Patents

Literature

32 results about "5083 aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

5083 aluminium alloy is an aluminium alloy with magnesium and traces of manganese and chromium. It is highly resistant to attack by seawater and industrial chemicals. Alloy 5083 retains exceptional strength after welding. It has the highest strength of the non-heat treatable alloys with a Ultimate Tensile Strength of 317 MPa or 46000 psi and a Tensile Yield Strength of 228 MPa or 33000 psi. It is not recommended for use in temperatures in excess of 65 °C.

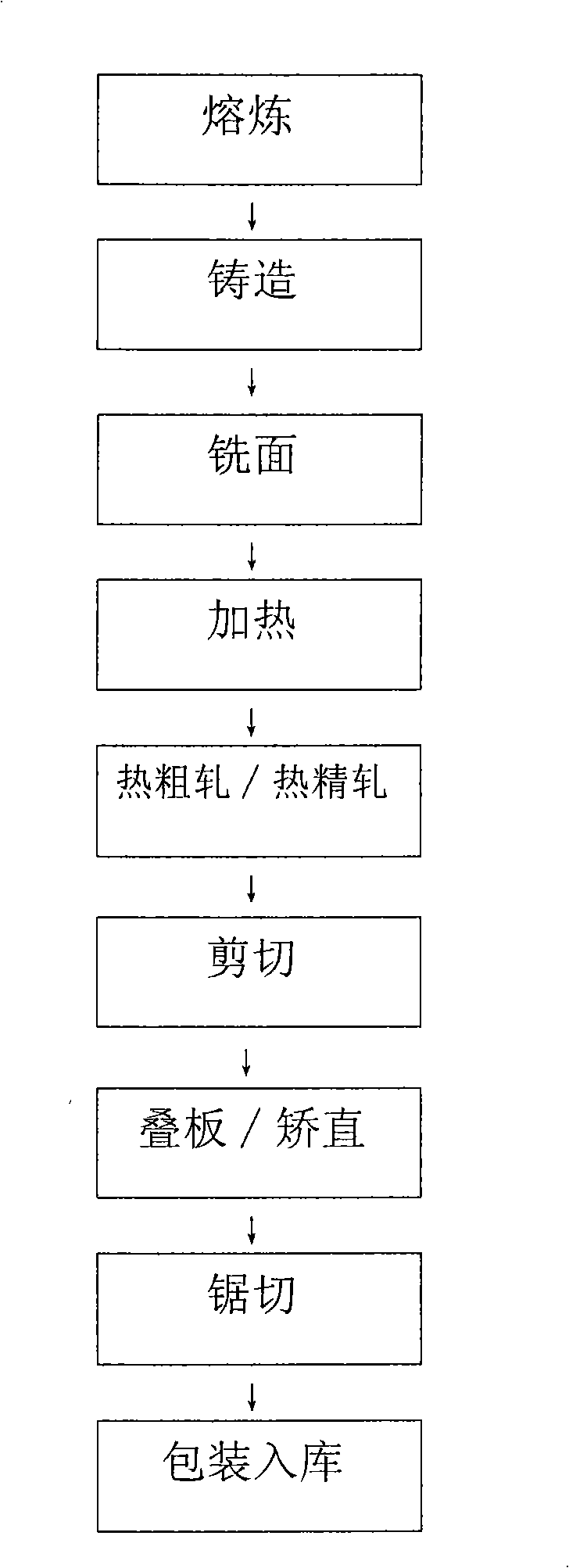

Production process of aluminum alloy hot rolling medium plate

The invention relates to a production process for hot-rolling medium plate by adopting aluminum alloy. The aluminum alloy materials are as follows according to the weight percentage: Fe is less than or equal to 0.35, Si is less than or equal to 0.25, Cu is less than or equal to 0.10, Mn is 0.70-0.90, Mg is 4.50-4.80, Cr is 0.10-0.20, Zn is less than or equal to 0.20, Ti is less than or equal to 0.10, other impurities are less than or equal to 0.15 in total, Na is less than or equal to 5pp,, Ca is less than or equal to 5ppm, and Al is the balance; and the sum of all components is 100. The main process comprises the following steps of melting, milling, heating, hot rough rolling or fine rolling. The invention adopts a soaking process during the processing of the aluminum alloy, mainly adopts two measures of milling sides and rolling the sides to solve the edge crack problem, controls the thickness difference and the plate form as well as oil spot and scuffing, and develops the production process for hot-rolling the medium plate by adopting the 5083 aluminum alloy.

