High-purity compact magnesium oxide target material and preparation method thereof

A magnesium oxide, dense technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of low productivity and incapable of mass production, and achieve low production cost, fine and uniform grain size, high purity uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

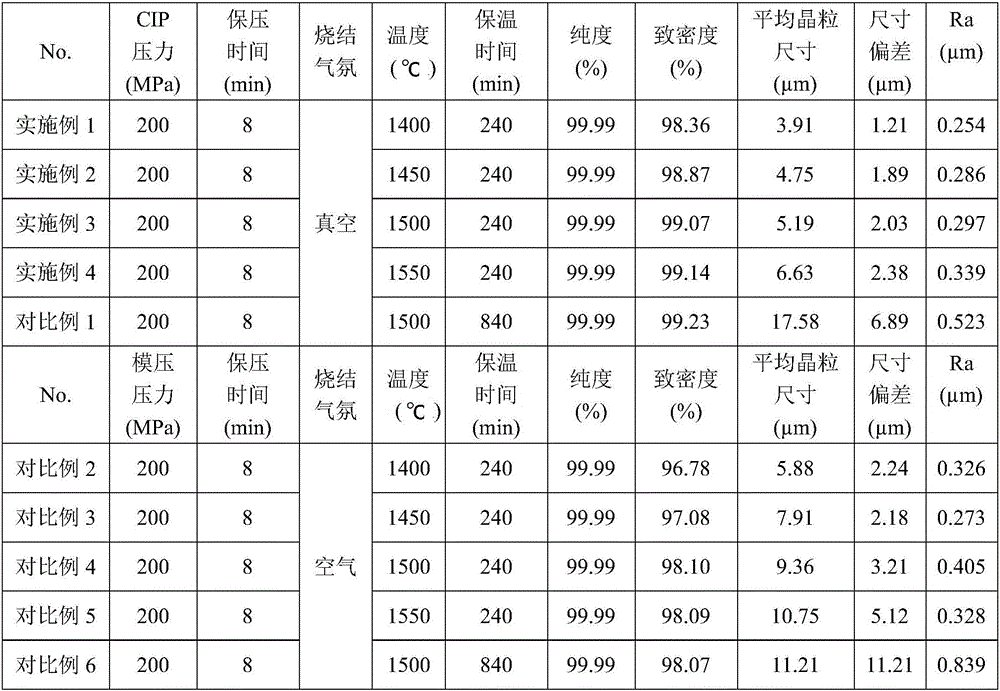

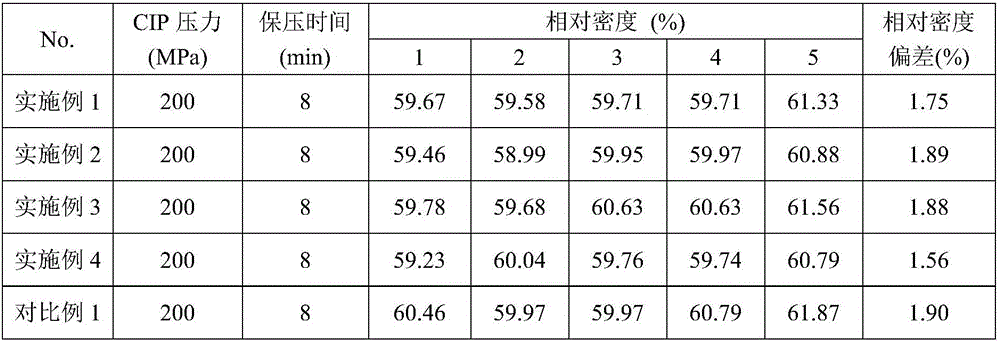

[0022] Example 1: Preparation of a high-purity dense magnesium oxide target

[0023] (1) Add zirconia balls to the original MgO powder with a purity of more than 99.99%, an average particle size of about 100nm, and a total content of impurity elements below 100ppm. 1:1, put it in a polyurethane ball mill tank, the speed is 200r / min, and grind for 16h to obtain MgO powder with good dispersibility, then take out the obtained MgO powder and pass it through a 200-mesh graduated sieve;

[0024] (2) Carry out cold isostatic pressing (CIP) molding to the powder after sieving in step (1), the molding pressure is 200MPa, and the holding time is 8min, obtains the MgO compact with certain strength;

[0025] (3) After calcining the MgO compact in step (2) at 500°C for 4 hours, heat up to 1000°C at a rate of 5°C / min and start vacuuming, and make the vacuum degree reach 0.85 Pa within 10 minutes; The heating rate is heated to the sintering temperature of 1400°C, and the sintering holding t...

Embodiment 2

[0028] The preparation method of the high-purity dense MgO target is the same as in Example 1, except that the vacuum sintering temperature is 1450°C.

Embodiment 3

[0030] The preparation method of the high-purity dense MgO target is the same as in Example 1, except that the vacuum sintering temperature is 1500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com