Pivot-adjustable gear-and-rack rock-loading bucket traction mechanism

A technology of rack and pinion and traction mechanism, which is applied in the direction of mechanically driven excavators/dredgers, etc., and can solve the problems of limited range of movement, impact, and narrow space of rock loaders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

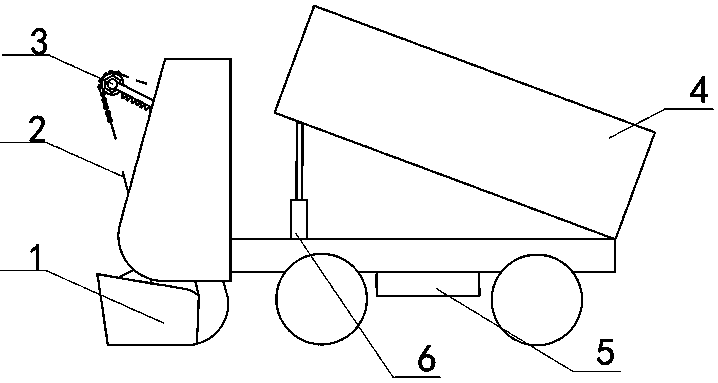

[0015] figure 1 It is an overall schematic diagram of the structure of the present invention; it includes a bucket [1], a chain [2], a sprocket [3], a storage bin [4], a bucket motor and a chain reel [5], and a bucket cylinder [6].

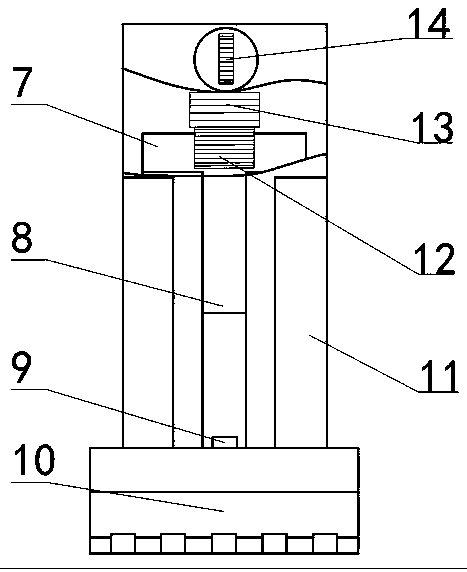

[0016] figure 2 It is the front view of the bucket; it includes the rotary shaft [7], the single rotary arm [8], the fixed pin [9], the bucket [10], the frame [11], the half gear [12], the rack [13], the chain wheel [14].

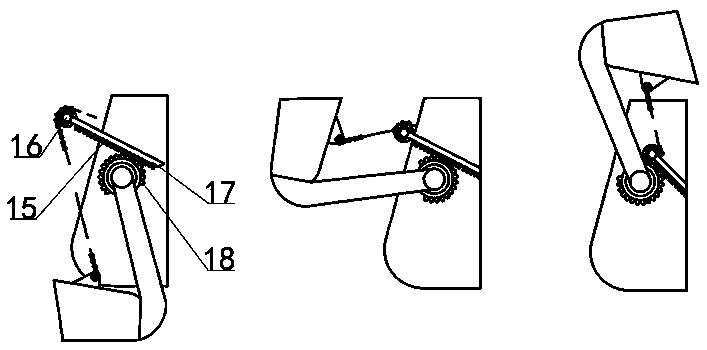

[0017] image 3 It is a schematic diagram of bucket work; it includes a sprocket support arm [15], a sprocket [16], a slideway [17], and a half gear [18].

[0018] Figure 4 Is rack and pinion schematic diagram; Contains sprocket support arm [19], tooth bar [20], slideway [21], slideway groove [22]. The slideway is fixed on the rock loader frame, and the rack drives the sprocket support arm to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com