Double-planetary-line hybrid coupling mechanism and motor vehicle

A hybrid, dual-planetary technology, applied in hybrid vehicles, motor vehicles, power units, etc., can solve the problems of high motor power requirements, low efficiency, heavy weight, etc., to optimize the working range, improve economic performance, and save money. Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

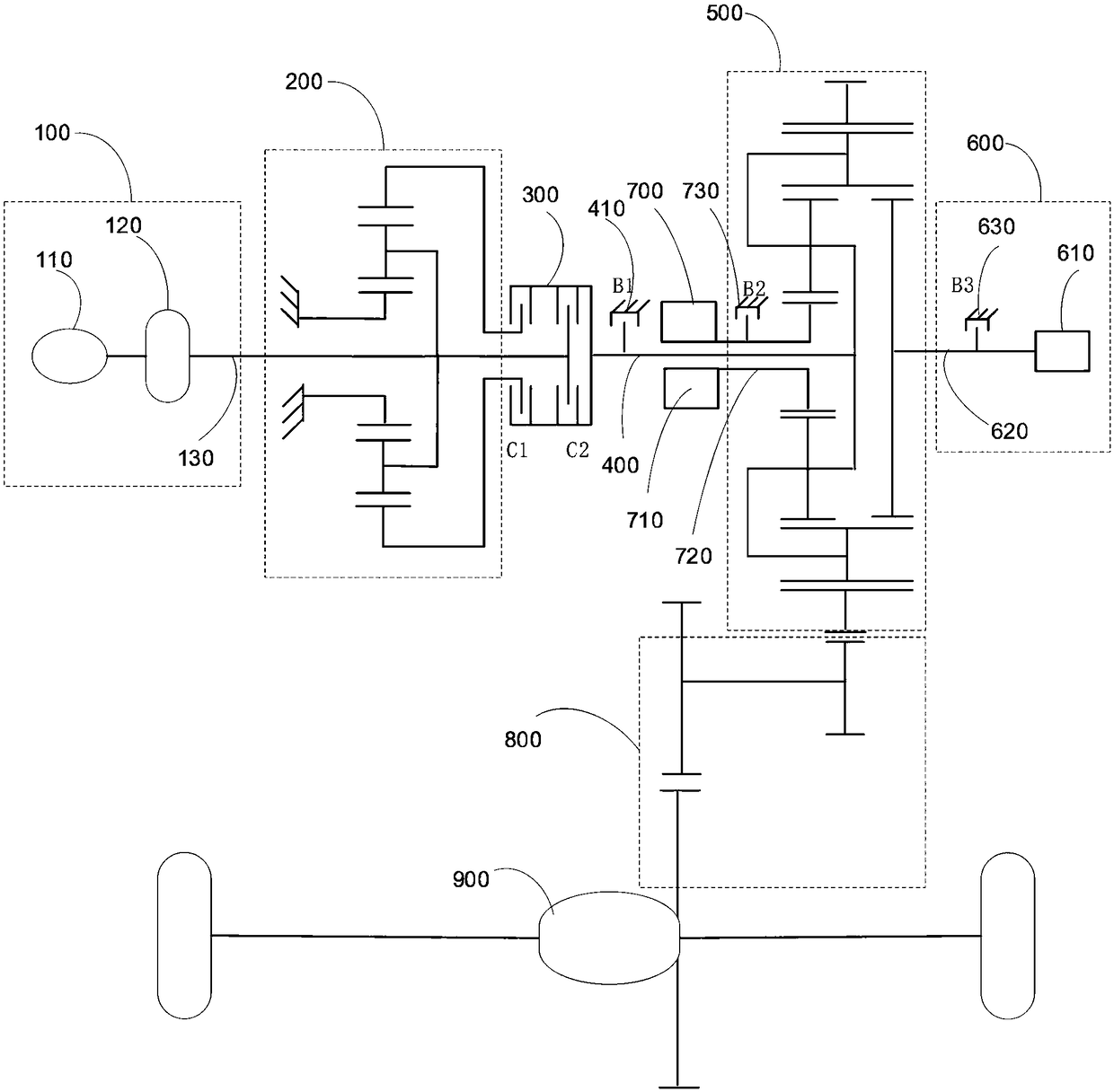

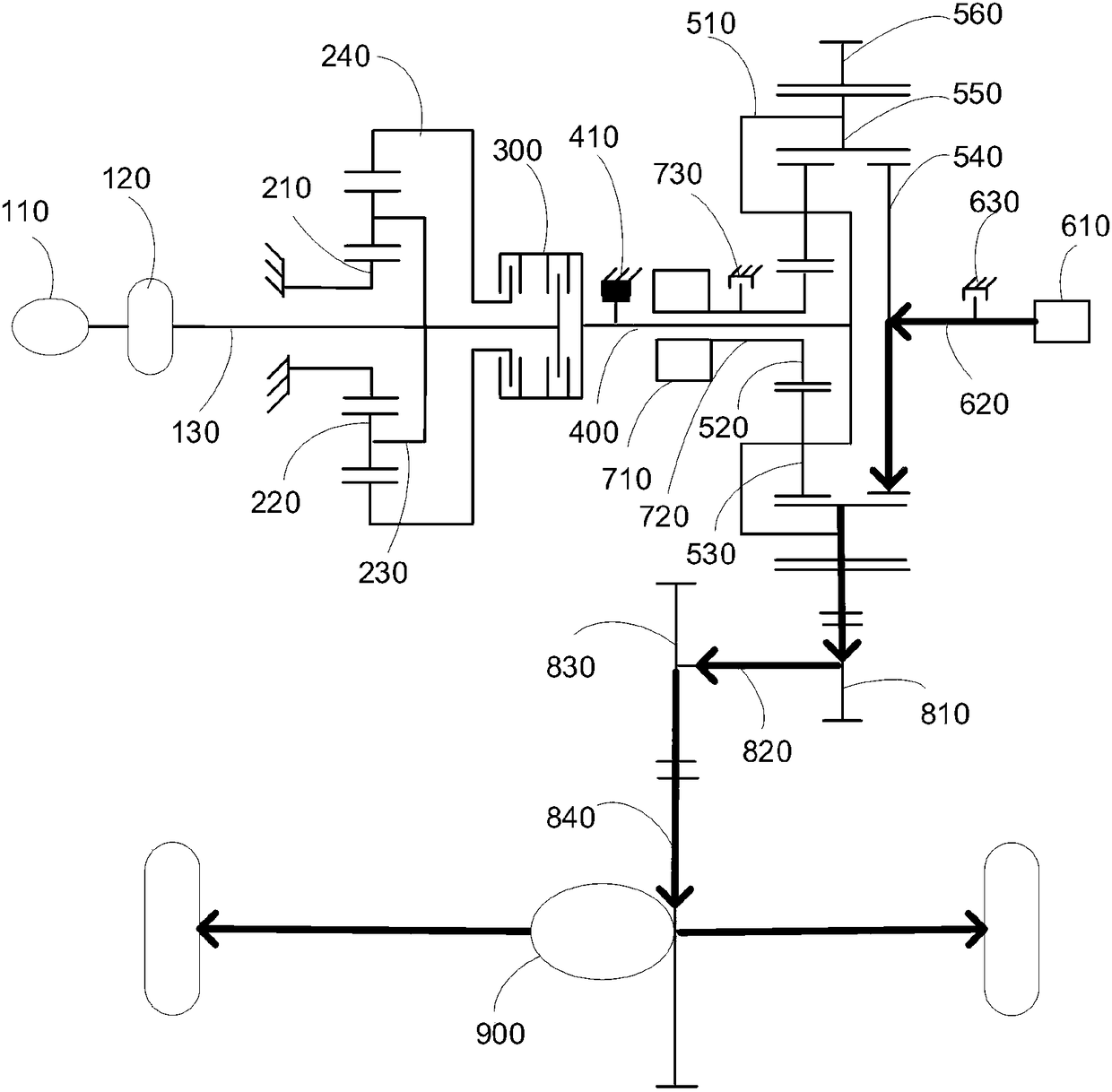

[0059] In this example, if figure 1 As shown, the present invention proposes a dual planetary gear hybrid coupling mechanism, including a fuel drive mechanism 100, a single planetary gear mechanism 200, a double clutch 300, an intermediate connecting shaft structure, a compound planetary gear mechanism 500, a first electric drive mechanism 700, the second electric drive mechanism 600 and a power output mechanism. Through the single planetary gear mechanism 200, the double clutch 300, the intermediate connecting shaft structure and the composite planetary gear mechanism 500, the fuel drive mechanism 100, the first electric drive mechanism 700, and the second electric drive mechanism 600 can be powered. Coupling, and outputting power through the power output mechanism, can realize multiple power driving modes, and can improve the efficiency and economy of the whole system.

[0060] Specifically, such as figure 2 As shown, the fuel-driven mechanism 100 includes an engine 110 ,...