Owner:中铝河南铝业有限公司

Manufacturing method of aluminum magnesium alloy

The invention relates to a manufacturing method of plates and particularly relates to a manufacturing method of an aluminum magnesium alloy thick plate, which can be used for solving the problems that a process for processing a plate made of aluminum alloy 5083 which is in the H321 state and is 12.5-75mm in thickness, and the aluminum alloy 5083 being in the H321 state and being 12.5-75mm in thickness, which is prepared by the existing casting method, is poor in strength and percentage elongation. The method comprises the steps of firstly, melting; secondly, casting; thirdly, evening fire; fourthly, rolling and fifthly, annealing. According to the method disclosed by the invention, the blank of the manufacturing method of an alloy thick plate 5083H321 being 12.5-75mm in thickness is filled; and according to the method, a reasonable technological process is selected, so that the yield strength of the plate is 275-293MPa, the tensile strength of the plate is 350-365MPa, and the percentage elongation of the plate is 10.8-11.9%. The aluminum magnesium alloy thick plate manufactured by the method can be used for the industrial fields of armored vehicles, ships, automobile industries, and canning.

Owner:NORTHEAST LIGHT ALLOY CO LTD

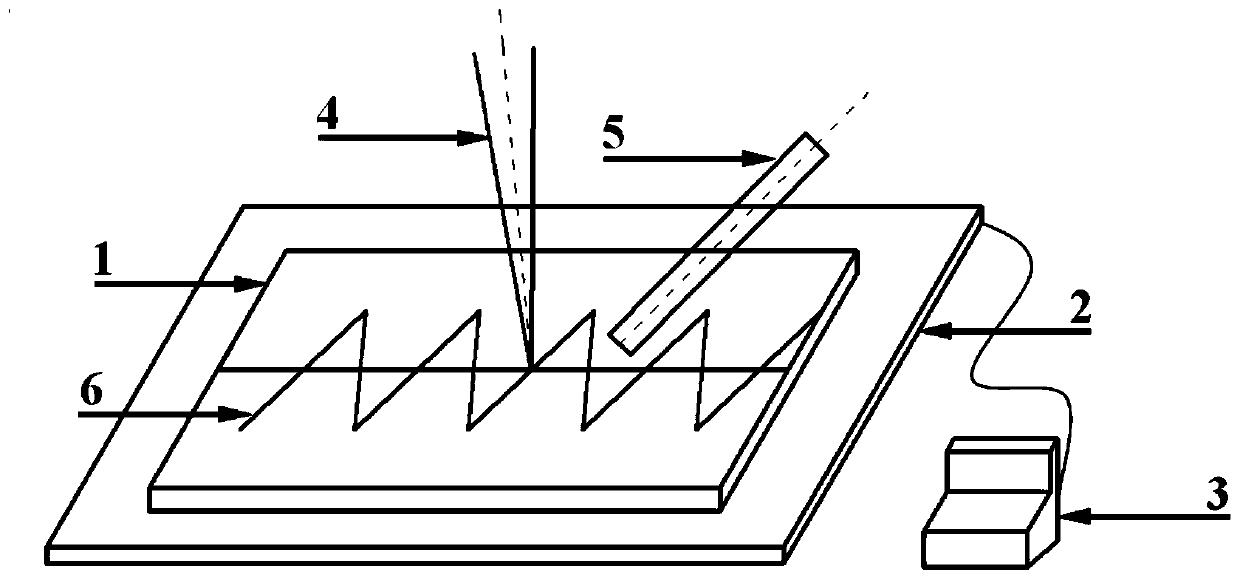

5083 aluminum alloy laser welding process method

ActiveCN109759699AReduce temperature gradientCrack suppressionLaser beam welding apparatusProduction rateHeat-affected zone

The invention discloses a 5083 aluminum alloy laser welding process method, and belongs to the technical field of welding. According to the method, pulse laser is used as a heat source, welding of the5083 aluminum alloy is realized by adopting a mode that laser is symmetrically swing along the two sides of a weld joint. The method comprises the following steps of firstly, removing oxide films onthe two sides of the 5083 aluminum alloy weld joint before welding; secondly, arranging a pulsed laser and a protective gas nozzle above the 5083 aluminum alloy, wherein the protective gas nozzle is used for blowing inert gas to the front side of the weld joint, and preheating the 5083 aluminum alloy by adopting a preheating device; finally adjusting the average power of the laser, the pulse frequency, the swing amplitude and the swing frequency to achieve 5083 aluminum alloy welding after heating to a preset temperature. According to the 5083 aluminum alloy laser welding process method, the conditions of low production rate and large heat affected area of a traditional aluminum alloy processing method can be improved, and the defects that a continuous laser processing aluminum alloy is large in heat input and poor in forming quality can be overcome. The method has the advantages that the defects of pores, cracks and the like can be effectively improved.

