Plasma-sprayed ceramic layer on neodymium-iron-boron permanent magnet material surface and preparation method of plasma-sprayed ceramic layer

A technology of surface plasma and permanent magnet materials, applied in metal material coating process, permanent magnet manufacturing, coating, etc., can solve problems such as low film formation rate, battery intergranular corrosion, protective layer foaming, etc., and achieve rapid The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

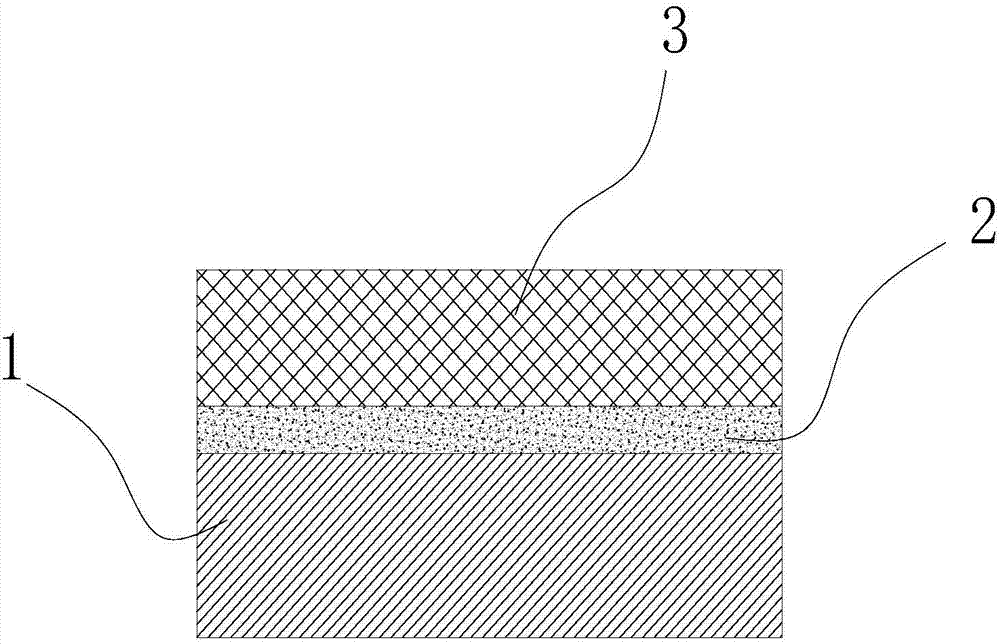

[0037] The present invention also provides a method for preparing a plasma-sprayed ceramic layer on the surface of an NdFeB permanent magnet material comprising the following steps:

[0038] Step 1, pretreating the NdFeB substrate 1: shaping the substrate, sandblasting to remove attachments on the surface of the substrate, and cleaning the roughened surface with high-pressure dry gas;

[0039] Step 2, preheating the pretreated NdFeB substrate 1 in a vacuum environment, the preheating temperature is 90-125° C., and the time is 8-10 minutes;

[0040] Step 3, preparing a Ni-Al alloy layer transition layer 2 on the surface of the preheated NdFeB substrate by plasma spraying;

[0041] Step 4, prepare a layer of Al on the surface of the transition layer 2 of the Ni-Al alloy layer by plasma spraying 2 o 3 -TiO 2 Composite ceramic layer 3.

[0042] In step one, the NdFeB substrate 1 is pretreated: the substrate is shaped, the attachments on the substrate surface are removed by san...

Embodiment 1

[0052] The preparation of the plasma-sprayed ceramic layer on the surface of the above-mentioned NdFeB permanent magnet material comprises the following steps:

[0053] Step 1: chamfering, degreasing and sandblasting the NdFeB substrate 1 until the gray-white fresh surface of the NdFeB substrate is exposed. The sandblasting parameters are: the sand material is brown corundum, the particle size is 22#, the compressed dry air pressure is 0.5MPa, the sandblasting distance is 65mm, and the sandblasting angle is 70°. The roughened surface is then surface-cleaned with high-pressure dry gas to prevent sand or loose NdFeB particles from being embedded in the matrix.

[0054] Step 2, heat the pretreated NdFeB substrate 1 in a vacuum environment at 90° C. for 10 minutes.

[0055] Step 3, using plasma spraying technology to prepare a layer of 26 μm self-adhesive primer layer (Ni-Al alloy layer transition layer 2) on the surface of the preheated NdFeB substrate 1 . Spraying parameters a...

Embodiment 2

[0059] The preparation of the plasma-sprayed ceramic layer on the surface of the above-mentioned NdFeB permanent magnet material comprises the following steps:

[0060] Step 1: chamfering, degreasing and sandblasting the NdFeB substrate 1 until the gray-white fresh surface of the NdFeB substrate is exposed. The sandblasting parameters are: the sand material is brown corundum, the particle size is 22#, the compressed dry air pressure is 0.5MPa, the sandblasting distance is 65mm, and the sandblasting angle is 70°. The roughened surface is then surface-cleaned with high-pressure dry gas to prevent sand or loose NdFeB particles from being embedded in the matrix.

[0061] Step 2, heat the pretreated NdFeB substrate 1 in a vacuum environment at 110° C. for 9 minutes.

[0062] Step 3, using plasma spraying technology to prepare a layer of 28 μm self-adhesive primer layer (Ni-Al alloy layer transition layer 2) on the surface of the preheated NdFeB substrate 1 . Spraying parameters a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com