Four-roller brushing machine

A technology of brushing and bristles, applied in textile and papermaking, roughening, fabric surface trimming, etc., can solve the problems of reducing the cloth running speed and efficiency, and achieve the effect of improving fabric adaptability, improving work efficiency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

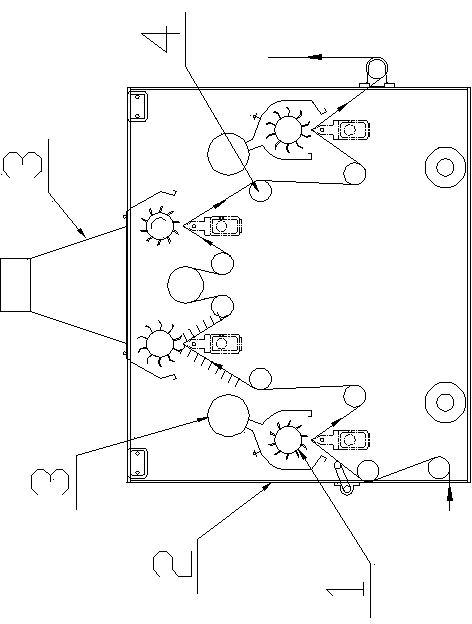

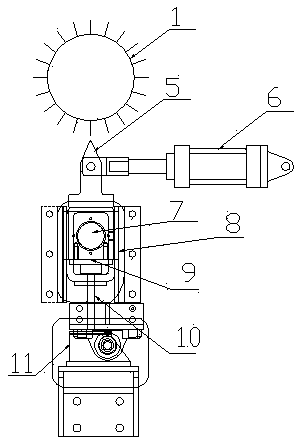

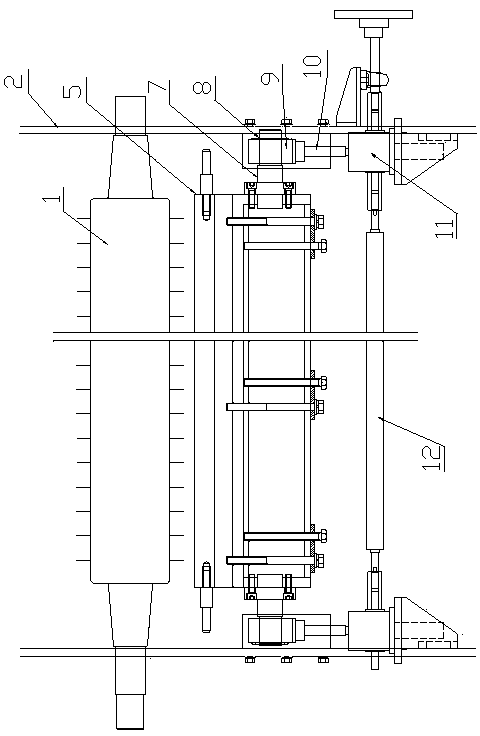

[0014] refer to figure 1 , figure 2 and image 3 , a four-roller brushing machine, comprising a frame 2, four groups of brushing devices arranged in parallel are arranged in the frame 2, dust suction devices 3 are arranged above each group of brushing devices, and on both sides of each group of brushing devices A cloth guide roller 4 arranged parallel to the axis of the brushing device is provided; the brushing device includes a brushing roller 1 horizontally arranged in the frame 2, and a support bracket 5 used in conjunction with the brushing roller 1 is provided below the brushing roller 1. The support bracket 5 is installed on the support bracket shaft 7 arranged parallel to the brush roller 1 axis, and the frame 2 inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com