Patents

Literature

71results about How to "Optimize workspace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

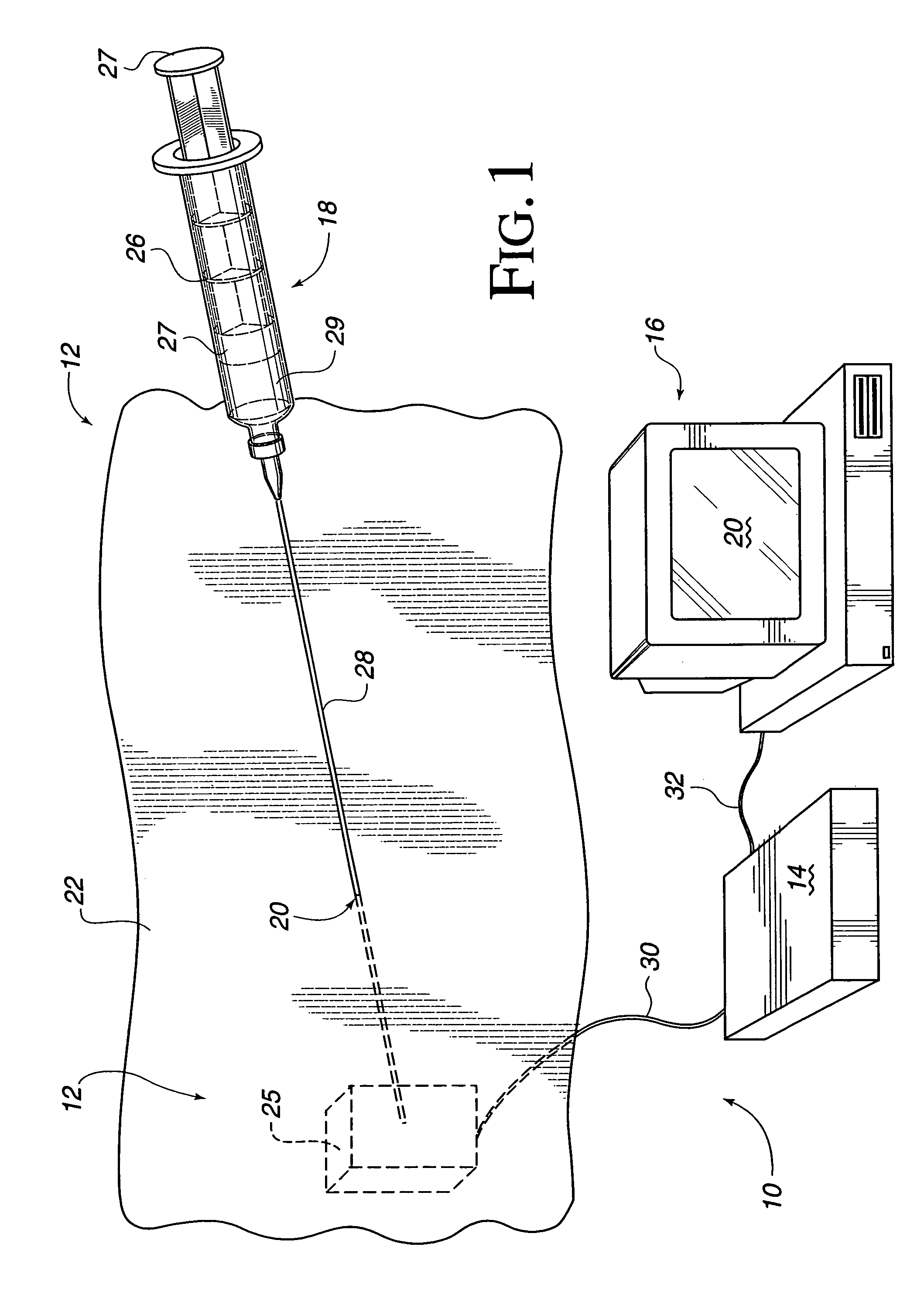

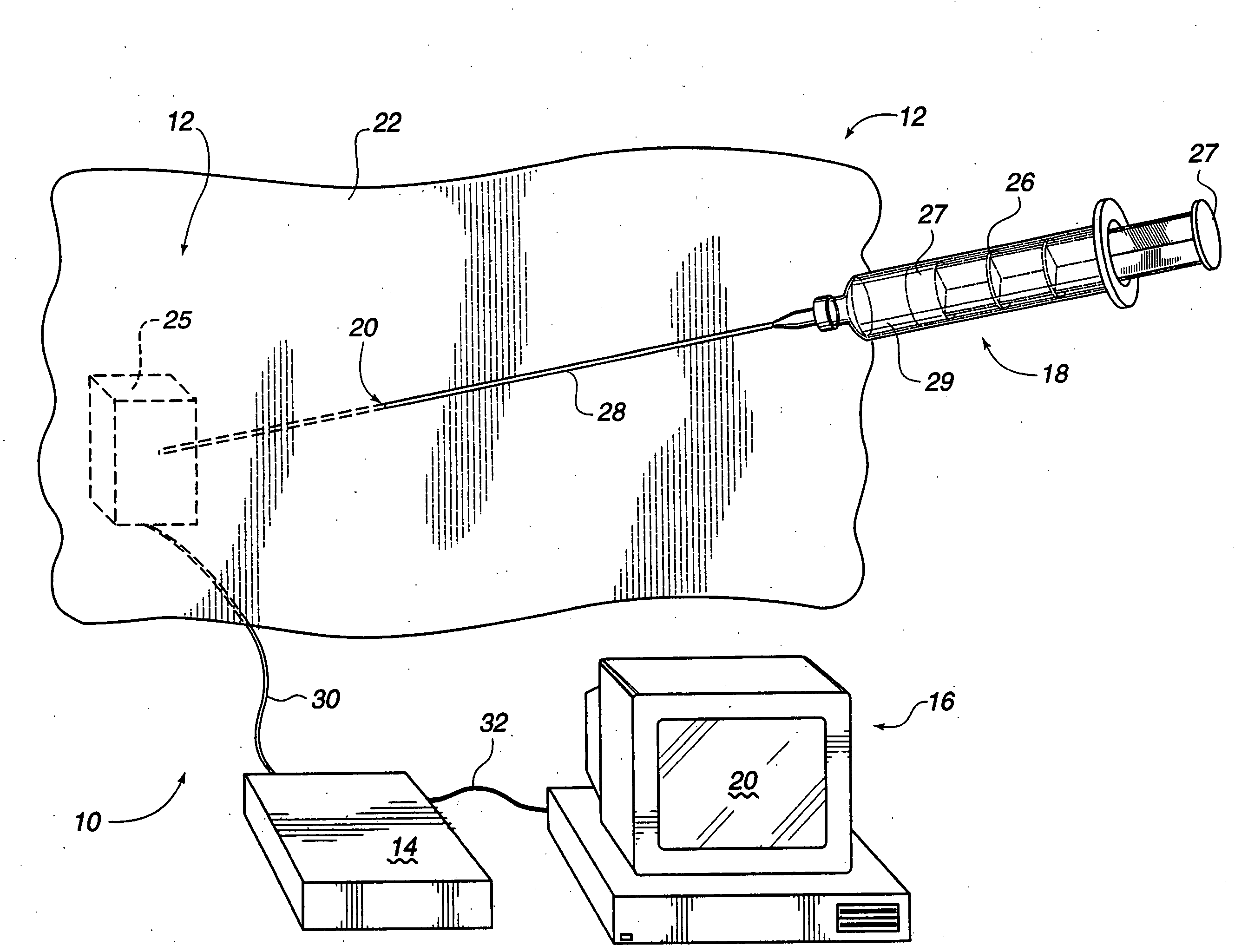

Method and apparatus for providing an interface mechanism for a computer simulation

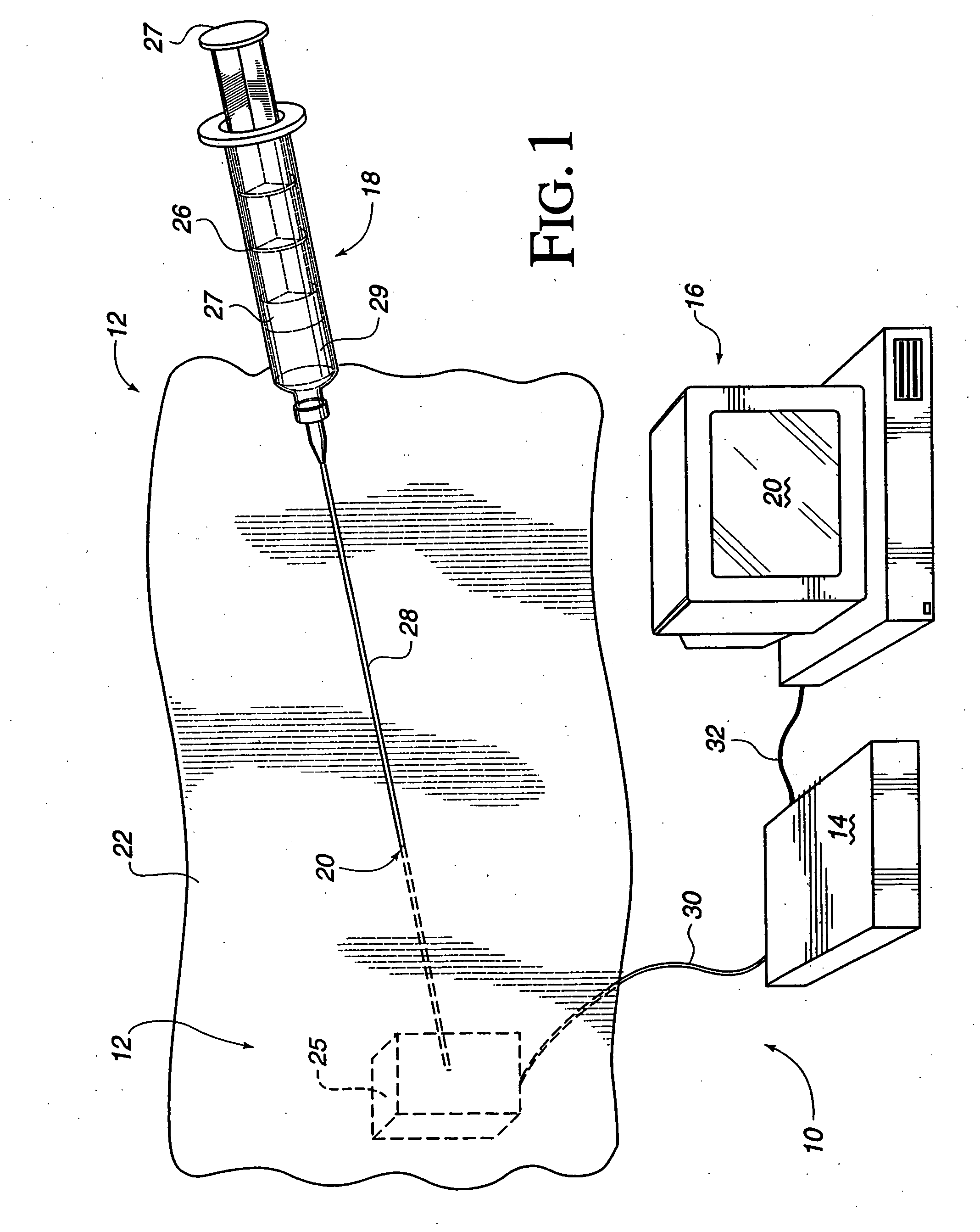

InactiveUS7249951B2Highly realistic feedbackHighly realistic motionManual control with multiple controlled membersDiagnosticsHigh bandwidthComputerized system

Owner:IMMERSION CORPORATION

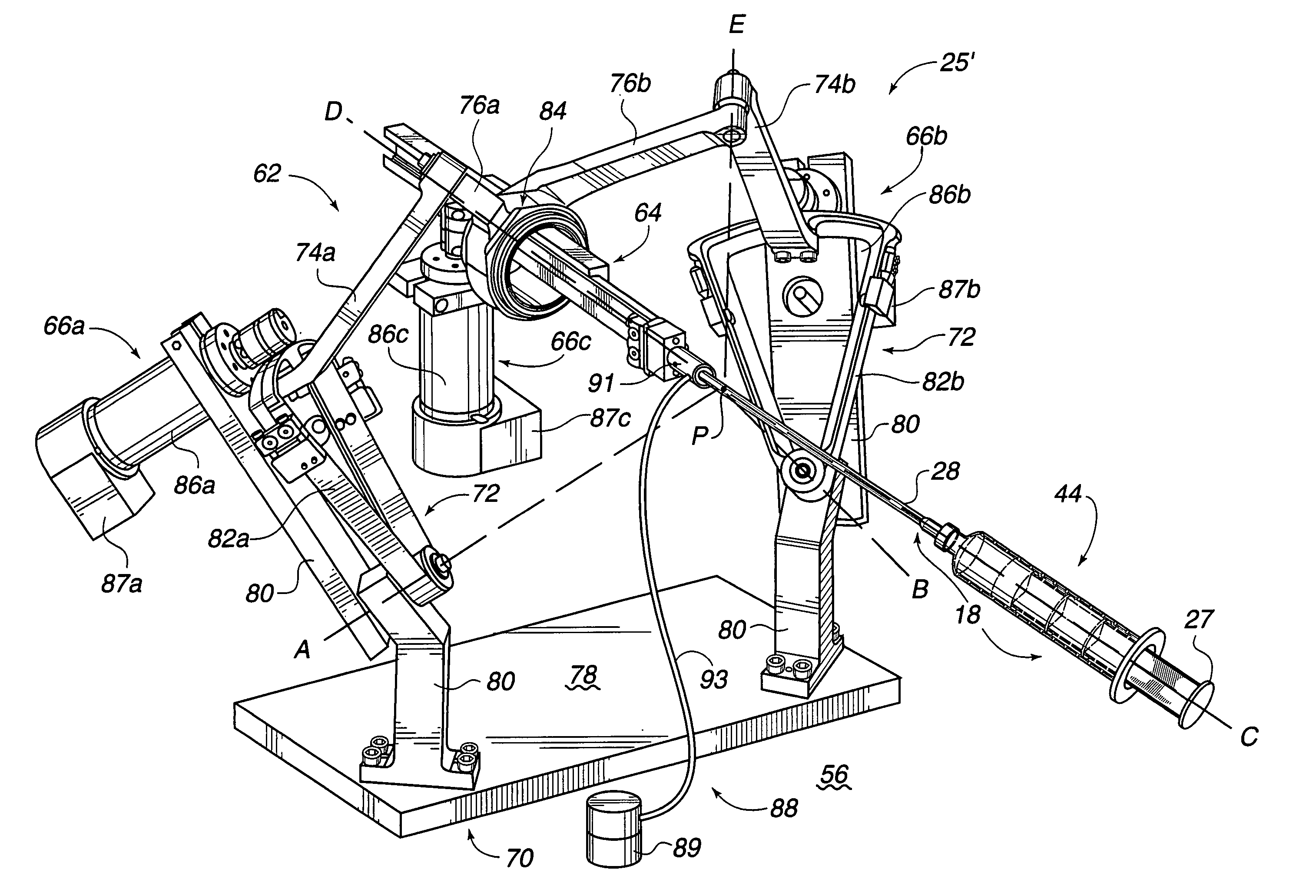

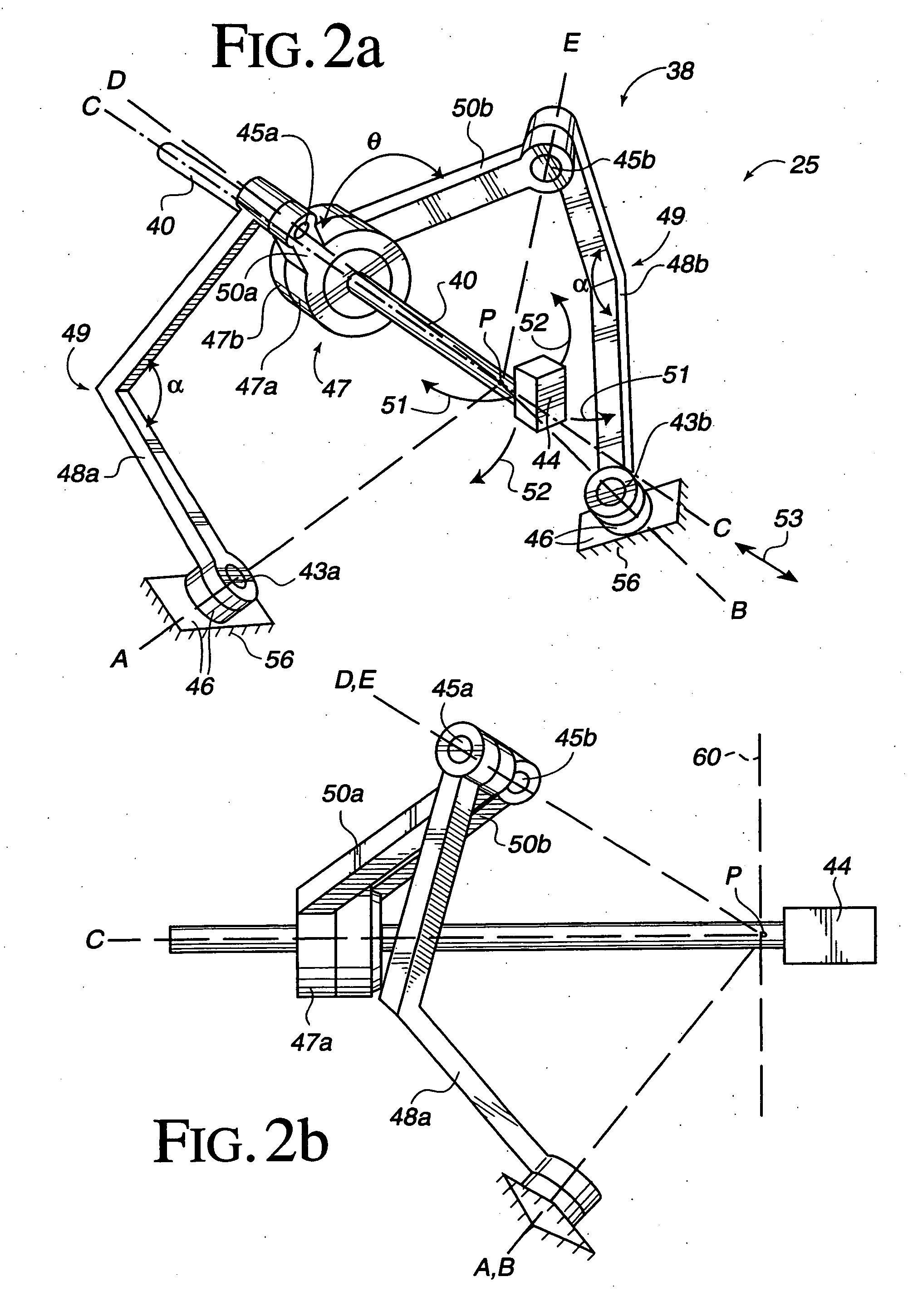

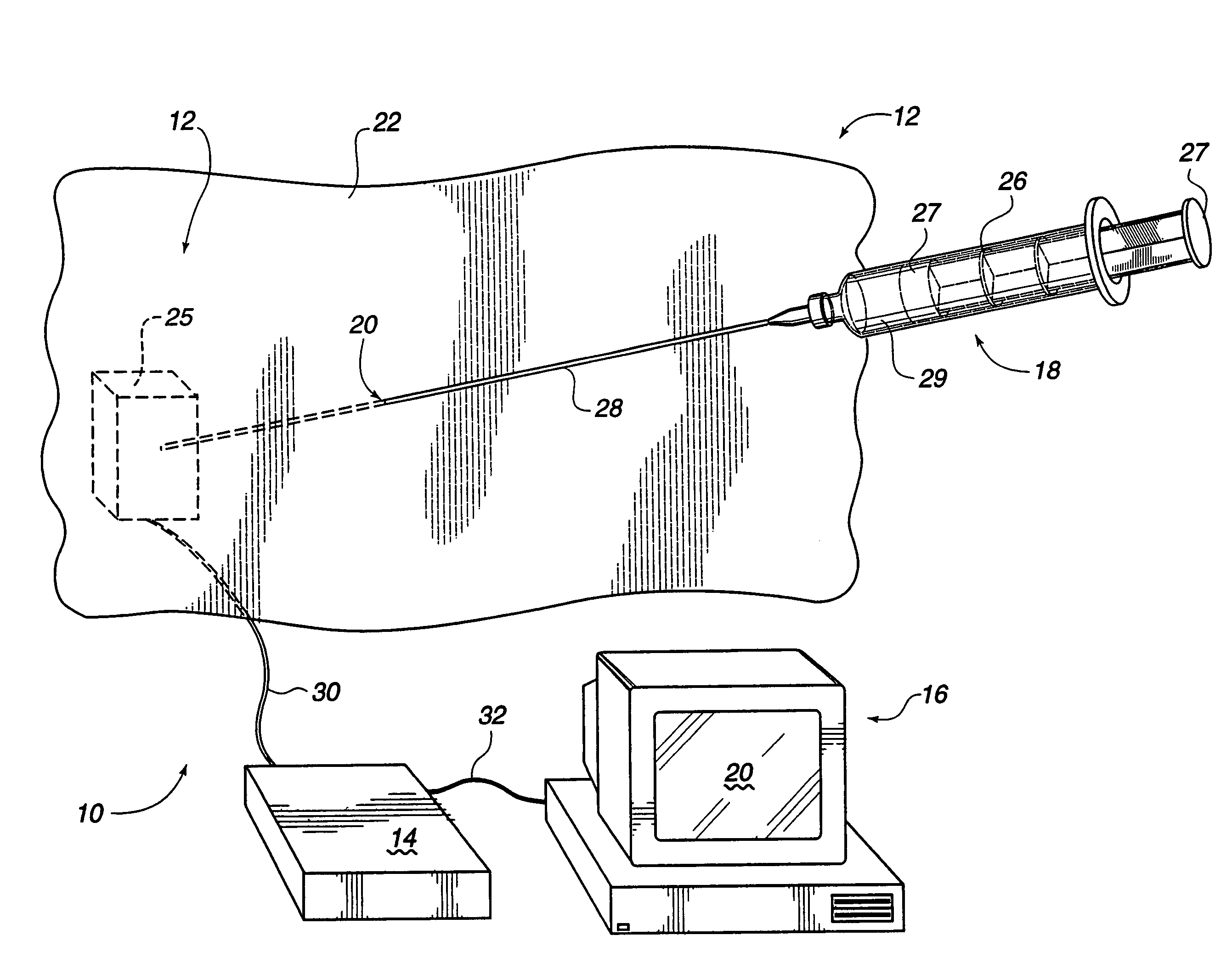

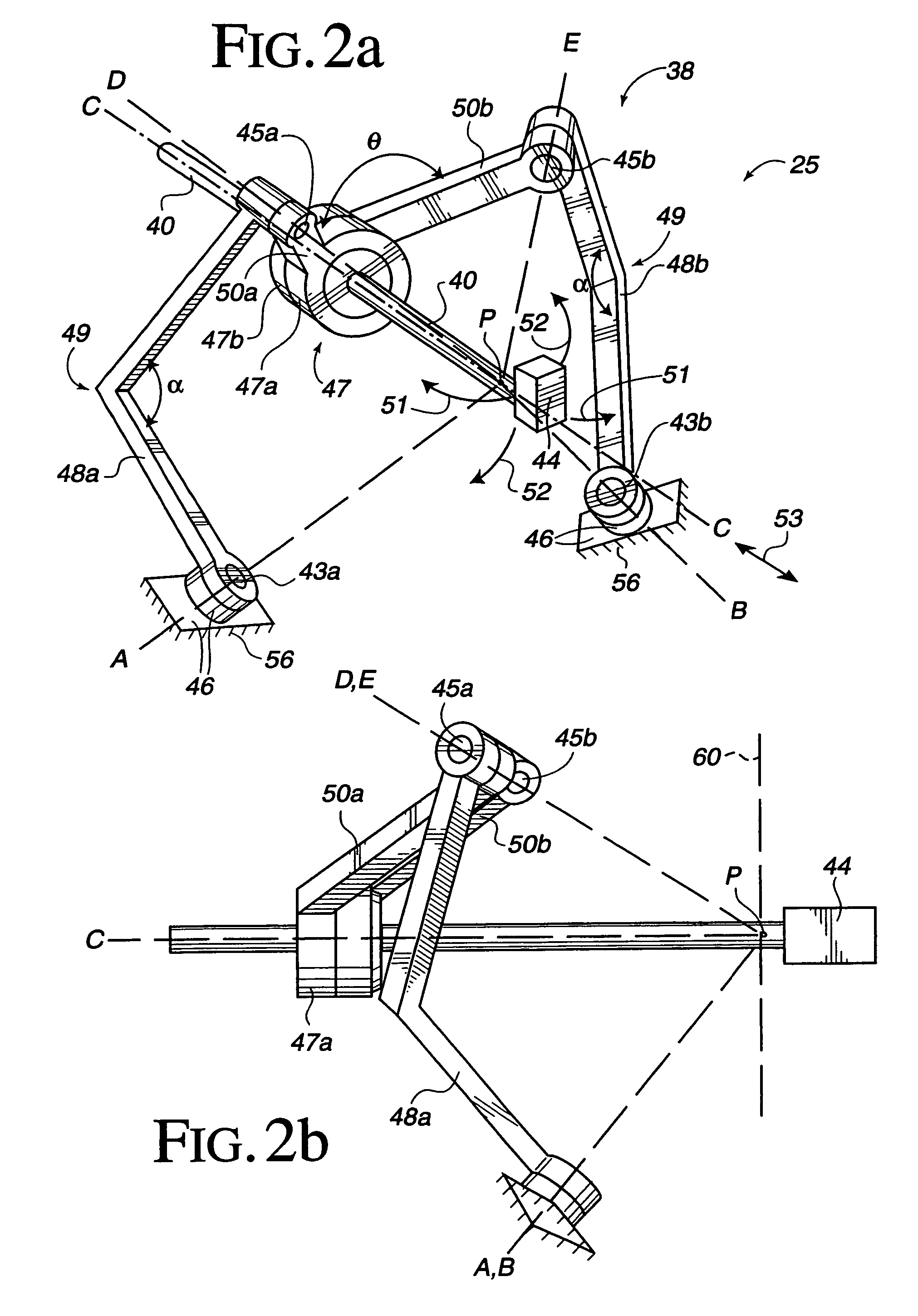

Hemispherical high bandwidth mechanical interface for computer systems

InactiveUS20060194180A1Highly realistic force feedbackHighly realistic motionManual control with multiple controlled membersDiagnosticsLow noiseHigh bandwidth

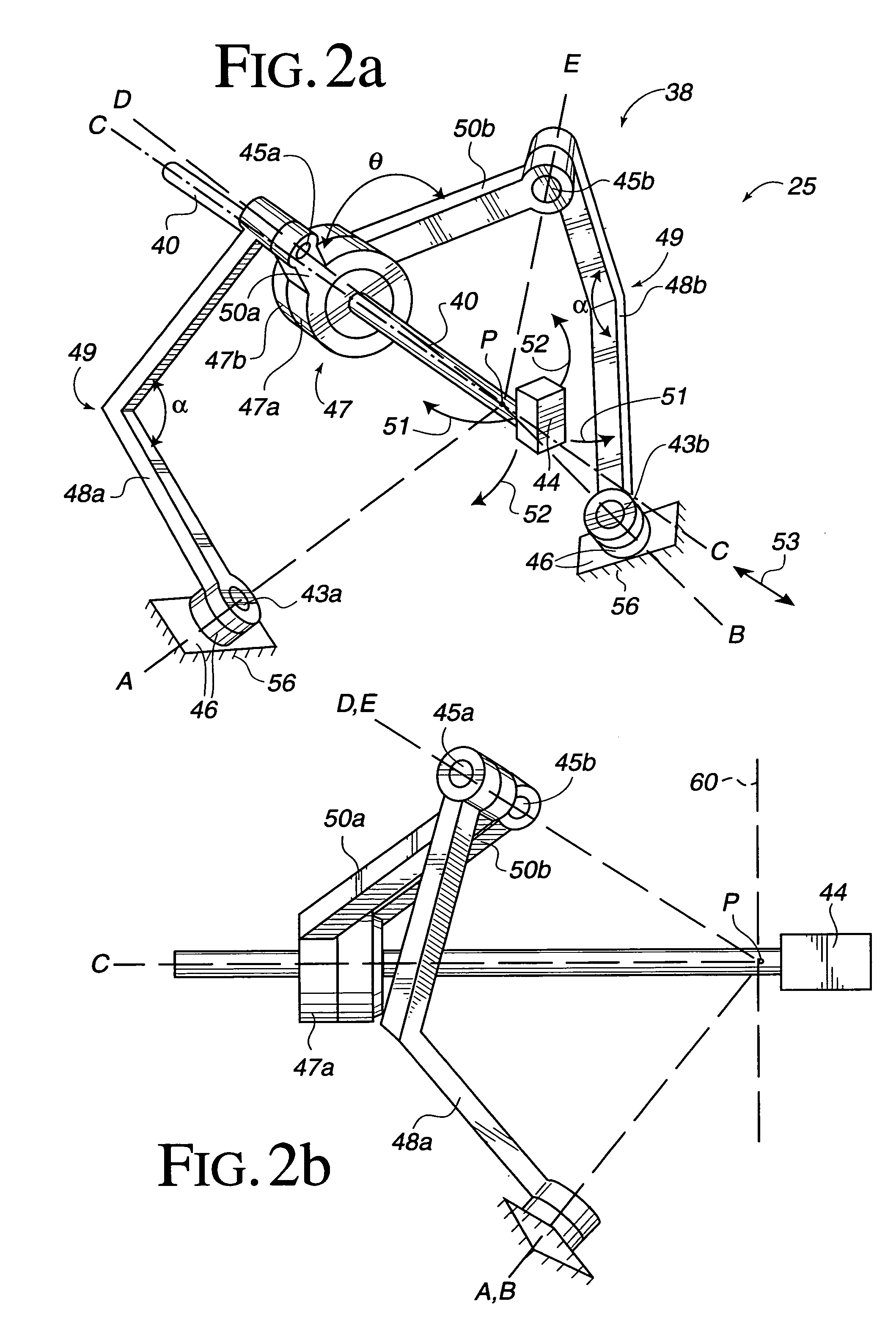

A mechanical interface for providing high bandwidth and low noise mechanical input and output for computer systems. A gimbal mechanism includes multiple members that are pivotably coupled to each other to provide two revolute degrees of freedom to a user manipulatable about a pivot point located remotely from the members at about an intersection of the axes of rotation of the members. A linear axis member, coupled to the user object, is coupled to at least one of the members, extends through the remote pivot point and is movable in the two rotary degrees of freedom and a third linear degree of freedom. Transducers associated with the provided degrees of freedom include sensors and actuators and provide an electromechanical interface between the object and a computer. Capstan band drive mechanisms transmit forces between the transducers and the object and include a capstan and flat bands, where the flat bands transmit motion and force between the capstan and interface members. Applications include simulations of medical procedures, e.g. epidural anesthesia, where the user object is a needle or other medical instrument, or other types of simulations or games.

