Method for improving corrosion resistance of 5083 aluminum alloy plate

A technology of aluminum alloy sheet and corrosion resistance, applied in the field of aluminum alloy processing, can solve the problems of high energy consumption, metal oxidation loss, long time, etc., and achieve the effects of improving economic benefits, reducing dislocation density, and enhancing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

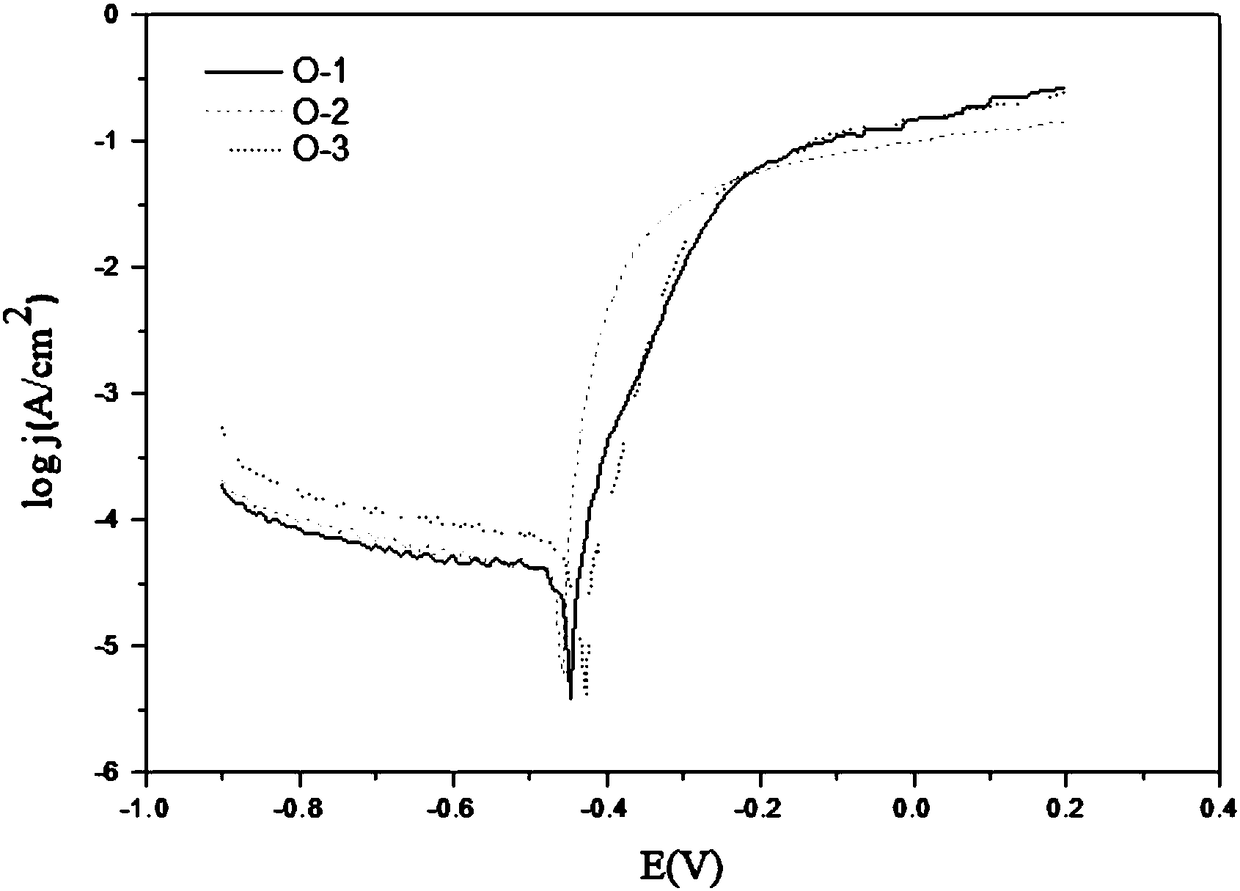

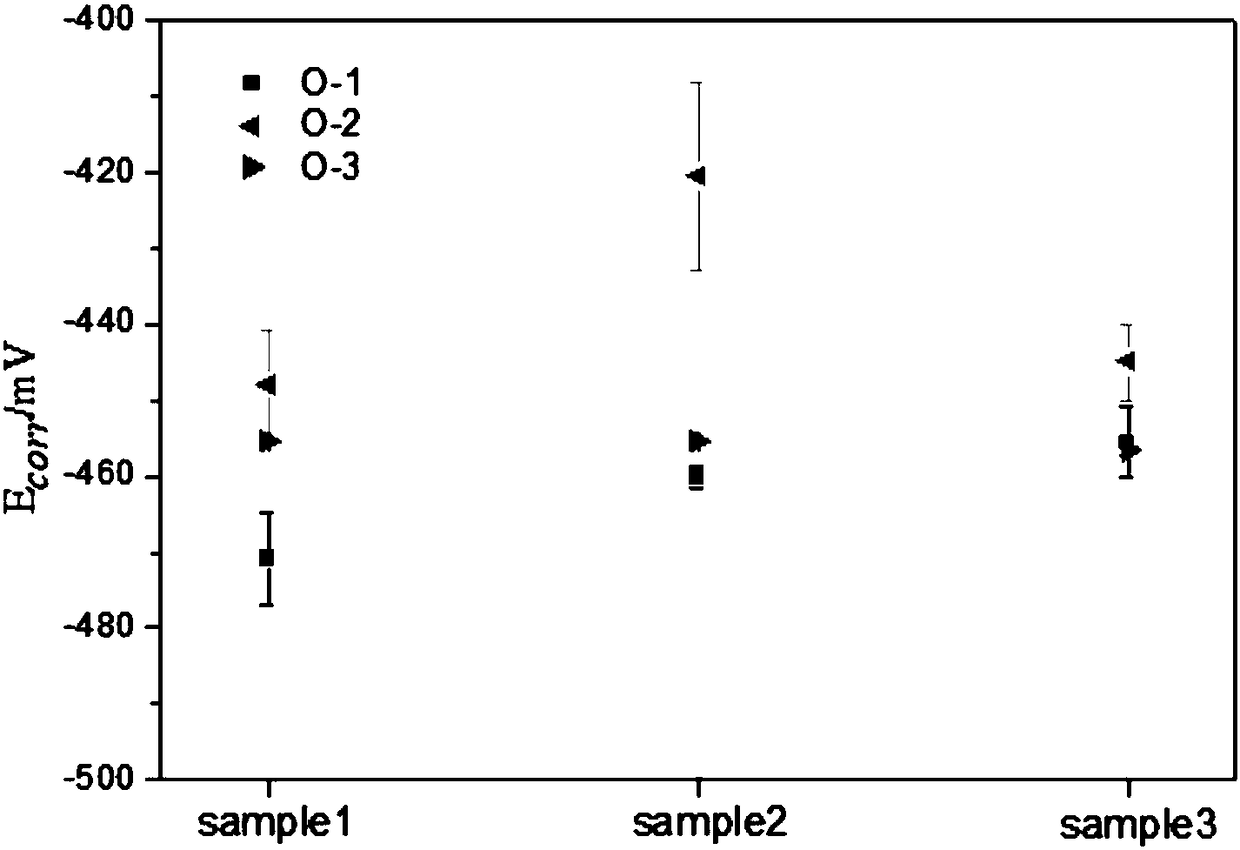

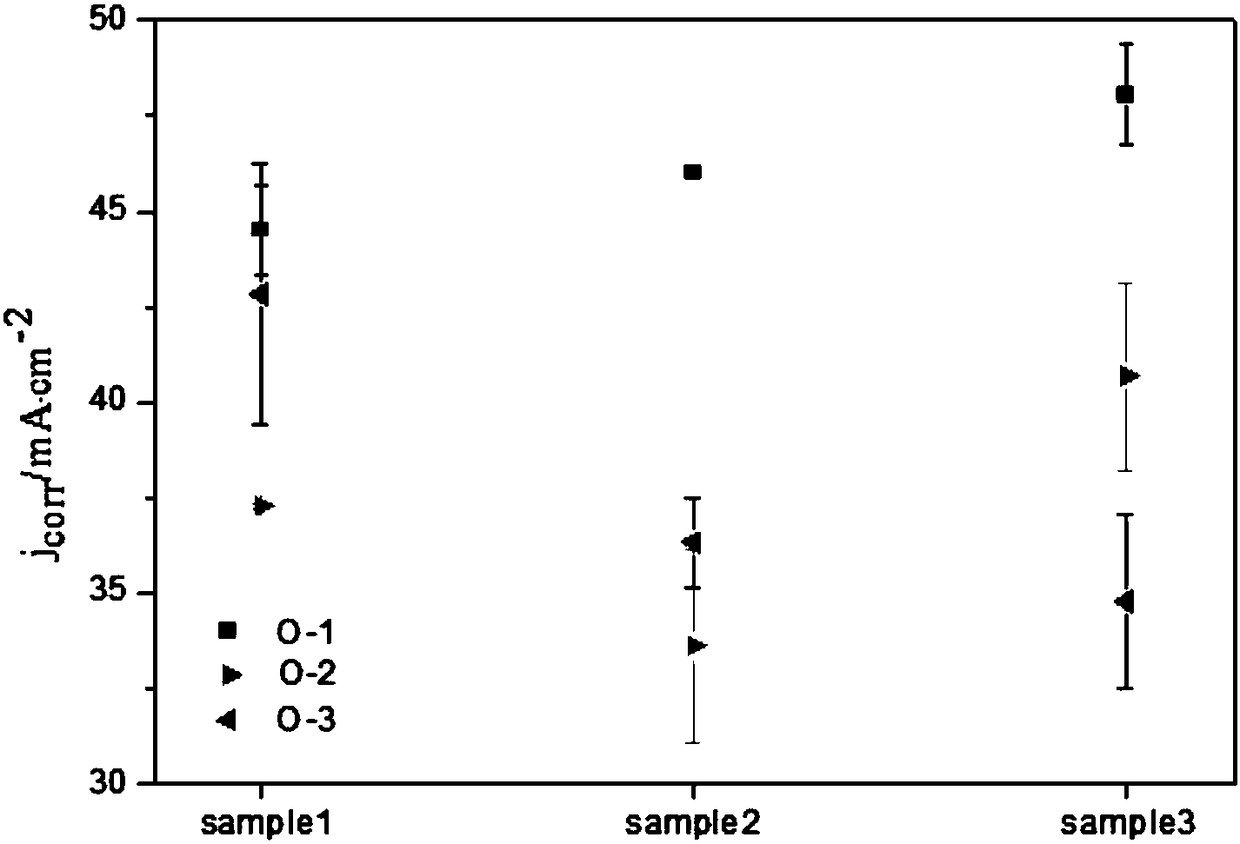

Embodiment 1

[0033] Cut the ingot into blocks with a thickness of 510mm; then heat the ingot at 500°C for 4 hours for homogenization; hot-roll the ingot at 510°C for 3 passes to 8mm, and ensure the temperature during