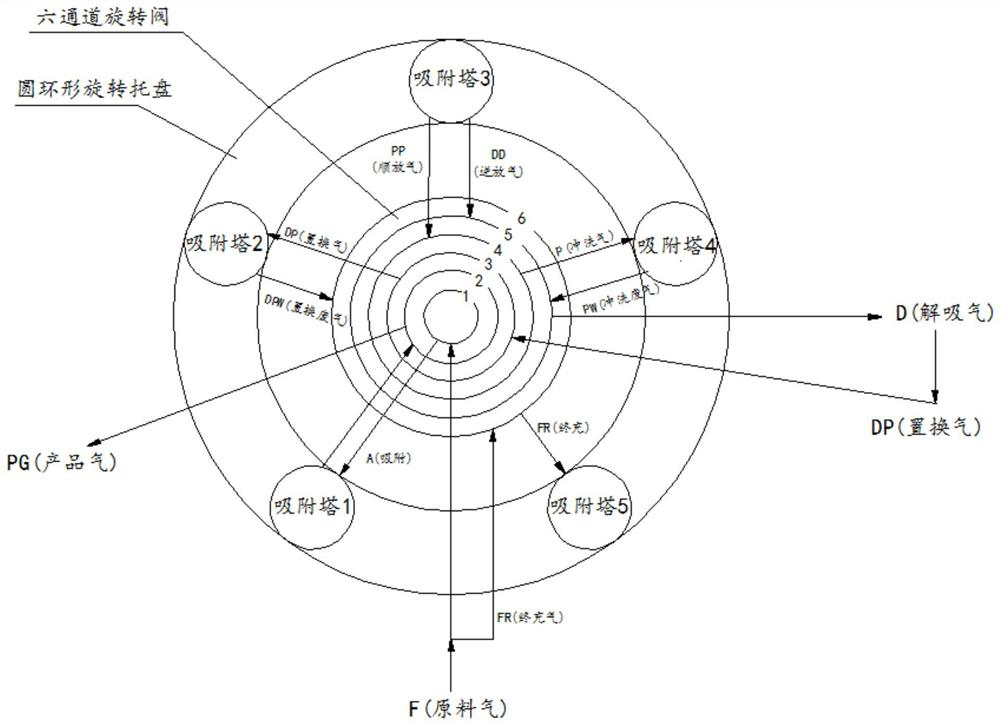

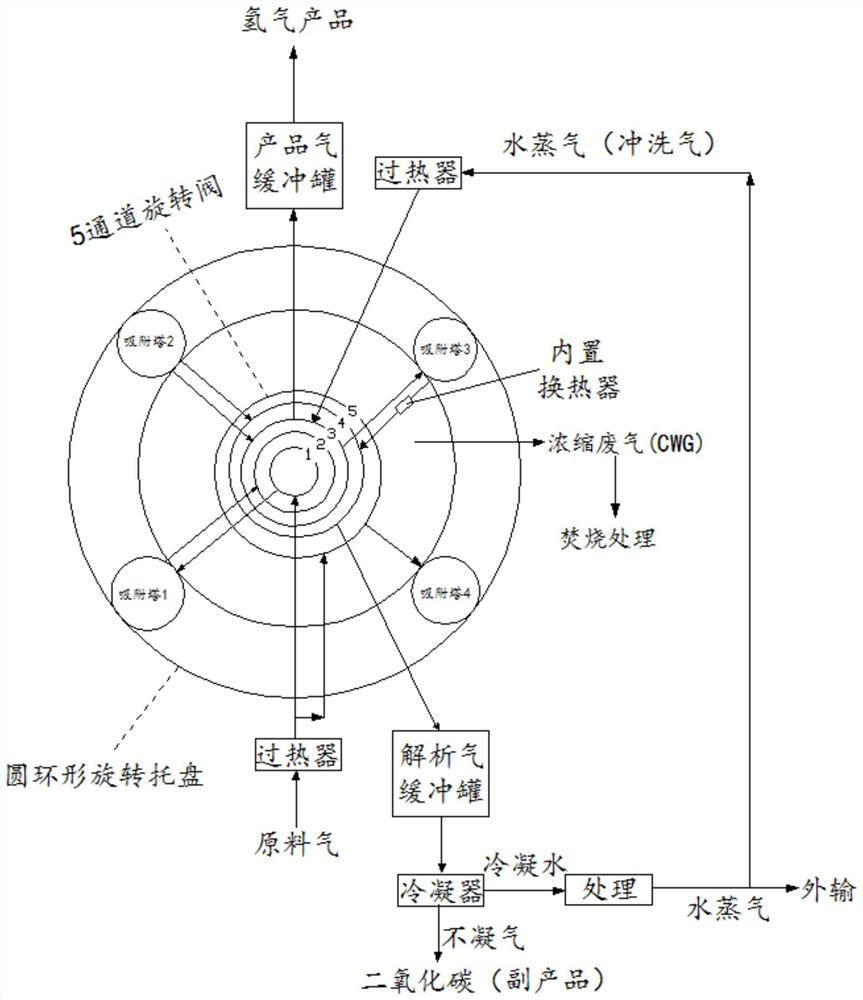

Full-temperature-range simulated rotating moving bed pressure swing adsorption FTrSRMPSA gas separation and purification method

ActiveCN114748979AReduced service lifeImprove processing efficiencyGas treatmentDispersed particle separationPurification methodsFixed bed

The invention discloses a full-temperature-range simulated rotating moving bed pressure swing adsorption FTrSRMPSA gas separation and purification method, and relates to the field of pressure swing adsorption PSA for gas separation and purification. The adsorption tower is provided with n axial flow fixed bed layers and is arranged on an annular rotating tray with the rotating speed omega 2; the rotating valve is provided with m channels and is arranged in the center of the annular tray and rotates at the rotating speed omega 1; the process pipeline is connected between the upper part and the lower part of the adsorption tower and the rotary valve through a built-in pipeline of the circular tray; the driving mechanism is used for correspondingly driving the circular tray and the rotary valve to rotate and regulating and controlling the rotating speeds omega1 and omega2 of the circular tray and the rotary valve; according to the device, the high purity and the high yield of a simulated rotary PSA process carried out on the basis of an axial flow fixed bed layer for PSA separation of each raw material gas and purification and extraction of product gas are realized.

Owner:SICHUAN TECHAIRS

