Sewing machine for clothes processing

A technology for sewing machines and clothing, which is applied to sewing machine components, sewing equipment, textiles, and papermaking. It can solve problems such as laborious operation, scattered on the ground, and single function, so as to achieve the goal of not occupying the working space, being convenient to take, and avoiding errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

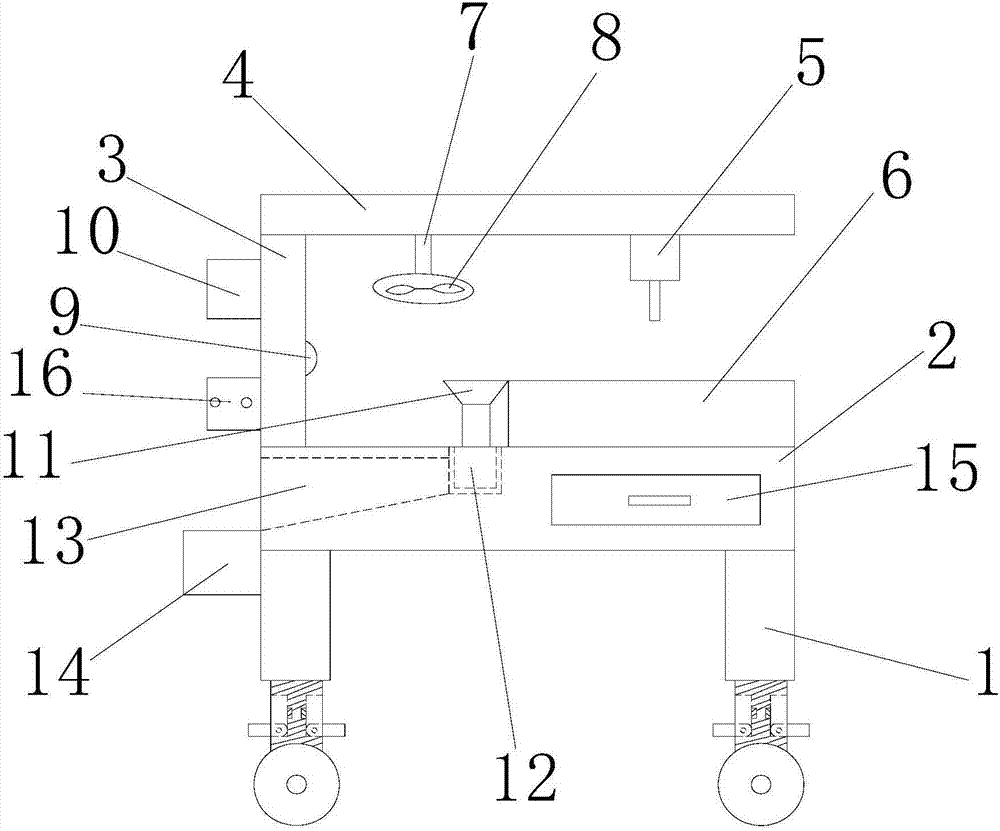

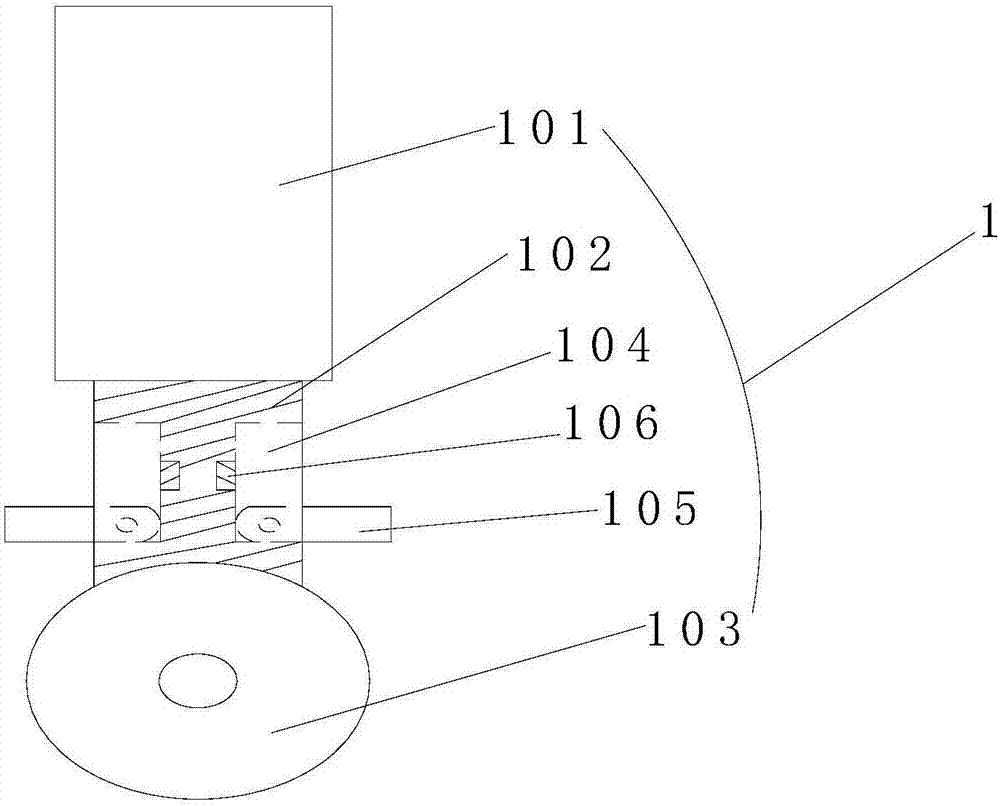

[0014] refer to figure 1 and 2 , a sewing machine for garment processing according to the present invention, comprising support legs 1, desktop 2, frame 3, top plate 4, machine head 5, workbench 6, gooseneck 7, fan 8, lighting lamp 9, cup holder 10, suction Dust hopper 11, dust suction pump 12, channel 13, collection box 14 and drawer 15, the bottom of described desktop 2 is provided with four supporting legs 1 in balance, and the left side of the top of described desktop 2 is fixedly provided with vertically arranged Frame 3, the upper end of described frame 3 is fixedly provided with the top plate 4 that horizontally arranges, and the bottom of described top plate 4 is fixedly provided with machine head 5, and the working head that is fixedly installed on desktop 2 tops is provided with just below described machine head 5. Platform 6, the lower part of the top plate 4 and the left side of the machine head 5 are connected with a fan 8 through a gooseneck 7, the right side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com