Composite filter material and preparation method thereof

A composite filter material and chemical fiber technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problem of increased demand for high-performance environmental protection filter materials, poor filtration performance or tolerance, and can not meet the actual use Requirements and other issues, to achieve excellent filtration performance, wide range of working conditions, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

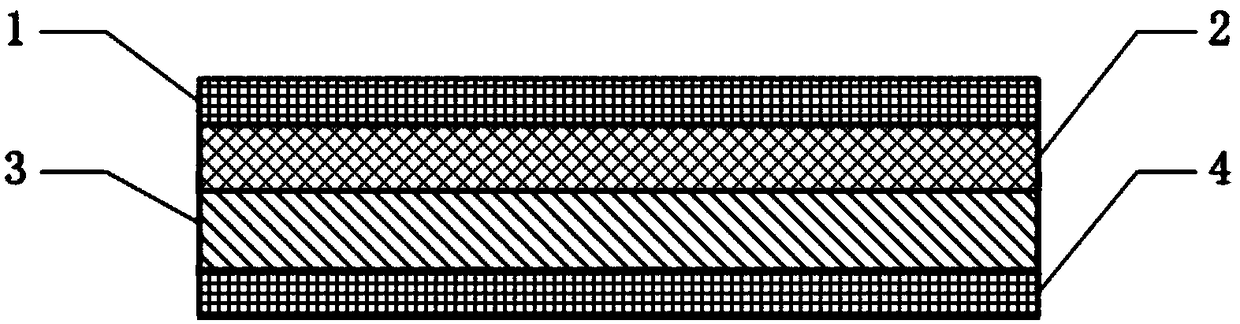

[0062] The present invention also provides a method for preparing the composite filter material described in the above technical solution, comprising the following steps:

[0063] a) Consolidating the chemical fiber net layer and the expanded glass fiber cloth layer by needle punching and / or hydroentanglement to obtain a composite;

[0064] b) impregnating, drying and heat-setting the composite to obtain a composite filter material.

[0065] Wherein, the characteristics such as the type, gram weight, aperture, and thickness of the chemical fiber net layer and the glass fiber expanded cloth layer are consistent with those described in the above technical solution, and will not be repeated here. The sources of the chemical fiber net layer and the expanded glass fiber cloth layer are consistent with those described in the above technical solution, and will not be repeated here.

[0066] In the present invention, there is no special limitation on the way of needle punching or spu...

Embodiment 1

[0072] S1: Superfine glass fiber drawing and forming→drawing and soaking treatment→spinning processing→bulking processing→1 / 3 twill weaving process, made into 350g / m 2 Ultra-fine glass fiber expanded cloth, warp and weft strength ≥ 1650N.

[0073] S2: unpacking of fine denier aramid fiber raw materials → spreading evenly → spraying 3% antistatic agent aqueous solution → standing for 12 hours → pre-opening → main opening → cotton box mixing → carding into a net, made into 240-260g / m 2 Aramid fiber mesh.

[0074] S3: The superfine glass fiber expanded cloth and the aramid fiber net are subjected to pre-needling-spunlace-shaving to obtain a composite.

[0075] S4: After impregnating the obtained composite, dry it at 100°C for 5 minutes, and then heat-set it at 230°C for 10 minutes to obtain a grammage of 600g / m 2 Composite filter material;

