Cable tunnel miniature automatic fire-proof door

A technology for cable tunnels and fire doors, which is applied to fire doors, windows/doors, door/window accessories, etc., can solve the problems of increasing the outer dimension of fire doors, limiting the travel of the passable space, and heavy workload. The effect of flexibility, compact structure and small blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

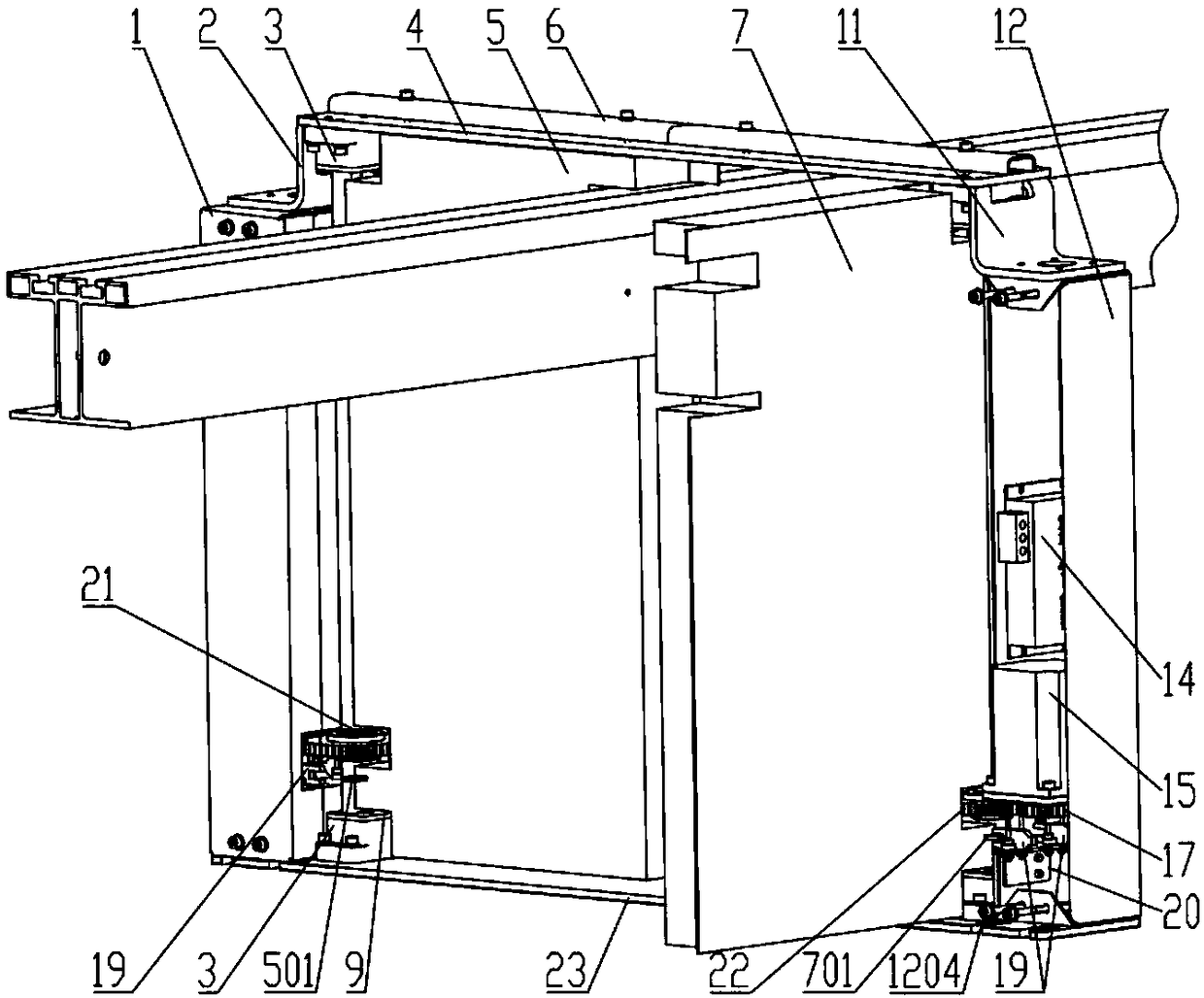

[0027] The present invention will be further described below in conjunction with accompanying drawing.