the entire thermal processing process Higher than 360°C; carry out five passes of cold rolling with low deformation, the cold rolling deformation is 45%-55%, and the thickness of the aluminum plate after rolling is 4mm; after cold rolling, the material is annealed at 500°C for 3 hours to obtain High corrosion resistance 5083 aluminum alloy O-state plate.

Embodiment 2

[0035] Cut the ingot into blocks with a thickness of 520mm; then heat the ingot at 530°C for 6 hours for homogenization; hot-roll the ingot at 510°C for 4 passes to 9mm, and ensure the temperature during the entire thermal processing process Higher than 360°C; carry out five passes of cold rolling with low deformation, the cold rolling deformation is 45%-55%, and the thickness of the aluminum plate after rolling is 4mm; after cold rolling, the material is annealed at 510°C for 3 hours to obtain High corrosion resistance 5083 aluminum alloy O-state plate.

Embodiment 3

[0037] Cut the ingot into blocks with a thickness of 530mm; then heat the ingot at 560°C for 8 hours for homogenization; hot-roll the ingot at 510°C for 3 passes to 10mm, and ensure the temperature during the entire hot processing process Higher than 360°C; five passes of cold rolling with low deformation, the cold rolling deformation is 45%-55%, and the thickness of the rolled aluminum plate is 4mm; after cold rolling, the material is annealed at 520°C for 3 hours to obtain High corrosion resistance 5083 aluminum alloy O-state plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com