Acid medium transmission pipeline welded joint and parent metal corrosion simulation testing device and method

A technology for acidic media and pipelines, which is applied in the field of dynamic corrosion simulation test devices, can solve the problems of small processing capacity, narrow range of applicable working conditions, short test loops, etc., and achieve welding quality safety, wide range of working conditions, The effect of reasonable material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

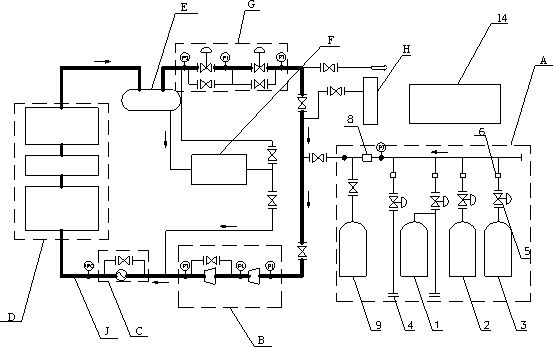

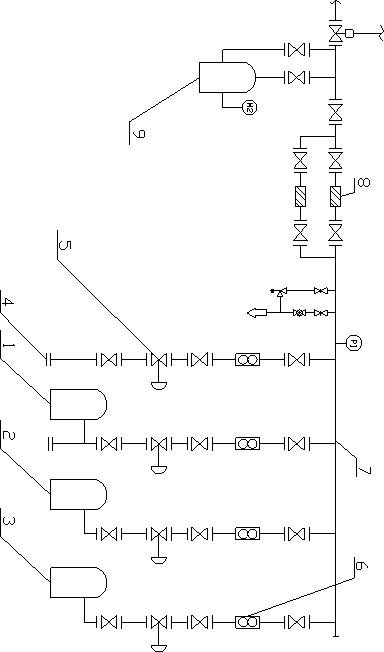

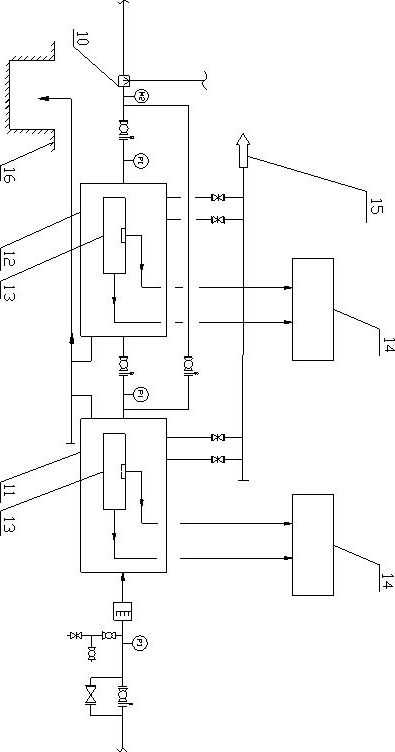

[0063] The technical solution of the test device used in the present invention is mainly composed of test loop system, test gas deployment and storage metering system, pressurization system, temperature control system, test test section system, filtration and separation system, pressure regulation system, liquid medium filling and recovery System, automatic control system and venting system, with the compressor as the power, the circulation of the medium is realized through the test loop. The test gas is adjusted into an acid gas that simulates the field test conditions through the deployment system, and the pressure and temperature conditions required for the test are reached through the pressurization of the pressurization system and the temperature adjustment of the temperature control system. On-line corrosion test of the weld seam, after the pressure is adjusted by the pressure regulating system, it returns to the compressor inlet for circulation.

[0064] The test gas de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com