Mechanical interface for a computer system

InactiveUS7500853B2Highly realistic feedbackHighly realistic motionManual control with multiple controlled membersDiagnosticsLow noiseHigh bandwidth

A mechanical interface for providing high bandwidth and low noise mechanical input and output for computer systems. A gimbal mechanism includes multiple members that are pivotally coupled to each other to provide two revolute degrees of freedom to a user manipulatable about a pivot point located remotely from the members at about an intersection of the axes of rotation of the members. A linear axis member, coupled to the user object, is coupled to at least one of the members, extends through the remote pivot point and is movable in the two rotary degrees of freedom and a third linear degree of freedom. Transducers associated with the provided degrees of freedom include sensors and actuators and provide an electromechanical interface between the object and a computer. Capstan band drive mechanisms transmit forces between the transducers and the object and include a capstan and flat bands, where the flat bands transmit motion and force between the capstan and interface members. Applications include simulations of medical procedures, e.g. epidural anesthesia, where the user object is a needle or other medical instrument, or other types of simulations or games.

Owner:IMMERSION CORPORATION

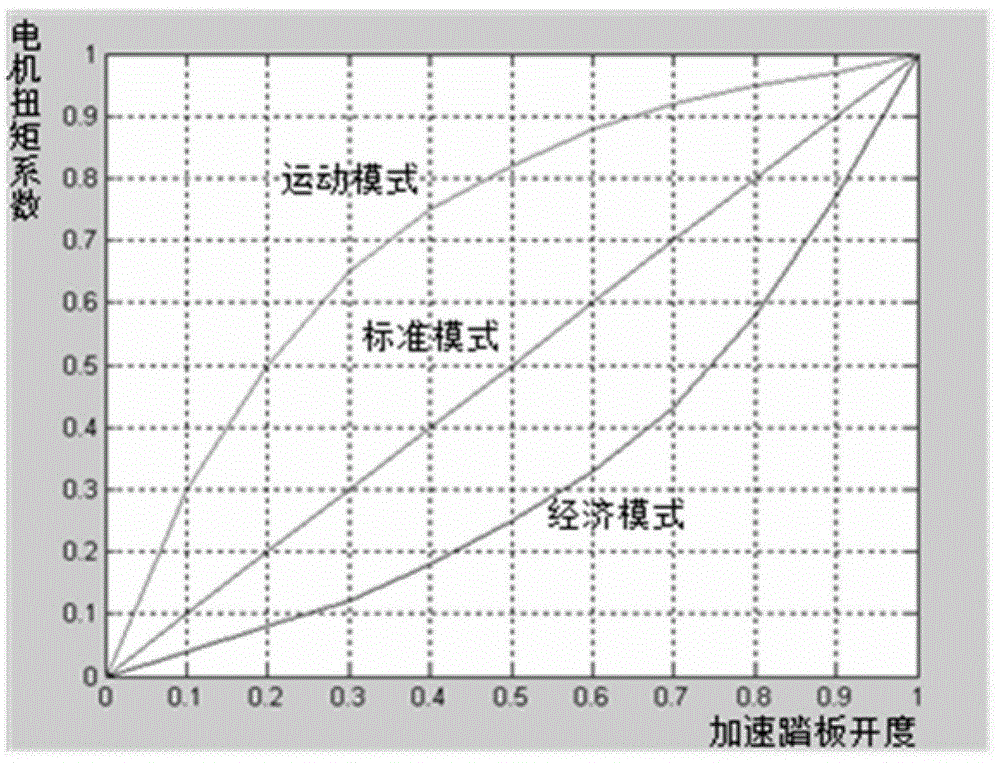

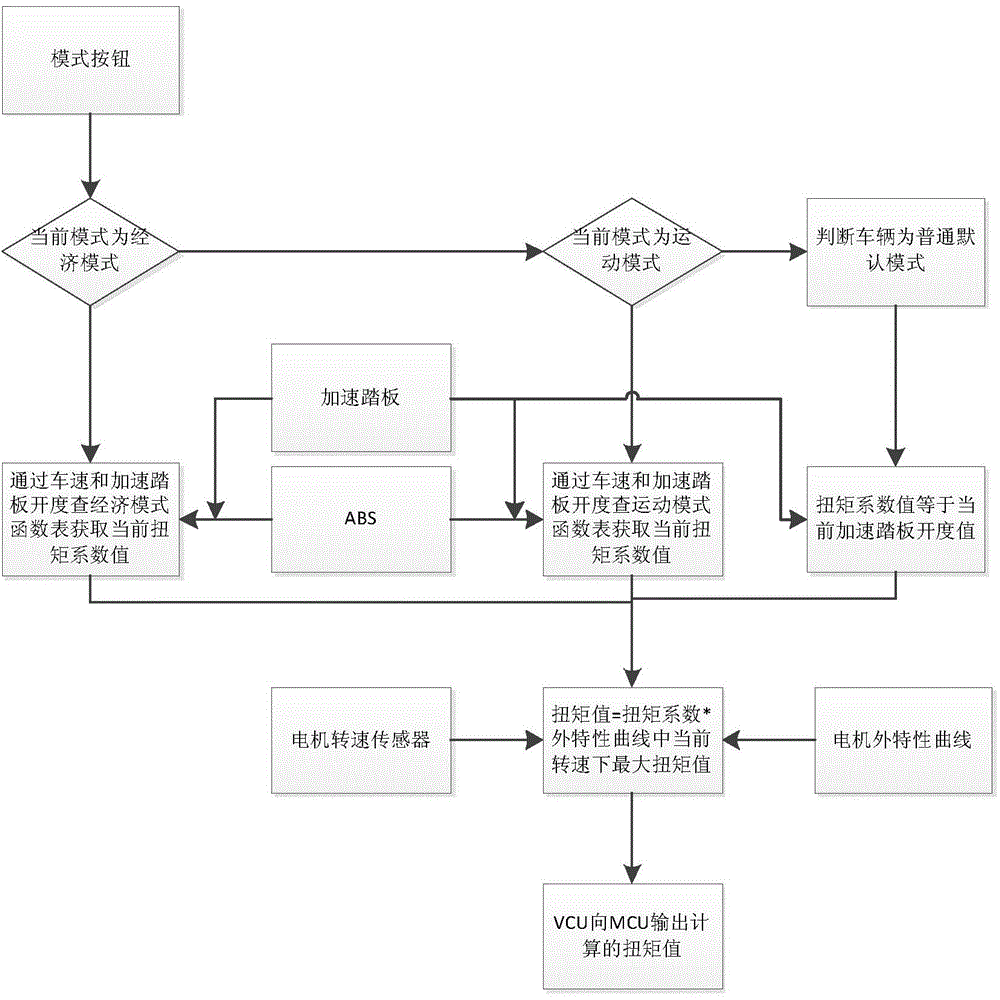

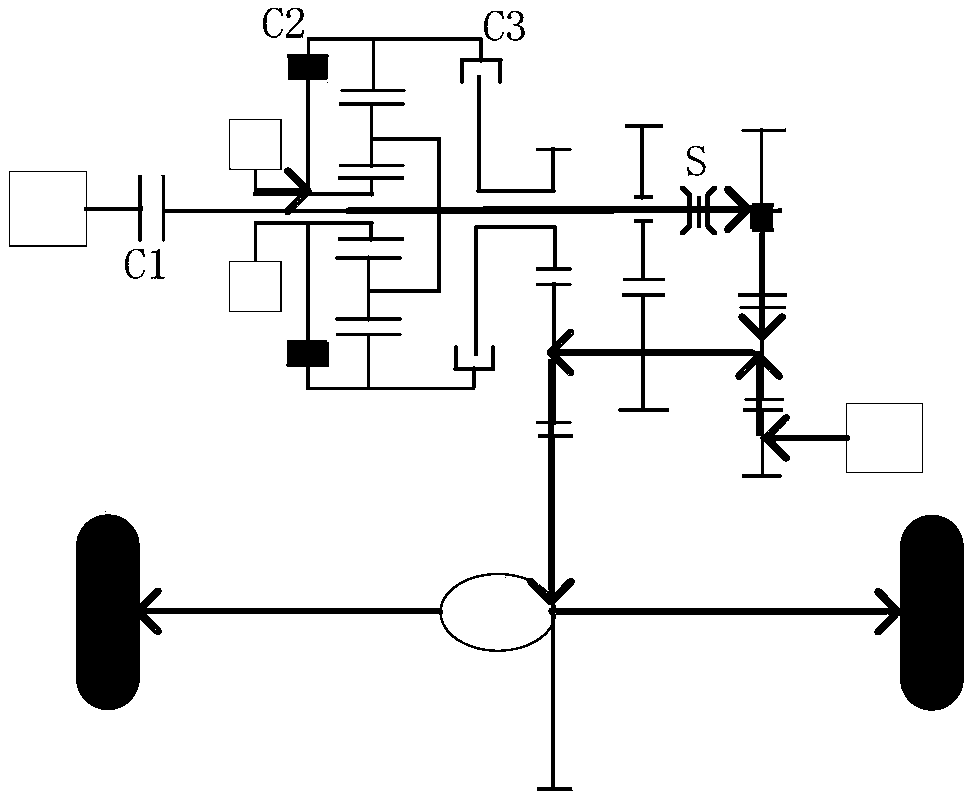

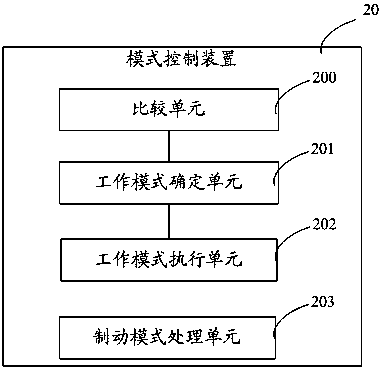

Multimode drive control method for pure electric vehicle

ActiveCN104648184AAvoid the disadvantages of insufficient torqueOptimize workspaceSpeed controllerElectric energy managementElectric machineryPeak value

The invention provides a multimode drive control method for a pure electric vehicle. The method comprises the steps that an overall vehicle controller judges the state of a driving mode of the vehicle, a torque parameter value is obtained by searching a function table through an input value in accordance with that different driving modes correspond to different function tables and input values of the function tables are current vehicle speed and openness of an accelerator pedal, and finally, a torque output value is determined by a product of the obtained torque parameter value and a peak torque value, which can be reached at a current revolving speed, of a motor. According to the method, through introducing a camber control strategy formulated through vehicle speed signals in various modes, the disadvantages resulting from the deficiency of torque of a rear segment of the driving motor are effectively avoided, the working interval of the driving motor is optimized, and the economical efficiency of the whole vehicle is increased.

Owner:BEIJING ELECTRIC VEHICLE

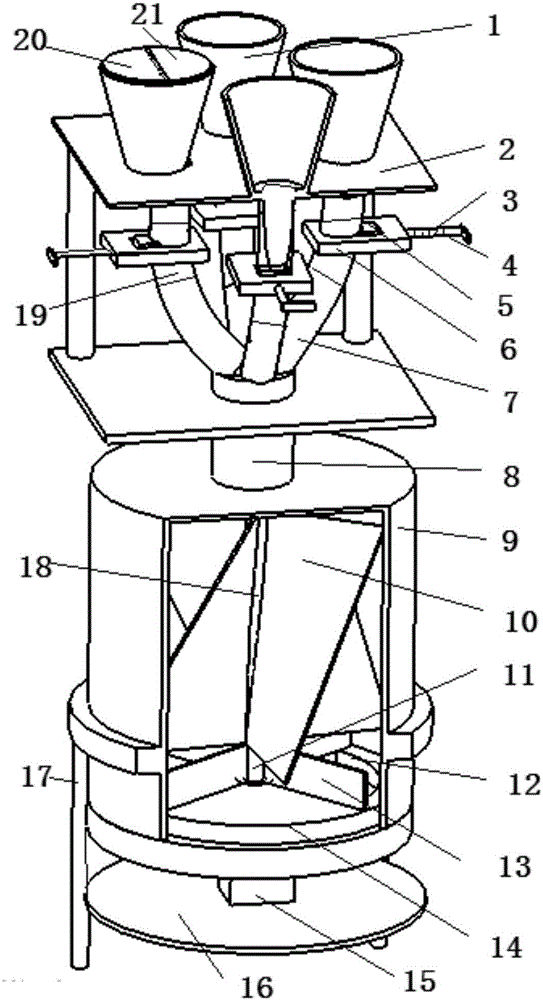

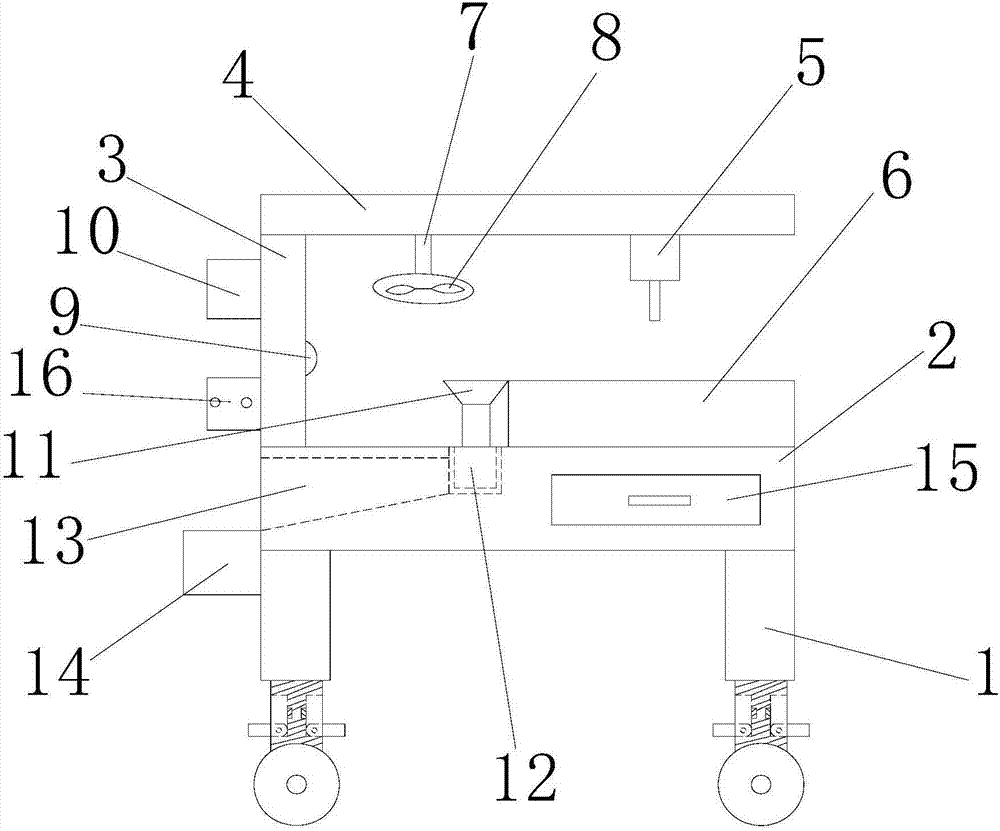

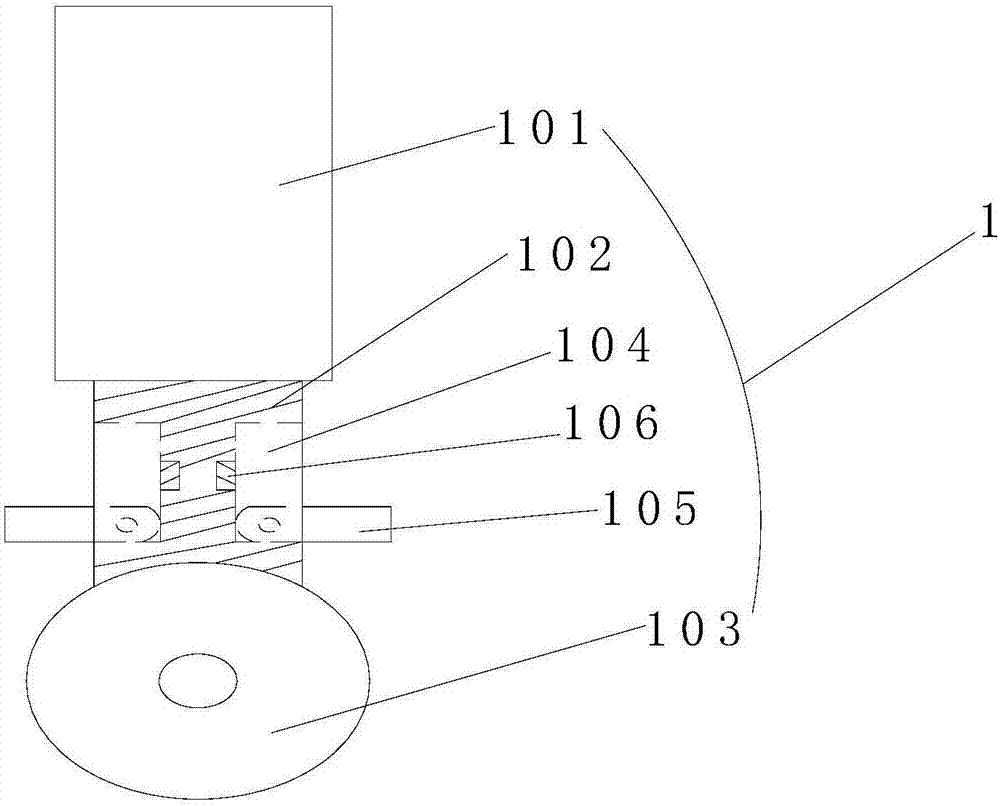

Quantitative powder mixing machine

InactiveCN106512821ARealize automatic proportioning and mixingReduce concentrationRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention provides a quantitative powder mixing machine, comprising a support and a feed hopper, wherein a first pipeline communicated with the feed hopper joins a second pipeline; the other end of the second pipeline is placed above and communicated with a mixing barrel; the inner surface of the bottom of the mixing barrel is rotatably connected with a discharging plate; the discharging plate is provided with discharging holes; the bottom of the mixing barrel is also provided with a discharging hole corresponding to the discharging plate; a stirring device is arranged in the mixing barrel; the first pipeline is provided with a section of an elastic pipe; and an adjusting device is arranged on the elastic pipe and comprises a clamp and an adjusting rod passing through and slidably connected with the clamp. The quantitative powder mixing machine realizes automatic proportioning and mixing of a plurality of materials and quantitative discharging through adjustment of the feed amounts of a plurality of feed inlets, reduces operation steps, lowers dust concentration during mixing, improves production efficiency and decreases cost.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

