Hybrid power coupling system and vehicle

A technology of hybrid power and coupling system, which is applied to hybrid vehicles, motor vehicles, power plants, etc., and can solve problems such as lack of power and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

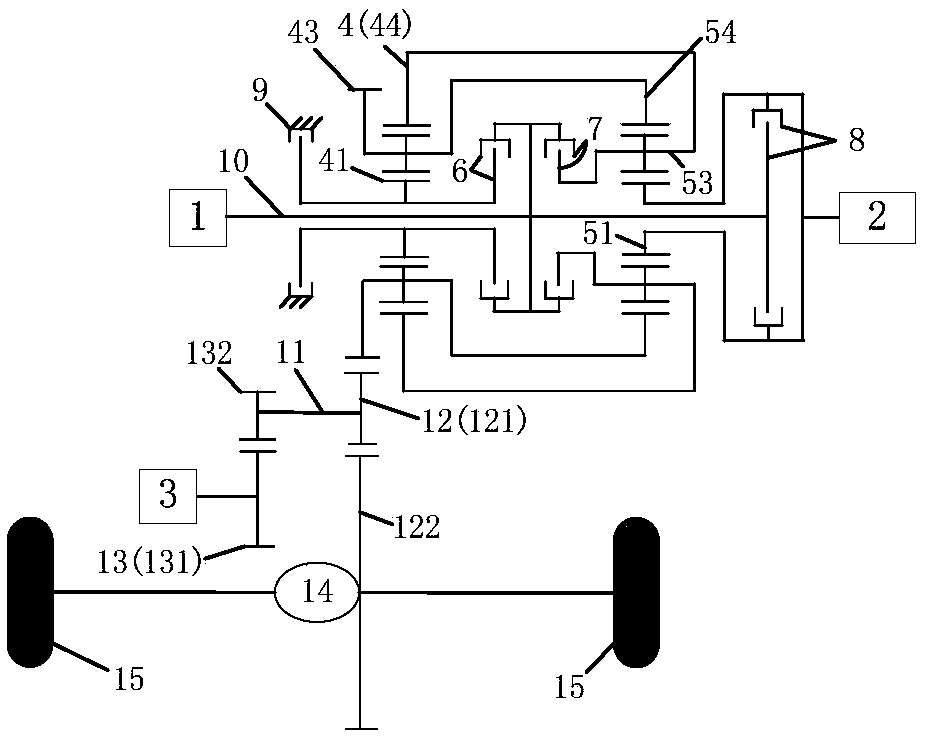

Embodiment 1

[0133] like Figure 1 to Figure 14 , when the generator 2 is connected to the input shaft 10 through the third clutch 8, and the housing of the third clutch 8 is connected to the rotating shaft of the generator 2 and the second sun gear 51, the hybrid power coupling system has a single motor pure electric mode, a dual Motor pure electric drive mode, hybrid drive mode (with three gears: first hybrid drive mode, second hybrid drive mode, third hybrid drive mode), engine direct drive mode (with three gears: first engine direct drive mode, second Six working modes including two-engine direct-drive mode, third-engine direct-drive mode), ECVT mode (with two gears: first ECVT mode, second ECVT mode) and extended range mode;

[0134] Among them, the aforementioned six working modes are shown in Table 1.

[0135] Table 1

[0136]

[0137] The following modes, combined with Figure 2 to Figure 14 Describe the power transmission route of the hybrid coupling system, where Figure 5...