Owner:DALIAN UNIV OF TECH

Medium-temperature aluminum-based foil strap brazing material and preparation method thereof

InactiveCN103008909AGood brazing processSimple preparation processWelding/cutting media/materialsSoldering mediaTorchShear strength

The invention discloses a medium-temperature aluminum-based foil strap brazing material and a preparation method thereof. The brazing material comprises the following components by mass percentage: 6.5-9.6 of Si, 16.0-20.0 of Cu, 8.0-10.0 of Ge, 2.0-6.0 of Zn, 0.5-1.0 of La and the balance of Al. The brazing material is prepared by rapid cooling of a melt, the melting point is lower than 495 DEG C, a foil strap is suitable for brazing of aluminum alloy with the solidus temperature higher than 520 DEG C, torch brazing, induction brazing, furnace brazing, gas protection brazing and the like can be performed, the brazing temperature is 510-520 DEG C, and the brazing material can be applied in brazing of precision components made of aluminum alloy. When the brazing material is used with 5083 aluminum alloy for QJ201 brazing, the shear strength of a brazed joint is higher than 80MPa.

Owner:ZHEJIANG UNIV +1

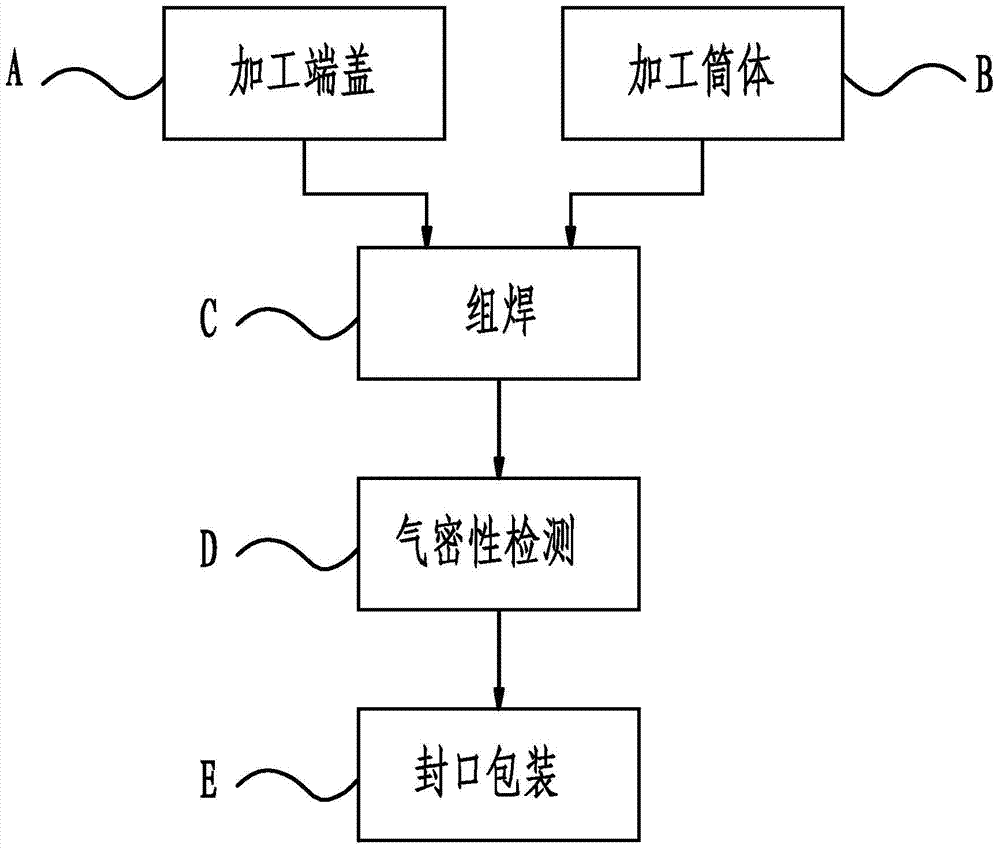

Method for machining aluminum alloy air tank

ActiveCN103612074AMeeting high standards of performanceMeet performance requirementsArc welding apparatusDomestic vesselsAir tightnessMachining

The invention discloses a method for machining an aluminum alloy air tank, and relates to the method for machining an automobile air tank. According to the method, aluminum alloy plates with marks being 5083 and the thicknesses being 2.8-3.0mm are respectively used for blanking and machining of end covers and a tank body, then, the end covers and the tank body are installed and welded, seal packaging is conducted after air tightness detection is qualified, and the surface of each adopted aluminum alloy plate is covered with a thin film in the blanking process. The method includes the following steps of A, end cover machining, B, tank body machining, C, installing and welding, wherein the end covers are welded to the end openings in the two ends of the tank body respectively, D, air tightness detection and E, seal packaging. By means of the method for machining the aluminum alloy air tank, the high-level performance requirement can be met, the high-level appearance requirement can also be met, and the method has the advantages of being high in welding quality, convenient to operate, capable of lowering labor intensity, saving in energy, environmentally friendly, long in service life, low in cost, good in development prospect and suitable for popularization and application.

