Human-machine cooperation oriented bionic lightweight mechanical arm

A human-robot collaboration and robotic arm technology, applied in the field of robotics, can solve the problems of control response speed sensor reliability limitation, small reachable range and flexible working range, decreased overall stiffness of the robot, etc., to achieve easy control and small motion inertia. , the effect of light weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

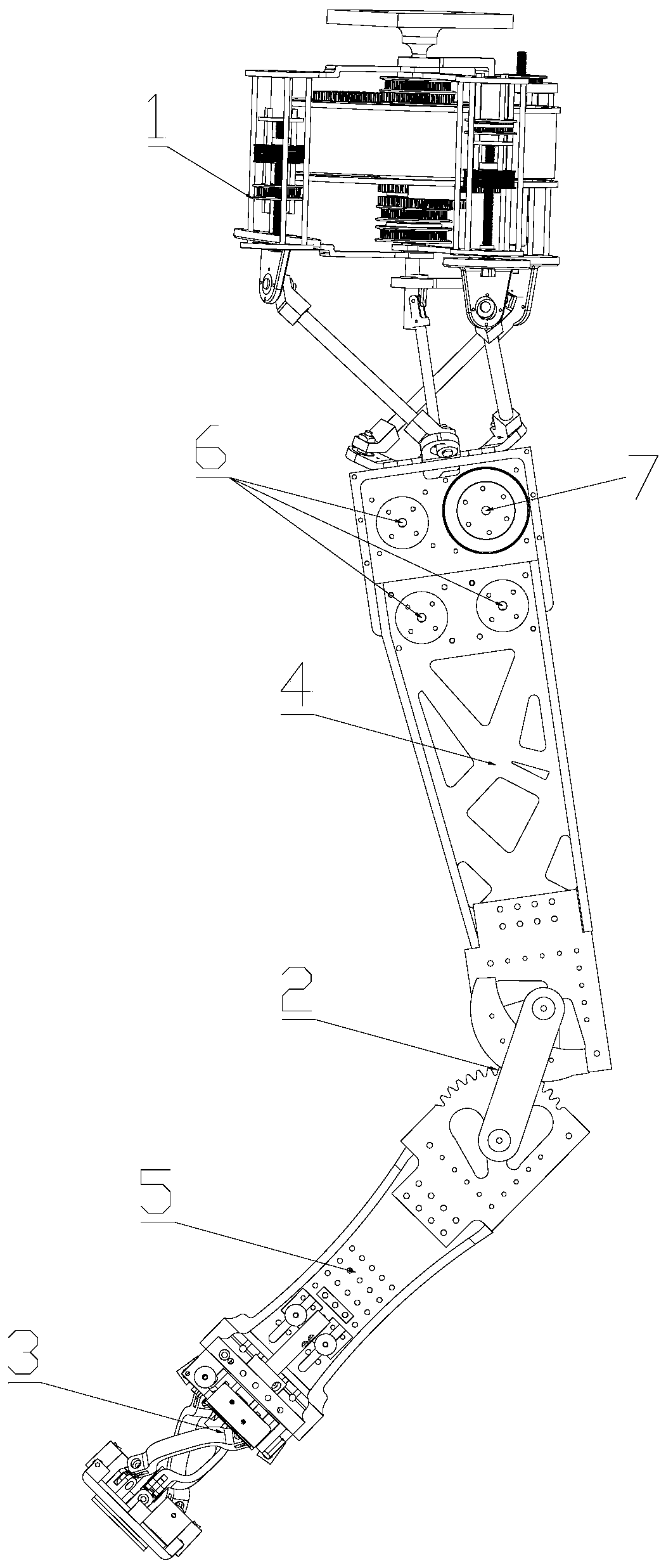

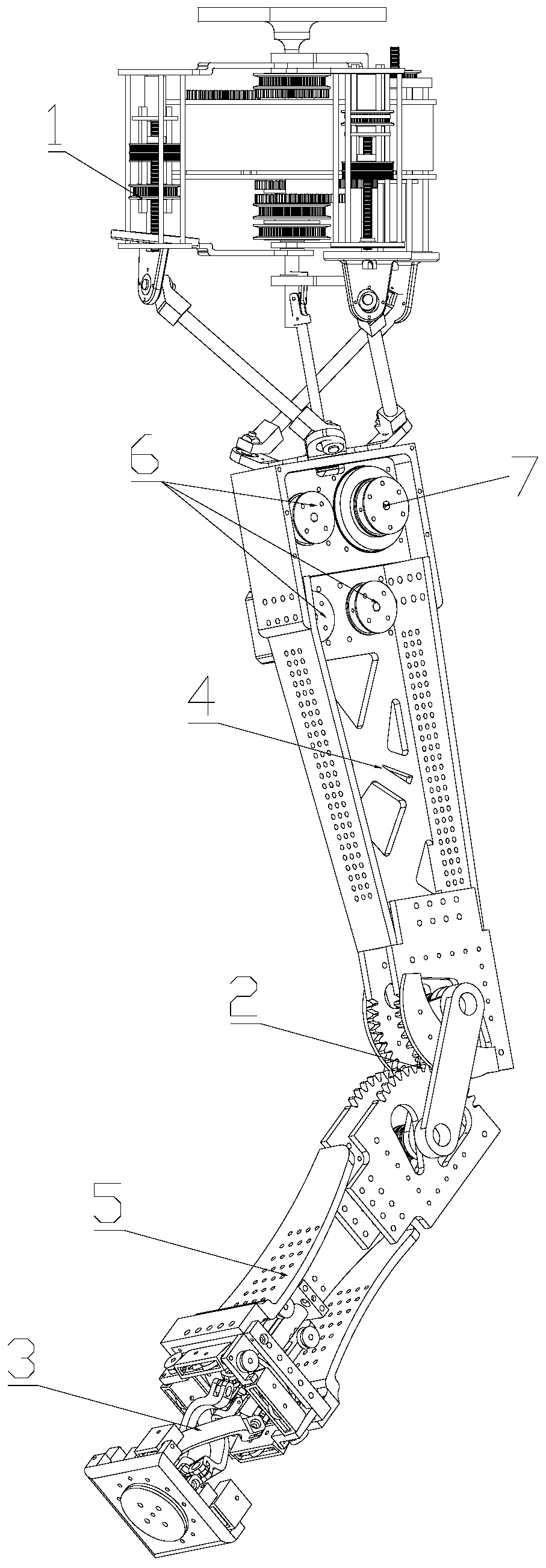

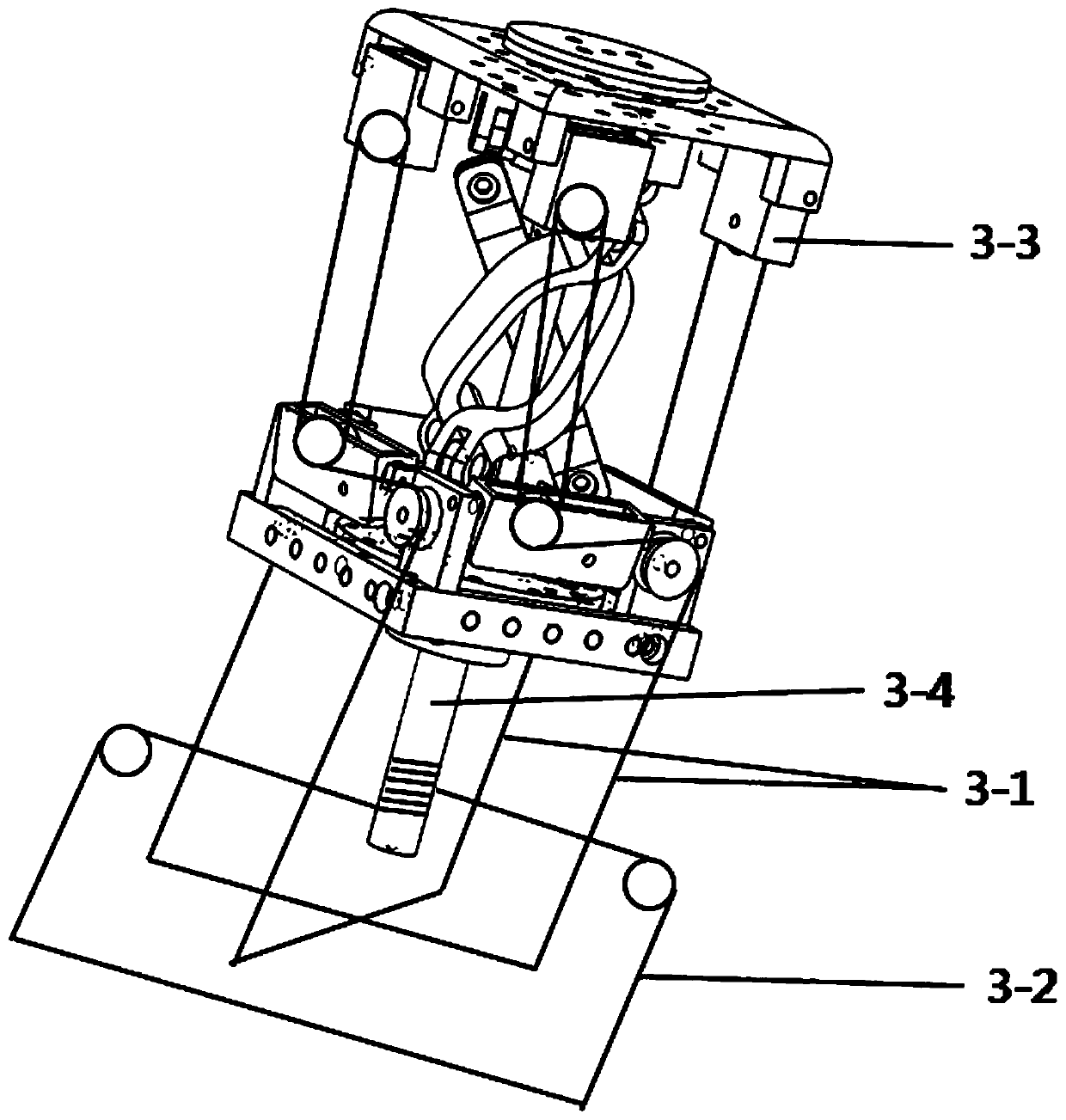

[0045] In this embodiment, a bionic lightweight mechanical arm oriented to human-machine cooperation, such as figure 1 and 2 As shown, including the first machine arm, the second machine arm, the wrist joint, the elbow joint and the shoulder joint, the one between the shoulder joint and the elbow joint is the first machine arm, and the one between the elbow joint and the wrist joint is the second machine arm , the wrist joint is a three-degree-of-freedom kinematic pair, the wrist joint includes a two-degree-of-freedom parallel mechanism connected in series with a single-degree-of-freedom Hooke hinge mechanism, the elbow joint is a single-degree-of-freedom rotational joint, and the shoulder joint is a three-degree-of-freedom parallel ball joint Mechanism, the mechanical arm is equipped with an elbow joint drive motor and three wrist joint drive motors, and the elbow joint drive motor and wrist joint drive motor located at the end of the second arm close to the shoulder joint co...

Embodiment 2

[0057] One kind of present embodiment, compared with embodiment 1, its difference lies in, such as Figure 13 As shown, the elastic member is connected in series in the rope drive transmission of the wrist joint drive motor and / or the elbow joint drive motor to adjust the stiffness of the wrist joint or elbow joint, and the elastic member can be a spring. The springs connected in series in the retractable rope can increase the flexibility of the robotic arm, thereby further enhancing the safety during the interaction process and meeting the actual needs of different working conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com