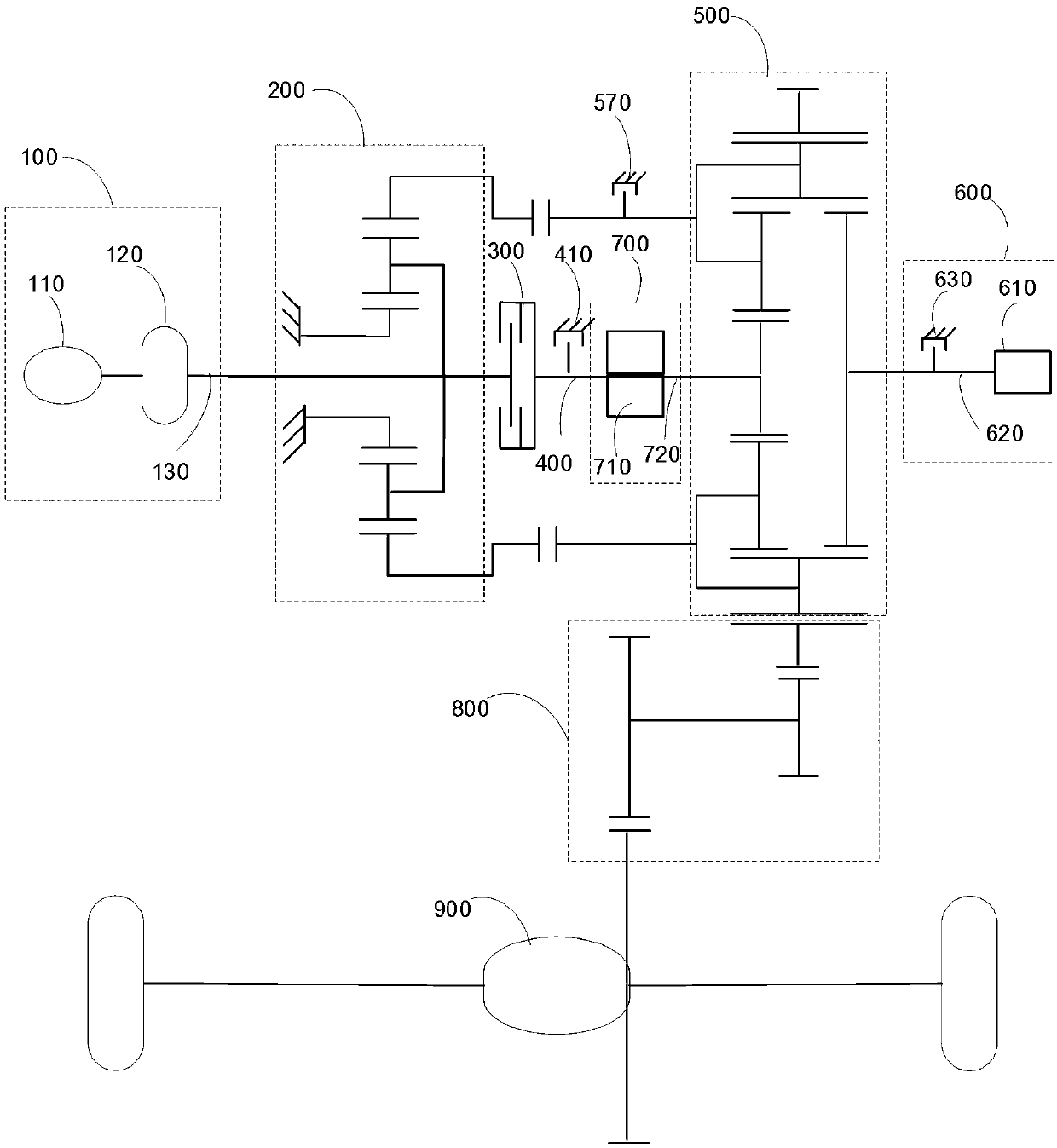

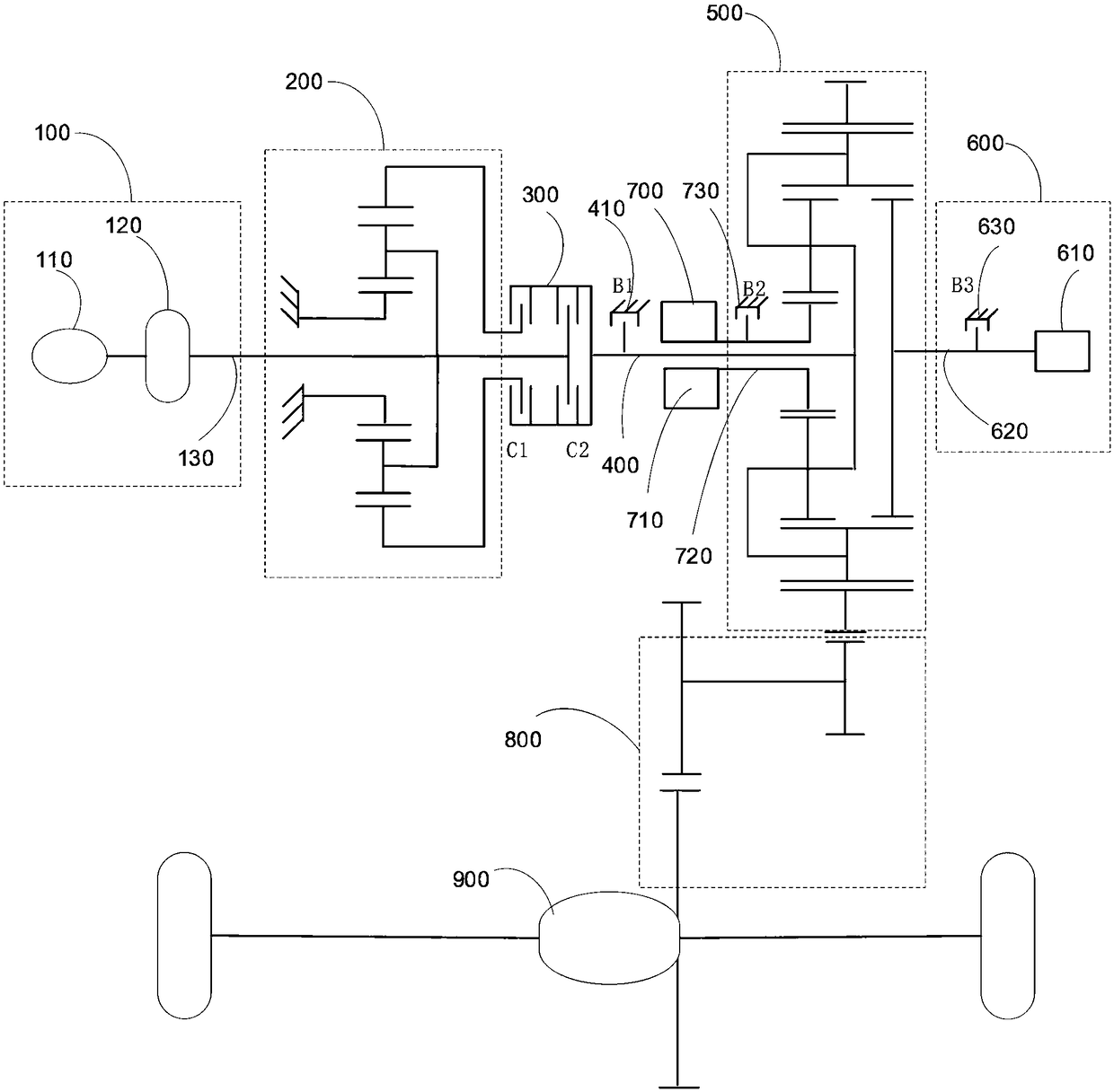

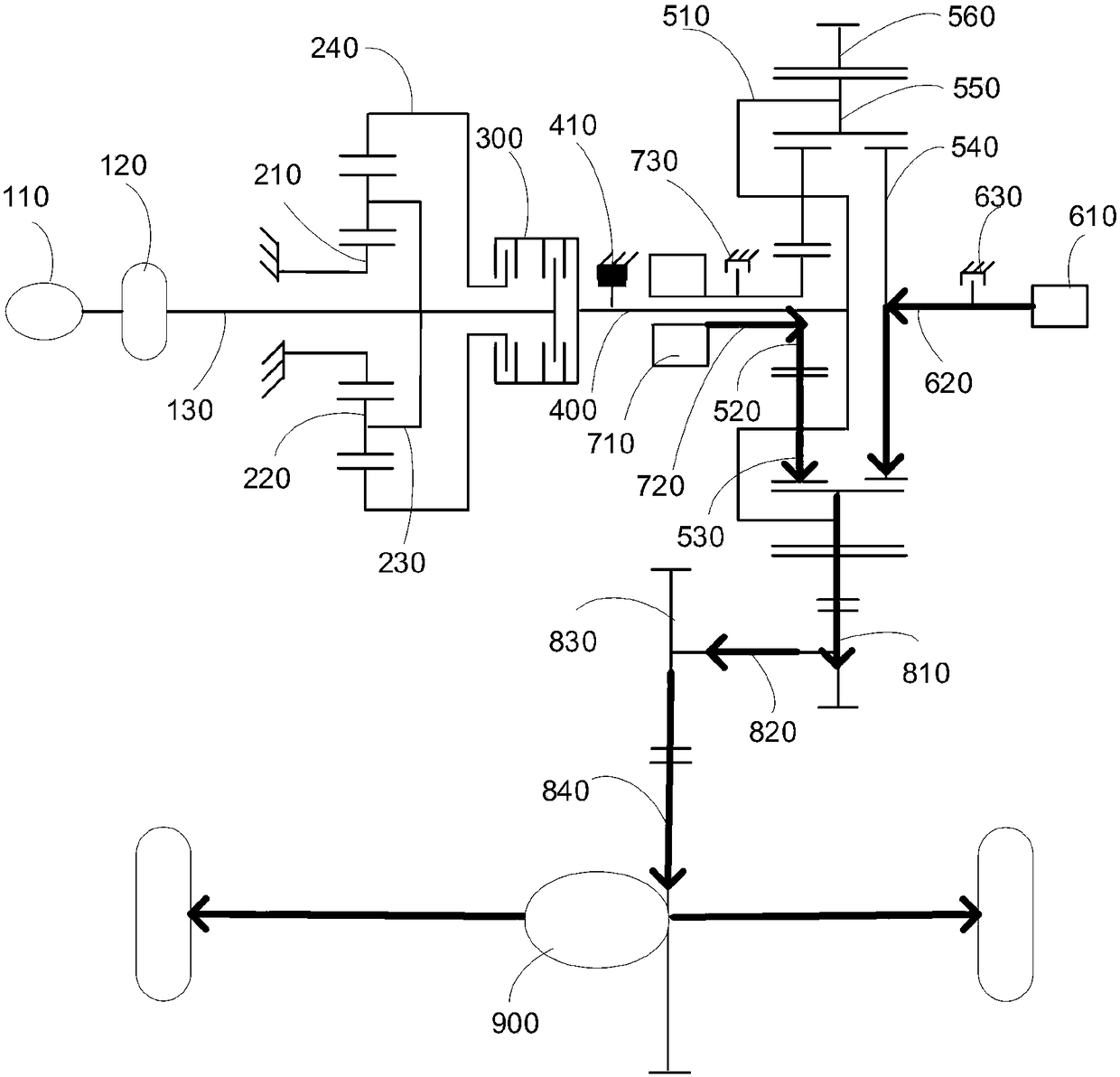

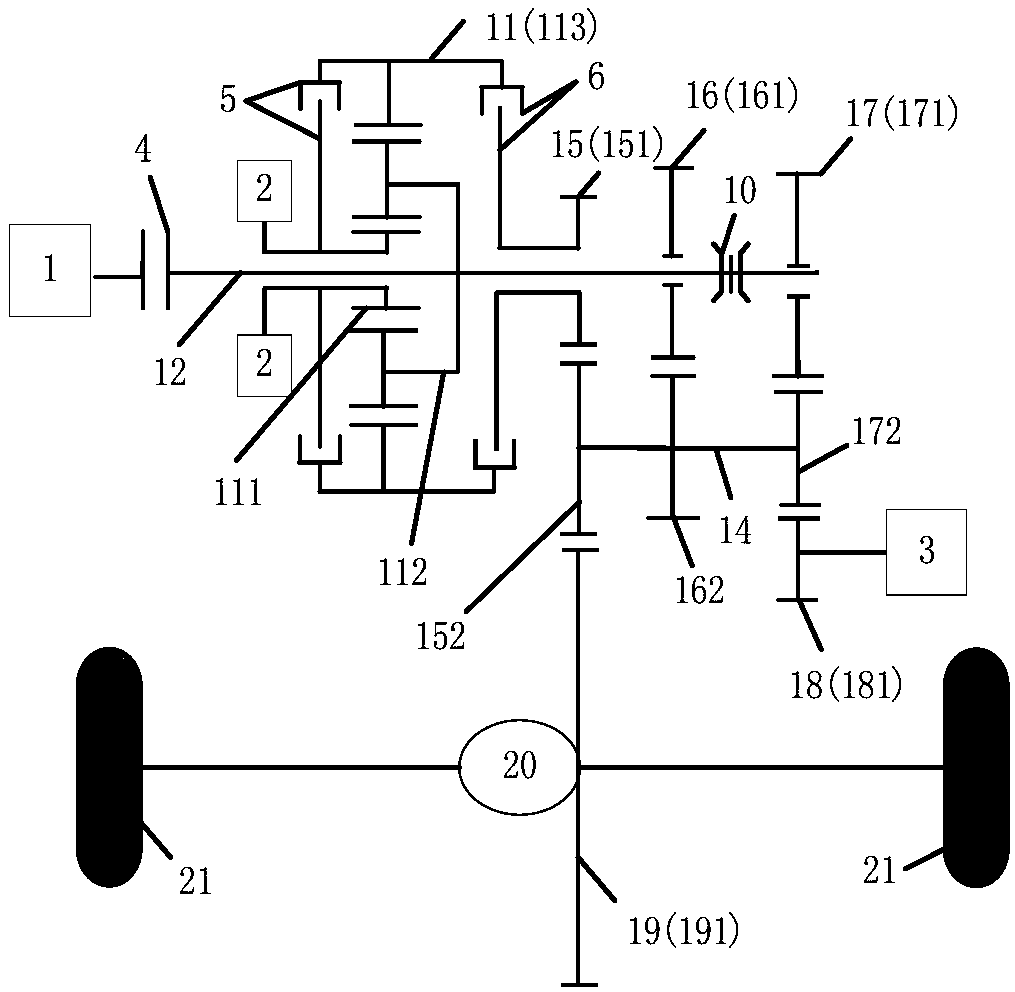

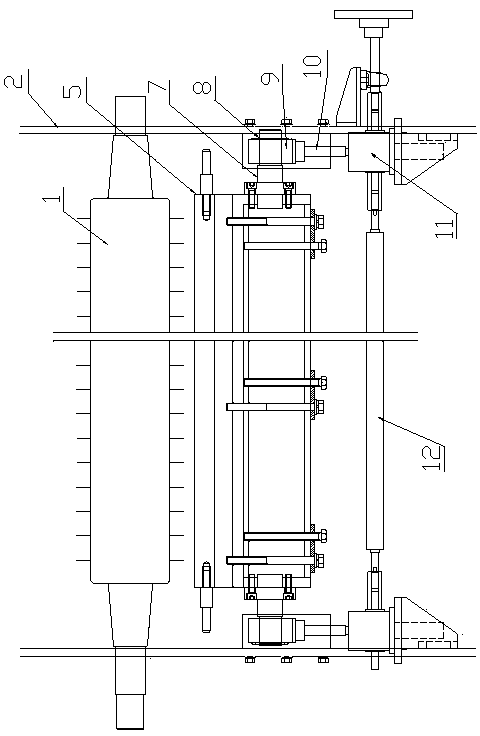

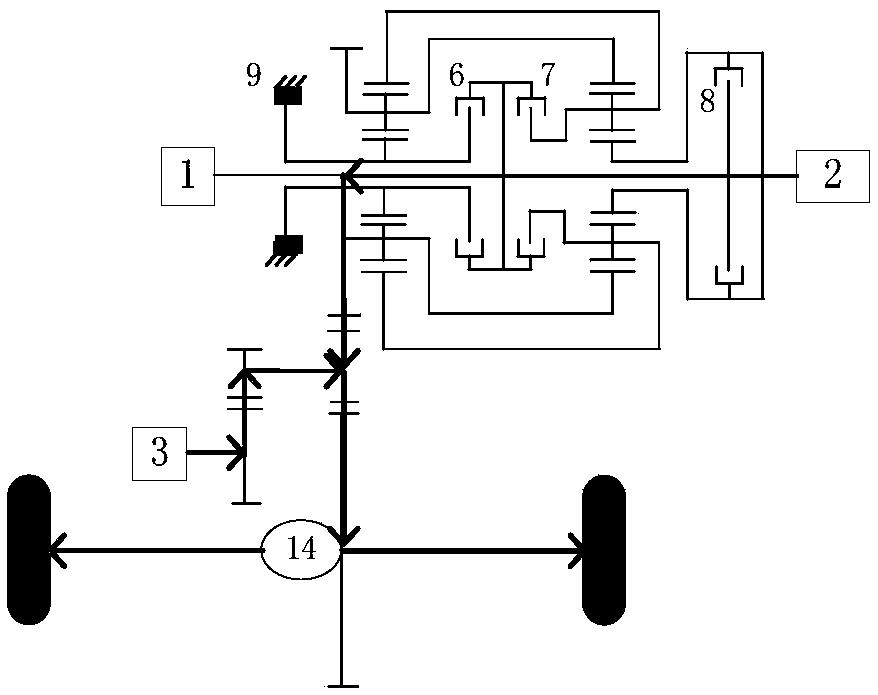

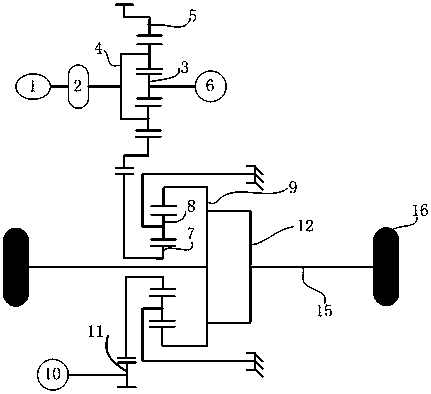

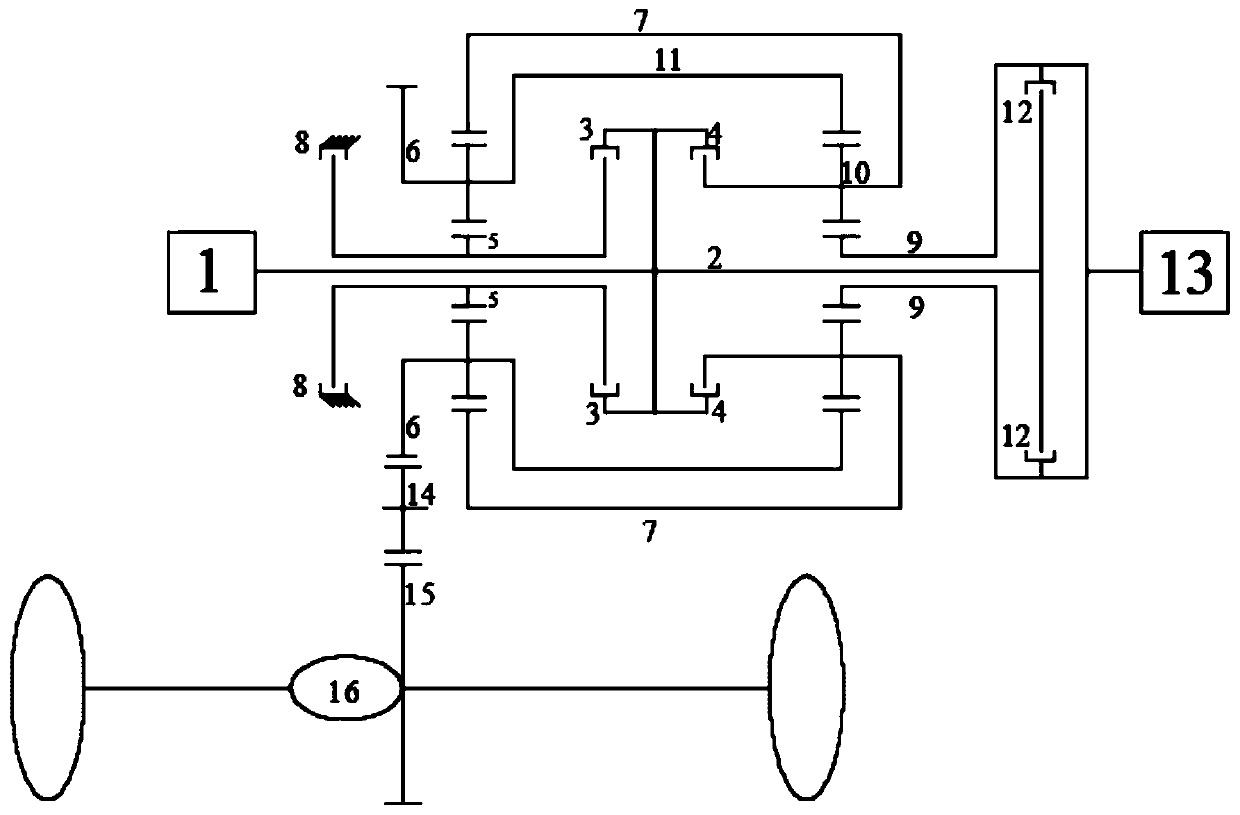

Novel hybrid power coupling mechanism and motor vehicle

ActiveCN107933285AReduce volumeOptimize volumeHybrid vehiclesGas pressure propulsion mountingMobile vehicleElectric machine

The invention provides a novel hybrid power coupling mechanism and a motor vehicle. The novel hybrid power coupling mechanism comprises a fuel driving mechanism, a single-planet-row gear mechanism, aclutch, an intermediate connecting shaft structure, a composite-planet-row gear mechanism, a first electric driving mechanism, a second electric driving mechanism and a power output mechanism, whereinthe fuel driving mechanism, the first electric driving mechanism and the second electric driving mechanism are connected for output through the single-planet-row gear mechanism and the composite-planet-row gear mechanism; and finally power output is implemented by the power output mechanism. By the novel hybrid power coupling mechanism and the motor vehicle, various power driving modes and outputspeed ratios can be provided according to actual conditions, the integral system efficiency can be high, the structure can further be simplified, and requirements to the motor are reduced.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

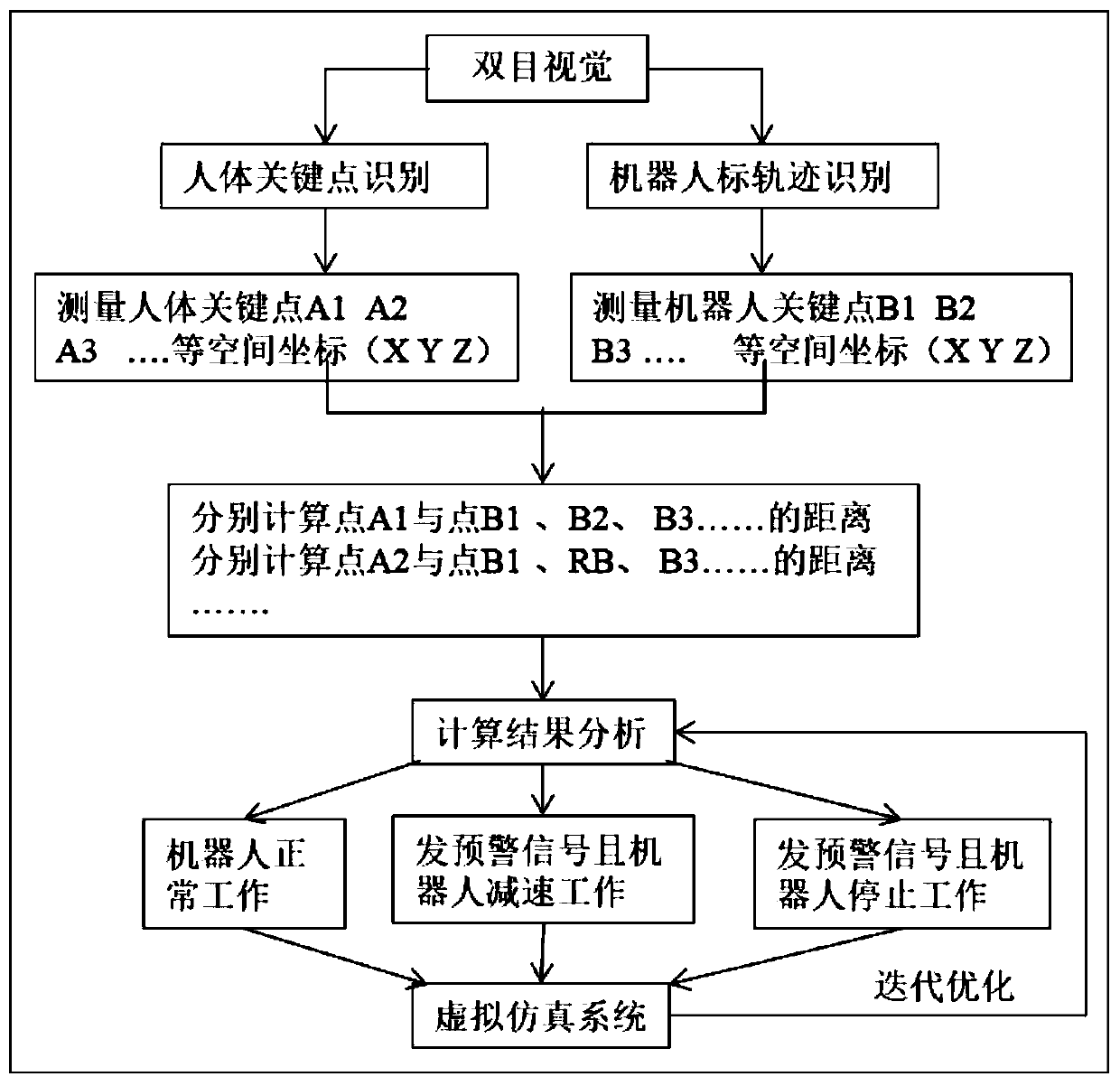

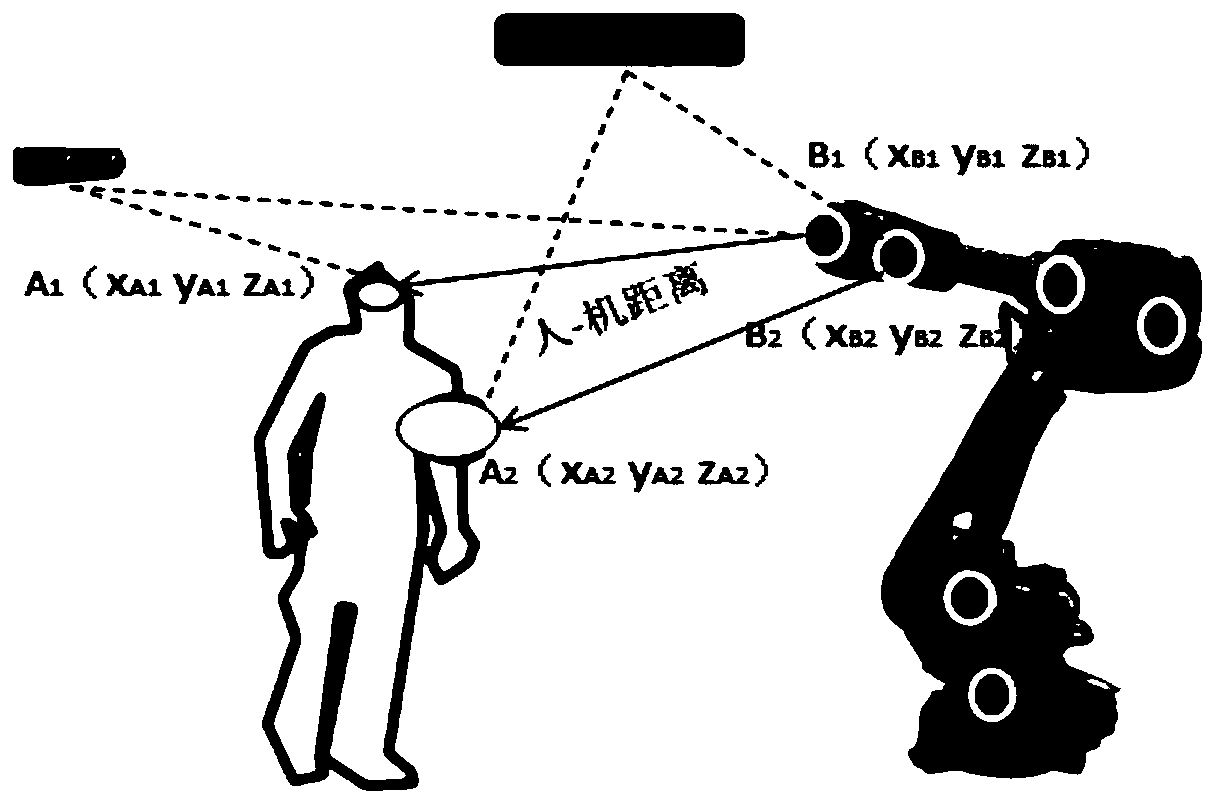

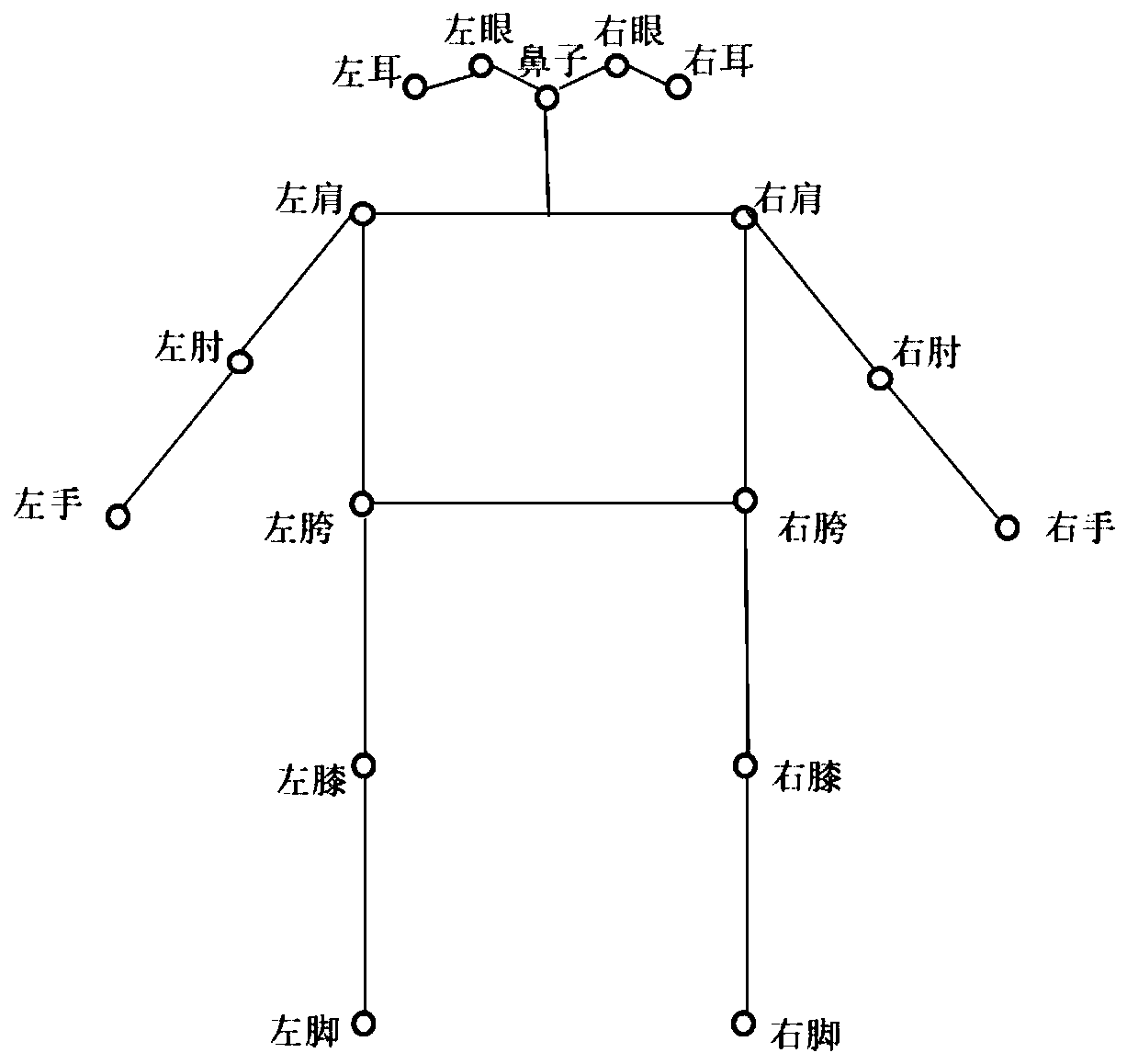

Human-computer interaction safety early warning and control method based on digital twinning

ActiveCN111563446ASimplified odometry modelIncrease workspaceCharacter and pattern recognitionPicture interpretationPattern recognitionHuman body