Embodiment 2

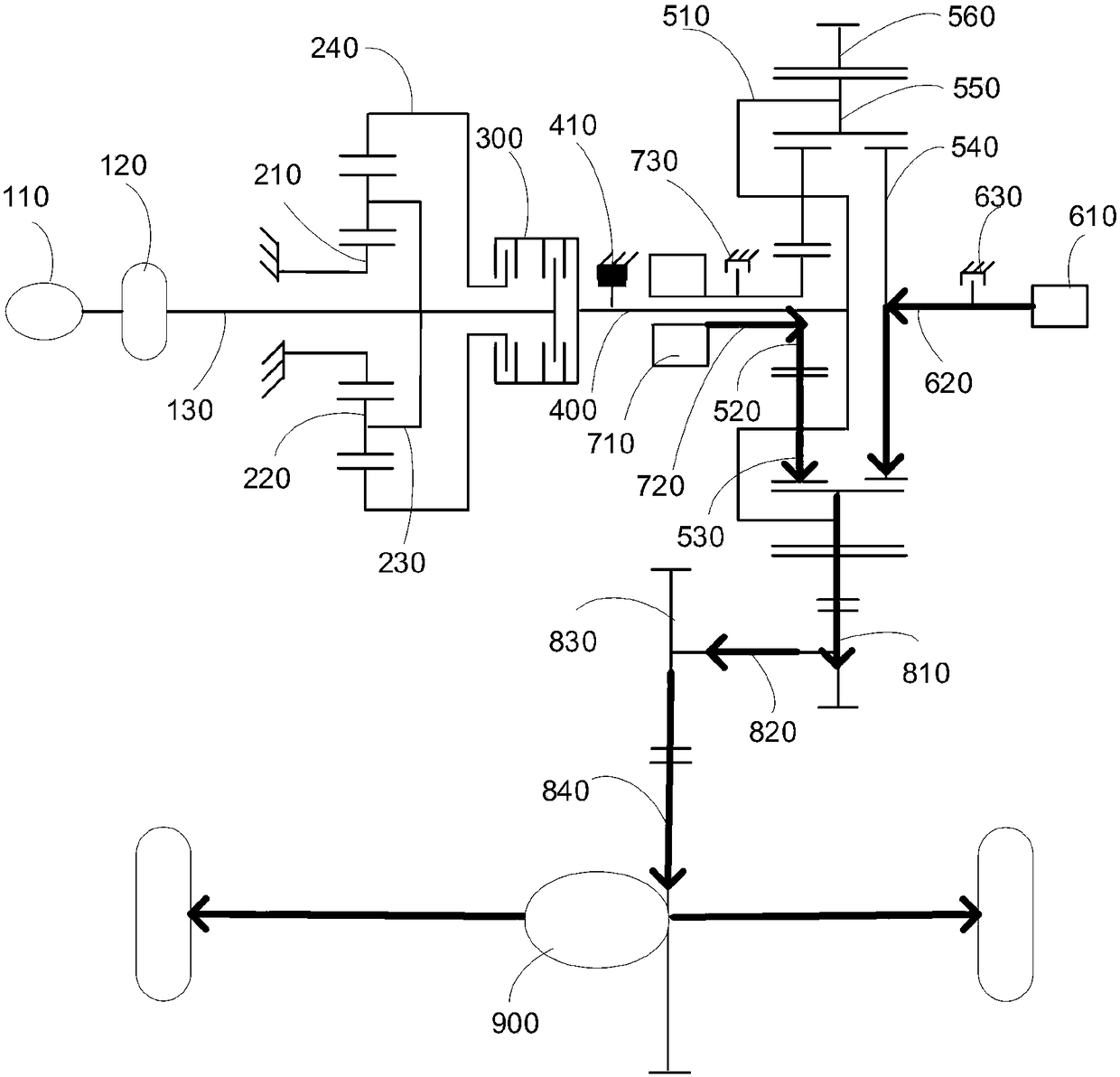

[0087] In this example, if Figure 11 As shown, the present invention proposes a dual planetary gear hybrid coupling mechanism, including a fuel drive mechanism 100, a single planetary gear mechanism 200, a double clutch 300, an intermediate connecting shaft structure, a compound planetary gear mechanism 500, a first electric drive mechanism 700, the second electric drive mechanism 600 and a power output mechanism. Through the single planetary gear mechanism 200, the double clutch 300, the intermediate connecting shaft structure and the composite planetary gear mechanism 500, the fuel drive mechanism 100, the first electric drive mechanism 700, and the second electric drive mechanism 600 can be powered. Coupling, and outputting power through the power output mechanism, can realize multiple power driving modes, and can improve the efficiency and economy of the whole system.

[0088] Moreover, in this embodiment, the main difference from the first embodiment above is that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com