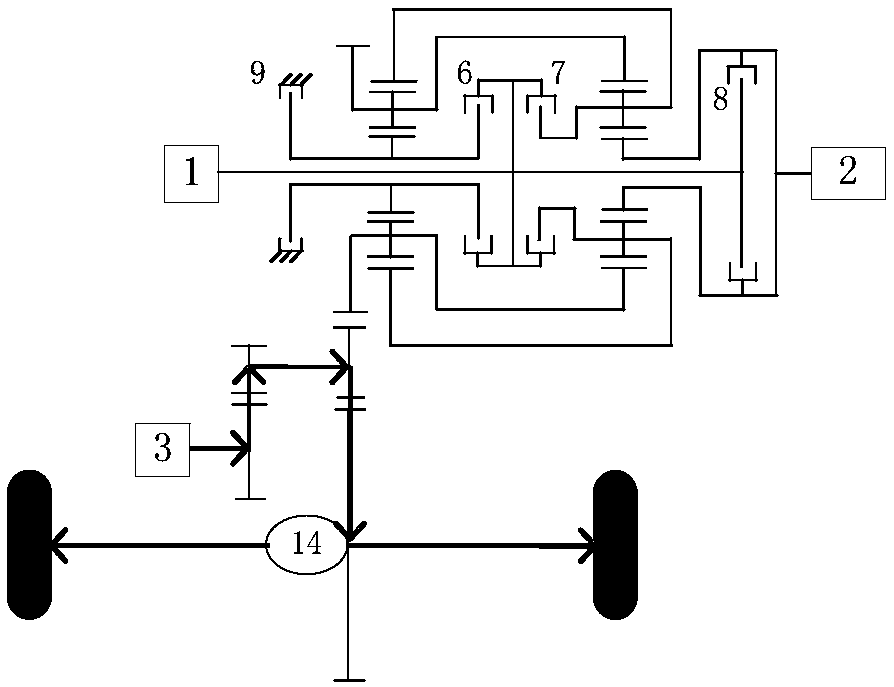

Embodiment 2

[0208] When the generator 2 is connected to the second sun gear 51 through the third clutch 8 and is not connected to the input shaft 10, the hybrid power coupling system reduces the first hybrid drive mode and the first engine direct drive mode on the basis of the first embodiment. and range-extending mode, and the third clutch 8 is combined only when the generator 2 is required to participate in driving or power generation, the power of the generator 2 is input into the second sun gear 51 through the third clutch 8, or the power of the second sun gear 51 is input through the third The clutch 8 is input to the generator 2;

[0209] If the third clutch 8 is canceled on the basis of the aforementioned scheme, it is sufficient to cancel the control of the third clutch 8 , and the power lines of each working mode do not need to pass through the third clutch 8 accordingly. To avoid repeating the details, the power routes of each working mode of the scheme will not be listed here; ...

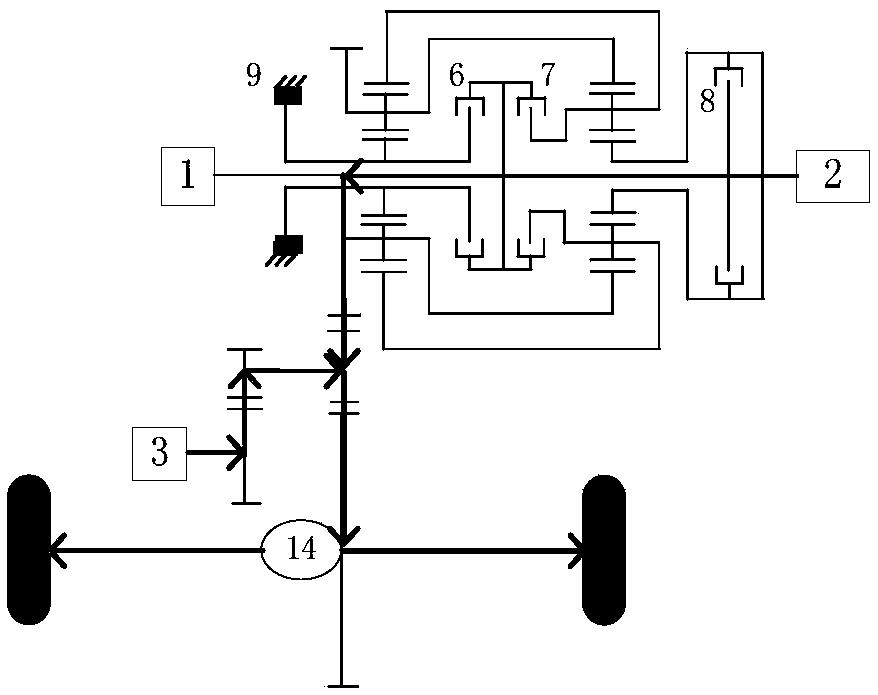

Embodiment 3

[0213] When the generator 2 is connected to the input shaft 10 through the third clutch 8 and is not connected to the second sun gear 51, the hybrid power coupling system reduces the first hybrid drive mode and the first engine direct drive mode on the basis of the first embodiment. 1. In the first ECVT mode and the second ECVT mode, one gear is added to the dual-motor pure electric mode (the two gears are respectively the first dual-motor pure electric mode and the second dual-motor pure electric mode). And the third clutch 8 needs to be combined when the generator 2 participates in driving or generating electricity. The power of the generator 2 is first transmitted to the input shaft 10, and then the CR-CR composite planet is input through the first clutch 6 or the second clutch 7 (embodiment three The power transmission path of the power of the generator 2 from the input shaft 10 to the first planet carrier 43 is consistent with the power transmission path of the power of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com