The invention provides a human-computer interaction safety early warning and control method based on digital twinning. The method comprises the following steps: identifying a worker in an image shot by a binocular camera and a human body key point position of the worker based on a deep learning algorithm; adhering a label to a moving joint of the robot, and identifying the position of the label inthe image through Canny edge detection and Hough circle detection algorithms to obtain the position of the robot; based on a binocular vision distance measurement principle, measuring space coordinates of key points and labels of a human body of a worker, and calculating a distance between the worker and the robot; building a man-machine interaction safety early warning twinning system, achievinginteraction co-fusion and iterative optimization of a man-machine interaction physical scene and a virtual scene, and visually monitoring the safety of the man-machine interaction process online in real time. The man-machine interaction safety early warning twinning system is driven by real-time data, the optimal work space can be optimized, the safety of the man-machine interaction process is guaranteed, and the man-machine cooperative work efficiency is improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

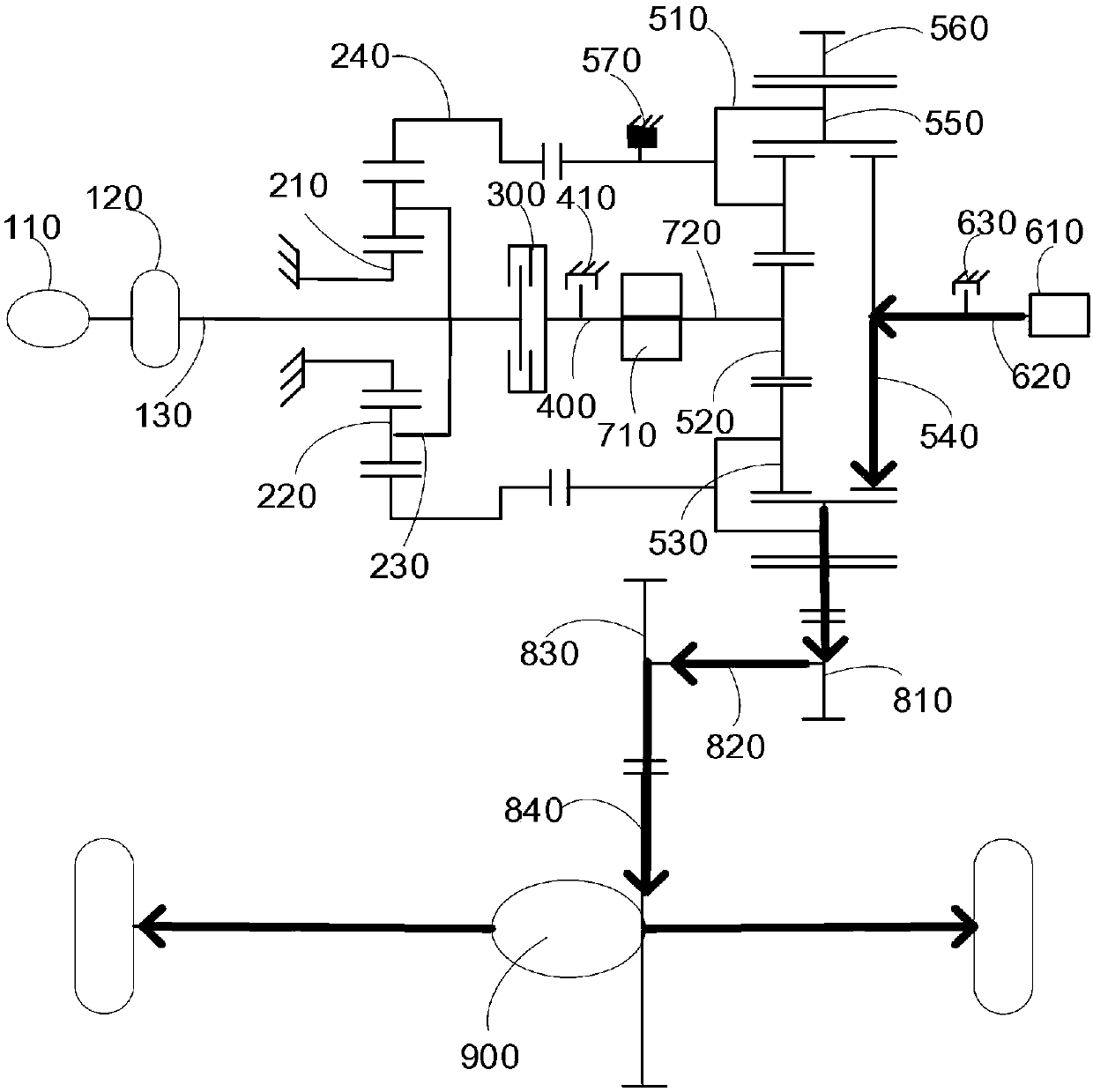

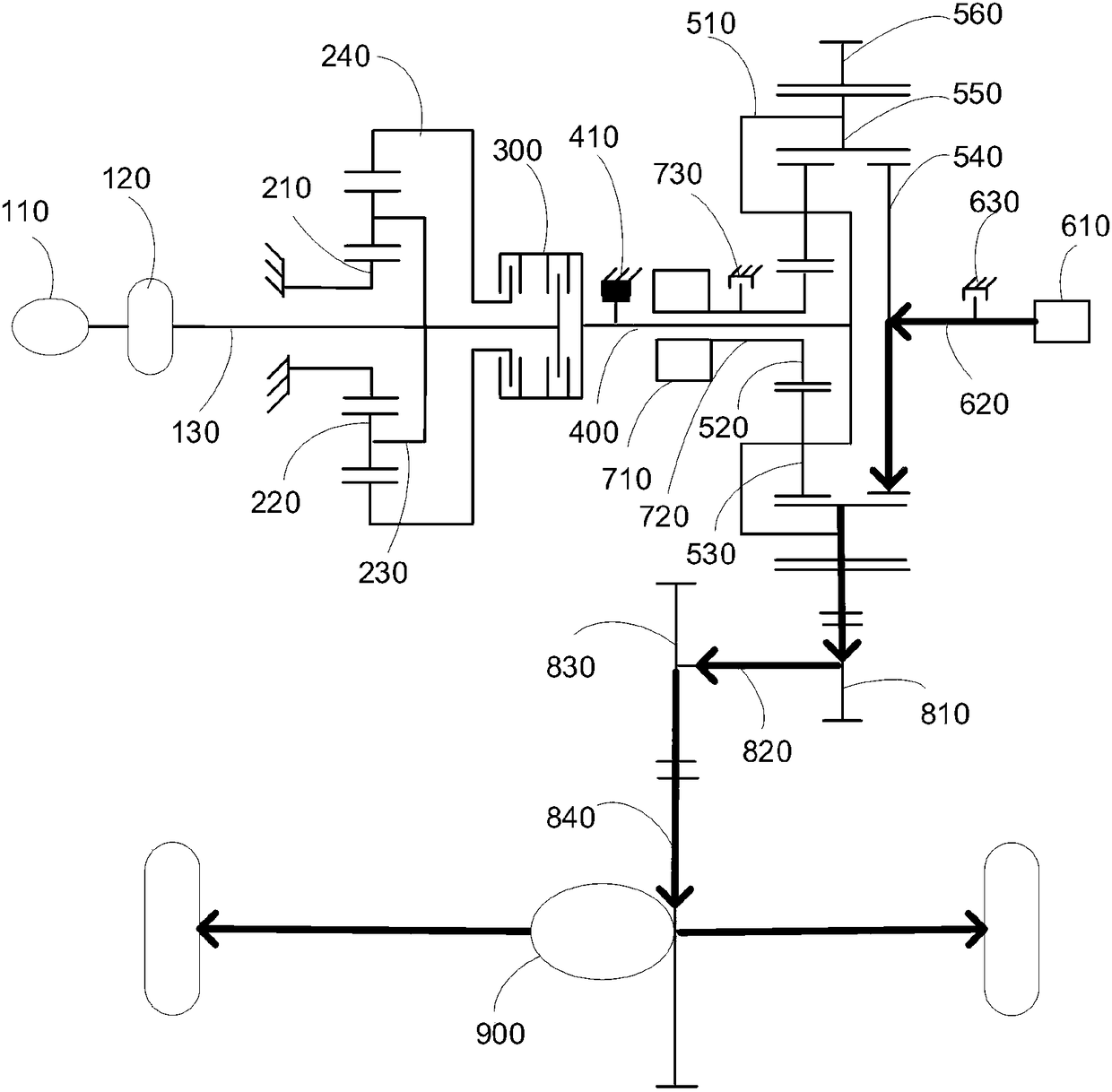

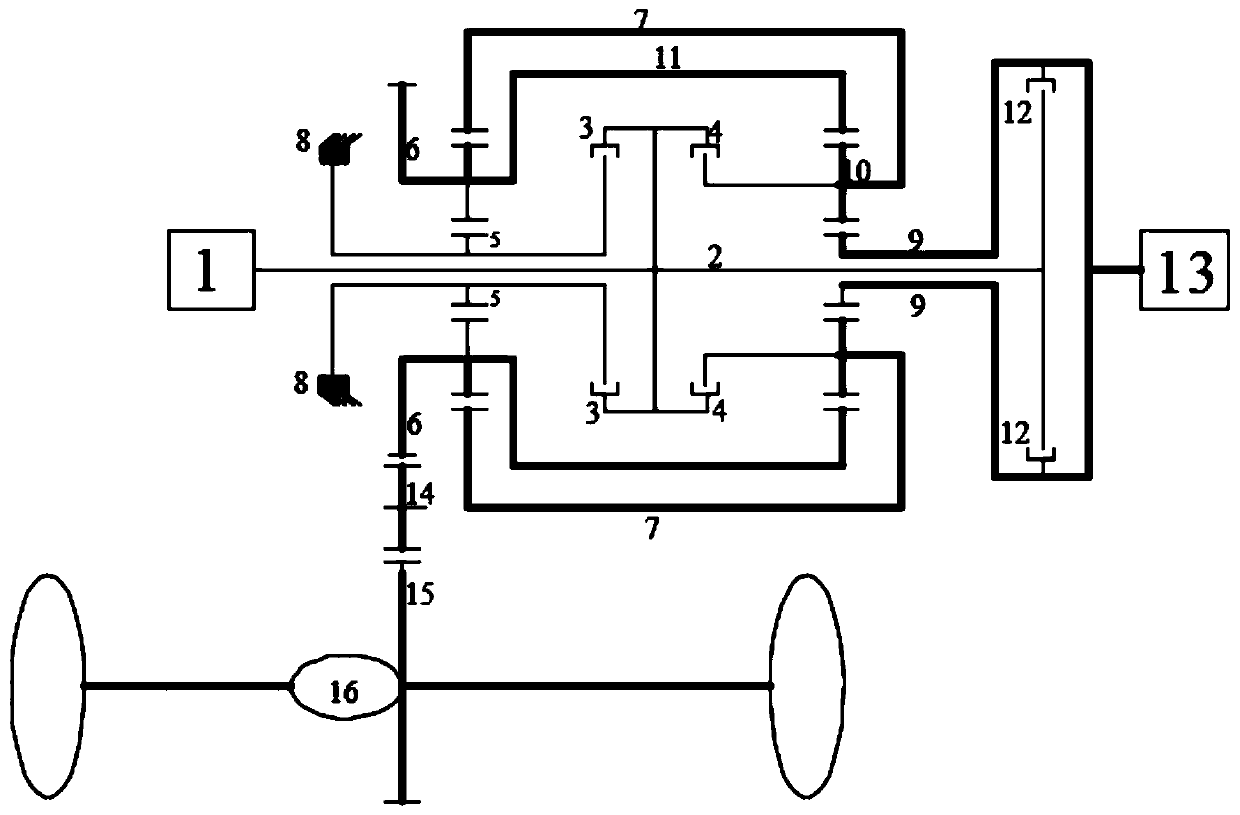

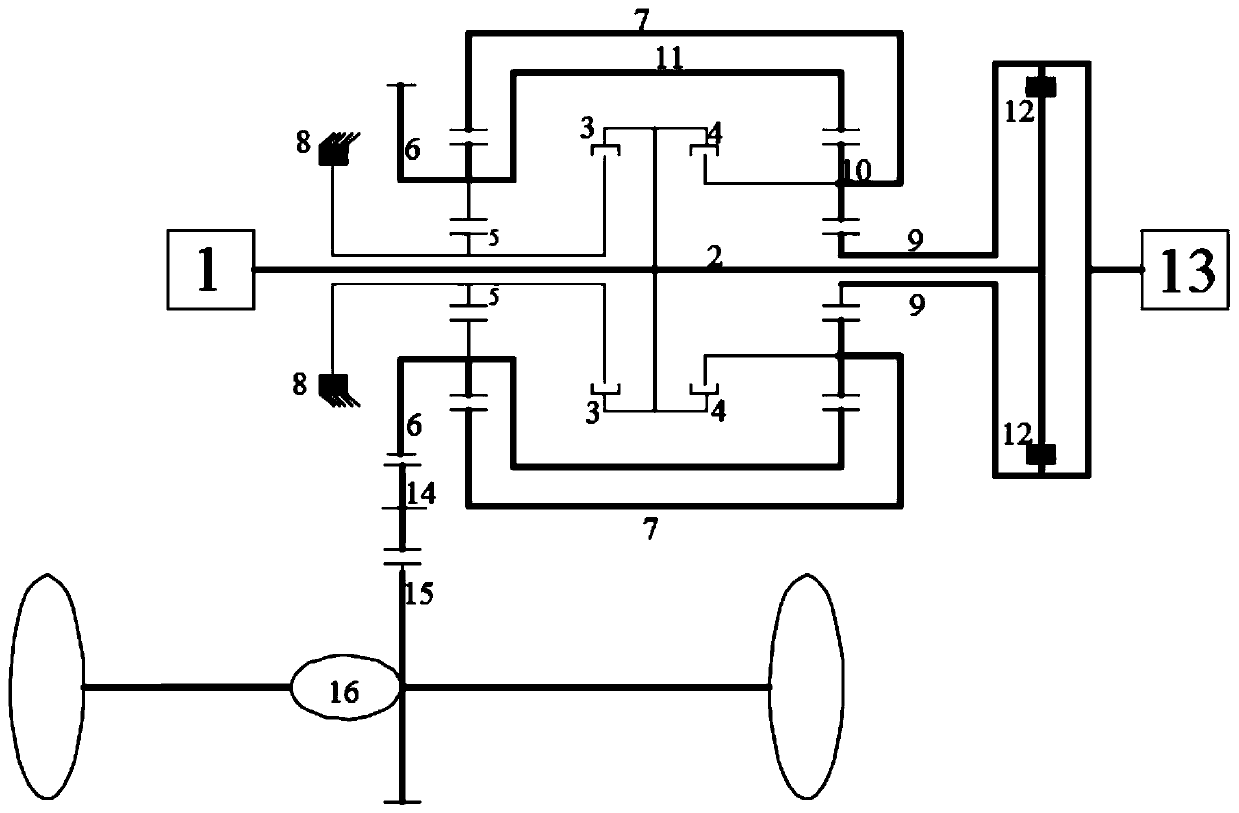

Double-planetary-line hybrid coupling mechanism and motor vehicle

ActiveCN108116217AReduced torque requirementsReduce volumeHybrid vehiclesGas pressure propulsion mountingMobile vehicleElectric machine

The invention provides a double-planetary-line hybrid coupling mechanism and a motor vehicle. The double-planetary-line hybrid coupling mechanism comprises a fuel driving mechanism, a single-planetary-line gear mechanism, double clutches, an intermediate connecting shaft structure, a composite planetary line gear mechanism, a first electric driving mechanism, a second electric driving mechanism and a power output mechanism, the fuel driving mechanism, the first electric driving mechanism and the second electric driving mechanism are in connection output by the single-planetary-line gear mechanism and the composite planetary line gear mechanism, and finally, power output is carried out by the power output mechanism. The invention provides the double-planetary-line hybrid coupling mechanismand the motor vehicle, various power driving modes and output speed ratios are provided according to actual conditions, the integral system is high in efficiency, the structure can further be simplified, and requirements for a motor are reduced.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

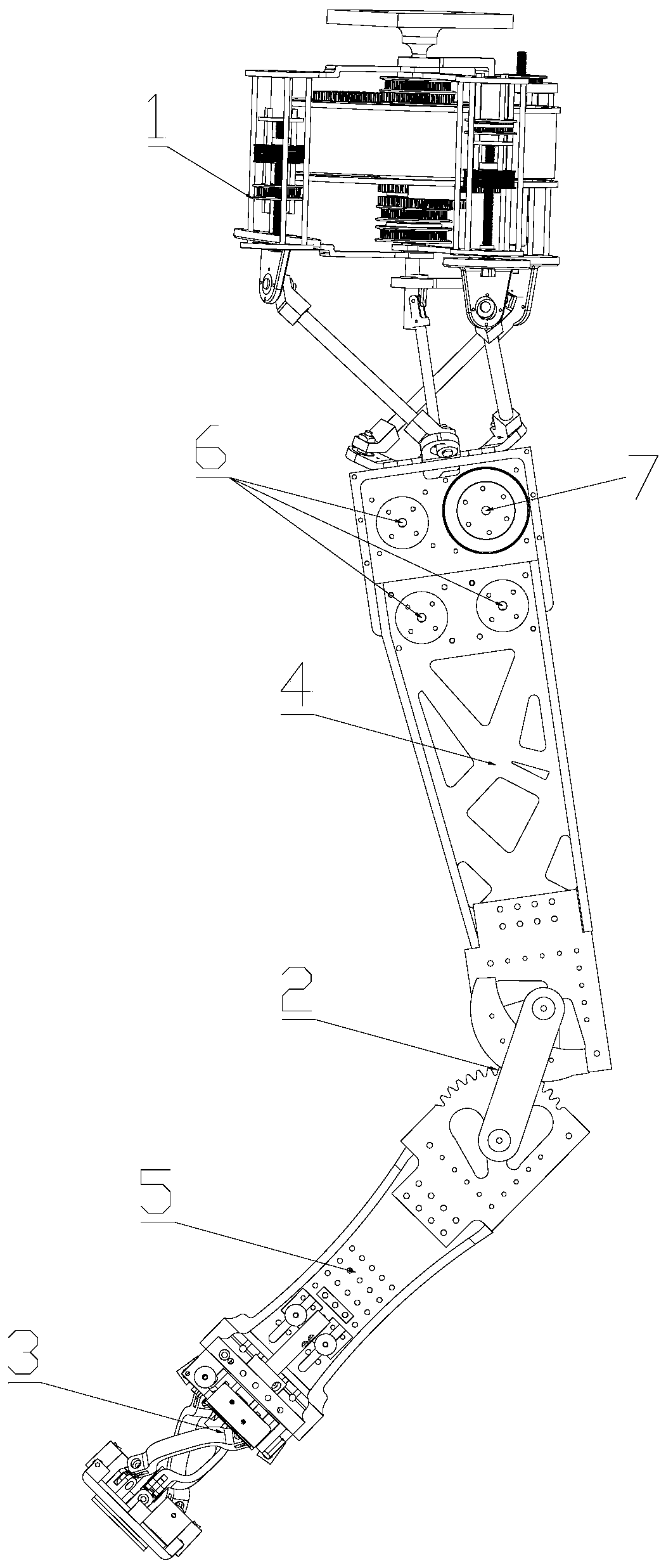

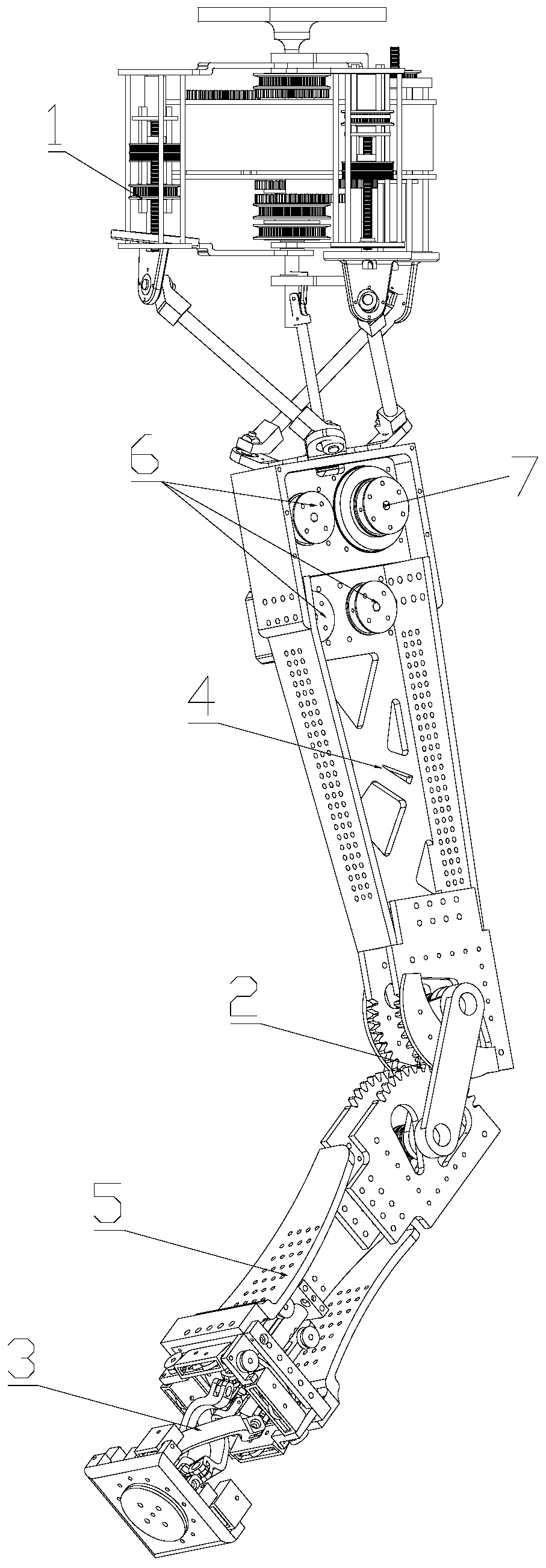

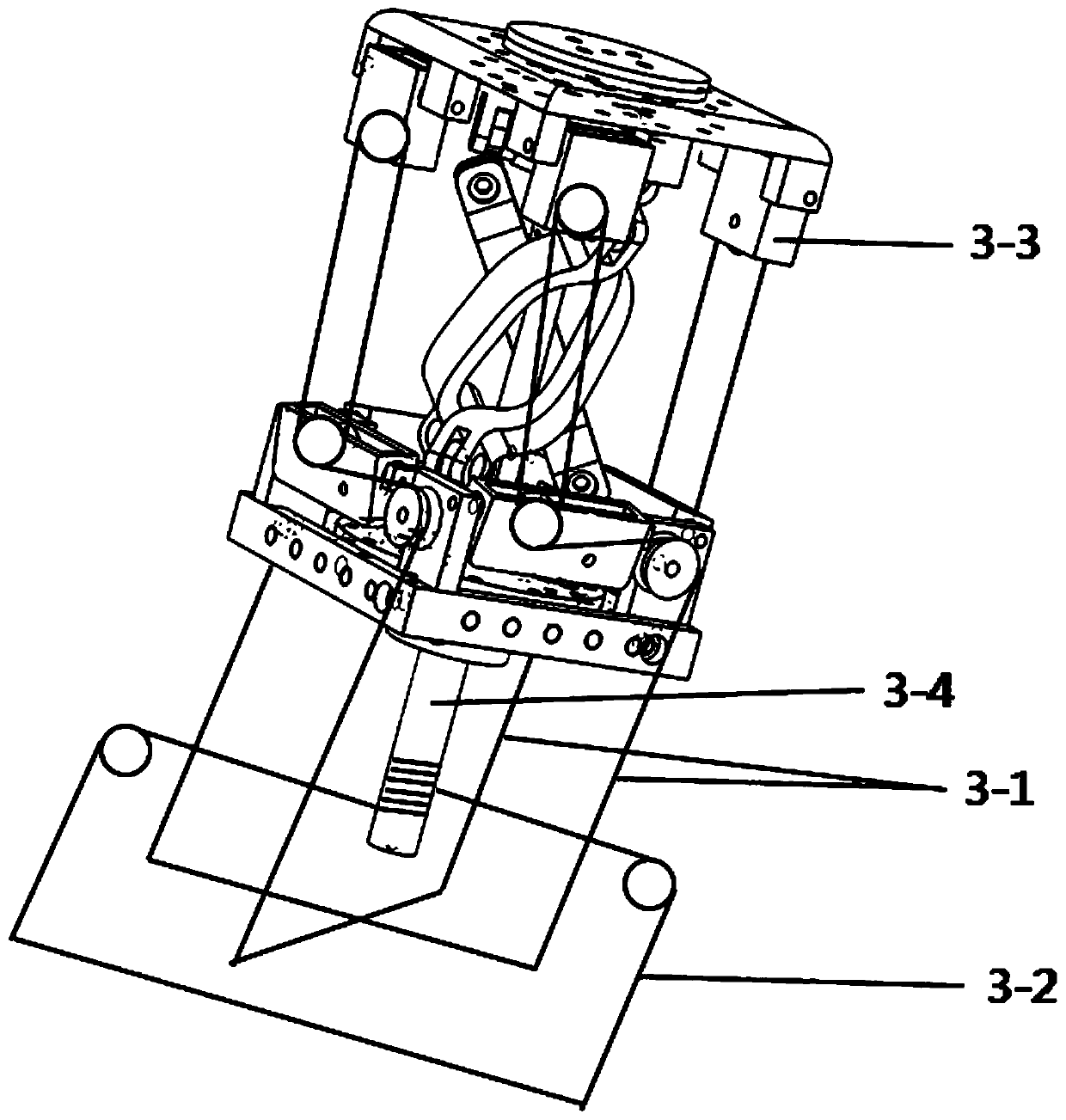

Human-machine cooperation oriented bionic lightweight mechanical arm

PendingCN110202559AGuaranteed symmetryIncrease stiffnessProgramme-controlled manipulatorEngineeringDrive motor

The invention discloses a human-machine cooperation oriented bionic lightweight mechanical arm comprising a first machine arm, a second machine arm, a wrist joint, an elbow joint and a shoulder joint.The first machine arm is arranged between the shoulder joint and the elbow joint, the second machine arm is arranged between the elbow joint and the wrist joint, the wrist joint is a three-degree-of-freedom motion pair, the wrist joint includes a two-degree-of-freedom parallel mechanism connected with a single-degree-of-freedom Hook hinge mechanism in series, the elbow joint is a single-degree-of-freedom rotational joint, and the shoulder joint is a three-degree-of-freedom parallel ball joint mechanism; and the mechanical arm further comprises an elbow joint drive motor and three wrist jointdrive motors, and the elbow joint drive motor arranged at the end, close to the shoulder joint, of the second machine arm and the wrist joint drive motors control the elbow joint and the wrist joint through rope drive transmission. By means of the mechanical arm, the collision inertia is reduced, and therefore the safety of human-computer interaction is improved.