Pipeline compressor model stage with flow coefficient being 0.0293 and impeller design method

InactiveCN106382256AHigh head coefficientWheel hub ratioGeometric CADPump componentsImpellerEngineering

The invention provides a pipeline compressor model stage with the flow coefficient being 0.0293. The pipeline compressor model stage comprises an impeller, a vaneless diffuser, a curve and a backflow device; the impeller is located at the position of an inlet of the model stage, the vaneless diffuser is arranged at an outlet of the impeller, the backflow device is located at the position of an outlet of the model stage, and the vaneless diffuser is communicated with the backflow device through the curve; and the machine mach number Mu2 of the model stage ranges from 0.35 to 0.65, the flow coefficient phi1 of a design point is equal to 0.0293, the energy head coefficient tau of the design point is equal to 0.614, the polytropic efficiency etapcl under the discharge coefficient working condition designed under all mach numbers ranges from 0.838 to 0.843, and the applied flow scope is 60% to 150% that of the design point. The invention further provides a design method of the impeller of the model stage. The model stage is high in efficiency, high in energy head coefficient, large in hub ratio and small in span; by means of the model stage, a light medium compressor can have the high running efficiency and the wide working condition scope; and meanwhile, the working rotating speed of a rotor can be reduced, the bearing span can be decreased, and the stability of the rotor is improved.

