Flat knitting machine with lighting device

A technology for flat knitting machines and lighting devices, which is applied to knitting, flat knitting machines with single-action needles, weft knitting, etc., which can solve the problems of inconvenient fault finding and inability to illuminate the working space of the slider

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

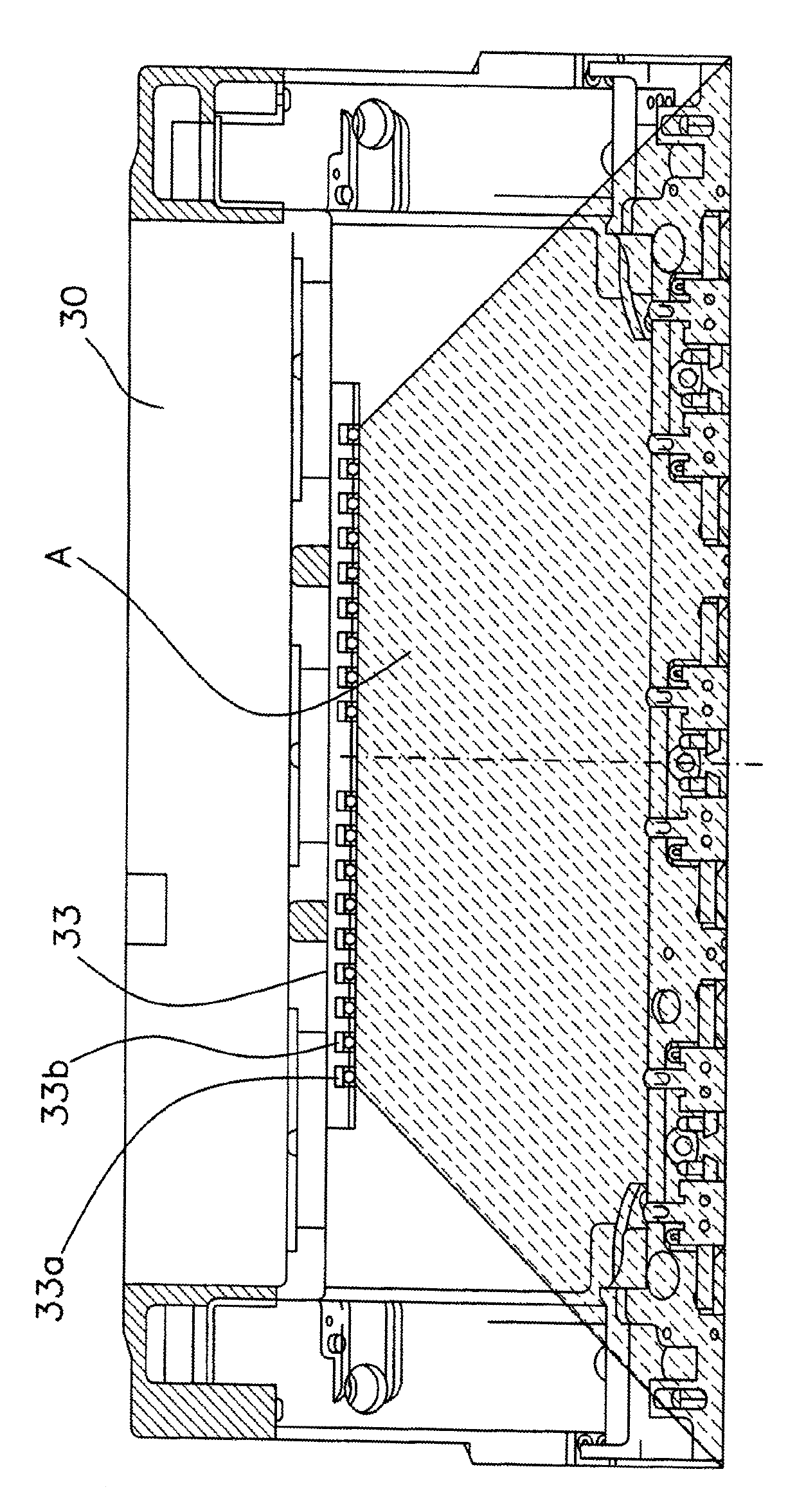

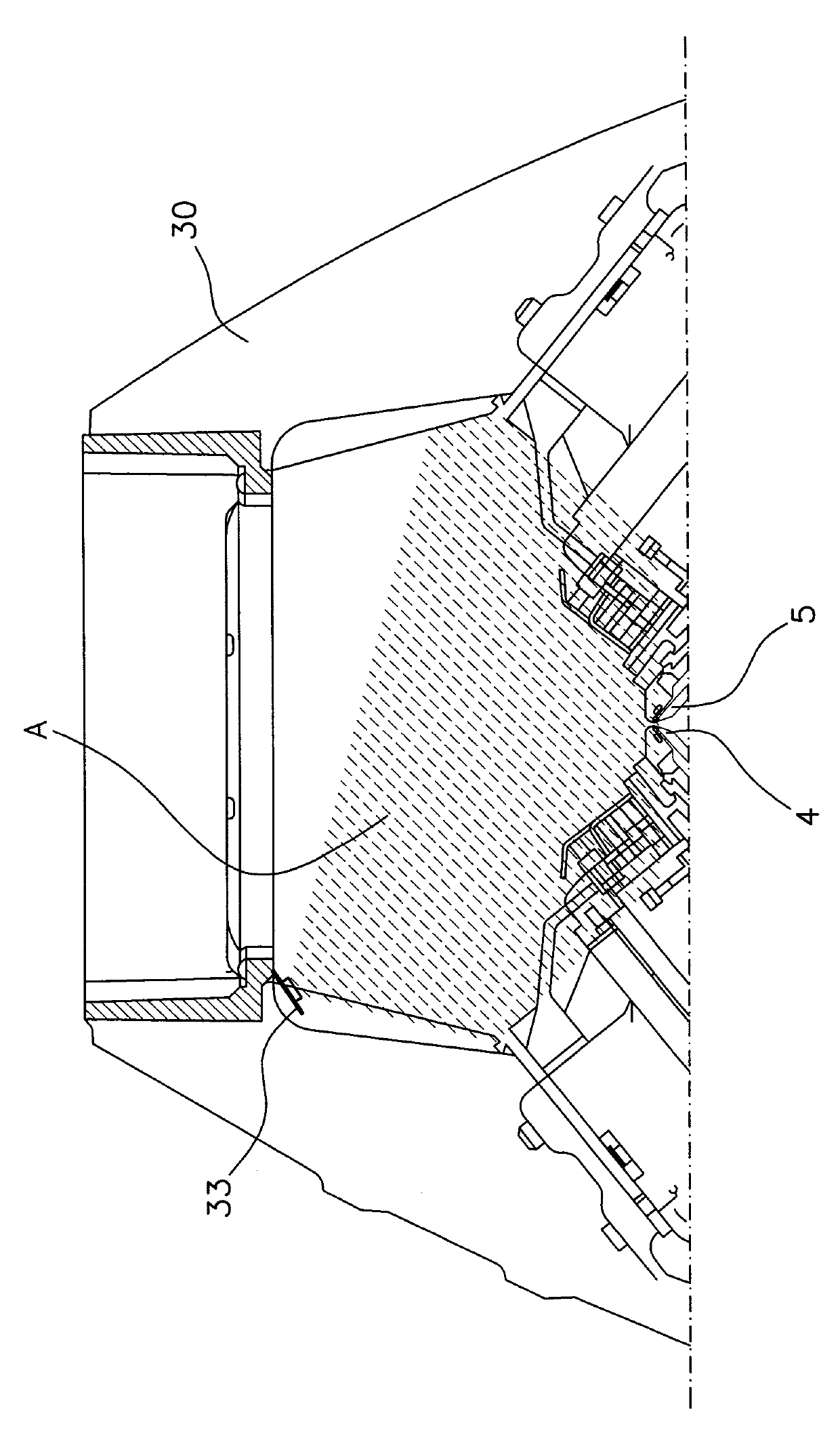

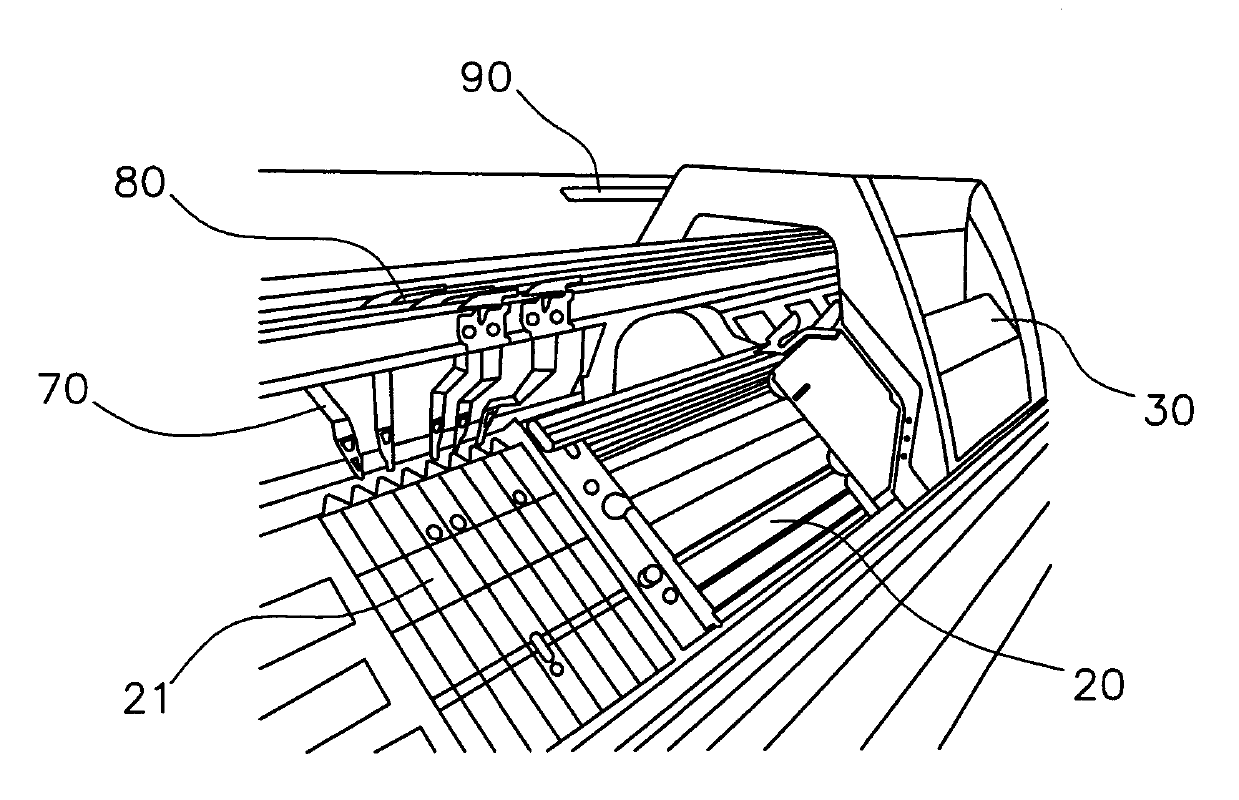

[0017] Figure 1a A flat knitting machine 100 is shown with a frame 10 and front and rear needle beds 20 . Introduced in the needle bed 20 are guide grooves for knitting elements such as needles or sliders. The knitting elements can be moved longitudinally in their guide grooves by means of a cam (not visible here) mounted on the machine carriage 30 . Furthermore, the machine carriage 30 is moved back and forth along the needle bed 20 . The thread 41 required for producing the knitted fabric extends from the yarn bobbin 40 through the yarn control unit 50 and the yarn feeder (Fournisseur) to the yarn guide 70 (which is also passed through a slide over the needle bed 20 after corresponding selection). seat 30 to move it and thus supply the selected needle with thread 41). Here, the thread guide 70 slides on a thread guide rod 80 which extends in its longitudinal direction above the needle bed 20 .

[0018] Such as Figure 1a As shown, an illumination device 90 is arranged ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com