Rotary air preheater sealing structure

A technology of air preheater and sealing structure, which is applied in the field of energy saving and environmental protection, and can solve the problems of short air leakage maintenance time of low air preheater, high price of superalloy materials, high processing accuracy and process requirements, and reduce direct air leakage, workmanship, etc. The effect of adapting to a wide range of conditions and avoiding maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention is described in further detail below in conjunction with accompanying drawing:

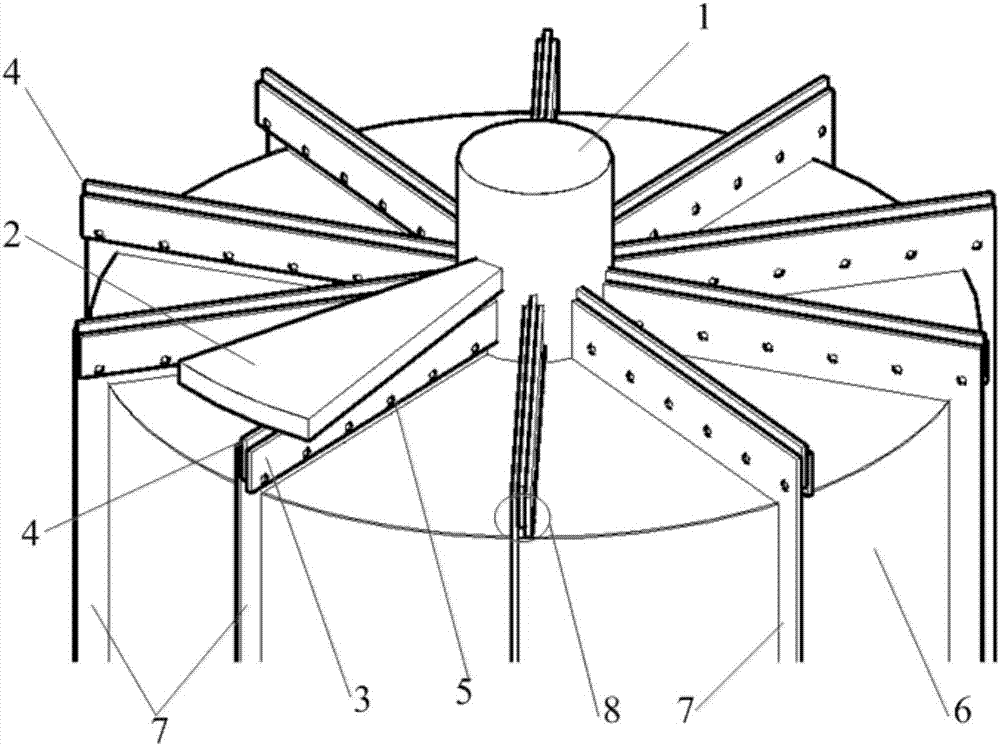

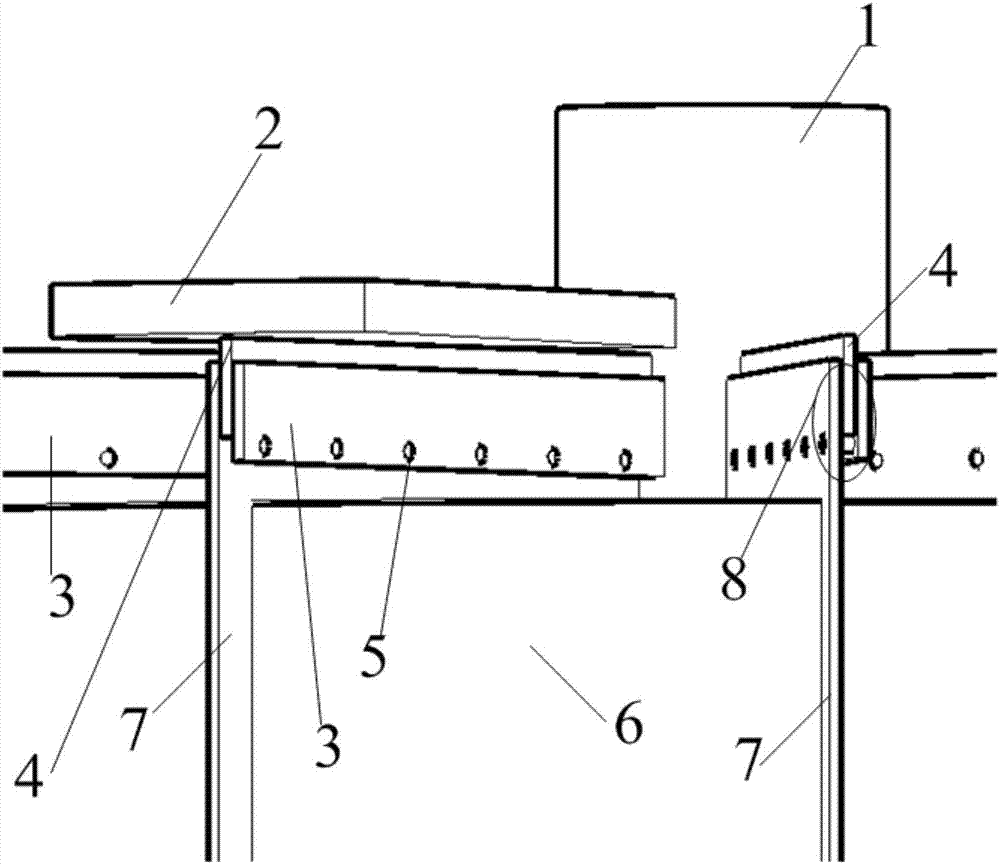

[0061] see figure 1 and figure 2 , The sealing structure of the rotary air preheater of the present invention is composed of a sealing groove 8 