Owner:SHENYANG TURBO MASCH CORP +1

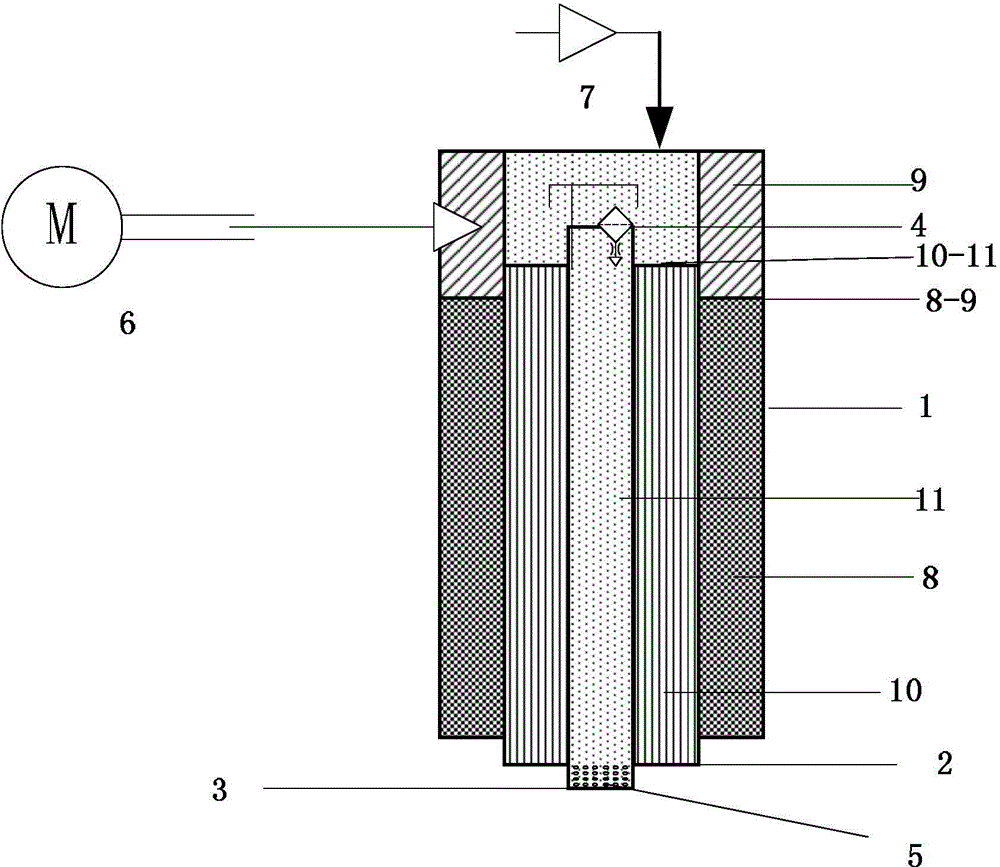

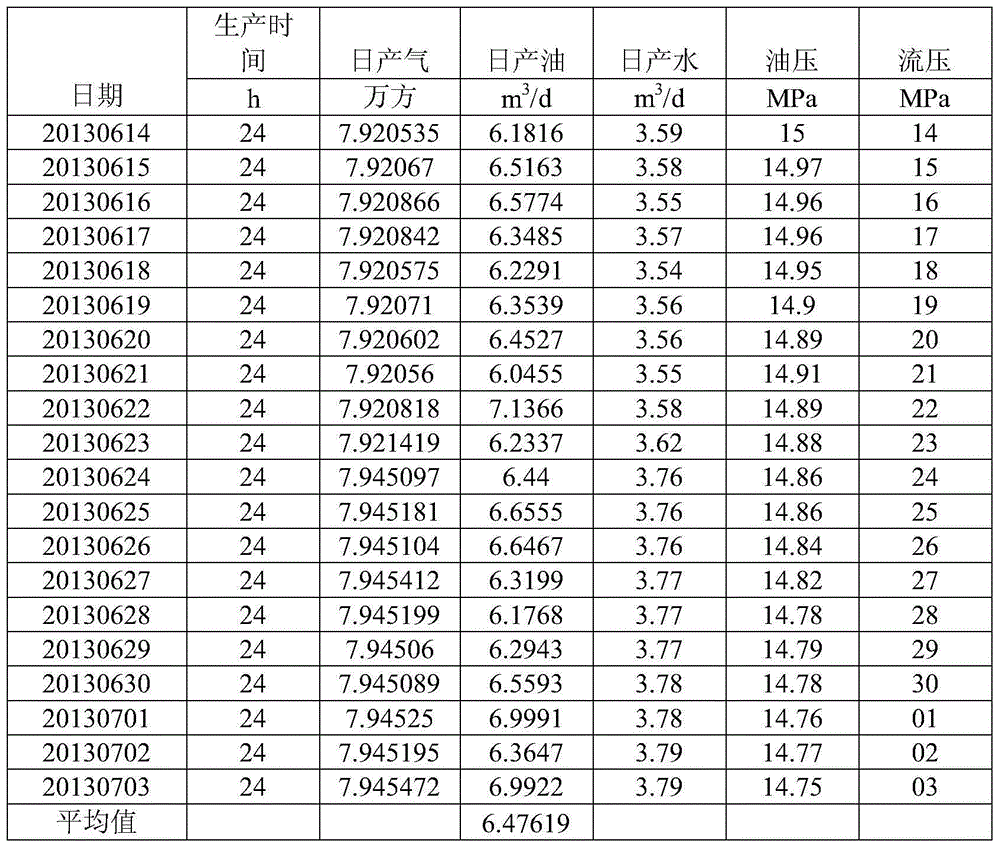

Method for exploiting oil sand through paraffin media

InactiveCN104533365AReduce consumptionRelease stabilityInsulationFluid removalParaffin waxLiquid water

The invention provides a method for exploiting oil sand through paraffin media. In at least one period, the method includes the following steps: a central tube is arranged on an oil deposit section in an oil well shaft, a sleeve is arranged outside the central tube, and annular space between the central tube and the sleeve is used for containing liquid water; a steam hole is formed in the upper end of the central tube, the position of the steam hole is higher than a working liquid level of the liquid water in the annular space between the central tube and the sleeve, and a steam outlet hole is formed in the lower end; the paraffin media are injected into annular space between the shaft and the sleeve to maintain the reservoir pressure, and are heated through a heating system; the liquid water is continuously injected into the annular space between the central tube and the sleeve; heat exchanging is carried out between the paraffin media and the liquid water to generate steam, and the steam enters the central tube through the steam hole of the central tube and flows out from the steam outlet hole to be in contact with an oil deposit for heat exchanging; when the steam injection amount meets the oil field steam flooding period heat supply requirement, heating is stopped, water is supplied, and oil extraction is carried out after a well is shut. The method is stable in steam generation, free of pollution, convenient to maintain and low in investment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Rotary air preheater sealing structure

