Control method for preventing heavy-load fault of double-core-rod transmission motor

A control method and technology for driving motors, which are applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as affecting normal production, difficult unmanned management, damage to structural components such as motor mandrel bases, etc. Realize the effect of unmanned management, ensure production efficiency, and prevent the occurrence of overloaded failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

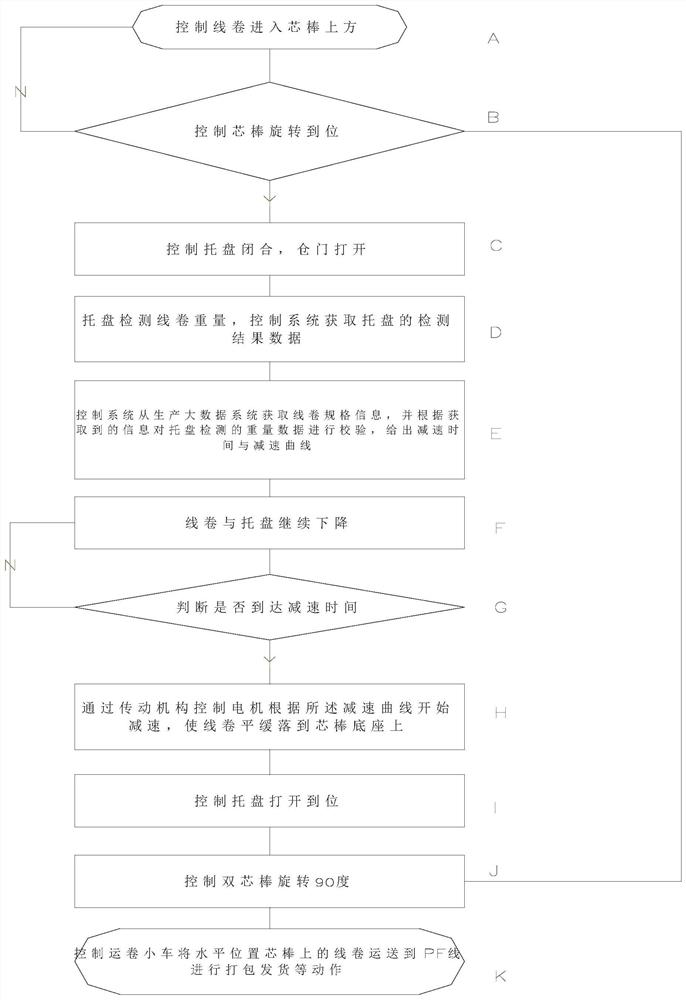

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] A control method for preventing heavy-load failure of a double-mandrel drive motor, involving equipment including a doffing bin door in a wire automatic collection system in a high-speed wire production line, double-mandrel equipment, a coil transport trolley, a detector, and the like. The double-mandrel equipment here mainly includes a tray and a double-mandrel (hereinafter referred to as mandrel A and mandrel B), which are respectively driven by a motor, and the motor is controlled by the transmission system of the double-mandrel equipment. The structural difference between the double mandrel equipment and the prior art is mainly that a weighing device is added on the tray. The specific steps of the control method in this embodiment are as follows, which are executed by the control system. The control system is used to intera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com