Waveform movable pressing pretightening butterfly spring

A wave and butterfly spring technology, applied in the field of wave dynamic pressure preload butterfly spring, can solve the problems of lack of secondary elastic force and overload protection ability, low compensation ability, fatigue and other problems, to prevent major failure accidents and economic losses, improve Reliability and service life, the effect of a wide range of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

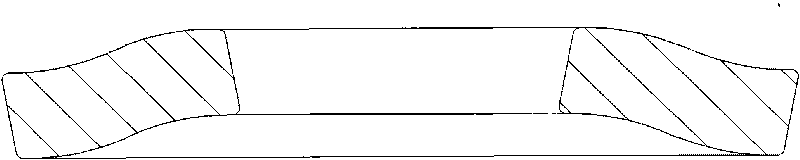

[0019] see figure 1 , The single-piece waveform dynamic pressure pre-tightened butterfly spring, the waveforms on the upper and lower sides of the back and the back are staggered and evenly arranged from the inner hole to the outer circumference. When the disc spring is compressed by force, the initial cone of the disc spring is flattened, and a corresponding primary rebound pre-tightening force is generated, and then the waveform of the disc spring tends to be flat, and a corresponding secondary active pressure is generated. The maximum load-bearing capacity of the elastic, wave-shaped live pressure preloaded disc spring is at least 3 times higher than that of the traditional disc spring, which greatly improves the preload safety guarantee and application range, as well as improves the reliability, safety and service life of the disc spring.

Embodiment 2

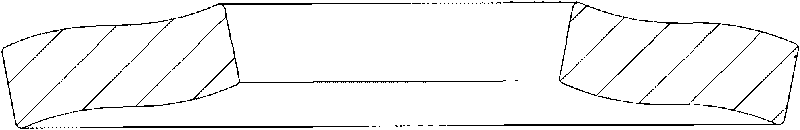

[0021] see figure 2 , The single-piece waveform dynamic pressure pre-tightened butterfly spring, the waveforms on the back of the upper and lower phases are staggered and evenly arranged in order from the outer radial to the inner hole. , when the disc spring is compressed by force, the initial cone of the disc spring is flattened, and a corresponding primary rebound preload is generated, and then the waveform of the disc spring tends to be flat, and a corresponding secondary active pressure is generated Rebound force, the maximum bearing capacity of the wave active preloaded disc spring is at least 3 times higher than that of the traditional disc spring, which greatly improves the preload safety guarantee and application range, as well as improves the reliability, safety and service life of the disc spring .

Embodiment 3

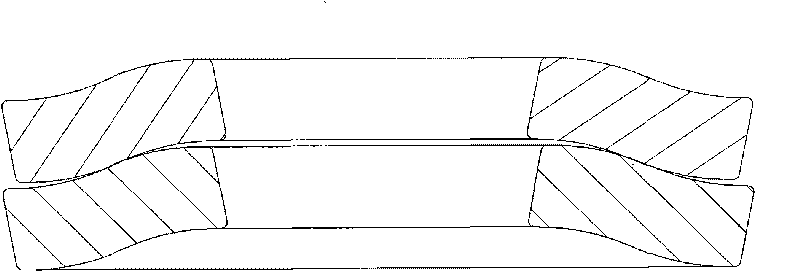

[0023] see image 3 , the waveforms on the back of the two upper and lower phases are staggered from the inner hole to the outer circumference, and the evenly arranged wave-shaped pre-tensioned butterfly springs are superimposed. , followed by the flattening of the disc spring's waviness. Its characteristics are that the distance of compression and rebound is unchanged, and the bearing capacity is doubled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com