PendingCN107355810AReduce power consumptionImprove efficiencyCombustion processHeat exhanger sealing arrangementAir preheaterEngineering

The invention discloses a rotary air preheater sealing structure. The sealing structure is mainly composed of seal washers and seal grooves. The seal grooves are radially arranged on air preheater rotors. The corresponding seal washers are embedded into the seal grooves, and one end of each seal washer is fixed to a central cylinder of an air preheater; the other end of the seal washer is free. The bottoms of the seal washers are embedded into the seal grooves, and the minimum rational clearance is kept between the top of each seal washer and a sector plate. In operation, the seal grooves incline toward the peripheries of the rotors from the central cylinder, while only one section of the seal washers is fixed to the central cylinder, and does not incline with the central cylinder. In this way, the bottoms of the seal washers are still embedded into the seal groove for a certain depth to ensure the sealing effect; and the minimum clearance can still be kept between the top of the seal washer and the sector plate. The air leakage rate of the air preheater is ensured to be unchanged under different working conditions for a long time, and is kept at a low level. The rotary air preheater sealing structure disclosed by the invention has the advantages of rational and simple structure, little maintenance, uneasy jamming, abrasion or deformation, and wide application scope of working conditions, and is an important innovation of a rotary air preheater seal.

Owner:XIAN XIRE ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com