Purification method for deep dehydration and impurity removal of olefin by full-temperature range adsorptive extraction

A deep dehydration, full temperature range technology, used in hydrocarbon oil dehydration/demulsification, extraction purification/separation, adsorption purification/separation, etc., can solve the prominent contradiction between adsorption and desorption, short service life of adsorbent, and troublesome regeneration gas treatment and other problems, to achieve the effect of reducing the co-adsorption phenomenon, preventing the self-polymerization of olefins, and expanding the room.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

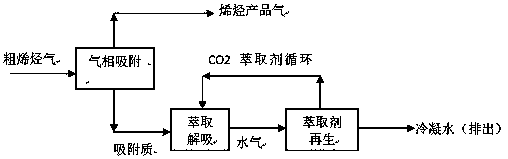

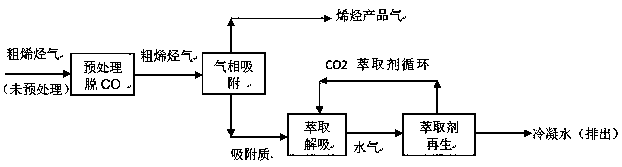

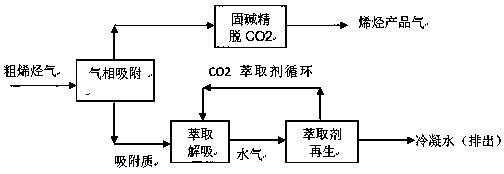

[0037] Such as figure 1 and figure 2 As shown, a purification method for deep dehydration and impurity removal of full-temperature adsorption extraction of olefins includes the following steps:

[0038] (1) Gas phase adsorption process, crude olefin raw material gas after the pretreatment unit removes alkyne, oxygen (O2), carbon monoxide (CO), arsenic / mercury and acid gas, the temperature is 60~80℃, 1.0~2.0MPa, It enters an adsorption tower and is adsorbed at an adsorption temperature of 60~80°C and an adsorption pressure of 1.0~2.0MPa. Water and trace impurities are used as adsorbates, which are adsorbed by the adsorbent loaded in the adsorption tower. After the adsorption is saturated, it enters the lower One-step process, extraction and desorption process; olefins are not adsorbed and flow out from the top of the adsorption tower to obtain olefin products with an olefin content greater than 99.9~99.99% (v / v); After extraction and desorption, it enters the gas phase adsor...

Embodiment 2

[0046] On the basis of the purification method of full-temperature adsorption, extraction, deep dehydration and impurity removal of olefins described in Example 1, further optimization, the raw material gas of crude olefins comes from the coal gasification synthesis of methanol to olefins (MTO / MTP) process, wherein , The content of trace impurities such as oxygen-containing compounds such as methanol and dimethyl ether and water is relatively high, which is 0.1~1.0% (v / v), and the temperature and pressure of the raw material gas remain unchanged. Due to the increase of water and impurity content in the feed gas, at first, it is necessary to increase the loading capacity of the adsorbent, and the loading capacity of the 13X type composite molecular sieve in this embodiment is about 20% more than that in Example 1; secondly, the extraction agent CCO The circulation The consumption needs to increase; the 3rd, the depressurization in the extractant regeneration process is lowered t...

Embodiment 3

[0048] On the basis of the purification method of a kind of olefin full-temperature adsorption extraction deep dehydration and impurity removal described in Example 1, it is further optimized, the composition of the raw material gas remains unchanged, and the scale of raw material feeding reaches more than 10 standard cubic meters per hour. The temperature is 100~120°C, the pressure is 2.0~3.0MPa, and it directly enters the gas phase adsorption process. The gas phase adsorption is carried out in a system consisting of an operating temperature of 100~120°C, an adsorption pressure of 2.0~3.0MPa, and 4 adsorption towers. The 4 adsorption towers are connected in parallel 2-2 respectively, 2 adsorption towers absorb, and the other 2 adsorption towers extract and desorb, and the 2 groups of adsorption towers operate alternately to ensure the continuous entry of raw materials. In this embodiment, the temperature and processing capacity of the raw material gas have been increased and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com