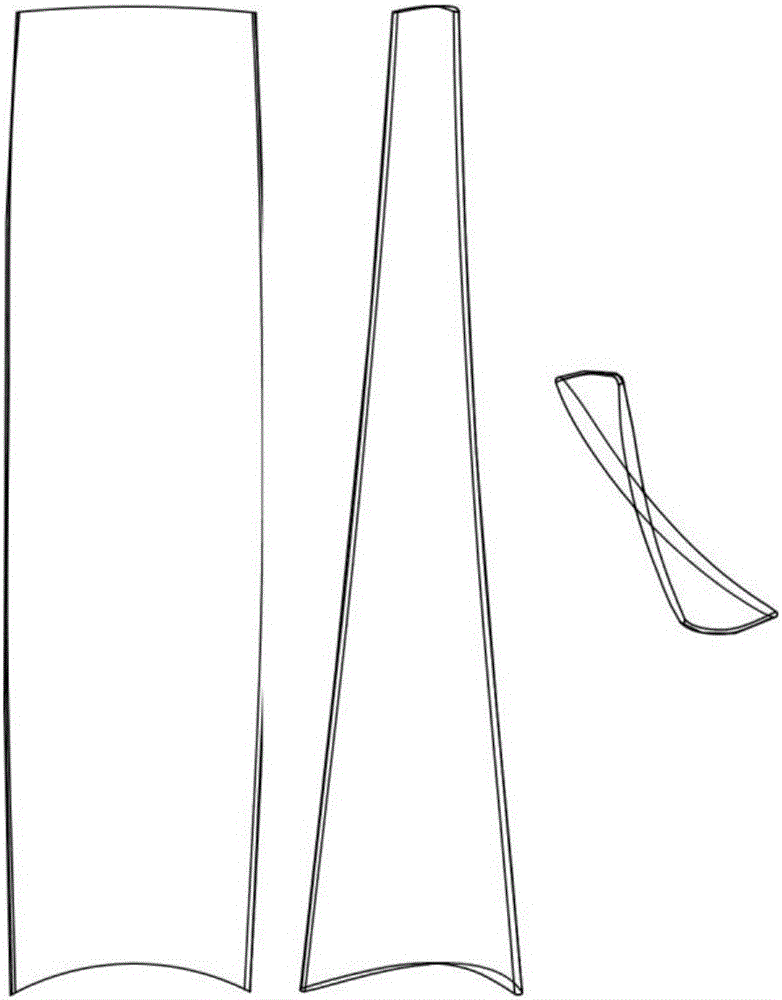

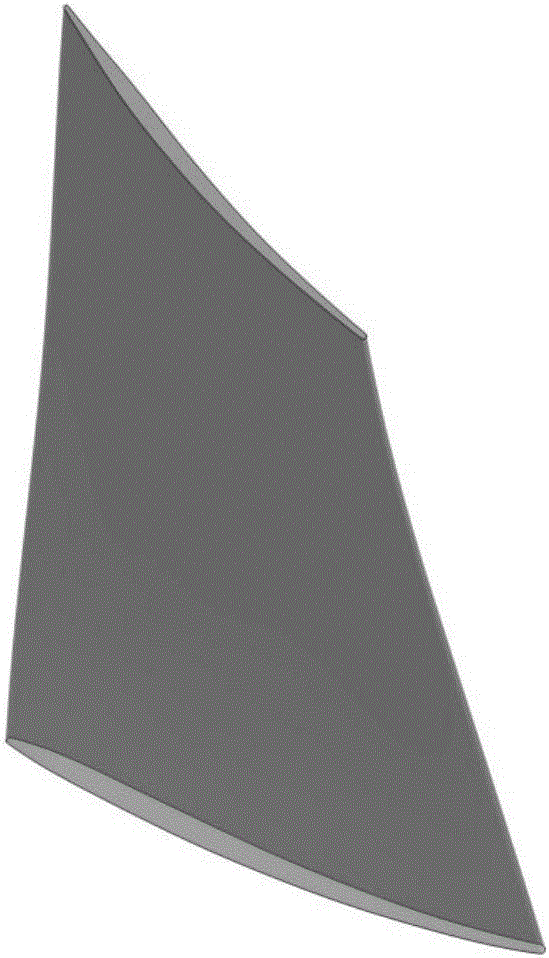

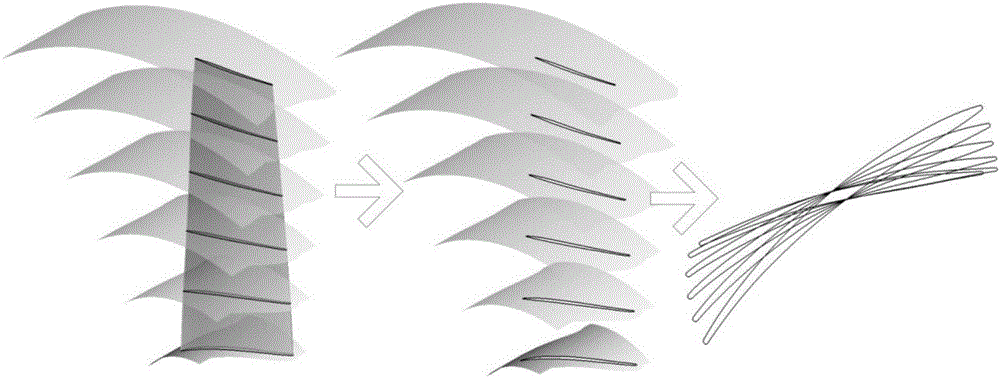

Axial flow blade form

An airfoil and axial flow technology, applied in the field of axial flow fan and axial flow airfoil, can solve the problem of low efficiency of axial flow blades, and achieve the effect of solving low impeller efficiency, high efficiency and wide range of working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The diameter of the impeller in this embodiment is 900 mm, the hub ratio is 0.211, and the number of blades is 7. The cubic spline curve of the blade inlet angle passes through 6 control points (1~6) in turn, and the position coordinates of these 6 control points are (coordinate format is (blade height percentage, blade inlet angle)): (0%, 23.46° ), (20%, 18.68°), (40%, 12.87°), (60%, 8.77°), (80%, 6.35°), (100%, 6.32°); the cubic spline curve of the blade outlet angle in turn After passing through 6 control points (1~6), the position coordinates of these 6 control points are (coordinate format is (blade height percentage, blade outlet angle)) in turn: (0%, 56.62°), (20%, 51.24°), (40%, 46.87°) (60%, 41.88°), (80%, 30.32°), (100%, 24.88°); six control points of the blade chord cubic spline curve (1- 6) Position coordinates (coordinates in the form of (blade height percentage, chord length)) are: (0%, 120.6mm), (20%, 115.4mm), (40%, 109.7mm) (60%, 105.0mm) , (80%, 100....

Embodiment 2

