Worm type lifting mechanism and system

A lifting mechanism, worm-type technology, applied in the direction of lifting devices, mechanical equipment, gear transmission devices, etc., can solve the problems of low lifting efficiency of electric lifting devices, time-consuming and labor-consuming lifting devices, high motor torque requirements, etc., to achieve fast locking and unlocking process Reliable, avoid safety hazards, safe and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

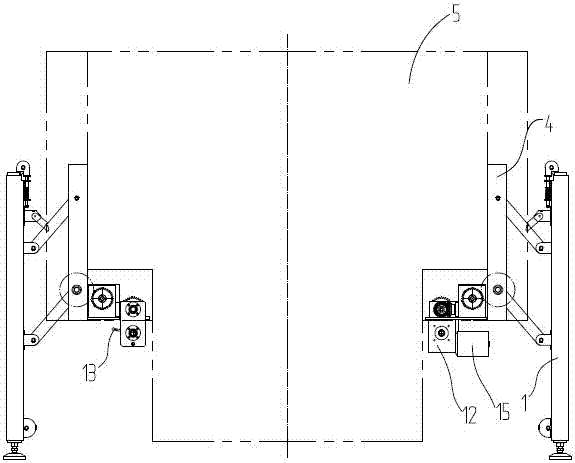

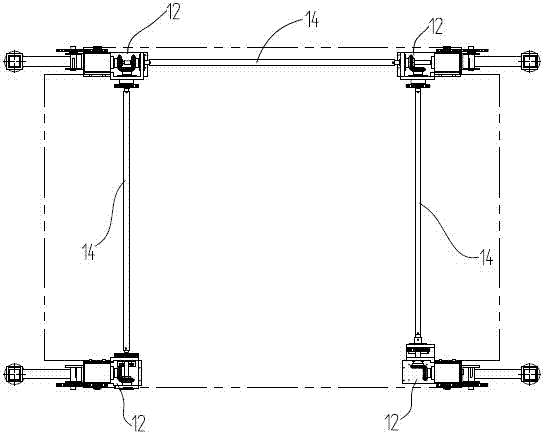

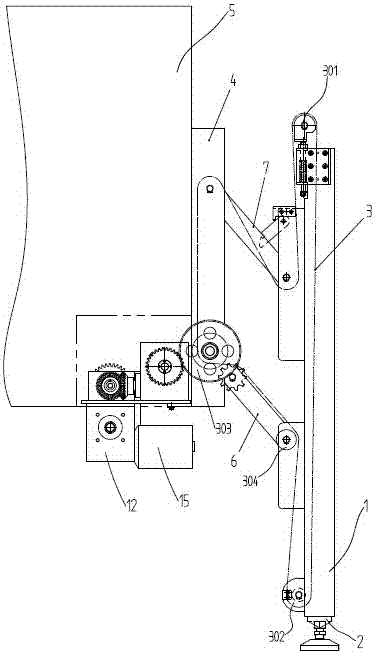

[0050] Such as Figure 1 to Figure 4 As shown, the worm-type lifting mechanism of this embodiment includes a grounding leg supported on the ground and a shelter support 4 connected to the shelter 5. The grounding leg includes an outer sleeve 1 and is arranged between the outer sleeve 1. The inner casing 2 in the inner casing also includes a transmission chain 3 connected to the shelter support 4 and the outer casing 1 respectively, and the transmission chain 3 is equipped with a driving wheel 303 connected with the driving device, and the transmission chain 3 passes through When the driving device is driven and running, the outer casing 1 and the shelter support 4 rise and fall synchronously; as a special design of the present invention, a worm gear reducer 12 is connected between the driving wheel 303 and the driving device. In this embodiment, the driving The device is a motor 15, and when the motor 15 drives the drive wheel 303 to rotate, the shelter support 4 lifts under t...

Embodiment 2

[0057] Such as Figure 5 to Figure 9 As shown, the worm-type elevating mechanism described in Embodiment 1 is provided with a forced opening and closing device on the upper connecting rod 7, including a deadbolt rod 9 cooperating with the locking hole 701 on the upper connecting rod 7. The middle part between the two ends of the deadbolt rod 9 is hinged on the pole connecting plate 17 on the outer sleeve 1, and the dead bolt hole 901 is correspondingly arranged in the middle part of the deadbolt rod 9, one end of the deadbolt rod 9 is a dead bolt, and the other end is hinged There is a transmission part, and the free end of the transmission part is hinged with a limiting part arranged at the lower end of the outer sleeve 1 , and the limiting part is hinged with the outer sleeve 1 .

[0058] Further, the transmission part is a long connecting rod 8 with a rod-shaped structure, which is arranged outside the grounding leg. The transmission part is set as a long connecting rod to...

Embodiment 3

[0064] Such as Figure 5 to Figure 9As shown, according to the worm-type lifting mechanism described in Embodiment 1, the limiting plate 10 and the inner sleeve 2 are also provided with a positioning structure correspondingly, and the positioning structure includes a positioning member arranged on the inner sleeve 2, And the positioning groove 1003 correspondingly provided on the limiting plate 10 , when the positioning piece is retracted into the outer sleeve 1 along with the inner sleeve 2 , the positioning piece is combined with the positioning groove 1003 . The positioning structure set by the limiting plate and the inner sleeve, when the shelter is lowered to the limit position, through the cooperation of the positioning piece and the positioning groove, the inner sleeve is restricted from continuously upward, which plays a role in safely protecting the entire lifting mechanism.

[0065] Such as Image 6 As shown, the limiting plate 10 is provided with a limiting shaft h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com