Method for exploiting oil sand through paraffin media

A technology of paraffin and medium, which is applied in the direction of mining fluid, earthwork drilling, isolation devices, etc., can solve the problems of uneven temperature field, heat loss, heating cycle, large energy loss, and large water consumption, so as to reduce the number of heat carriers, Increased heat transfer efficiency and high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

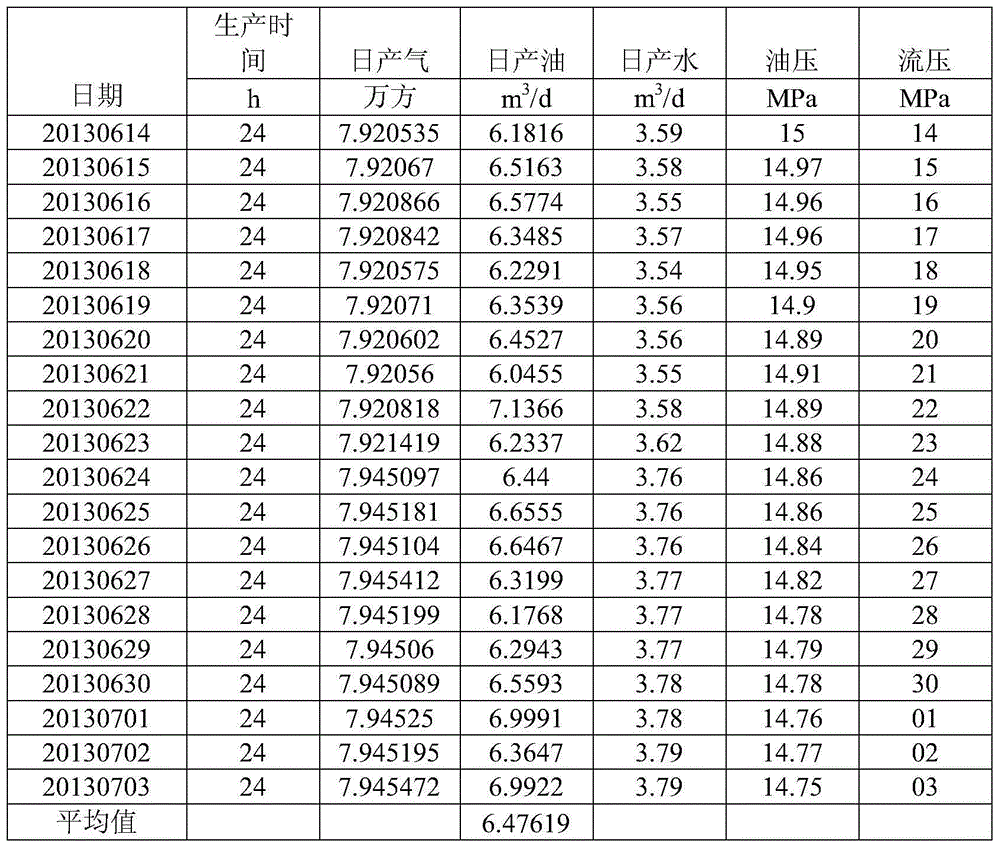

[0043] Since 2013, the daily oil production of production wells has been maintained at 3m 3 / d, which is lower than the historical average level, it is decided to use the method described in this method for gas injection thermal recovery.

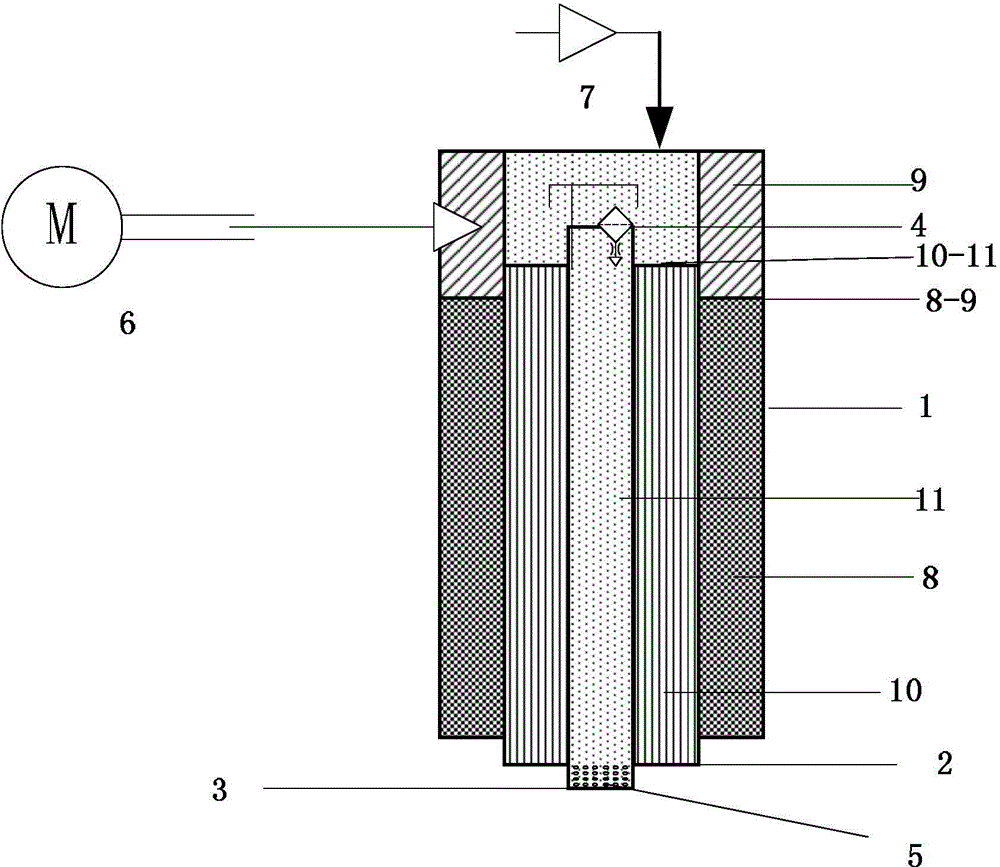

[0044] See figure 1 , the present embodiment is a method for in-situ mining of oil sands using solar power to heat a paraffin injection vertical well, the method comprising the following steps:

[0045] After the well test operation, combined with the previous exploration data, the basic data of the reservoir are obtained: reservoir depth: 350m; reservoir thickness: 12m; reservoir temperature: 38.5°C; geothermal gradient: 4.85°C / 100m; reservoir pressure: 5.5MPa; : 0.6D; oil layer vertical permeability: 0.2~0.3D; degassed crude oil viscosity: 25000mPa s; oil well storage water: 1000m 3 ;

[0046] Deploy a square five-point well pattern according to the steam stimulation method, and the injection-production well spacing is 100m;

[0047] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com