Owner:SOUTH CHINA UNIV OF TECH

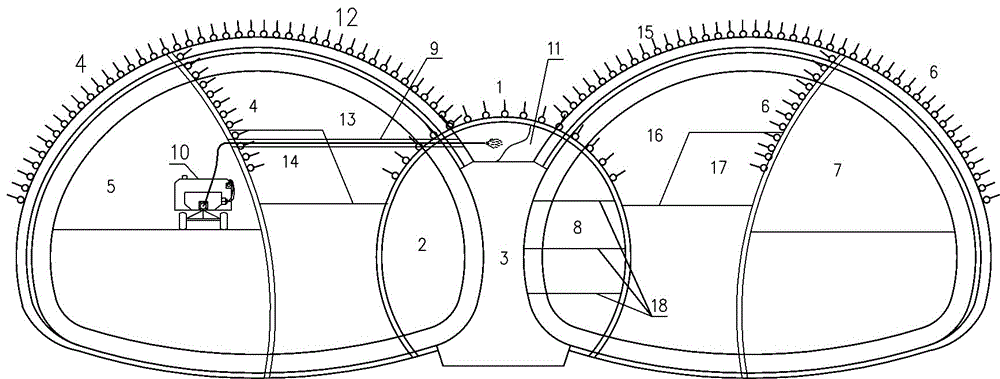

Twin-arch tunnel middle pilot tunnel vault backfilling construction method

ActiveCN105673046AReduce effective working timeSolve technical problems that cannot be backfilledUnderground chambersTunnel liningShotcreteClerestory

The invention provides a twin-arch tunnel middle pilot tunnel vault backfilling construction method. The method comprises the following steps that a middle pilot tunnel is excavated, and a support is constructed; after the middle pilot tunnel is excavated and the support extends forwards by a certain distance, a left pilot tunnel is excavated, and a support is constructed; after the middle pilot tunnel is excavated to a certain depth, a middle partition wall is poured; an in-the-hole drill is arranged in position, drill holes are formed, and the drill holes are led to a middle pilot tunnel vault space in the top of the middle partition wall from the left pilot tunnel or a right pilot tunnel; a conveying pipe is installed in the drill holes so that sprayed concrete can enter the middle pilot tunnel vault space in the top of the middle partition wall; twin-arch tunnel middle pilot tunnel vault backfilling construction is achieved. Backfilling of the middle pilot tunnel vault is conducted in the manner that upper steps of the left pilot tunnel are drilled to form the holes. The technical problem that under the working condition that pouring of the middle partition wall is conducted in two directions, the middle pilot tunnel vault can not be backfilled is solved, middle pilot tunnel vault backfilling and middle partition wall pouring are conducted at the same time, and the effective working time is shortened greatly.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

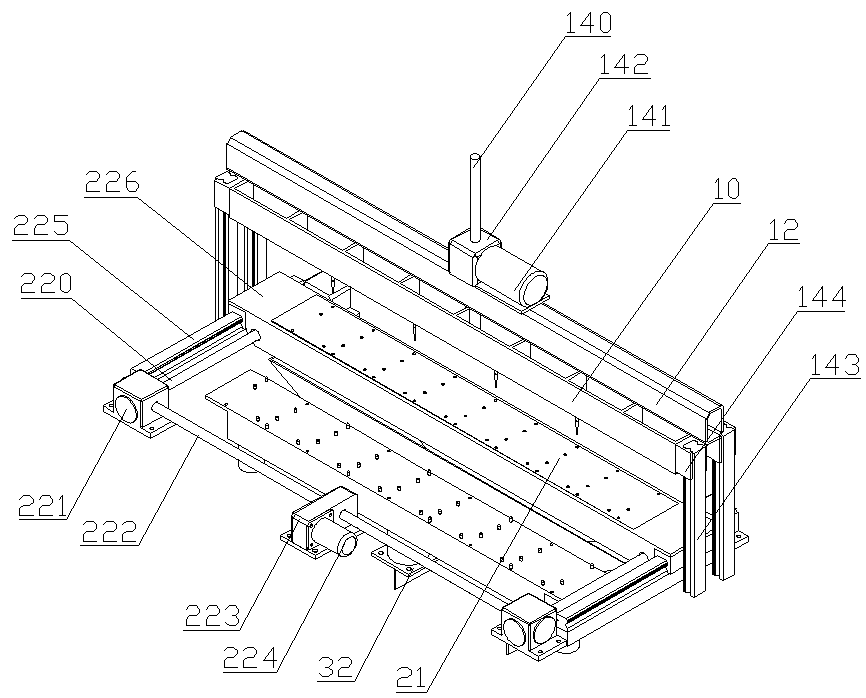

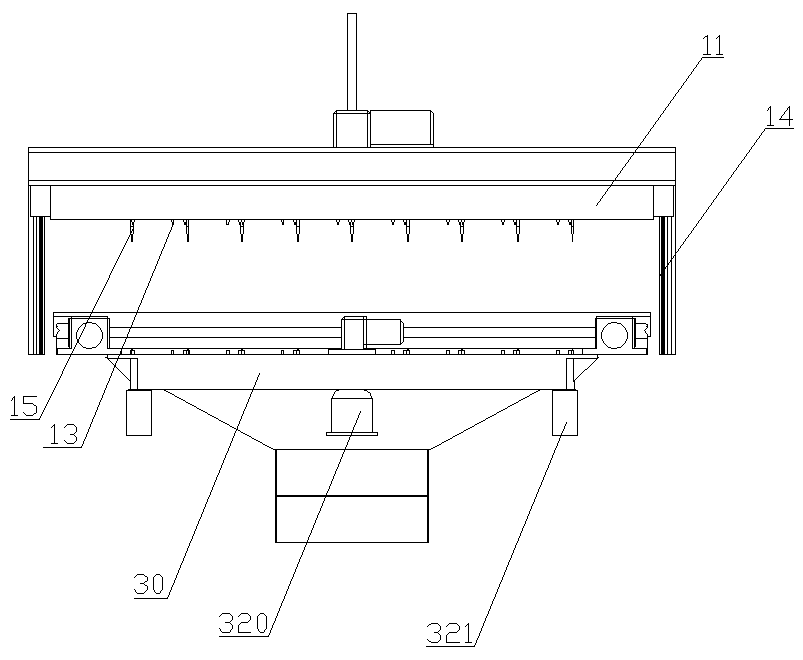

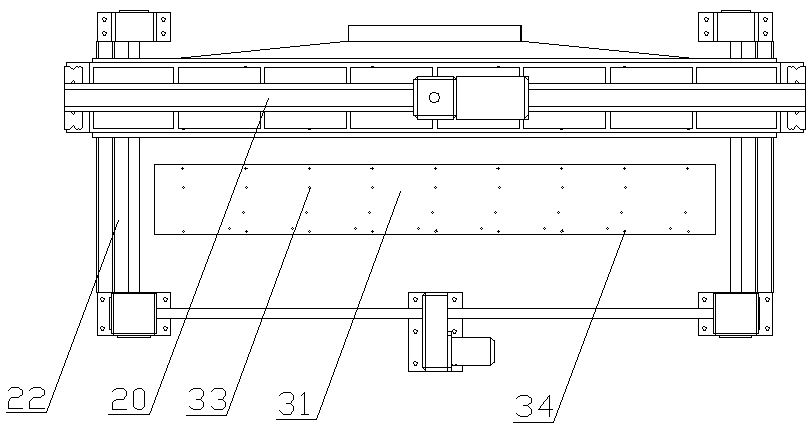

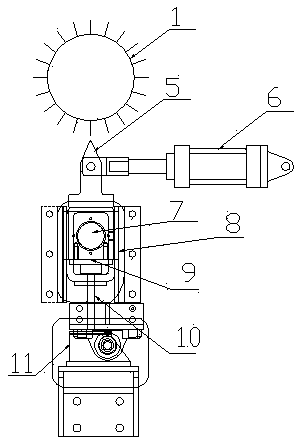

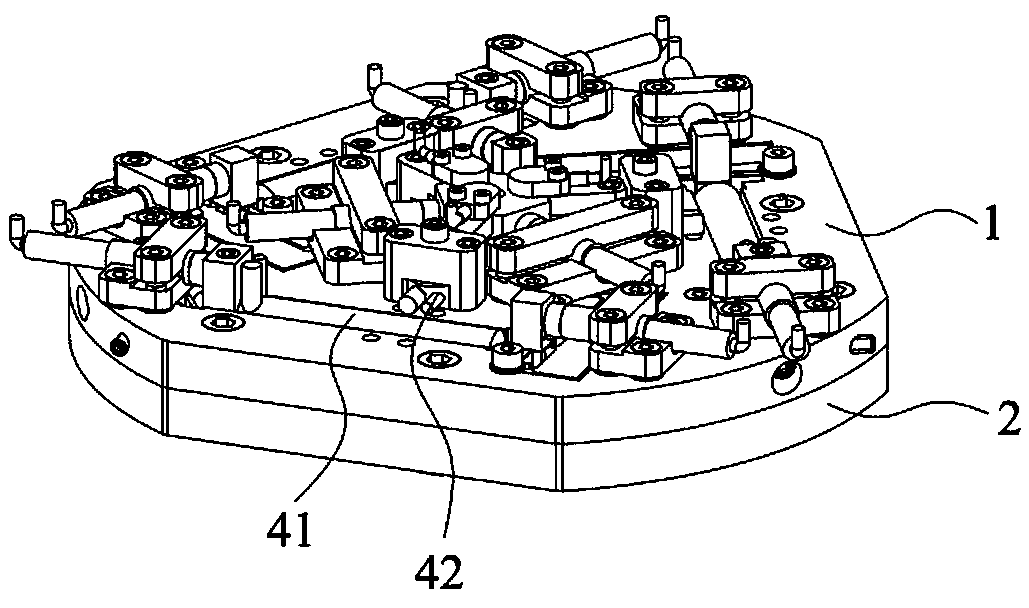

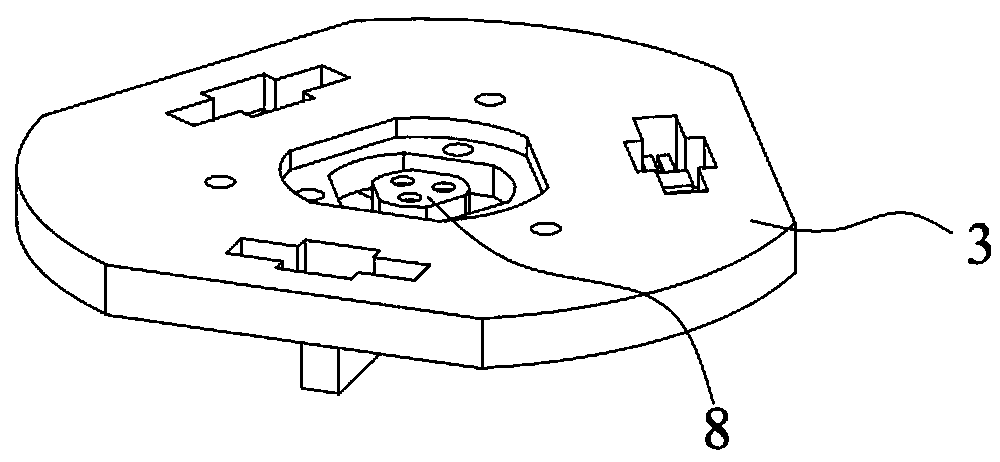

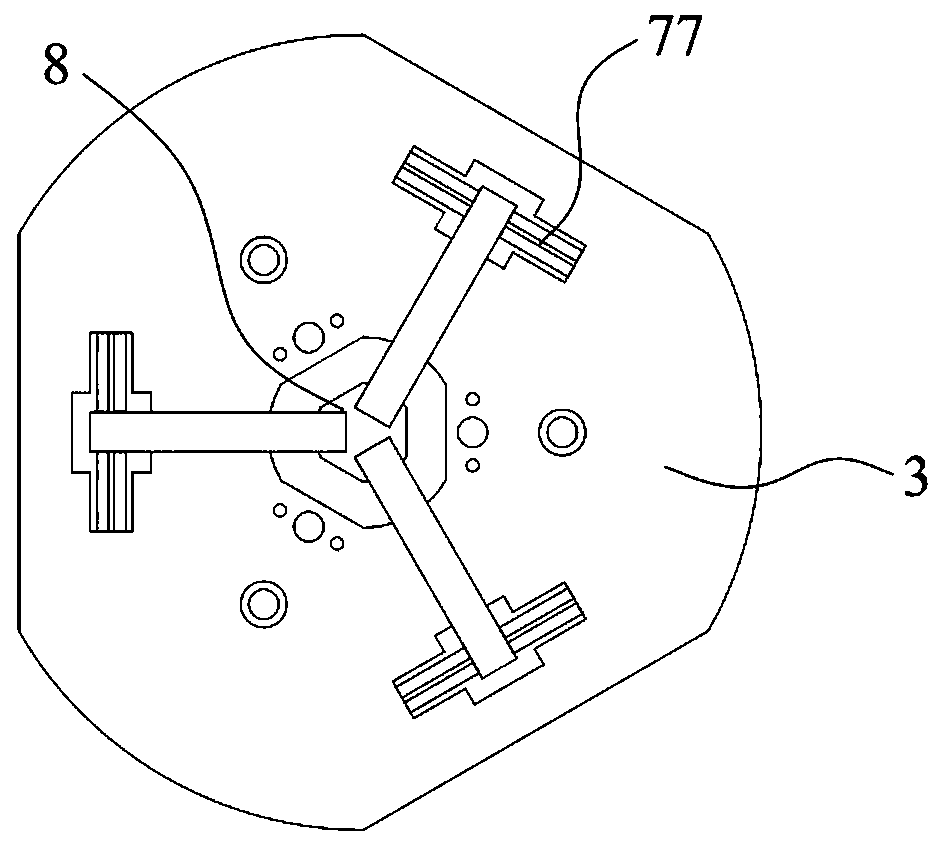

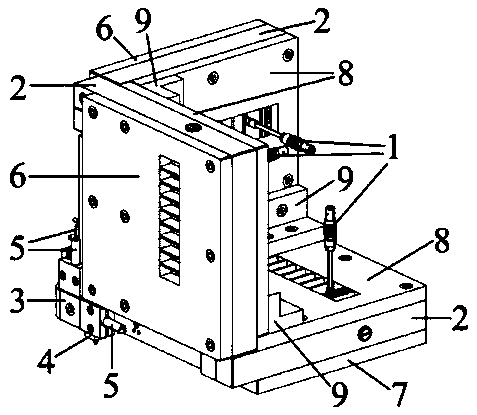

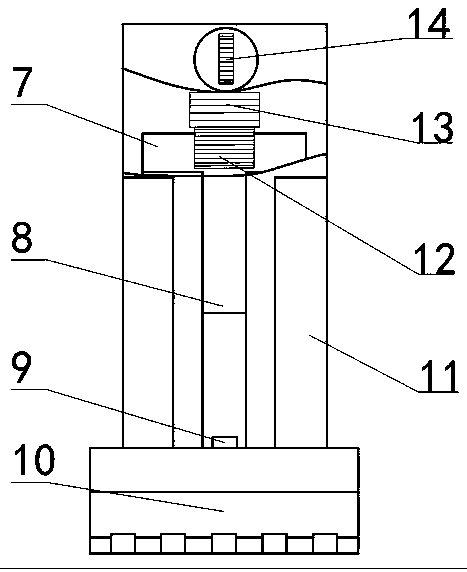

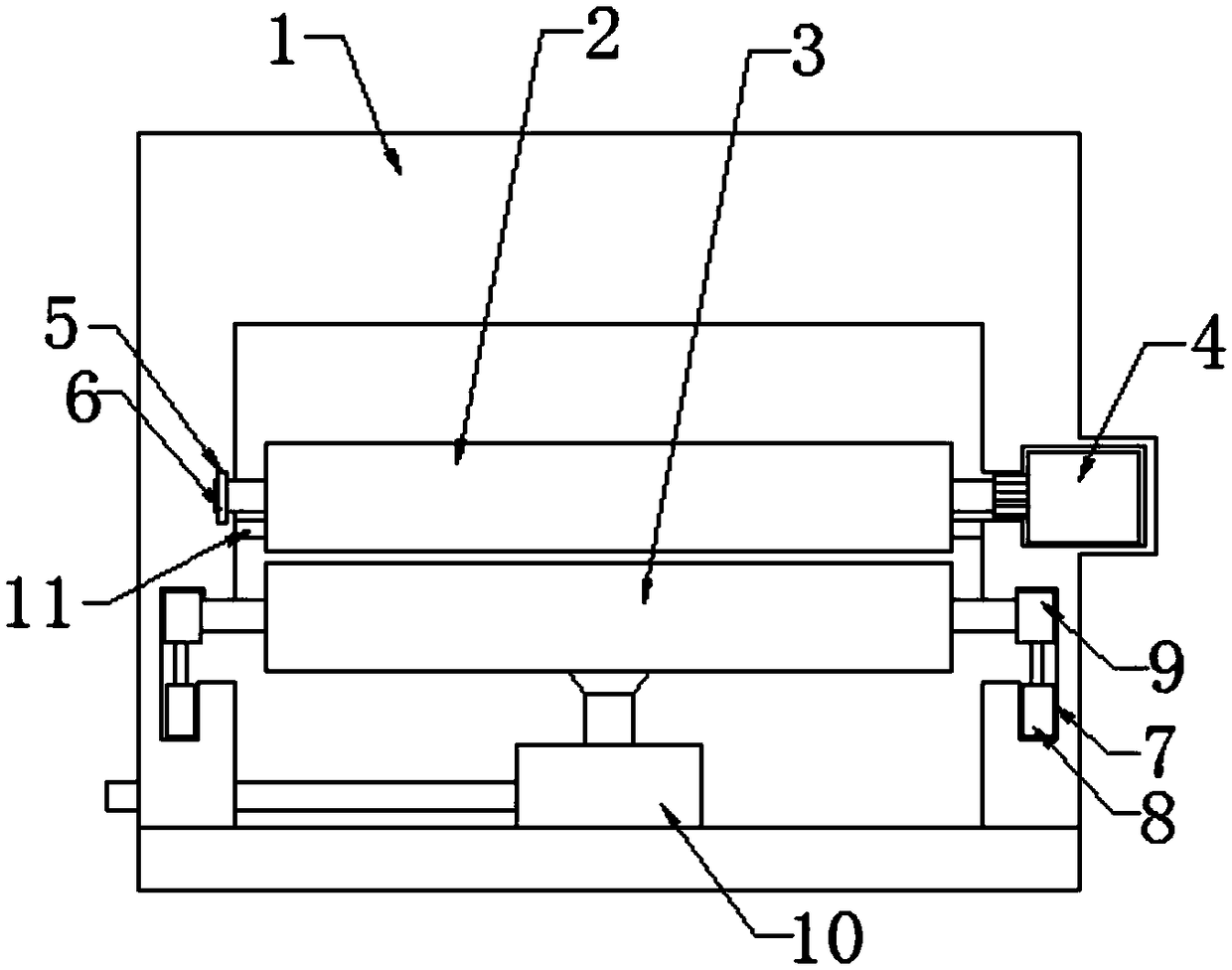

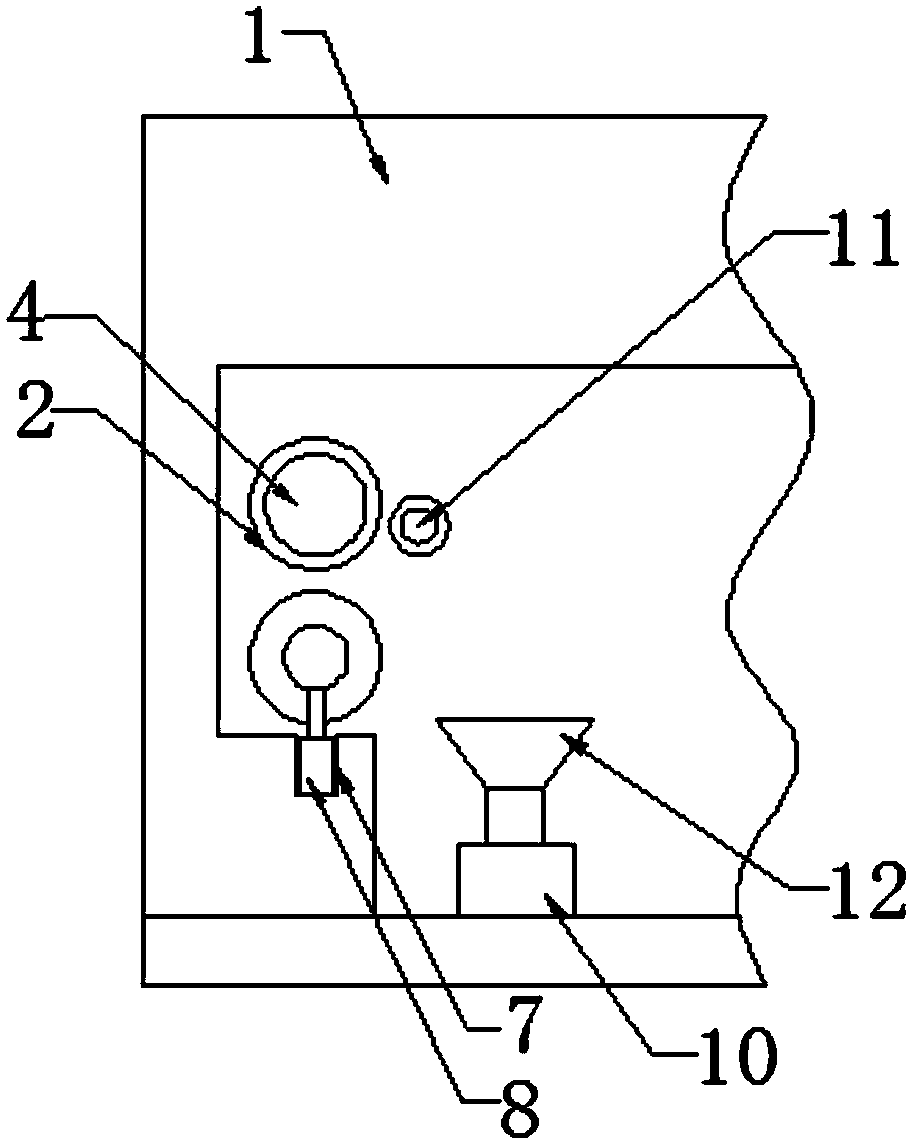

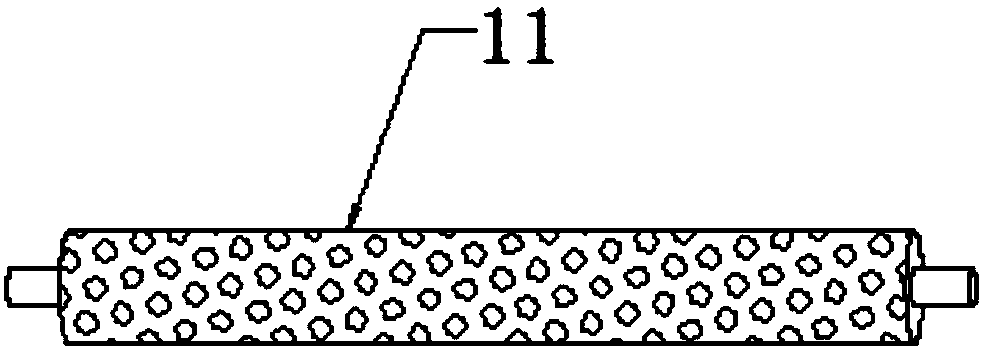

Automatic graphite boat sticking point exchanging machine die

PendingCN109161872ASo as not to damageReduce labor intensityFinal product manufactureChemical vapor deposition coatingWorking environmentGraphite

The invention belongs to the field of manufacturing of solar batteries, and particularly relates to an automatic graphite boat sticking point exchanging machine die. The automatic graphite boat sticking point exchanging machine die comprises an upper die assembly, a middle die assembly and a lower die assembly, when the automatic graphite boat sticking point exchanging machine die is used, a graphite boat of which sticking points need exchanging is placed in a graphite boat carrying platform in the middle die assembly, old sticking points are unloaded by the upper die assembly through utilizing upper die point unloading columns on the upper die assembly, then the middle die assembly is subjected to displacement to a point loading position, and the lower die assembly is also lifted and is subjected to displacement to the point loading position at the same time; new sticking points are mounted on the graphite boat through a point loading machine; the lower die assembly is used for achieving the effects of supporting and positioning in the course of loading the sticking points. The automatic graphite boat sticking point exchanging machine die disclosed by the invention is high in automation degree, easy and simple to operate, high in working efficiency and exchanging quality, and free from damaging the sticking points; the qualified rate of products is increased, the labor intensity of operators is alleviated, the working space and working environment are improved, and the application prospect is wide.

Owner:江苏润阳悦达光伏科技有限公司

Sewing machine for clothes processing

The invention discloses a sewing machine for clothes processing. The sewing machine for clothes processing comprises support legs, a table surface, a rack, a top plate, a machine head, a working table, a goose neck tube, a fan, a lighting lamp, a cup holder, a dust collection hopper, a dust collection pump, a channel, a collection box and a drawer, wherein four support legs are uniformly arranged at the lower part of the table surface; the rack is fixedly and vertically arranged on the left side of the upper part of the table surface; the top plate is fixedly horizontally arranged at the upper end of the rack; the machine head is fixedly arranged at the lower part of the top plate; the working table is fixedly and horizontally arranged at the upper end of the rack; the machine head is fixedly arranged below the top plate; the working table which is fixedly mounted on the table surface is arranged right below the machine head; the fan is connected below the top plate and positioned on the left side of the machine head through the goose neck tube; the lighting lamp is arranged at the right side part of the rack. Compared with the prior art, the working performance of the sewing machine is improved, the adaptability of the sewing machine is improved, functions of the sewing machine are enriched, the working intensity of operators is alleviated, and great convenience is brought to clothes processing.