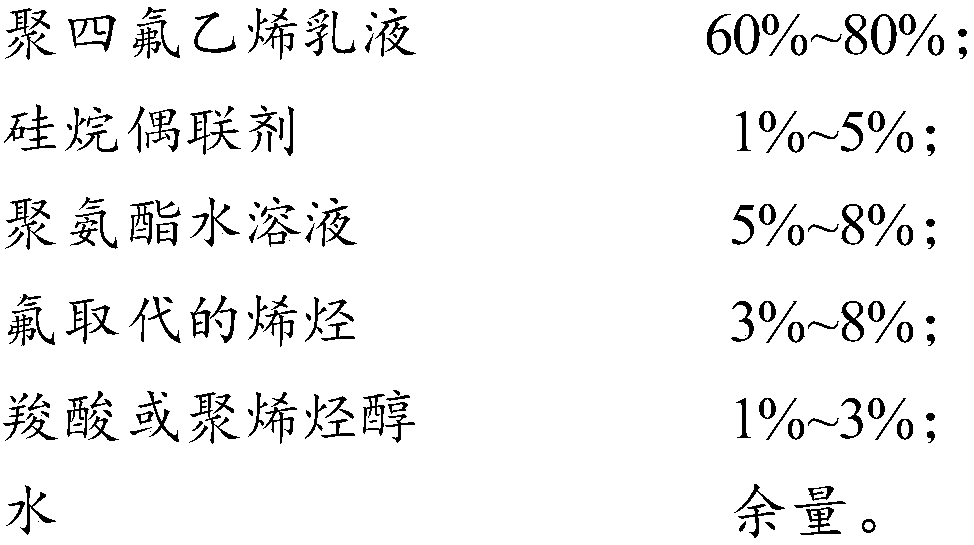

[0076] The impregnating liquid formula that above-mentioned dipping treatment adopts is as follows:

[0077] Polytetrafluoroethylene e...

Embodiment 2

[0079] S1: Superfine glass fiber drawing and molding→drawing and soaking treatment→spinning processing→bulking processing→1 / 3 twill weaving process, made into 420g / m 2 Superfine glass fiber expanded cloth, warp and weft strength ≥1850N.

[0080] S2: unpacking of fine denier P84 fiber raw materials → spreading evenly → spraying 3% antistatic agent aqueous solution → standing for 12 hours → pre-opening → main opening → cotton box mixing → carding to form a web of 300-350g / m 2 P84 fiber mesh.

[0081] S3: The superfine glass fiber expanded cloth and the aramid fiber net are subjected to pre-needling-spunlace-shaving to obtain a composite.

[0082] S4: After impregnating the obtained composite, dry it at 120°C for 4 minutes, and then heat set it at 240°C for 8 minutes to obtain a grammage of 750g / m 2Composite filter material;

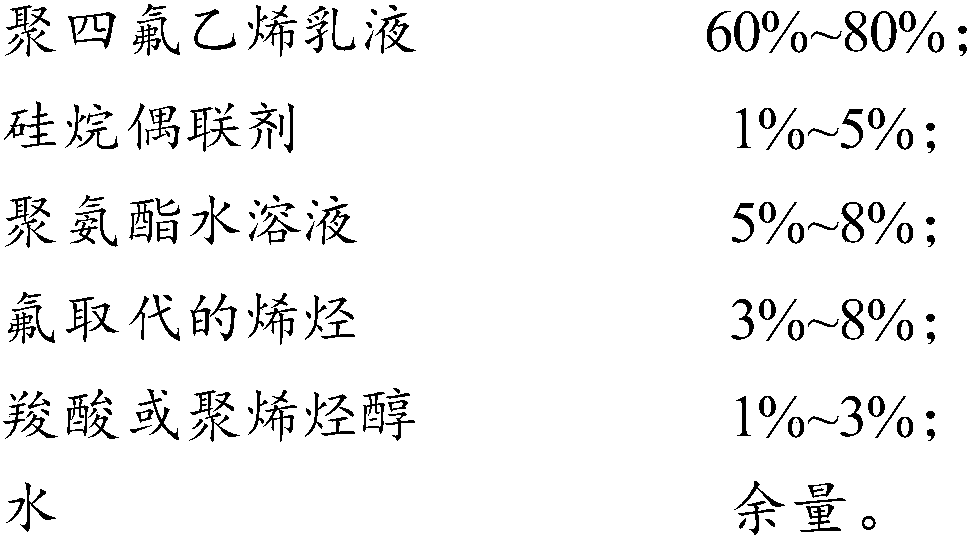

[0083] The impregnating liquid formula that above-mentioned dipping treatment adopts is as follows:

[0084] Polytetrafluoroethylene emulsion (solid co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com