[0095] The diameter of the impeller in this embodiment is 900 mm, the hub ratio is 0.211, and the number of blades is 7. The cubic spline curve of the blade inlet angle passes through 6 control points (1~6) in turn, and the position coordinates of these 6 control points are (coordinate format is (blade height percentage, blade inlet angle)): (0%, 28.46° ), (20%, 23.68°), (40%, 17.87°), (60%, 13.77°), (80%, 11.35°), (100%, 11.32°); the cubic spline curve of the blade outlet angle in turn After passing through 6 control points (1~6), the position coordinates of these 6 control points are (coordinate format is (blade height percentage, blade outlet angle)): (0%, 61.62°), (20%, 56.24° ), (40%, 51.87°) (60%, 46.88°), (80%, 35.32°), (100%, 29.88°); 6 control points (1-6) of blade chord cubic spline curve The position coordinates (coordinate format is (blade height percentage, chord length)) are: (0%, 120.6mm), (20%, 115.4mm), (40%, 109.7mm) (60%, 105.0mm), ( 80%, 100.1mm), (100%, ...

Embodiment 3

[0097] The diameter of the impeller in this embodiment is 900 mm, the hub ratio is 0.211, and the number of blades is 7. The position coordinates of the 6 control points (1-6) of the cubic spline curve of the blade inlet angle (the coordinates are in the form of (blade height percentage, blade inlet angle)) are: (0%, 33.46°), (20%, 28.68° ), (40%, 22.87°), (60%, 18.77°), (80%, 16.35°), (100%, 16.32°); 6 control points (1-6 ) position coordinates (the coordinate form is (blade height percentage, blade inlet angle)) in turn: (0%, 66.62°), (20%, 61.24°), (40%, 56.87°) (60%, 51.88°) , (80%, 40.32°), (100%, 34.88°); the position coordinates of 6 control points (1-6) of the cubic spline curve of blade chord length (the coordinate form is (blade height percentage, chord length)) in turn For: (0%, 120.6mm), (20%, 115.4mm), (40%, 109.7mm) (60%, 105.0mm), (80%, 100.1mm), (100%, 90.6mm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com