Owner:嘉兴永盛服饰有限公司

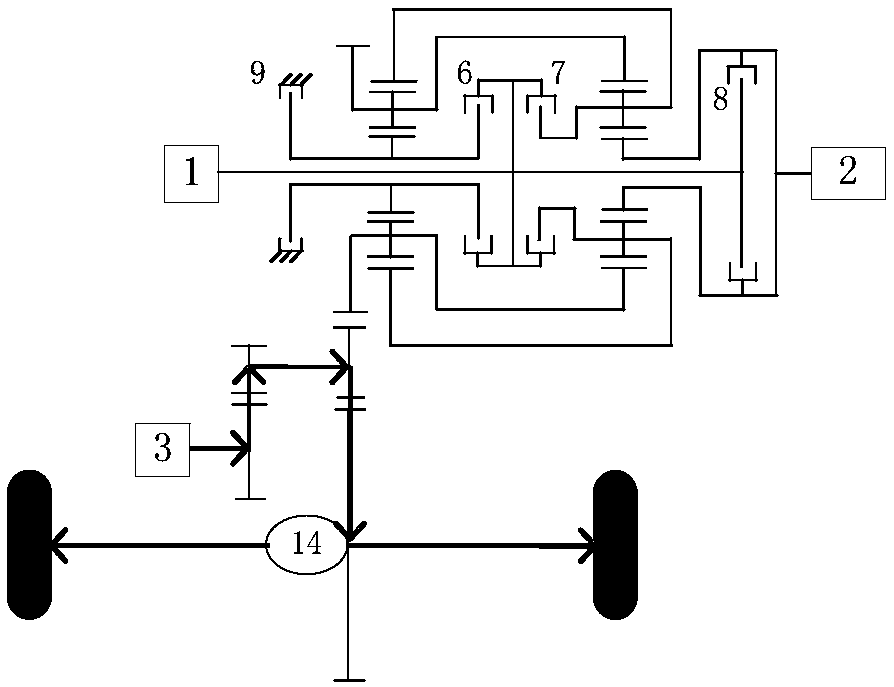

Power split hybrid power coupling system and vehicle

ActiveCN111114284AImprove economyImprove powerHybrid vehiclesGas pressure propulsion mountingPower splitNew energy

The invention belongs to the field of new energy vehicles, and relates to a power split hybrid power coupling system and a vehicle. The power split hybrid power coupling system comprises an engine, agenerator, a driving motor, a second clutch, a third clutch, a shifter, a planet row, a first input shaft, an intermediate shaft, a first reduction gear pair and a second reduction gear pair, whereinthe first reduction gear pair and a second reduction gear pair are different in speed ratio; the is connected with a first input shaft; the first input shaft is connected with the intermediate shaft through the shifter and the second reduction gear pair; an output shaft of the generator is rotatably arranged on the first input shaft in a sleeving mode; a sun gear of the planet row is arranged on the output shaft of the generator; a planet carrier is connected with the first input shaft; and an inner gear ring is connected with the generator through the second clutch; the inner gear ring is also connected with the intermediate shaft through a third clutch and the first reduction gear pair; the driving motor is connected with the intermediate shaft, and the intermediate shaft outputs power to wheels. The hybrid power system facilitates reduction of system load, can realize multiple driving modes, is adjustable in speed ratio, has higher transmission efficiency, and improves the power performance and economy of the whole vehicle.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

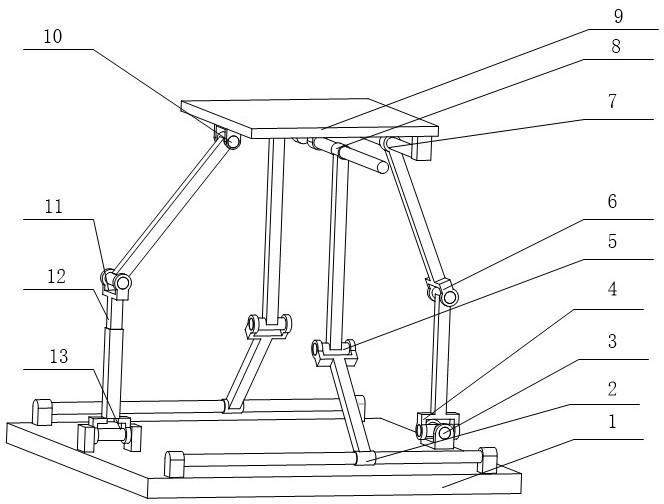

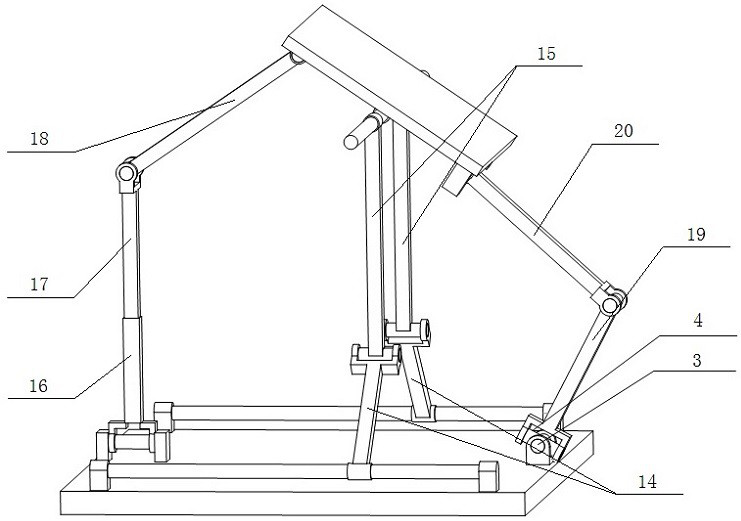

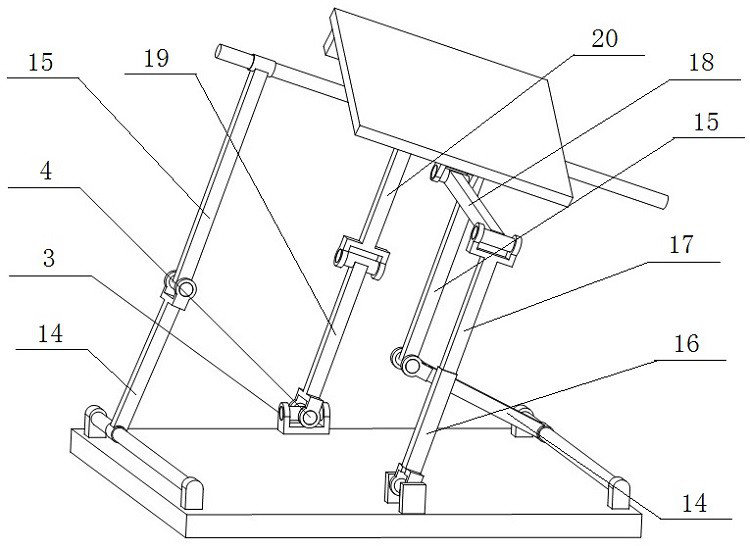

Parallel mechanism with 2R1T and 2T1R motion bifurcation characteristics

ActiveCN112706152AIncrease stiffnessImprove bearing capacityProgramme-controlled manipulatorMotion ModeControl engineering

The invention discloses a parallel mechanism with 2R1T and 2T1R motion bifurcation characteristics, and relates to the technical field of mechanisms and robots. The parallel mechanism comprises a fixed platform, a movable platform, two first branch chains, a second branch chain and a third branch chain. The two sides of the fixed platform are connected with the bottom ends of the first branch chains correspondingly, and the two sides of the movable platform are connected with the top ends of the first branch chains correspondingly. One end of the fixed platform is connected with the bottom end of the second branch chain, and one end of the movable platform is connected with the top end of the second branch chain. The other end of the fixed platform is connected with the bottom end of the third branch chain, and the other end of the movable platform is connected with the top end of the third branch chain. The parallel mechanism has two different motion modes, and has the advantages of being large in rotation angle, large in bearing capacity, high in rigidity, large in working space, good in dynamic performance, simple in structure, easy to control and the like; and different operation task requirements are met, and the fixed freedom degree and the single motion mode of a traditional parallel robot are overcome.

Owner:YANSHAN UNIV

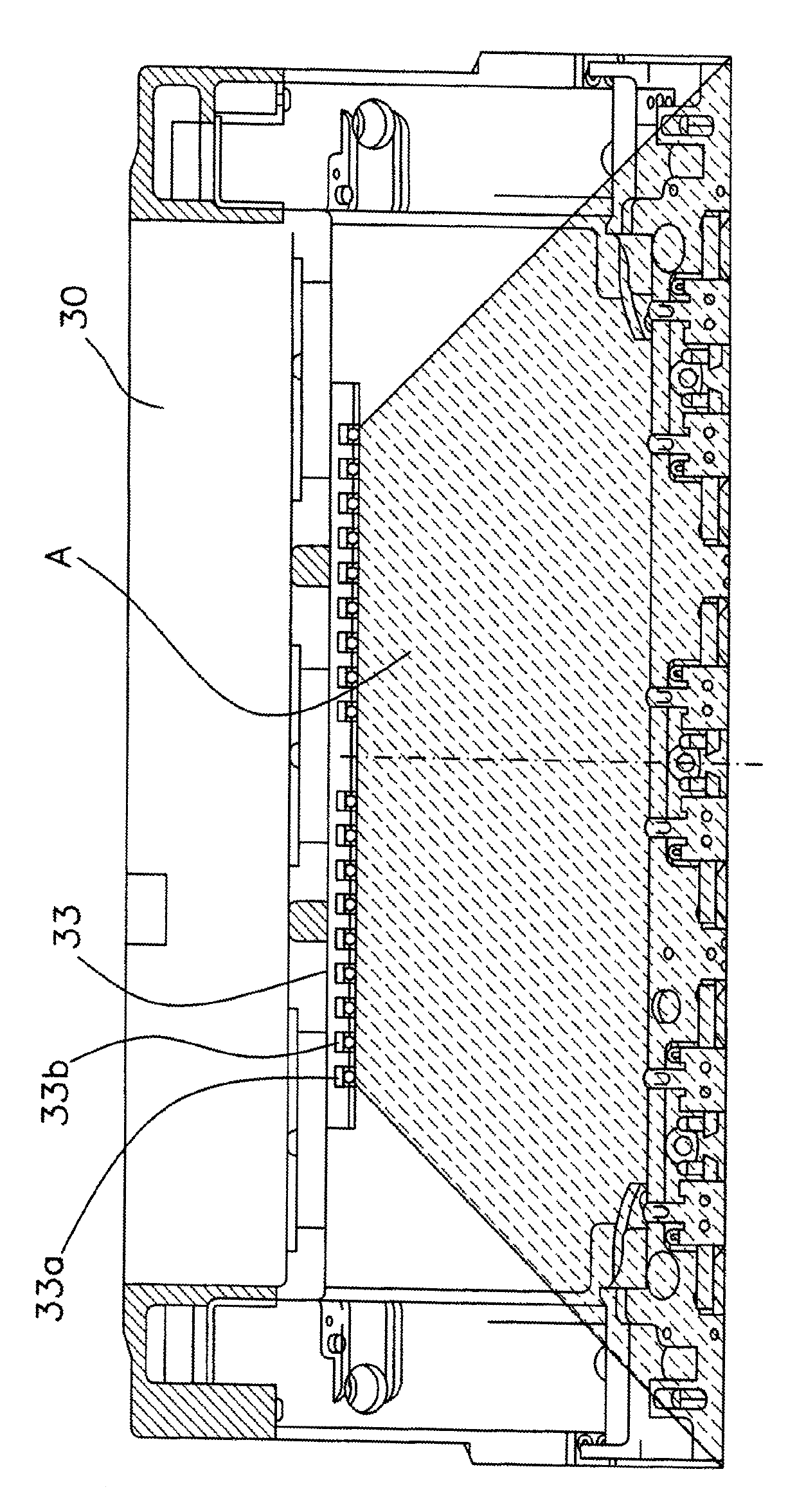

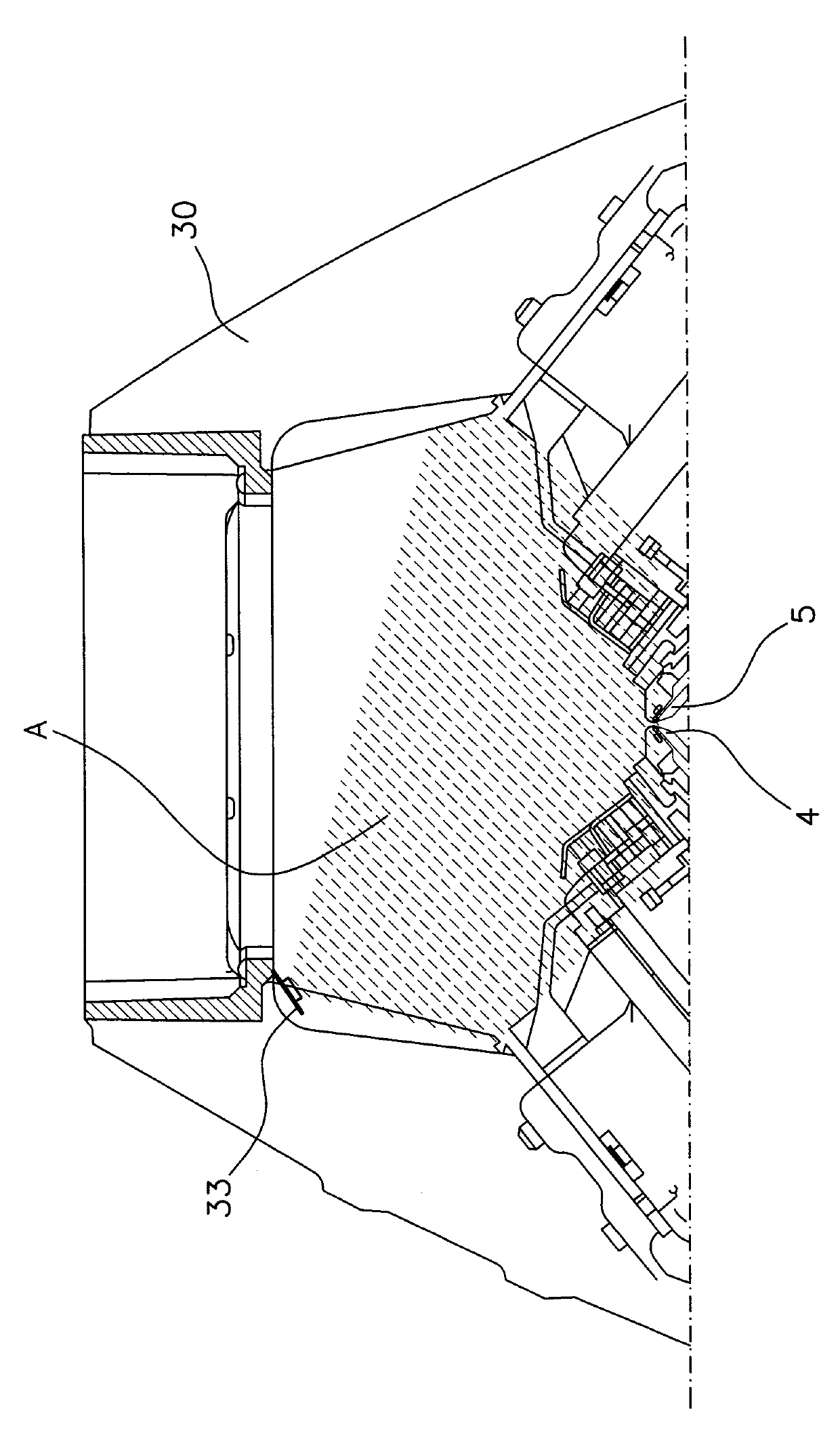

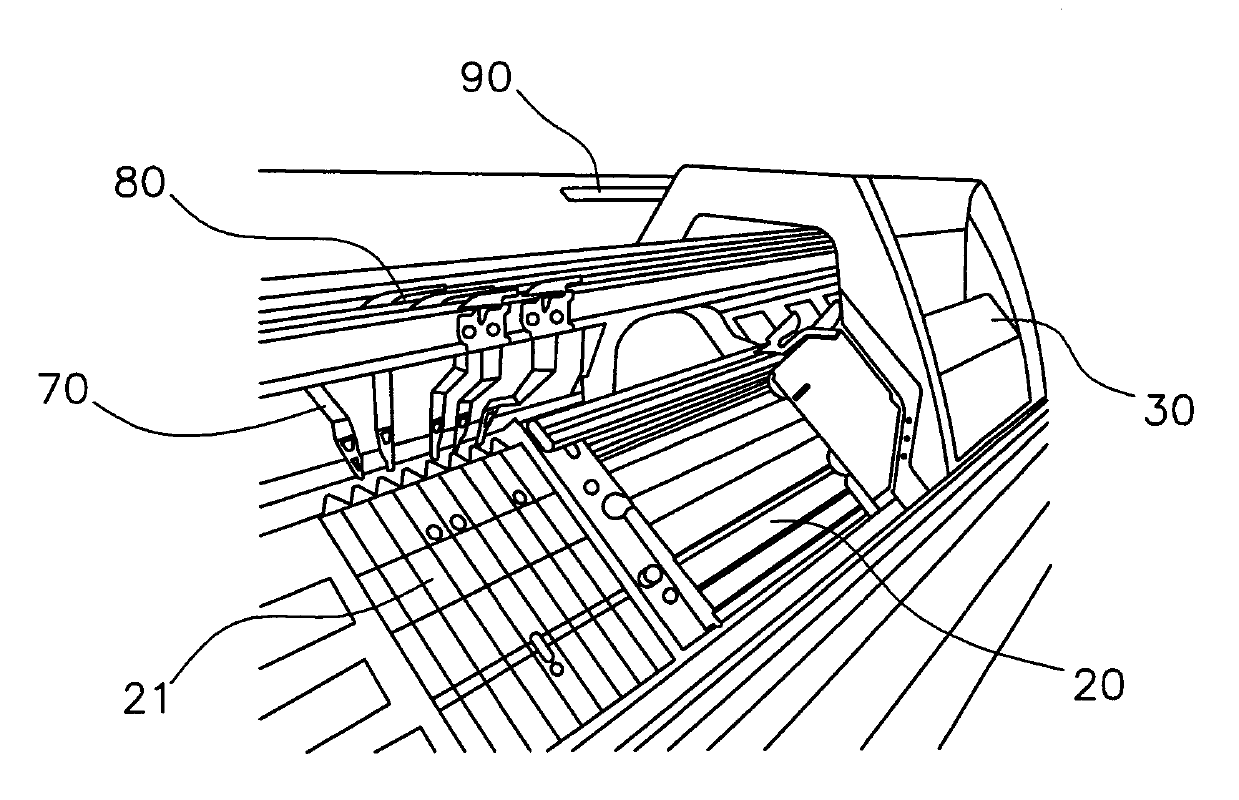

Flat knitting machine with lighting device

ActiveCN103628245AAutomatic activationEasy to adaptFlat-bed knitting machinesBiomedical engineeringLighter device

The machine has machine carriages (30) moved over rear and front needle beds (4, 5) for controlling needle movements. An illumination device (33) is adjustably arranged at the carriages for illuminating a knitting chamber below the carriages. The illumination device is switched manually and / or by a machine controller and / or a knitting program. The illumination device comprises sealing strips. The illumination device is arranged at the carriages over the rear and front needle beds. The illumination device is provided with LEDs as lights.

Owner:KARL MAYER STOLL R&D GMBH

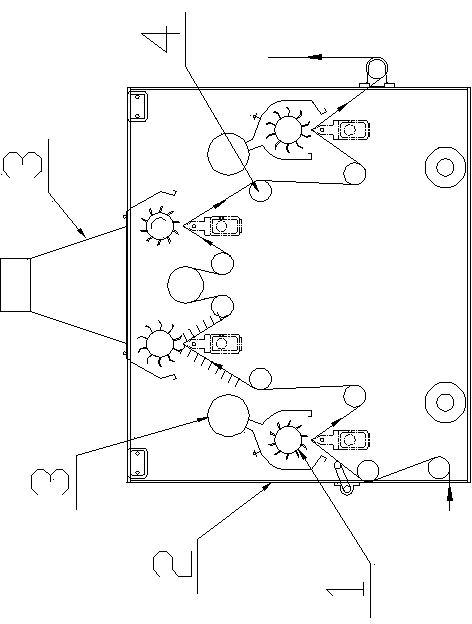

Four-roller brushing machine

ActiveCN103628268AEasy to cleanImprove fabric adaptabilityRougheningBrush deviceMechanical engineering

The invention discloses a four-roller brushing machine. The four-roller brushing machine comprises a rack, wherein the rack is internally provided with four groups of brushing devices; the brushing devices are externally covered with air absorbing covers, and the brushing devices comprise brushing rollers which are horizontally arranged in the rack; a support matched with the brushing rollers for use is arranged below the brushing rollers, is arranged on a support shaft which is parallel to axes of the brushing rollers; the inner wall of the rack arranged on the two ends of the support shaft is provided with a vertical slide way, a sliding block is arranged in the vertical slide way, and is connected with a support shaft head; a lifting device for driving the sliding block to move in an up-down manner is arranged below the vertical slide way, and an oscillating cylinder for driving the support to leave a sewing head is arranged among the two ends of the support and the inner wall of the rack. According to the four-roller brushing machine provided by the invention, the brushing rollers are arranged above the support, the on-line production of the brushing machine and the other machines is realized, a dust exhaust apparatus is arranged outside the brushing rollers, the brushing rollers are convenient to clean, the work efficiency is improved, the two ends of the support shaft are provided with synchronous lifting devices, the support can move in an up-down manner, and the fabric adaptability of the brushing rollers is improved.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

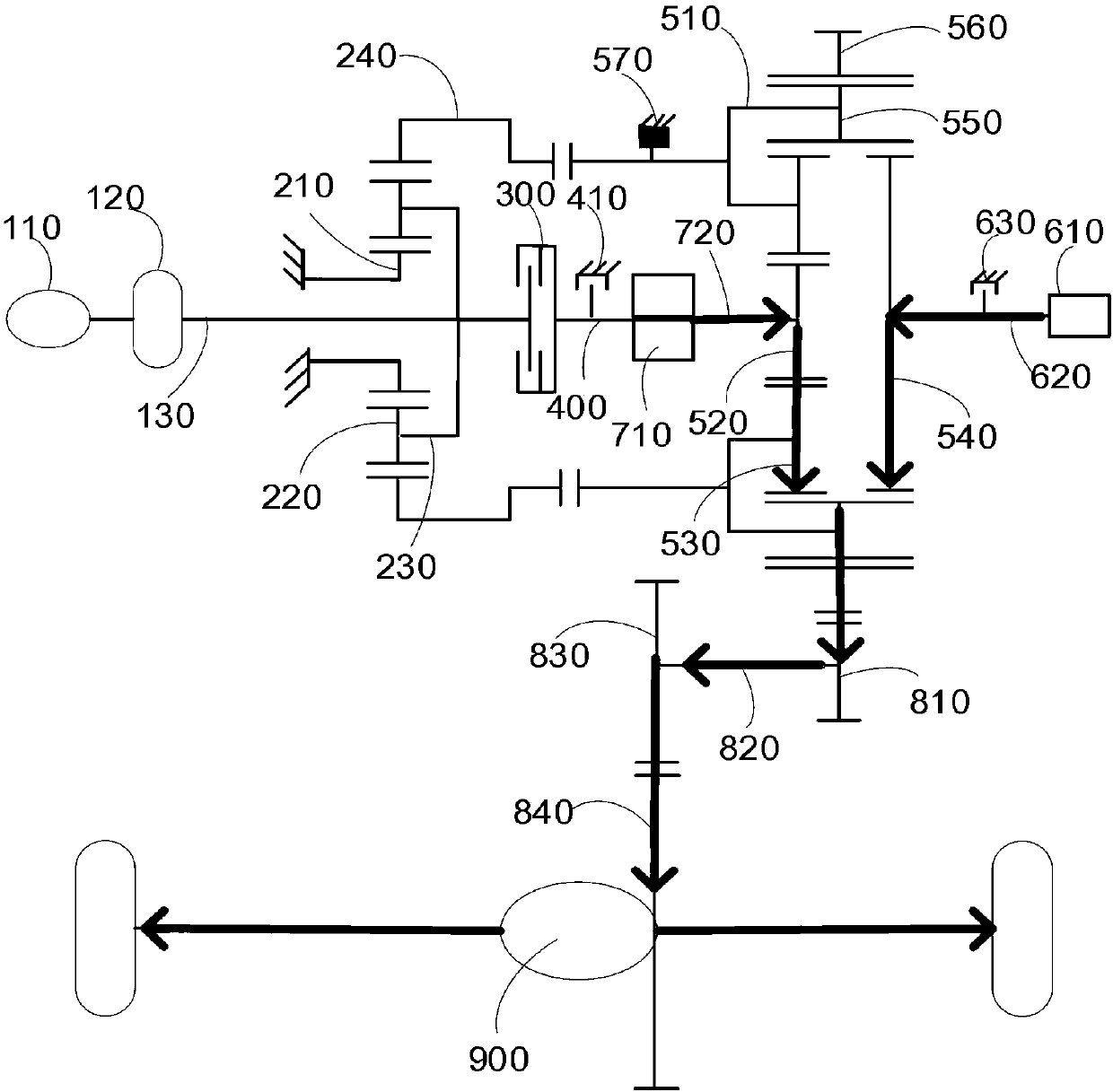

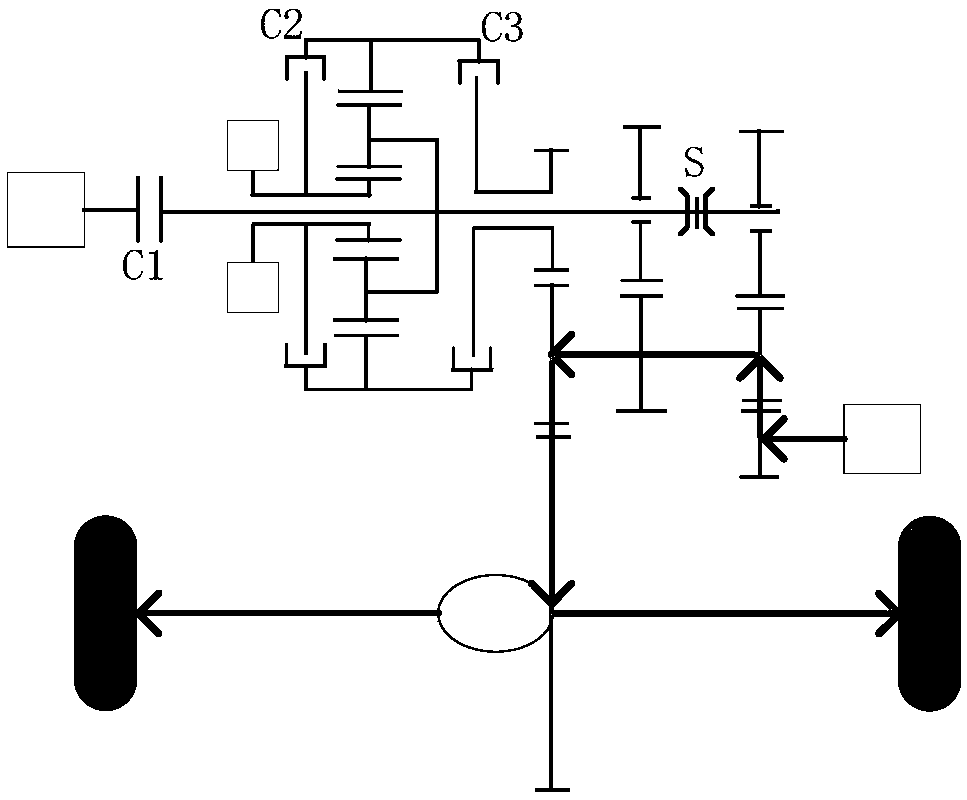

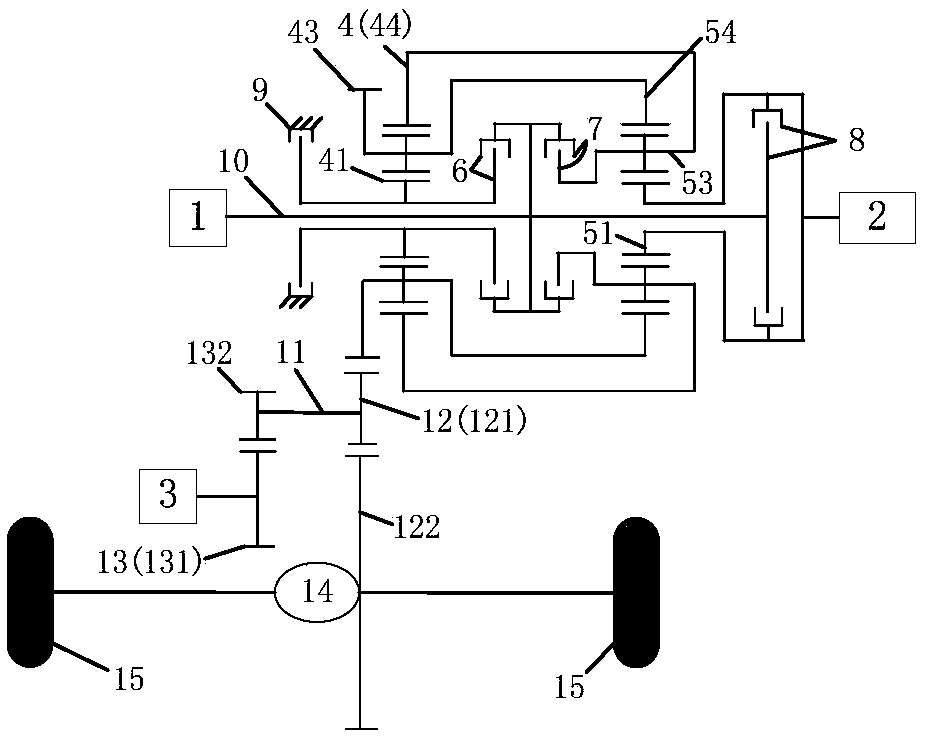

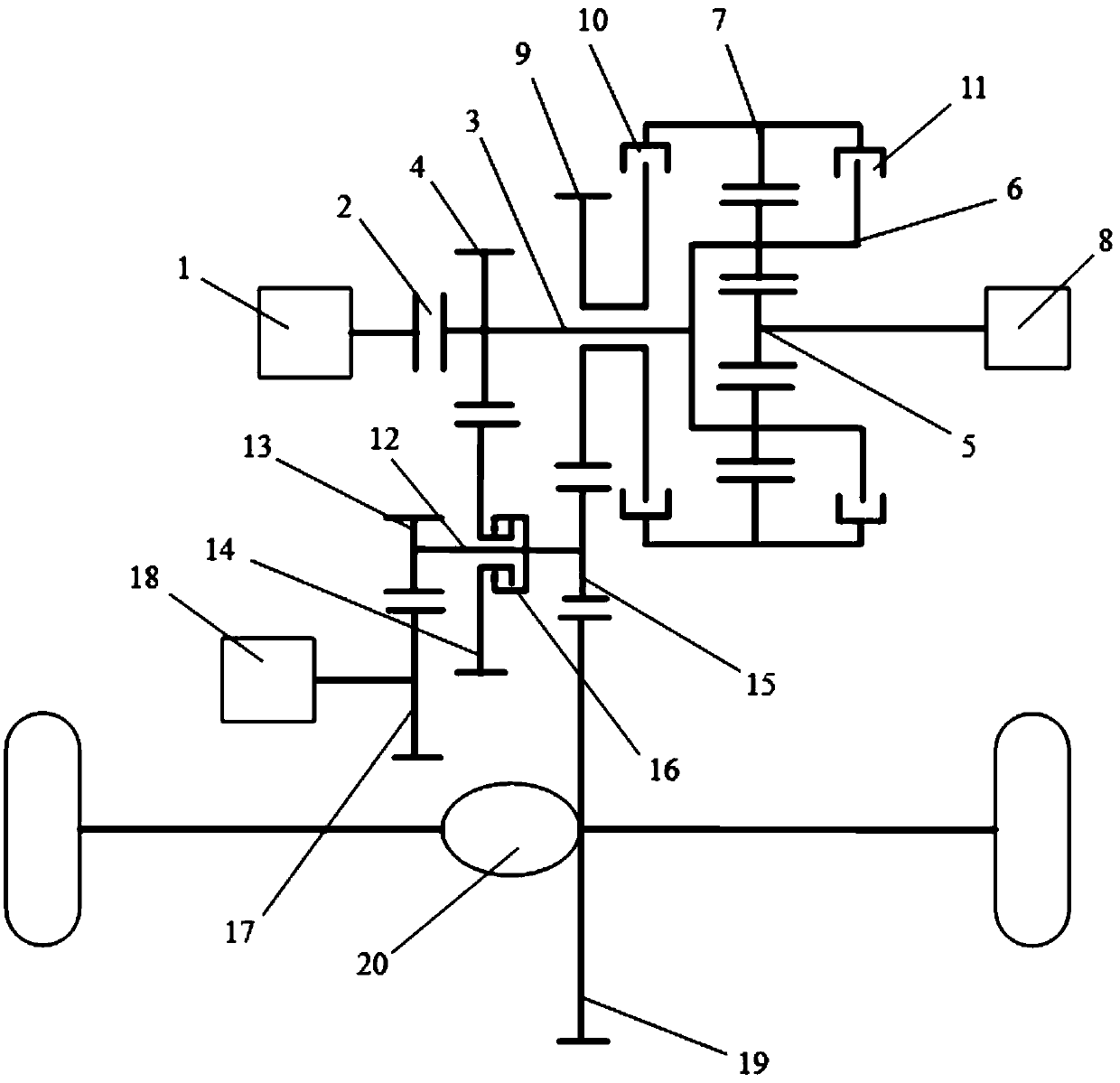

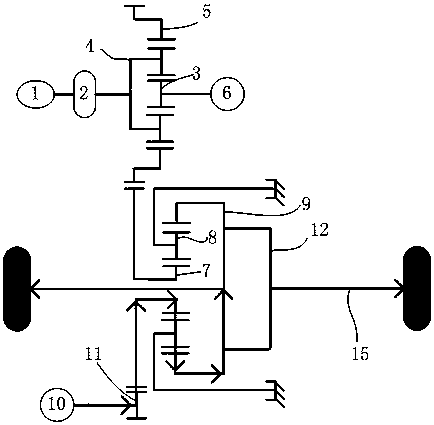

Hybrid power coupling system and vehicle

PendingCN111376699AImprove economyImprove powerHybrid vehiclesGas pressure propulsion mountingGear wheelDrive motor