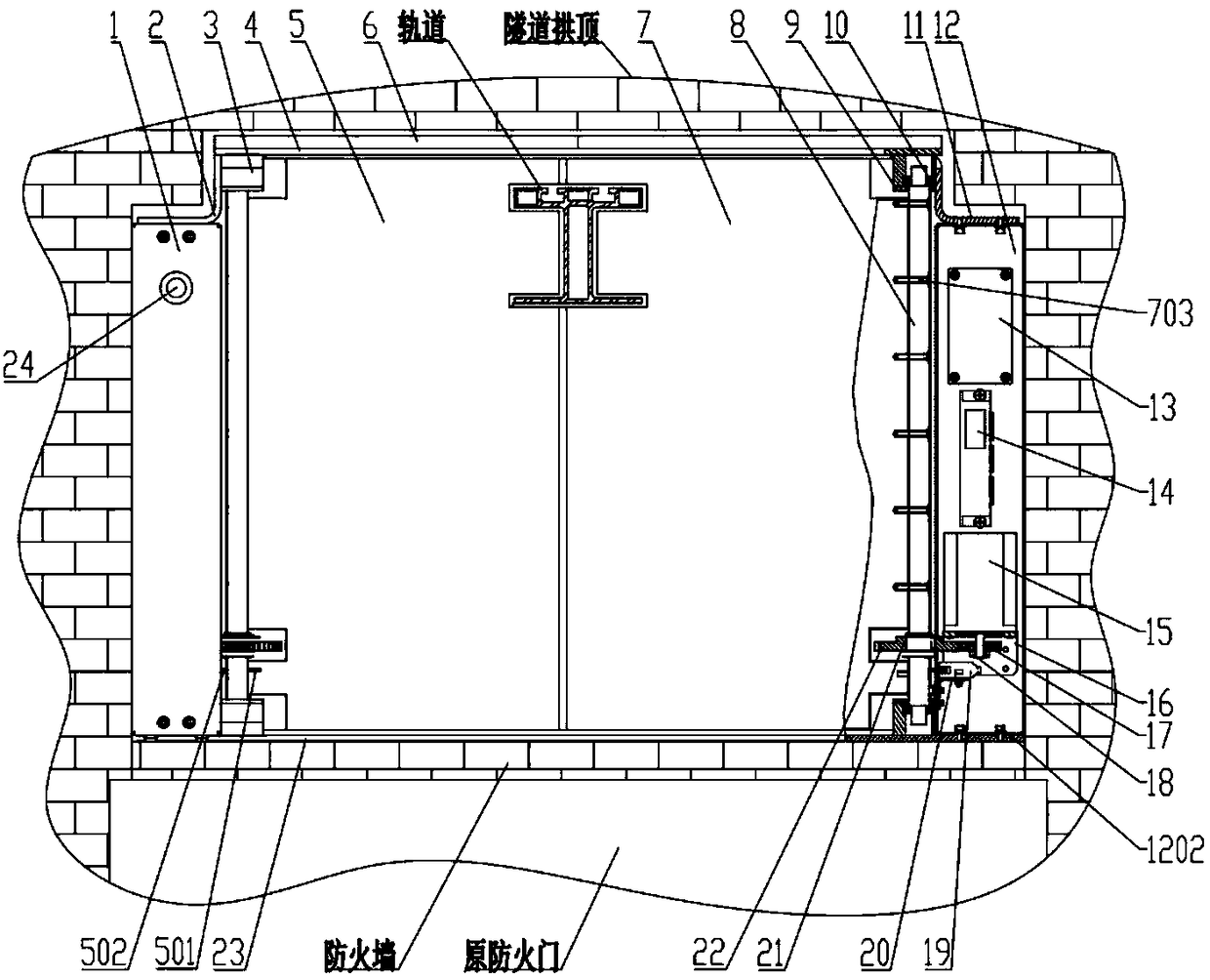

[0028] The invention discloses a cable tunnel miniature automatic fire door, such as figure 1 As shown, without doing harmful transformation to the original fire-fighting facilities in the cable tunnel, reducing the difficulty of transformation and reducing the workload of transformation, a miniature automatic fire-proof door is added to the upper space of the original fire-proof door to facilitate the passage of orbital robots. The two kinds of fire-proof doors perform their respective functions. ,Work independently.

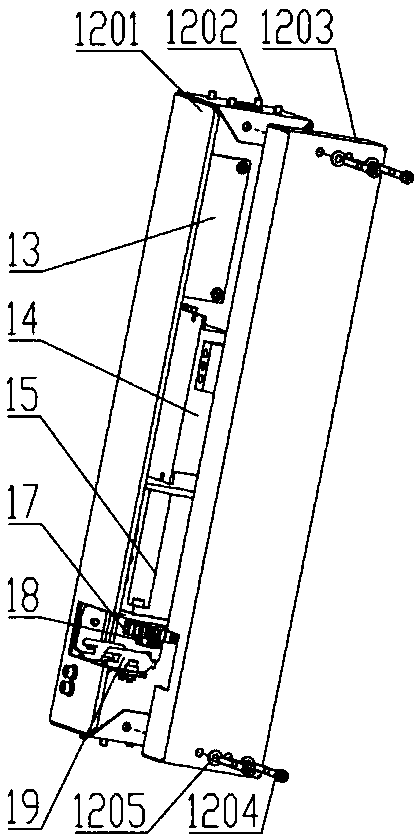

[0029] Miniature automatic fire doors for cable tunnels include:

[0030] Left door frame 1 is formed by bending galvanized steel plate, and structure and function are identical with right door frame 12.

[0031] The left upper connecting plate 2 is formed by bending a galvanized steel plate, and plays the role of connecting the left door frame 1 and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com