Method for monitoring safe operation of catalytic oil-free compression system

A compression system and safe operation technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the lagging of detection data of oil content detection equipment, the inability to feed back oil content in advance, and the inability to effectively protect catalytic purification equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

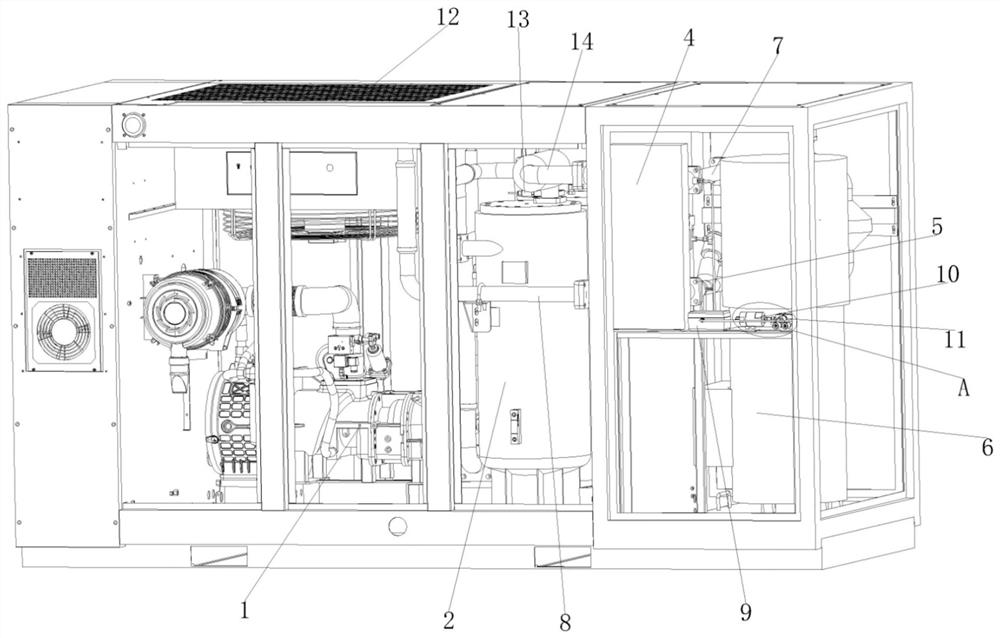

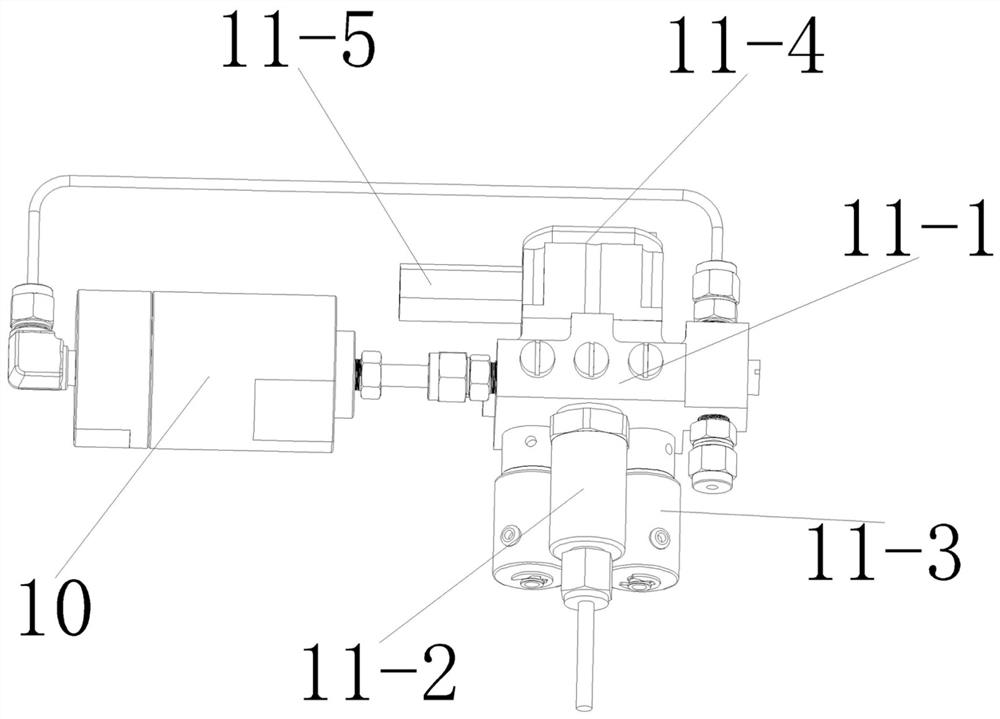

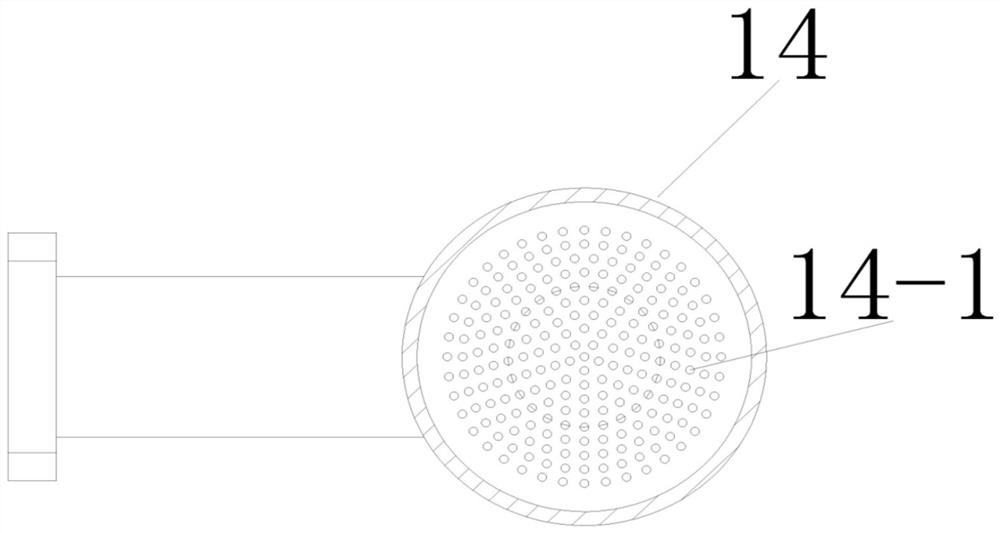

[0030] The method for monitoring the safe operation of the catalytic oil-free compression system of the present invention uses a catalytic oil-free compression system such as figure 1 As shown in , including compressor, oil-gas separator (not shown), gas-liquid separator 2, catalytic converter 6, heat exchanger, first oil content detection device 13, second oil content detection device 11, electronic cooling 9, filter adsorption tank 10, radiator 12, buffer separation pipe 14, display screen (not shown) and alarm (not shown), the compressor adopts oil-injected screw compressor 1, and radiator 12 is installed on the oil-injected Above the screw compressor 1, the oil-injected screw compressor 1 compresses air and is lubricated with lubricating oil during operation, and the radiator 12 radiates heat and cools down the oil-injected screw compressor 1 in time. The heat exchanger adopts a partition wall heat exchanger 4, and two heat exchange pipes are arranged in the partition wall...

Embodiment 2

[0041] The difference between the method for monitoring the safe operation of the catalytic oil-free compression system in this embodiment and Embodiment 1 is that in the catalytic oil-free compression system adopted in this embodiment, the catalytic intake pipe 5 is provided with a catalytic converter intake pipe and an air-to-air The exhaust pipe, the catalytic converter intake pipe is connected and communicated with the intake port of the catalytic converter. The catalytic converter intake pipe is used to introduce compressed gas into the catalytic converter. The empty discharge pipe is used to discharge the compressed gas to the air. Valves are installed in both the intake pipe of the catalytic converter and the empty discharge pipe. The valve of the intake pipe of the catalytic converter allows the compressed gas to be introduced into the catalytic converter, and closes the valve of the empty exhaust pipe; when the first oil content detection device 13 detects that the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com