Double rotary device for vehicle-mounted aerial work platform

A high-altitude work platform, double-turn technology, used in lifting devices, transmission devices, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

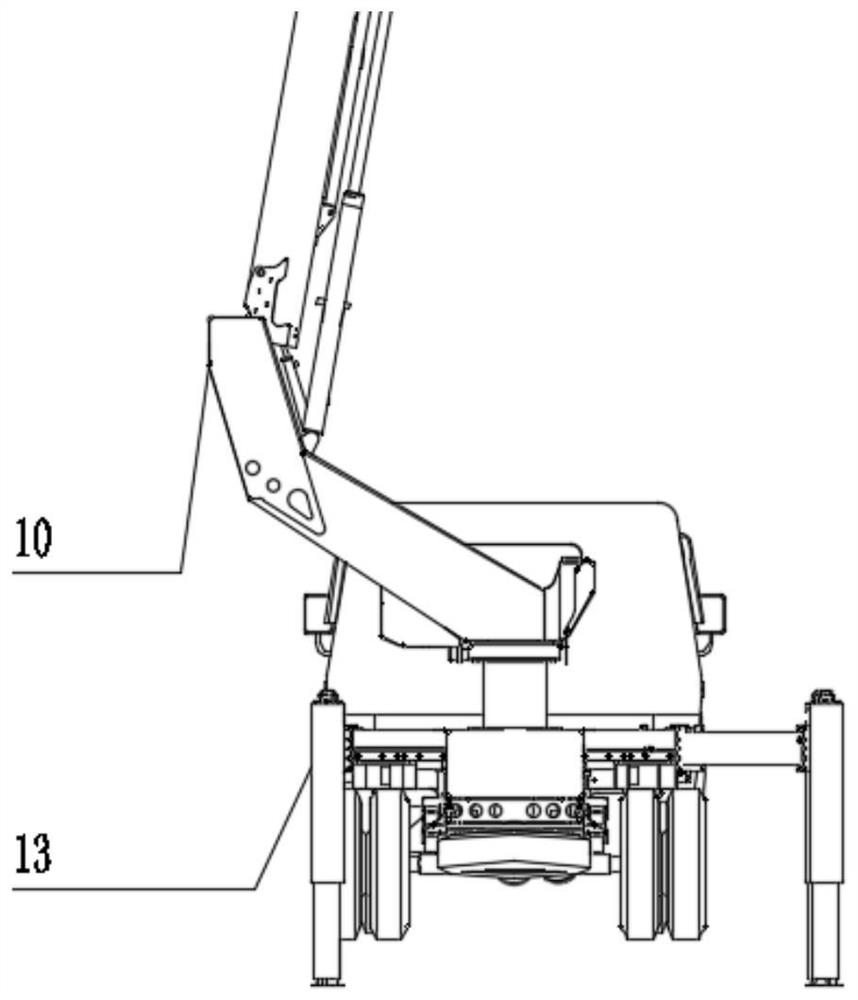

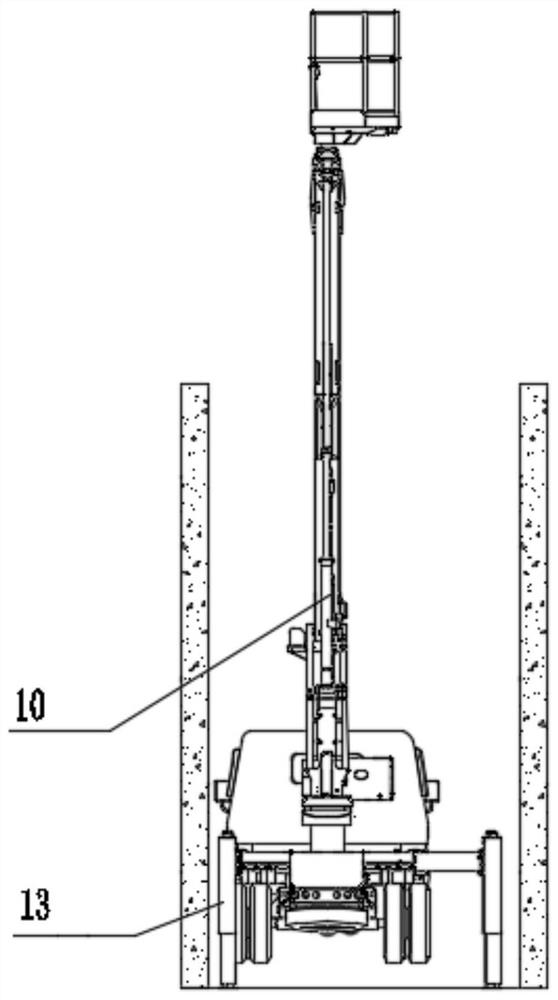

[0060] The embodiment of the present application provides a double-rotating device for a vehicle-mounted aerial work platform, including a double-rotating body 17, which is arranged between the base 32 of the vehicle-mounted aerial work platform and the working top 10, so that both the double-rotating body 17 and the working top can be Turn at the same time.

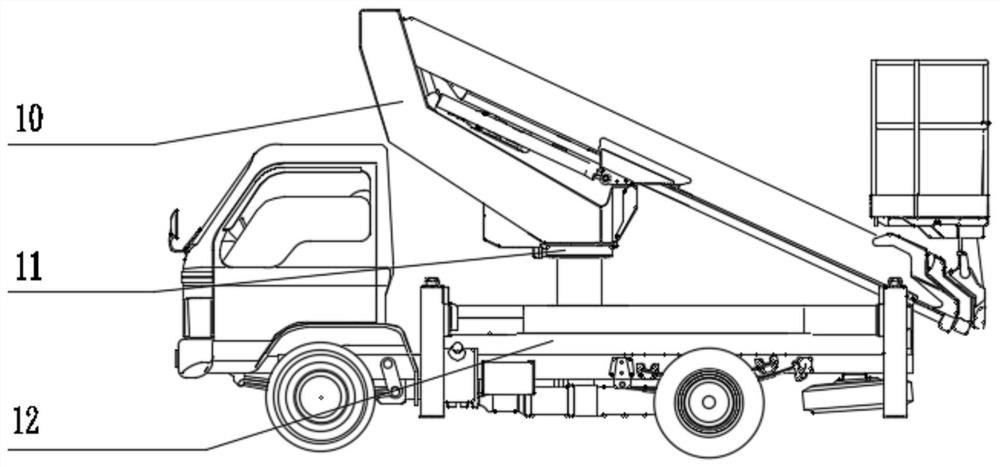

[0061] Existing vehicle-mounted high-altitude vehicle comprises base modification assembly 12, center rotation 11 and work tops 10, such as figure 1 As shown, the work top 10 can only be rotated, so that the left edge of the work top 10 will partially exceed the left edge of the car body 13 during work, such as figure 2 shown.

[0062] And when the double-rotating body 17 of the present application rotates clockwise, the work top 10 rotates counterclockwise to the side position direction, and the position that needs to work can be reached by adjusting the telescopic arm, as image 3 As shown, the edge of the side of t...

Embodiment 2

[0067] On the basis of Example 1, such as Figure 10 As shown, it is a schematic structural diagram of another double-slewing device for vehicle-mounted aerial work platforms provided by the embodiment of the present application. The second transmission device in the device can adopt gear transmission, specifically including the first gear 19, which is meshed in sequence, The second gear 20 and the third gear 21 , the first gear 19 is fixedly connected to the base 32 , the second gear 20 is connected to the double-rotating body 17 , and the third gear 21 is fixedly connected to the work top 10 .

[0068] Such as Figure 11 shown, for Figure 10 Schematic diagram of the top view structure of the middle double rotary device. When the double rotary body 17 rotates, the second gear 20 drives the third gear 21 to rotate in the opposite direction relative to the double rotary body 17. Specifically, the second gear 20 is a transmission gear, and the first worm gear When the compone...

Embodiment 3

[0070] The embodiment of the present application provides another double-slewing device in which the first power transmission device and the second transmission device are linked and driven, such as Figure 12 As shown, it is a schematic structural diagram of another double-rotation device for vehicle-mounted aerial work platforms provided by the embodiment of the present application. The first transmission device includes a gear column assembly, and the gear column assembly is connected with the double-rotation body 17 to drive the double-rotation body 17 rotations; specifically, the gear column assembly includes a first gear column 22 and a second gear column 23 that mesh with each other, the second gear column 23 is fixedly connected with the base 32, the first gear column 22 is arranged on the second gear column 23 and Engaging with the second gear column 23, the first gear column 22 is connected with a driving device such as a rotary motor system 26, and the first gear col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com