and a sealing plate 4, which are radially arranged on the rotor 6 of the air preheater, matching with the compartment structure of the air preheater. The sealing piece 4 is embedded in the sealing groove 8 , one end is fixed on the central tube 1 of the air preheater, and the other end is in a free state, completely independent of the sealing groove 8 . At the same time, there is a minimum reasonable gap between the top of the sealing sheet 4 and the fan-shaped plate 2 .

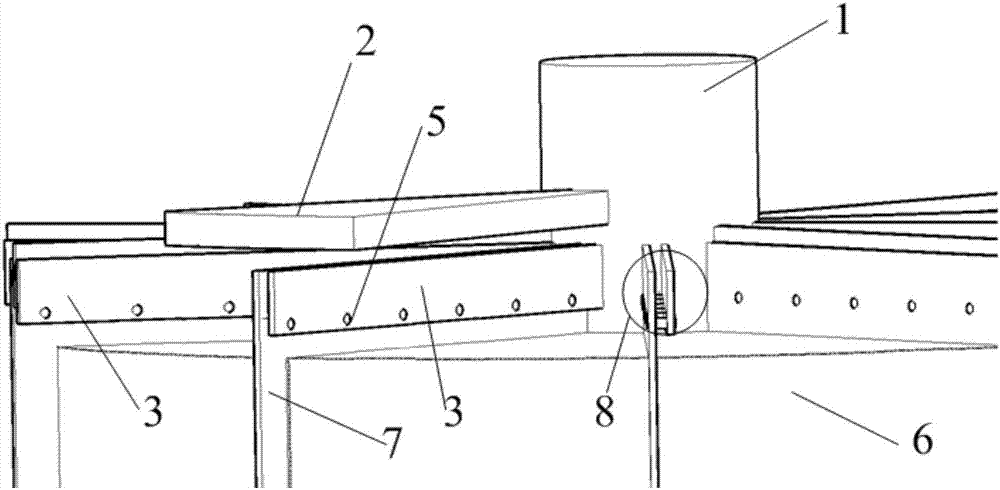

[0062] Such as image 3 As mentioned above, the seal groove 8 is formed by the seal groove side plate 3 and the rotor compartment partition 7, the seal groove side plate is connected by the bolt 5 at the bottom of the seal groove 8, forms a seal groove wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com