The invention discloses a hybrid power coupling system and a vehicle. The system comprises an engine, a generator, a driving motor, a first planet row, a second planet row, a brake, a first clutch, asecond clutch, an input shaft and an intermediate shaft for outputting power to wheels, wherein the first planet row comprises a first sun gear, a first planet carrier and a first gear ring, and the second planet row comprises a second sun gear, a second planet carrier connected with the first gear ring and a second gear ring connected with the first planet carrier; the engine is connected with the input shaft; the input shaft is connected with a first sun gear and a second planet carrier through the first clutch and the second clutch respectively; the brake is used for braking the first sun gear, and the first planet carrier is meshed with a first gear arranged on the intermediate shaft; the generator is connected with the second sun gear or the input shaft; and the driving motor is connected with the intermediate shaft. The system load is facilitated to be reduced, multiple driving modes can be achieved, higher transmission efficiency is achieved, and the power performance and economy of the whole vehicle are improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

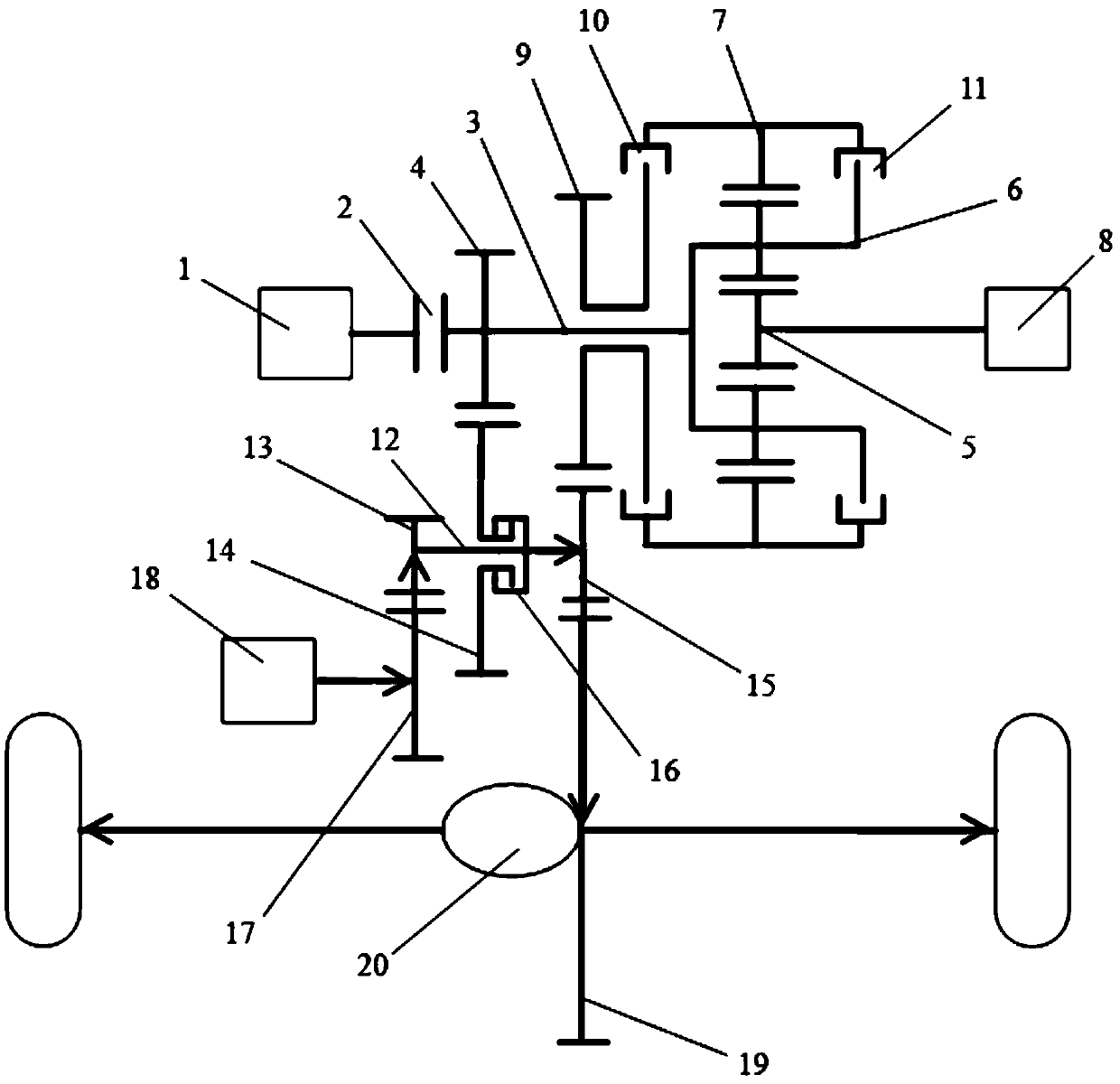

Hybrid power driving system and hybrid power automobile

PendingCN111016618AReduce volumeOptimize workspaceHybrid vehiclesGas pressure propulsion mountingGear wheelElectric machinery

The invention belongs to the technical field of hybrid power, and relates to a hybrid power driving system and a hybrid power automobile. The hybrid power driving system comprises an engine, a first clutch, an input shaft, a first gear, a single planet row, a first motor, a second gear, a second clutch, a third clutch, an intermediate shaft, a third gear, a fourth gear, a fifth gear, a fourth clutch, a sixth gear, a second motor, a seventh gear and a differential mechanism. The hybrid power driving system can achieve three hybrid drive modes and an engine direct drive mode through reasonable layout of the engine, the first motor, the second motor, the single planet row, the multiple gears and the multiple control elements (the first clutch, the second clutch, the third clutch and the fourth clutch), so that the automobile is enabled to have high transmission efficiency under the medium-high speed working condition, and the economical efficiency is good.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

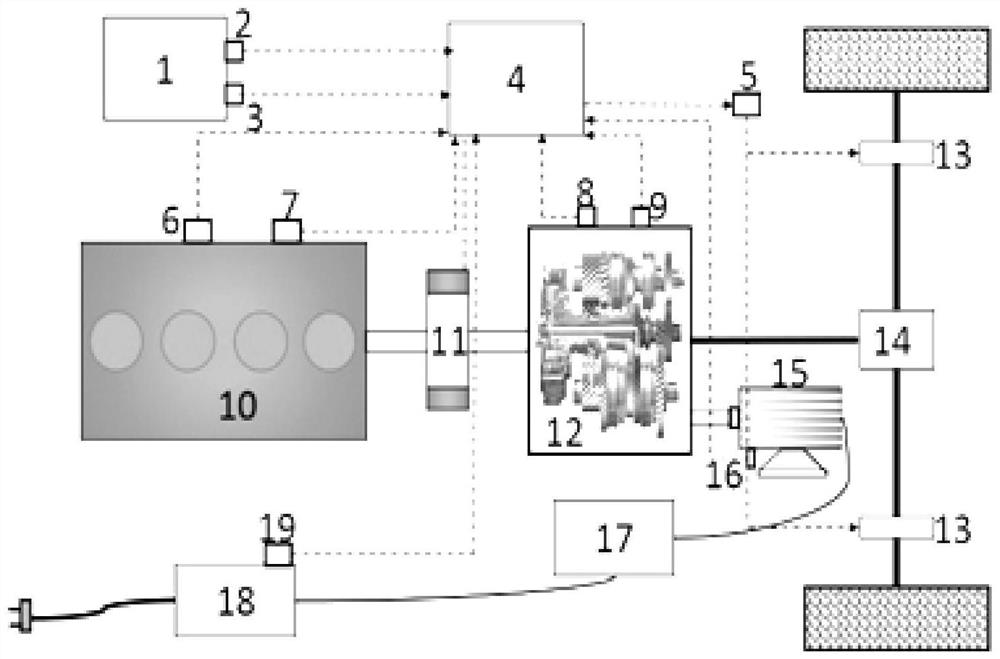

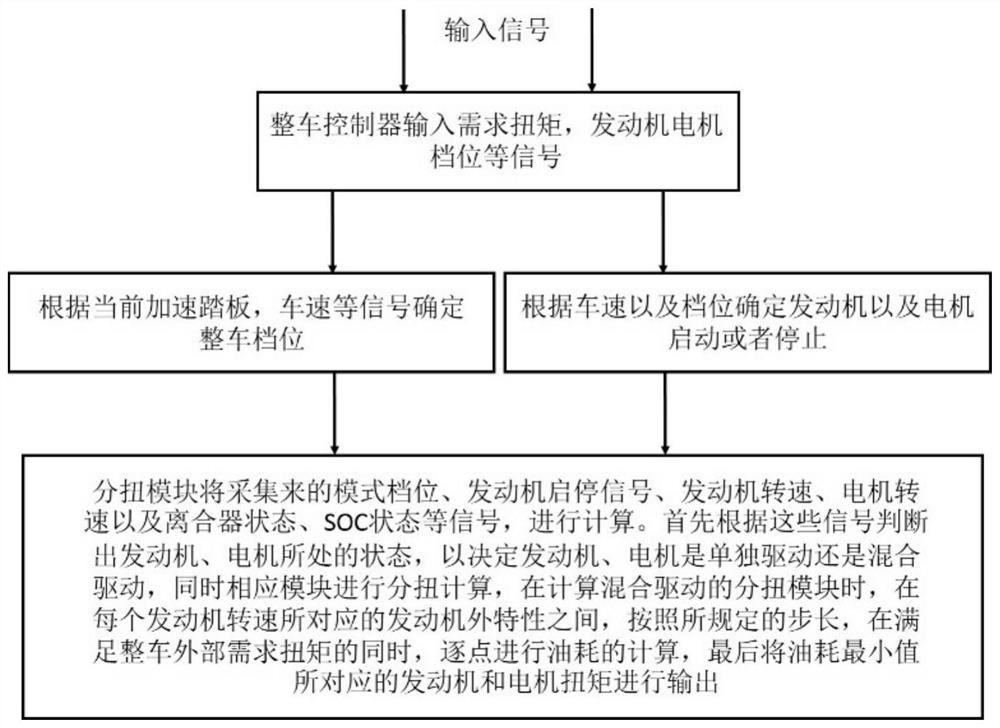

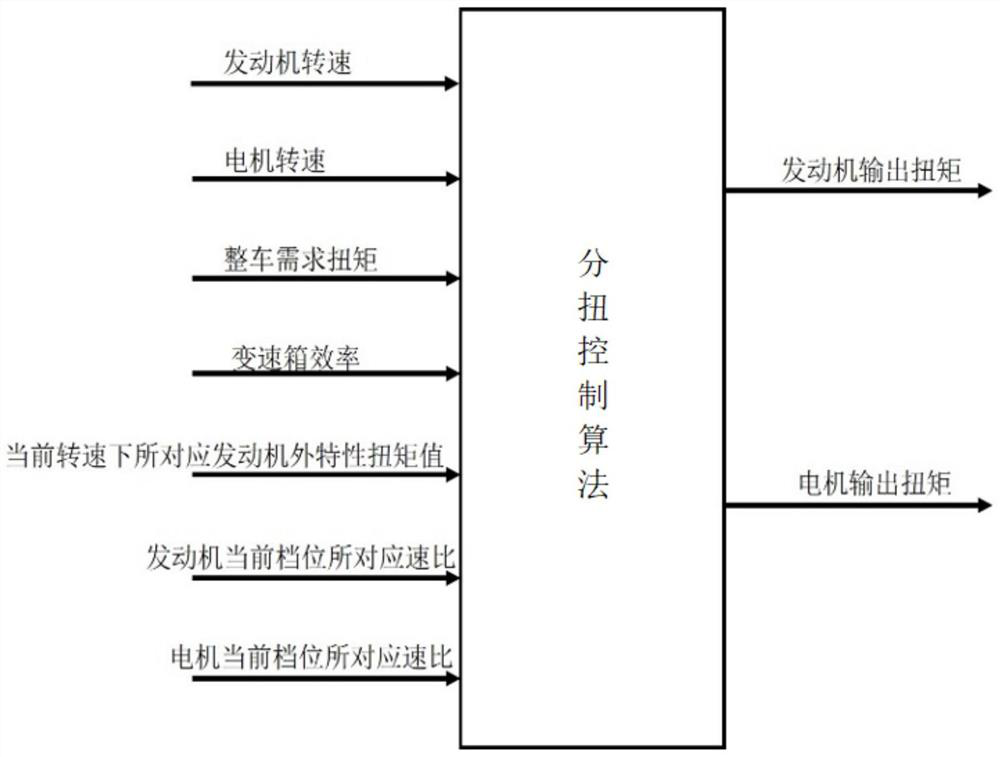

Multivariable torque optimization control distribution method for engine and motor of hybrid electric vehicle

ActiveCN112849119AOptimize workspaceImprove fuel economyHybrid vehiclesData processing managementTorque optimizationNerve network

The invention relates to a multivariable torque optimization control distribution method for an engine and a motor of a hybrid electric vehicle. The method comprises the following steps of: training a neural network by using actually measured engine torque and rotating speed and an equal fuel consumption value as a training set, and exporting the trained neural network when the training is finished and a training result meets a precision requirement; introducing the trained neural network in a torque division control algorithm, taking the whole vehicle working condition parameters as input, calculating an equal fuel consumption value of the engine in real time, and converting instantaneous power values of the engine and the motor into instantaneous fuel consumption; and taking the torque of the engine and the motor corresponding to the minimum instantaneous oil consumption as the optimal torque value at the moment, and outputting the optimal torque value to an engine controller and a motor controller. According to the method, the torque of the engine is not limited to three areas divided by the SOC any more, the oil consumption is calculated point by point while the external required torque of the whole vehicle is met, finally, the engine torque and the motor torque corresponding to the minimum oil consumption value are output, the working interval of the engine is optimized, and the fuel economy of the whole vehicle is further improved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

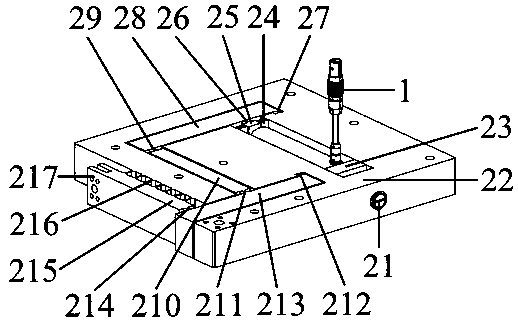

Multi-degree-of-freedom nanometer positioning platform based on flexible parallel mechanism

ActiveCN109502542AHigh precisionHigh output stiffnessMicrostructural devicesPosition/direction controlMicro nanoHigh bandwidth

The invention relates to the technical field of micro-nano machining and manufacturing devices, in particular to a multi-degree-of-freedom nanometer positioning platform based on a flexible parallel mechanism. Branch movement chains include a first branch movement chain and a second branch movement chain; one end of the first branch movement chain is connected with a first fixed base, and the other end of the first branch movement chain is connected with an end executor; and one end of the second branch movement chain is connected with the first fixed base, a supporting point is provided by asecond fixed base, and the other end of the second branch movement chain is connected with the end executor. The end executor can realize single-degree-of-freedom output through the multi-axis secondbranch movement chain in a vertical direction; through redundant driving with the nanoscale precision, high output rigidity, high acting force, large load capacity, high bandwidth and high precision in the vertical direction can be realized; and the platform can be used as a main shaft in the fields of micro-nano machining and manufacturing, and the like.

Owner:GUANGDONG UNIV OF TECH

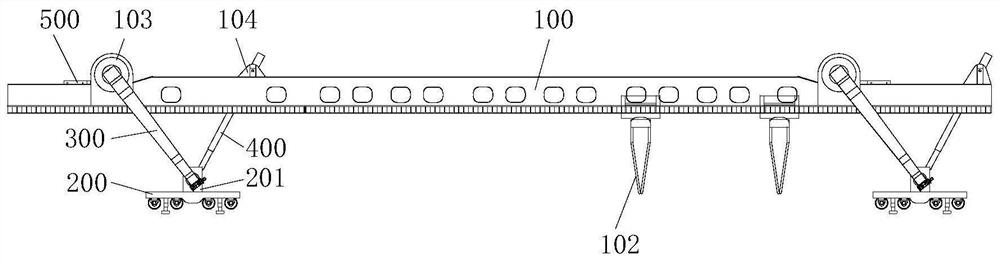

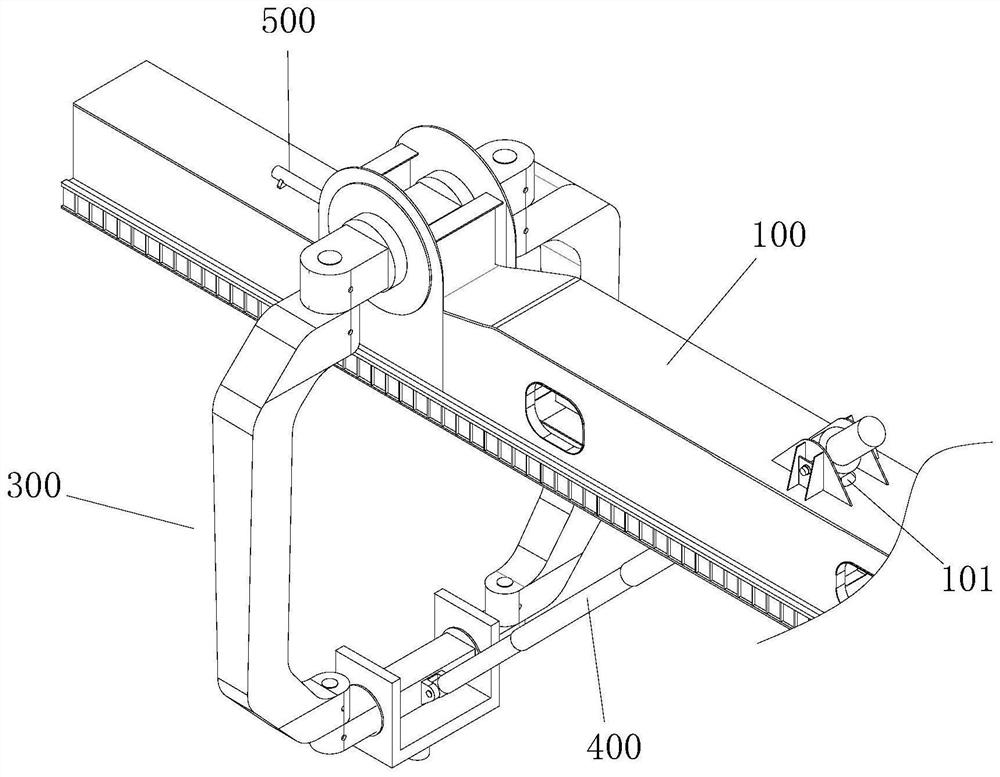

Beam changing method with foldable beam changing machine

ActiveCN112359733AReduce investmentOptimize workspaceRailway transportBridge erection/assemblyStructural engineeringMechanical equipment

The invention relates to the technical field of bridge frame changing, and particularly relates to a beam changing method with a foldable beam changing machine. The method comprises the steps that 1,a first beam conveying special train, a guide beam with a lifting function and a second beam conveying special train enter an area in sequence, a containing part is arranged on the guide beam, and a lifting hydraulic rod is hinged into the containing part; 2, the lifting hydraulic rod is controlled to extend so as to jack the guide beam; 3, the lifting hydraulic rod is controlled to contract, andthe lifting hydraulic rod is stored in the containing part again; 4, an old beam is hoisted to the first beam conveying special train by utilizing a pair of beam hoisting trolleys matched with two beam carrying trolleys on the first beam conveying special train; and 5, the pair of two beam hoisting trolleys is used for being matched with the two beam carrying trolleys on the second beam conveyingspecial train to lift a new beam to a to-be-replaced frame hole position. Rapid switching of the working states of the guide beam can be achieved through the lifting hydraulic rod and the containing part so that the construction efficiency is effectively improved, and the investment of mechanical equipment is effectively reduced.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

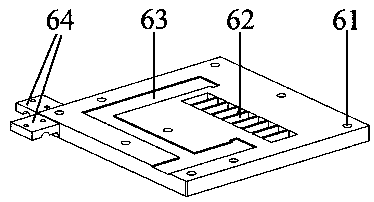

Three-axis cutter servo device based on compliant parallel mechanism

ActiveCN109079552ARealize displacement outputIncrease stiffnessFeeding apparatusHigh bandwidthHigh stiffness

The invention relates to the technical field of nano-positioning, measuring and machining devices, in more particularly to a three-axis cutter servo device based on a compliant parallel mechanism. Thethree-axis cutter servo device comprises outer side fixing bases, an inner side fixing base, uniaxial nano-positioning platforms and a three-axis end actuator, wherein the uniaxial nano-positioning platforms and the three-axis end actuator transfer motion through compliant hinges and flexible rod pieces. The three-axis end actuator is connected with a cutter and provided with a capacitive sensor,and the capacitive sensor is connected with a controller. The output end of the controller is connected with a piezoelectric ceramic driver, the piezoelectric ceramic driver is connected to the inputends of the uniaxial nano-positioning platforms, and the three-axis end actuator is connected to the output ends of the three uniaxial nano-positioning platforms. According to the three-axis cutter servo device based on the compliant parallel mechanism, nanoscale linear displacement of the three-axis end actuator can be output, meanwhile, end output displacement is directly measured through the sensor, feedback control is conducted, and the three-axis cutter servo device has high stiffness, high precision, the high bandwidth, the large stroke, the high speed, high acceleration, the large bearing capacity and excellent decoupling performance.

