Power split hybrid power coupling system and vehicle

A hybrid power and coupling system technology, applied in the direction of hybrid vehicles, motor vehicles, power plants, etc., can solve the problems of insufficient power and economy, and achieve the effect of optimizing the working area, reducing the number of parts, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

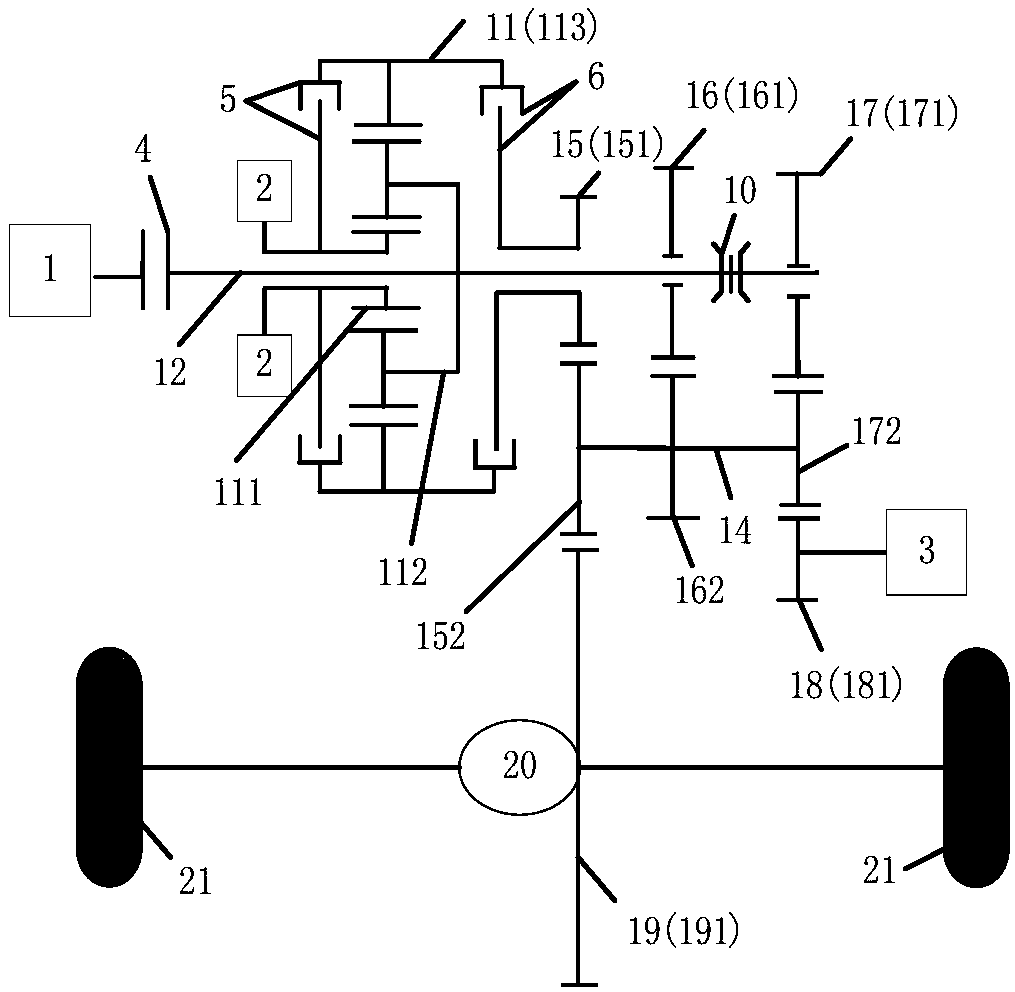

Embodiment 1

[0108] When the second clutch 5, the third clutch 6 and the shifter are provided, the power split hybrid coupling system has a single-motor pure electric mode and a dual-motor pure electric drive mode (with two gears: the second dual-motor pure electric mode and the second Three dual-motor pure electric mode), hybrid drive mode (with E-CVT mode-the first hybrid drive mode, and two gears: the third hybrid drive mode and the fourth hybrid drive mode), engine direct drive mode (with two gears: Five working modes including the second engine direct drive mode and the third engine direct drive mode) and range-extending mode;

[0109] Among them, the aforementioned five working modes are represented in Table 1, and C1, C2, C3, and S in Table 1 represent the first clutch 4, the second clutch 5, the third clutch 6 and the shifter respectively.

[0110] Table 1

[0111]

[0112] (1) Single motor pure electric mode

[0113] Disconnect the second clutch 5, disconnect the third clutch...

