Alarming type constant force spring hanger

A constant force spring and hanger technology is applied in the field of alarm type constant force spring hangers, which can solve the problems of overload failure of elastic elements and failure of constant force spring hangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

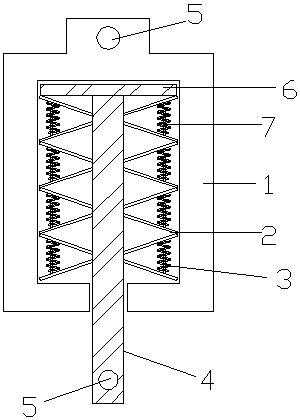

[0016] figure 1 It is a schematic diagram of the structure of the present invention. The names of the parts in the figure are: cylinder 1, butterfly spring 2, spring 3, pull rod 4, hook hole 5, pull plate 6, and column 7. It can be seen from the accompanying drawings that the alarm type constant force spring hanger includes a cylinder body, one end of the cylinder body is integrally closed and formed with the cylinder body, and a hanging ear is arranged outside the end, this end is called the top of the cylinder body, and the cylinder body The other end of the cylinder is called the bottom end of the cylinder. There is a pull rod in the cylinder. One end of the pull rod is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com