Owner:GUANGDONG UNIV OF TECH

Hybrid powercoupling mechanism, control system and control method

PendingCN108128138AAdjustable speed ratioLarge speed ratioHybrid vehiclesGas pressure propulsion mountingControl systemGear wheel

The invention discloses a hybrid power coupling mechanism. The hybrid power coupling mechanism comprises two motors, two planetary lines, an axial gear system and the like, wherein an engine is connected with a planet carrier of the first planetary line and is connected with a sun gear of the first planetary line; a driving motor is connected with a sun gear of the second planetary line through agear pair, a planet carrier of the second planetary line is fixed, and an inner gear ring of the second planetary line is output. The invention further discloses a corresponding control system and a control method. By means of the hybrid power coupling mechanism, the control system and the control method, multiple driving mode of a pure electric mode, a hybrid power mode and the like can be achieved, only three shafts need to be arranged, the structure is compact, and requirementsfor the space are lowered.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

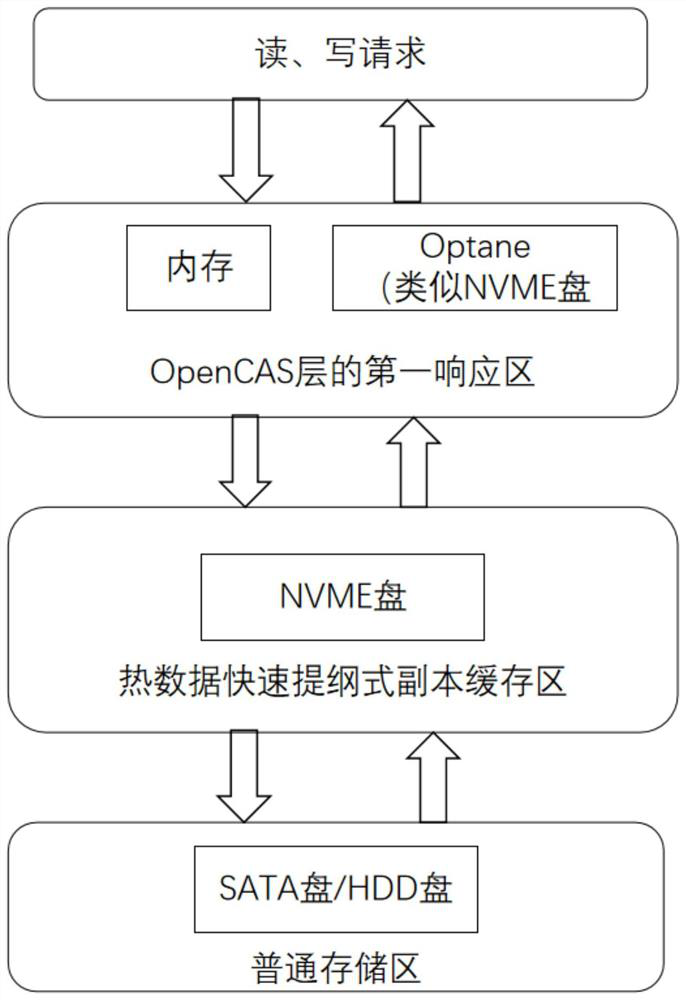

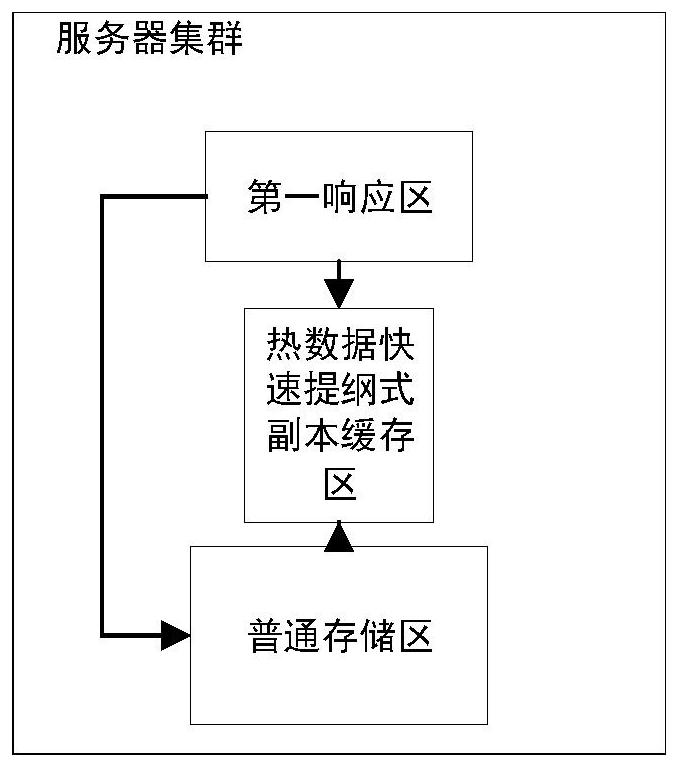

Data storage structure optimization method and system and medium

ActiveCN112732190AIncrease flexibilityReduce write loadInput/output to record carriersEngineeringDatabase

The invention discloses a data storage structure optimization method, which comprises the following steps: creating a first response area, creating a quick cache area and a common storage area, when a server cluster receives a data reading request, the first response area responding, and if the first response area does not have data corresponding to the reading request, enabling the quick cache area to response; if the server cluster receives data corresponding to the reading request, the quick cache area makes a response, if the quick cache area does not have data corresponding to the reading request, the common storage area makes a response, and when the server cluster receives the data, the first response area caches the data and asynchronizes the data to the common storage area and the quick cache area. The distributed storage structure can be optimized, the flexibility of data writing and reading of the server cluster is improved, the writing load of the server cluster is reduced, the bandwidth of data reading is improved, and an excellent working space and an excellent working state are provided for an application program.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

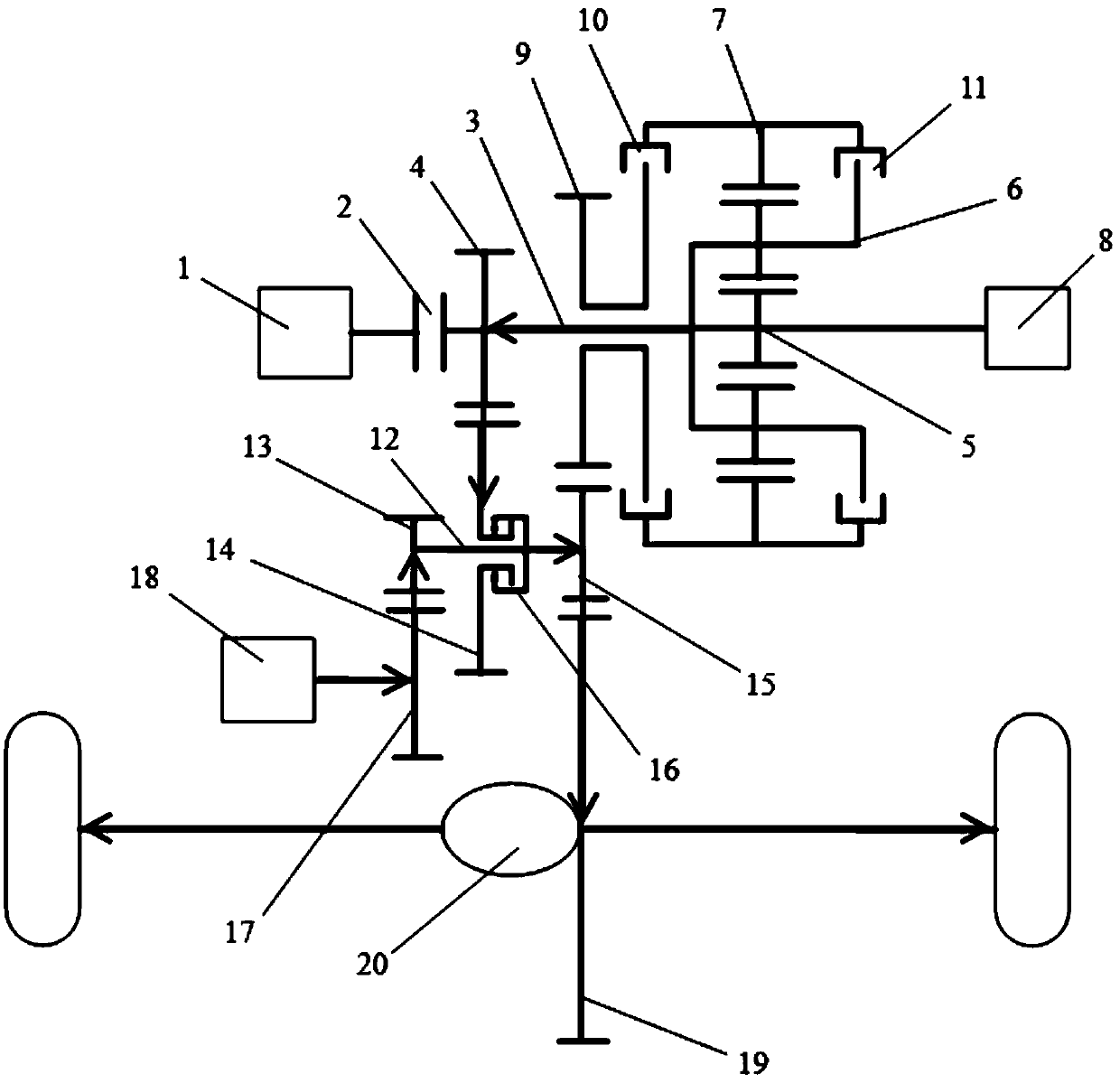

Power shunting hybrid power coupling mechanism and control method thereof

PendingCN110303873AOptimize workspaceImprove economic performanceHybrid vehiclesGas pressure propulsion mountingClutchDouble row

The invention discloses a power shunting hybrid power coupling mechanism and a control method thereof. The coupling mechanism comprises an engine, a motor, a compound planetary gear mechanism, clutches and a shaft gear system; the compound planetary gear mechanism is a double-row compound planetary mechanism, wherein a first planetary carrier is connected with a second inner gear ring, and a firstinner gear ring is connected with a second planet carrier; and the motor is connected with a second sun gear. According to the power shunting hybrid power coupling mechanism, a pure electric power mode, two hybrid power modes and three power shunting modes can be arranged, the mode can be switched through opening and closing between the clutches and the operation of a brake, so that the power efficiency can be effectively improved, and the economy is improved; and the engine and the motor of the whole mechanism are connected through the planetary gear, so that the adjustable range of the speed ratio is wide, the size of the motor can be reduced, and the operating range of the engine can be optimized.

Owner:江门宇度科技有限责任公司

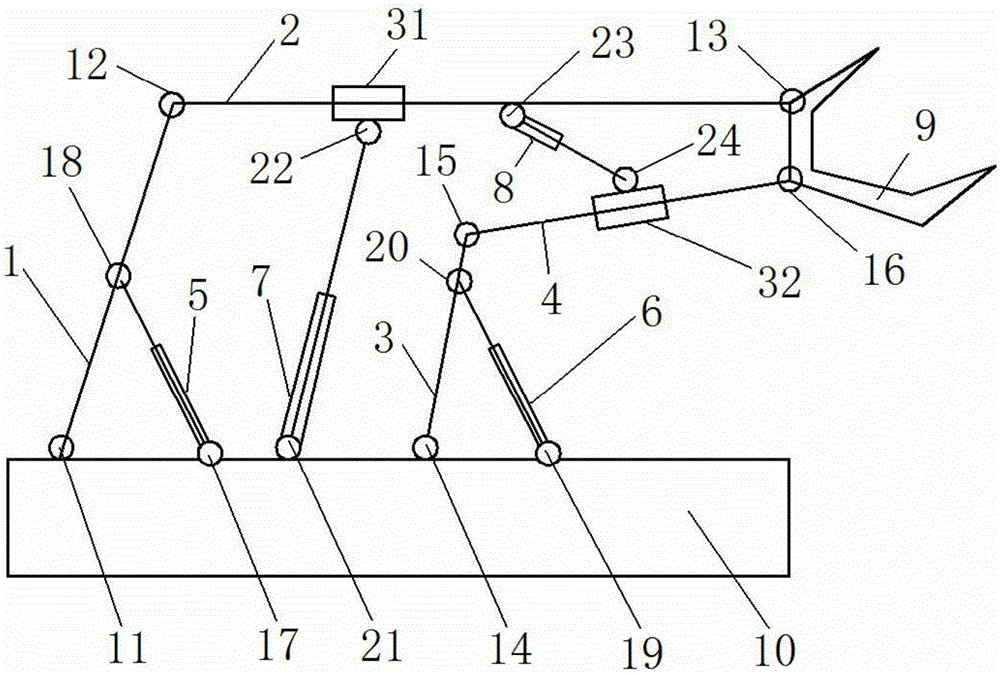

Connecting rod controllable type excavation mechanism capable of working by multiple angles

The invention relates to a connecting rod controllable type excavation mechanism capable of working by multiple angles. One end of a first connecting rod is connected to a rack. The other end of the first connecting rod is connected with one end of a second connecting rod. The other end of the second connecting rod is connected to a bucket. One end of a third connecting rod is connected to the rack. The other end of the third connecting rod is connected with one end of a fourth connecting rod. The other end of the fourth connecting rod is connected to the bucket. One end of a first telescopic rod is connected to the rack. The other end of the first telescopic rod is connected to the first connecting rod. One end of a second telescopic rod is connected to the rack. The other end of the second telescopic rod is connected to the third connecting rod. One end of a third telescopic rod is connected to the rack. The other end of the third telescopic rod is connected to a first sliding block. The second connecting rod is sleeved with the first sliding block. One end of a fourth telescopic rod is connected to the second connecting rod. The other end of the fourth telescopic rod is connected to a second sliding block. The fourth connecting rod is sleeved with the second sliding block. The connecting rod controllable type excavation mechanism is light in motion part, high in speed, good in dynamic response, flexible in mechanism output track, large in work space and high in work efficiency, and the problem that a traditional single-freedom-degree mechanical excavator cannot achieve complex action can be solved.

Owner:GUANGXI UNIV

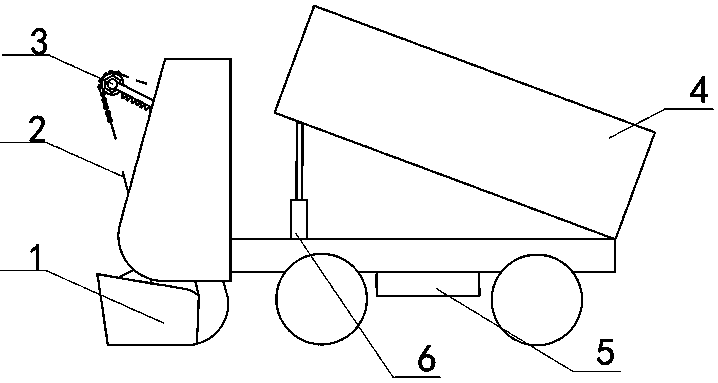

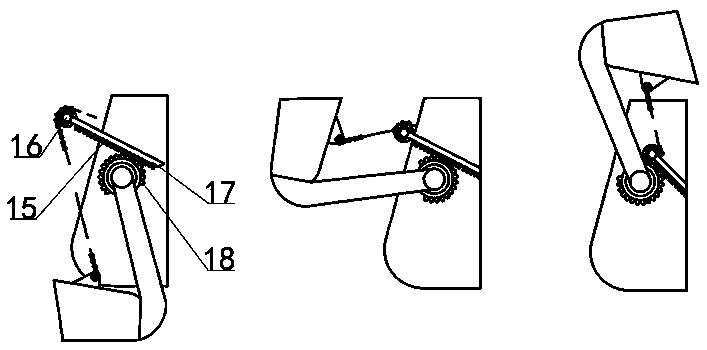

Pivot-adjustable gear-and-rack rock-loading bucket traction mechanism

ActiveCN110552386ARealize the function of steering freeExtended service lifeMechanical machines/dredgersGear transmissionTraction system

The invention discloses a pivot-adjustable gear-and-rack rock-loading bucket traction mechanism, and belongs to the field of loading and transport machines for mine roadways. The mechanism mainly comprises a framework, a bucket system, a basket system, an adjustable traction system and a storage bin. The mechanism integrates the functions of loading, transport and unloading, and the basket systemis driven by a chain to enable the bucket system to work; the adjustable traction system makes a chain wheel supporting arm stretch out and draw back under rack-and-gear transmission, and the length for which the chain wheel supporting arm stretches out and draws back is coupled with the motion of a bucket. The mechanism optimizes the working space of all the systems and integrates the functions of loading, transport and unloading; the motions of the mechanism do not mutually interfere on the premise that the occupied space is small, therefore, the mechanism can work with high efficiency in anadit with a narrow space, the technological dependence on workers is reduced, and the gangue collecting work is safer and more reliable.

Owner:SHANDONG UNIV OF TECH

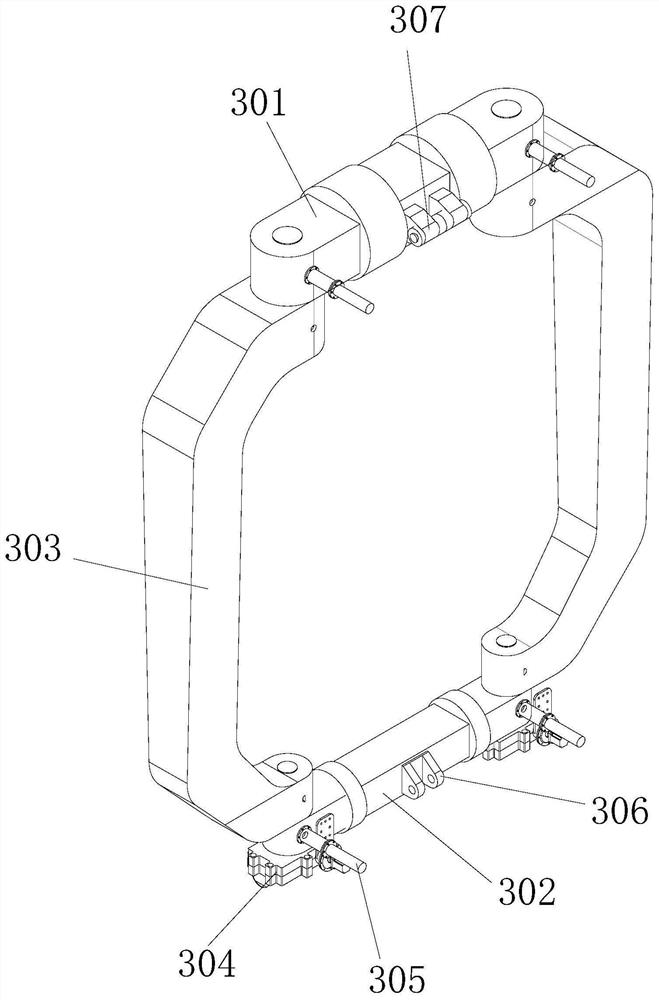

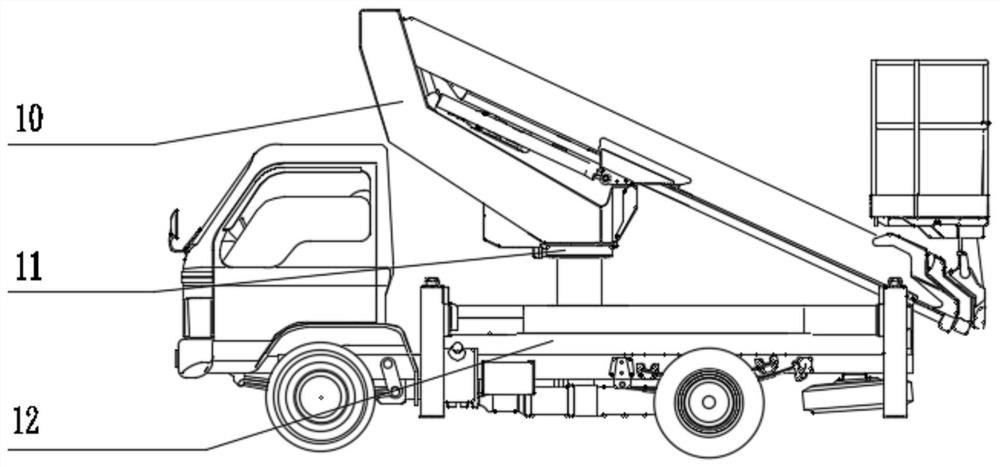

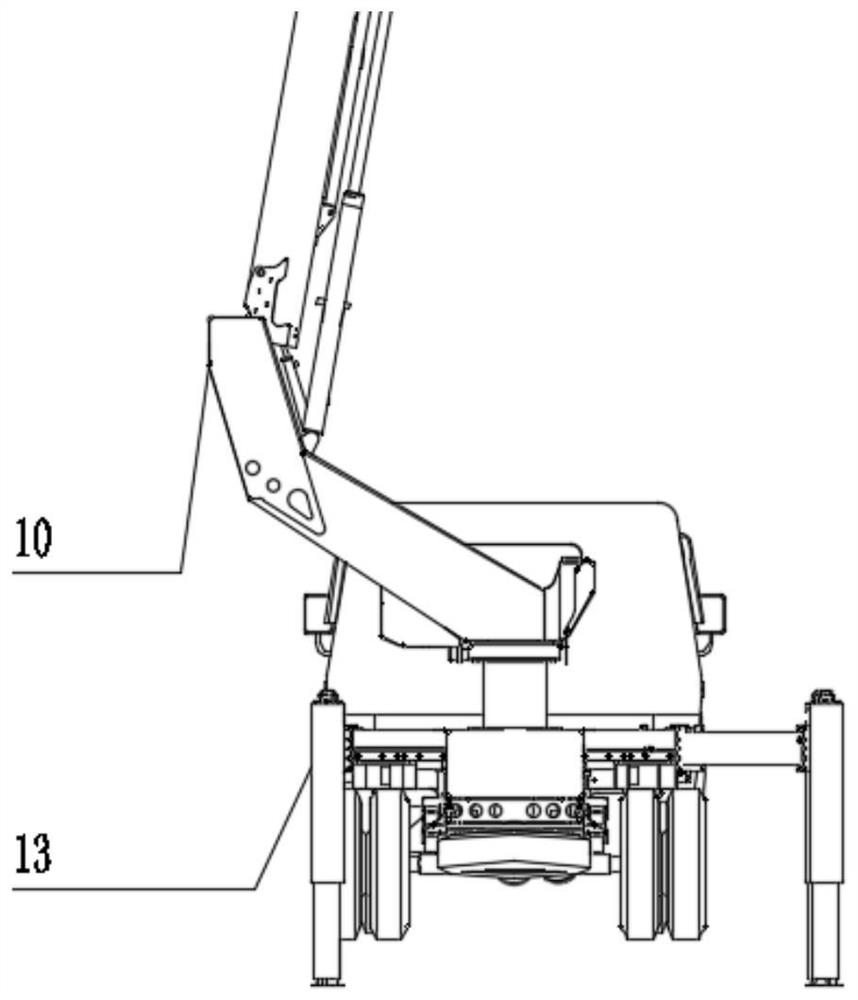

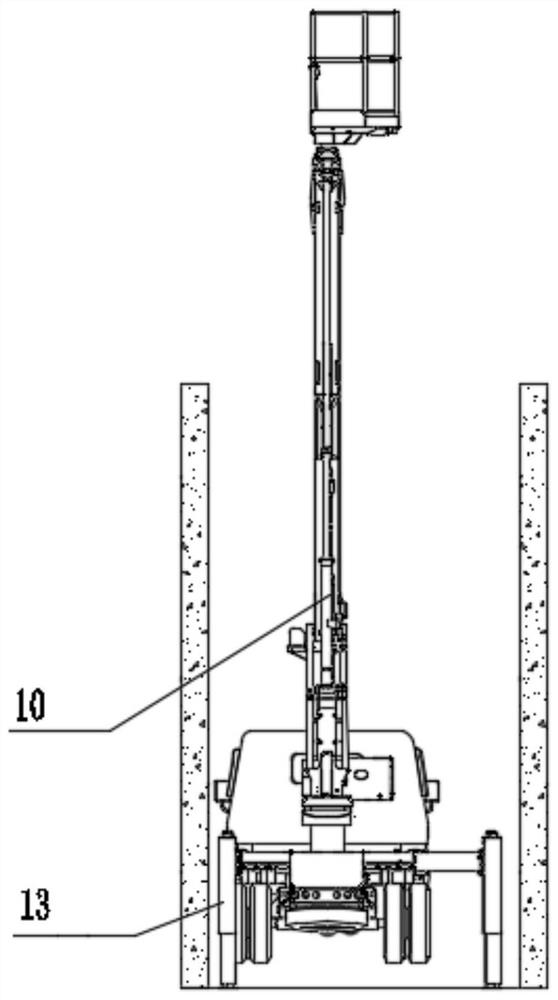

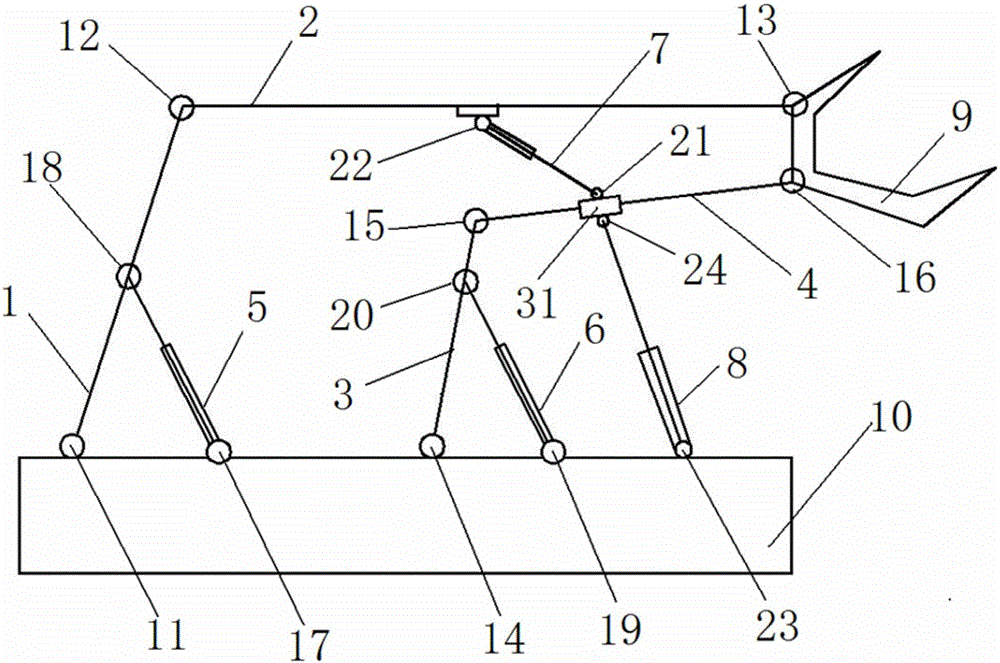

Double rotary device for vehicle-mounted aerial work platform

PendingCN111847334ASmall turning radiusOptimize workspaceGearingLifting devicesIn vehicleAerial work platform

The embodiment of the invention provides a double rotary device for vehicle-mounted aerial work platform, and relates to the technical field of rotary driving. The double rotary device comprises a double rotary body, a first transmission device and a second transmission device, wherein a first end of the double rotary body is rotatably connected with a base, and a second end of the double rotary body is rotatably connected with a working upper tool; the first transmission device is connected with the double rotary body and used for driving the double rotary body to rotate relative to the base;and the second transmission device is connected with the working upper tool and used for driving the working upper tool to rotate relative to the double rotary body. A double rotary structure is adopted, and the problem that an existing vehicle-mounted aerial vehicle cannot work in an extremely narrow working space is solved.

Owner:SANY PALFINGER SPECIAL VEHICLE

Linkage-mechanism excavator

A linkage-mechanism excavator is characterized in that one end of a first connecting rod is connected onto a rack; the other end of the first connecting rod is connected with one end of a second connecting rod; the other end of the second connecting rod is connected onto a bucket; one end of a third connecting rod is connected to the rack; the other end of the third connecting rod is connected with one end of a fourth connecting rod; the other end of the fourth connecting rod is connected to the bucket; one end of a first telescopic rod is connected to the rack; the other end of the first telescopic rod is connected onto the first connecting rod; one end of a second telescopic rod is connected onto the rack; the other end of the second telescopic rod is connected on the third connecting rod; one end of a fourth telescopic rod is connected onto the rack; the other end of the fourth telescopic rod is connected onto a first sliding block; the first sliding block sleeves the fourth connecting rod; one end of a third telescopic rod is connected onto the first sliding block; and the other end of the third telescopic rod is connected onto the second connecting rod. According to the linkage-mechanism excavator provided by the invention, the complete machine structure is simple and compact, and the part manufacturing and machining requirements are low; and the linkage-mechanism excavator can play a relatively good role in a severe-environment and narrow-space construction site as well as an accident rescue scene where rapid excavation, obstacle clearance and flattening are required.

Owner:GUANGXI UNIV

Fabric presser for textile machines

InactiveCN108570787AWide range of weavingImprove practicalityDirt cleaningTextile shapingArchitectural engineeringWorking environment

The invention discloses a fabric presser for textile machines, which comprises a body, an upper press roller and a lower press roller are arranged inside the body, a servo motor is mounted on one sideof the internal wall of the body, the output end of the servo motor is transmissively connected to one end of the upper press roller, the other end of the upper press roller is fixedly connected to the internal side of a first bearing block, both sides of the bottom of the internal wall of the body are provided with recesses, electric telescopic rods are mounted in the two recesses, the retractable ends of the two electric telescopic rods are respectively fixedly connected to the external walls of two second bearing blocks, and a dust collector is arranged on the bottom of the body. Accordingto the solution, by arranging the electric telescopic rods, the upper press roller and the lower press roller, corresponding adjustment can be conveniently carried out according to the thickness of afabric, consequently, the weaving range of the textile machine becomes wider, and the practicability of the textile machine is increased; and the arranged dust collector can clean off dust in the textile machine, thus the working environment of the workshop is guaranteed and creation of a good working space is facilitated.

Owner:湖州南浔兴科纺织品原料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com