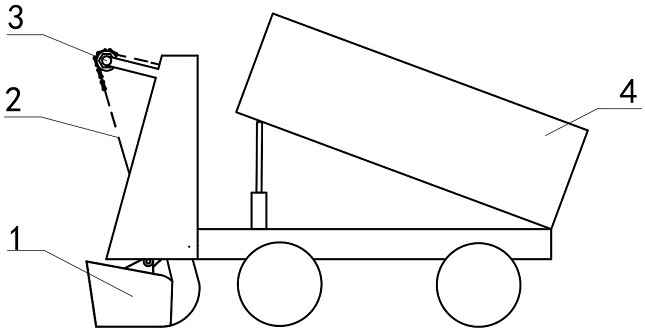

An adjustable bucket mechanism coupled with traction device and chain reel

A traction device and adjustable technology, which is applied in the field of mine roadway loading and transportation machinery, can solve the problems of limited range of movement of rock loaders and difficulty in direction adjustment of rock loaders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

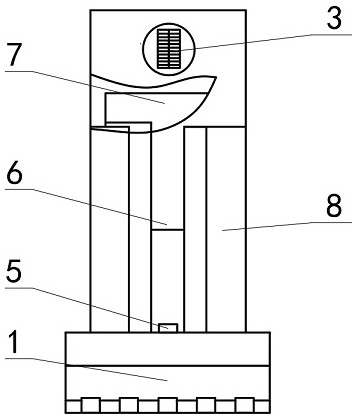

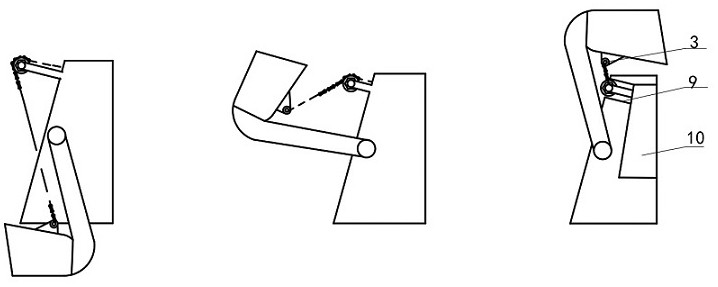

[0017] Working process: the mechanism advances the bucket [1] to be filled with gangue, the motor drives the reel chain to work, and the chain [2] pulls the hook [5] to drive the bucket [1] to turn over, and at the same time, the cam mechanism keeps the sprocket support arm [ 11] The longest state; when the chain drum works for a period of time, the cam [14] of the cam drive mechanism turns to the other side, the sprocket support arm [11] begins to shorten, and the sprocket support arm [11] enters the slide [ 9] Start shortening, the bucket [1] is slowly lifted, and finally the gangue slides down to the storage bin [4]; after the gangue is unloaded, the bucket [1] falls by its own weight, and the chain drum works at the same time as the cam transmission mechanism cam [14] Turn to the other side, and the sprocket support arm [11] begins to stretch to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com