Embodiment 2

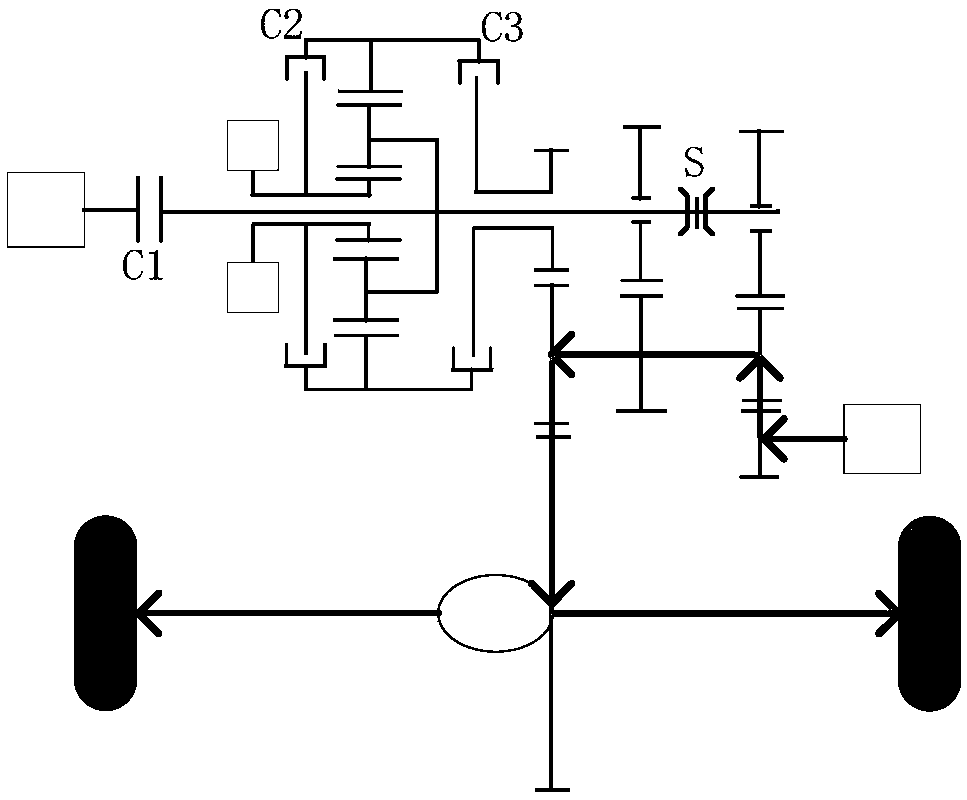

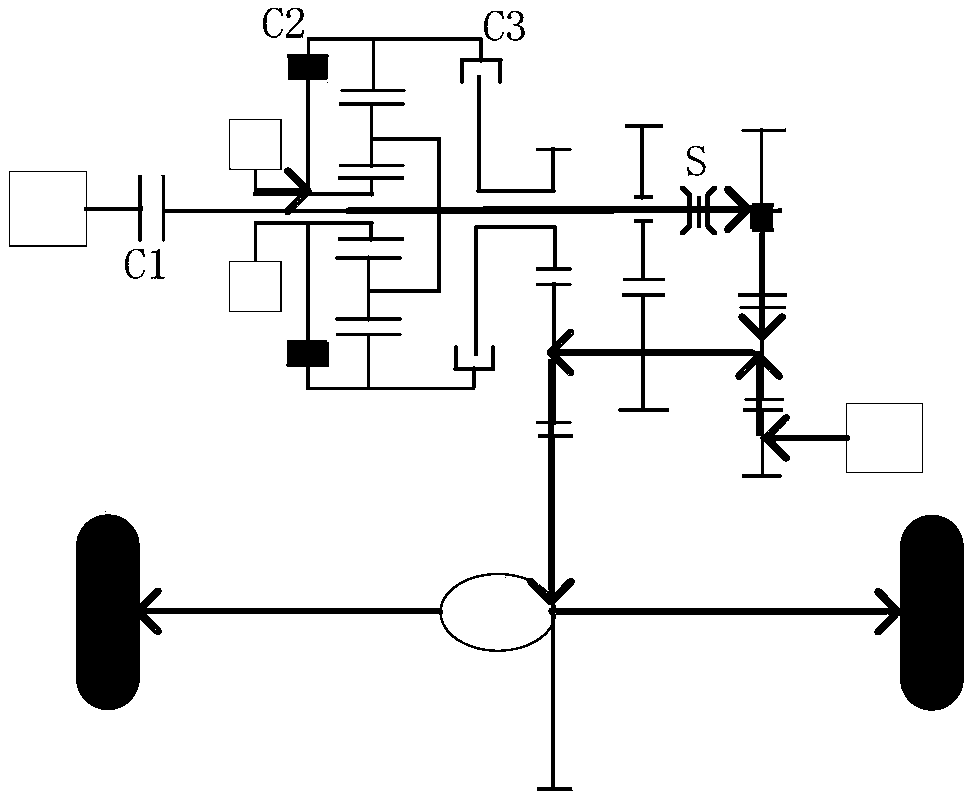

[0136] When the second clutch 5, the third clutch 6 and the synchronizer 10 are provided, the power-split hybrid coupling system has a single-motor pure electric mode and a dual-motor pure electric drive mode (with three gears: the first dual-motor pure electric mode, the second The second dual-motor pure electric mode and the third dual-motor pure electric mode), hybrid drive mode (with E-CVT mode-the first hybrid drive mode, and the third gear: the second hybrid drive mode, the third hybrid drive mode and the fourth Hybrid drive mode), engine direct drive mode (with three gears: the first engine direct drive mode, the second engine direct drive mode and the third engine direct drive mode) and the extended range mode and other five working modes;

[0137] Among them, the aforementioned five working modes are reflected in Table 2, and Table 2 and Figure 2 to Figure 13 C1, C2, C3 and S (S2, S3) in the formula respectively represent the first clutch 4, the second clutch 5, the ...

Embodiment 3

[0206] When the second clutch 5, the third clutch 6, the fourth clutch 7 and the fifth clutch 8 are provided, the power split hybrid power coupling system has a single-motor pure electric mode and a double-motor pure electric drive mode (with three gears: the first double Motor pure electric mode, second dual-motor pure electric mode and third dual-motor pure electric mode), hybrid drive mode (with E-CVT mode-first hybrid drive mode, and third gear: second hybrid drive mode, third Hybrid drive mode and fourth hybrid drive mode), engine direct drive mode (with three gears: the first engine direct drive mode, the second engine direct drive mode and the third engine direct drive mode) and the extended range mode. ;

[0207] Among them, the aforementioned five working modes are reflected in Table 3, and Table 3 and Figure 15 to Figure 26 C1, C2, C3, C4, and C5 represent the first clutch 4, the second clutch 5, the third clutch 6, the fourth clutch 7, and the fifth clutch 8, resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com