Distribution mechanism

A material distribution mechanism and rack technology, applied in solid materials, conveyor objects, packaging, etc., can solve problems such as high power, high energy consumption, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

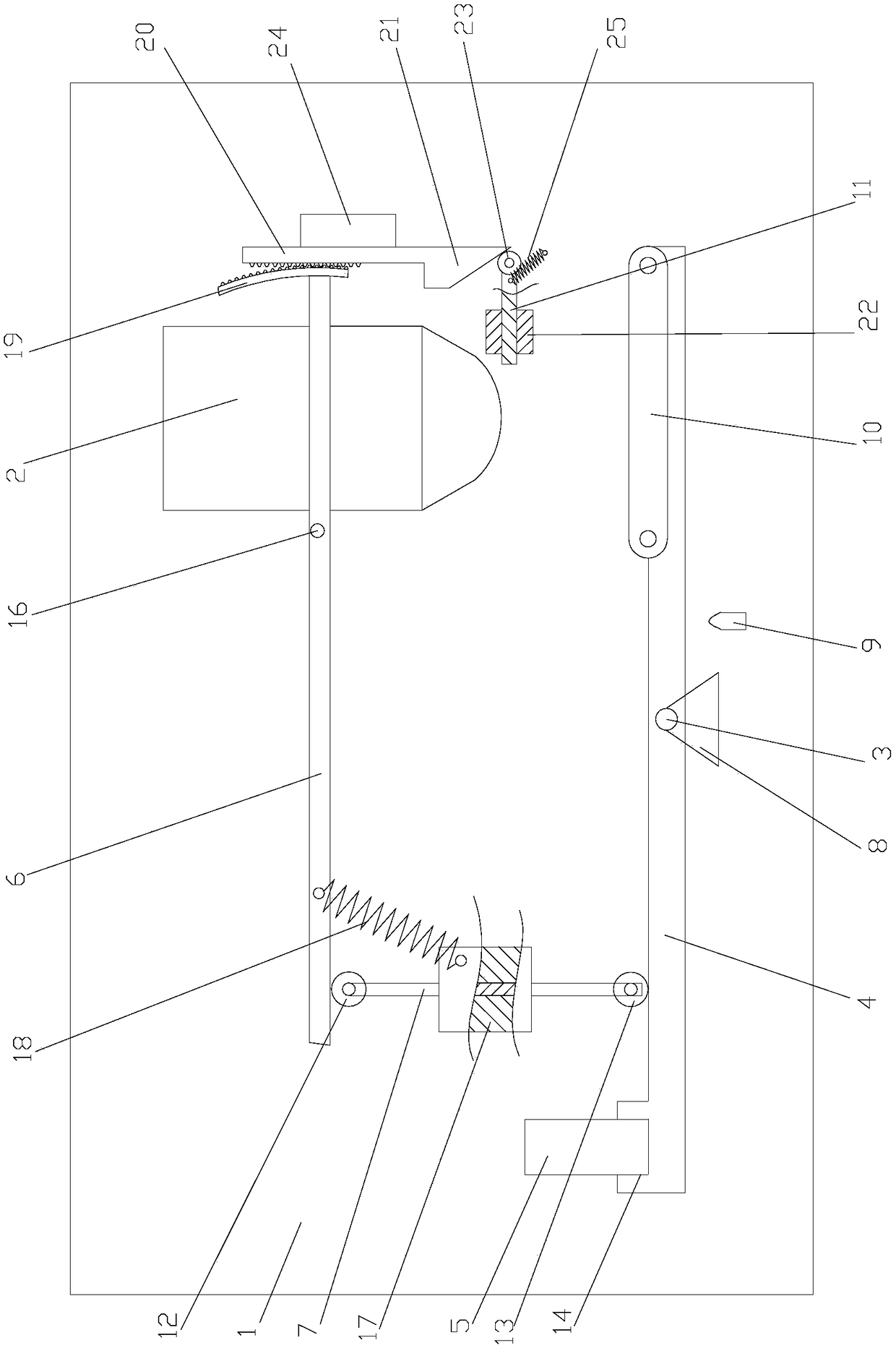

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] The material distributing mechanism of the present invention comprises a frame 1, which is provided with a barrel 2 for placing materials, and the frame 1 is rotatably connected with a swing rod 4 through a first hinge point 3, and one end of the swing rod 4 is provided with a counterweight 5 , the other end is provided with a belt transmission mechanism 10, and the belt transmission mechanism 10 is located below the barrel 2; the first hinge point 3 is used as the dividing point on the swing rod 4, and the end close to the counterweight 5 is the transmission area, that is, the swing rod in the figure The left end of 4; Near one end of belt drive mechanism 10 is the blanking area, that is, the right end of fork 4 in the figure; rotatably connected with cross bar 6 on frame 1, cross bar 6 is positioned at fork 4 top, and cross bar 6 is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com