Owner:LIUZHOU LIUHE FANGSHENG MACHINERY

Method for manufacturing large-sized 5083 aluminum alloy slab ingot

The invention discloses a method for manufacturing a large-sized 5083 aluminum alloy slab ingot, and relates to the technical field of aluminum alloy manufacturing. The method includes the steps that raw and auxiliary materials are prepared; the temperature of melt in the smelting process is 700-750 DEG C, the temperature of a converter is 740+ / -5 DEG C, the refining temperature is 720-730 DEG C, and refining gas is nitrogen-chlorine mixed gas; standing is conducted for 30 minutes after refining, and the temperature of a maintaining furnace is 705-715 DEG C; Al5Ti0.2B titanium wires are used for conducting grain refinement, and the additive quantity is 0.25%; chlorine-argon mixed gas with the flow being 4-5 m<3> / h is used for conducting on-line degassing; molten aluminum alloy is released into a distributing launder, and an automatic large-sized all-aluminum oil lubrication crystallizer is led in for casting; the casting temperature is 673+ / -5 DEG C, the automatic start filling time is 135 s, and the automatic oil lubrication pulse value is 5; and saw cutting and face milling are carried out. The method solves the problems that the production efficiency is low and the rate of finished products is also low when an existing aluminum alloy slab ingot is used for producing wide aluminum plates.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

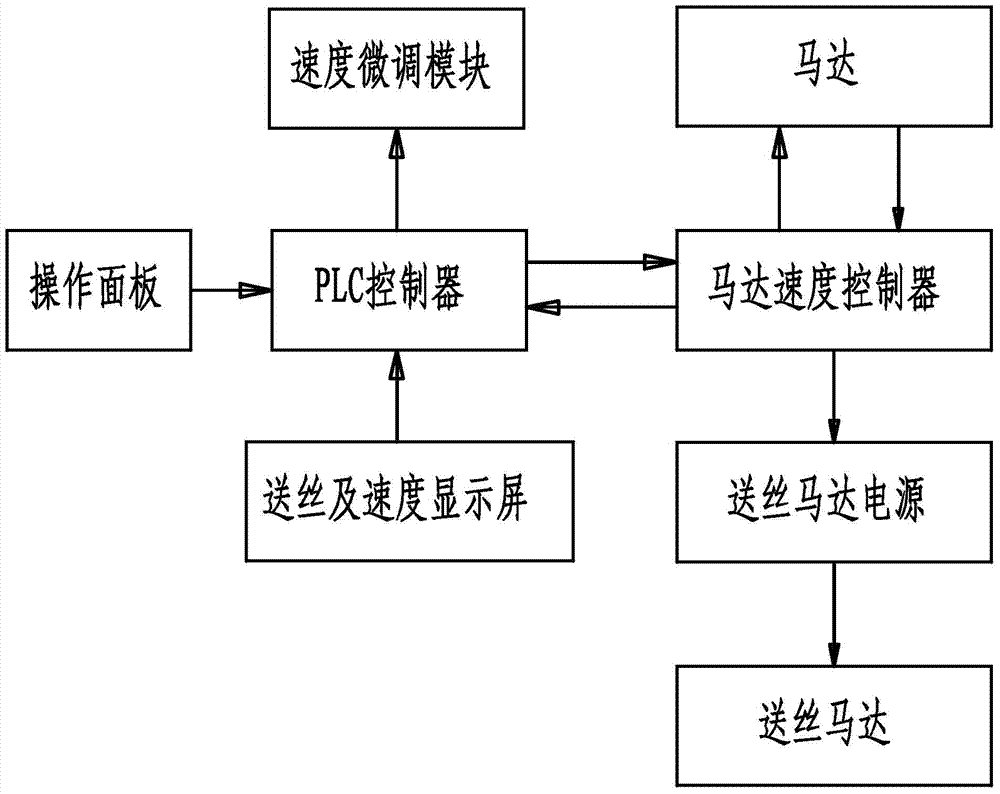

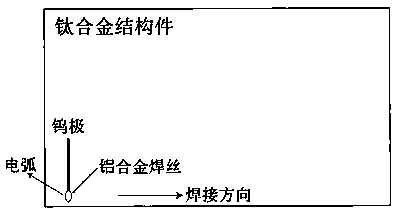

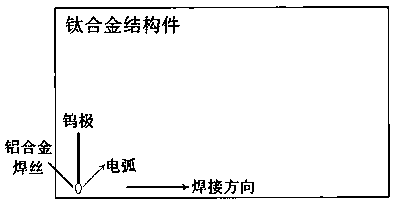

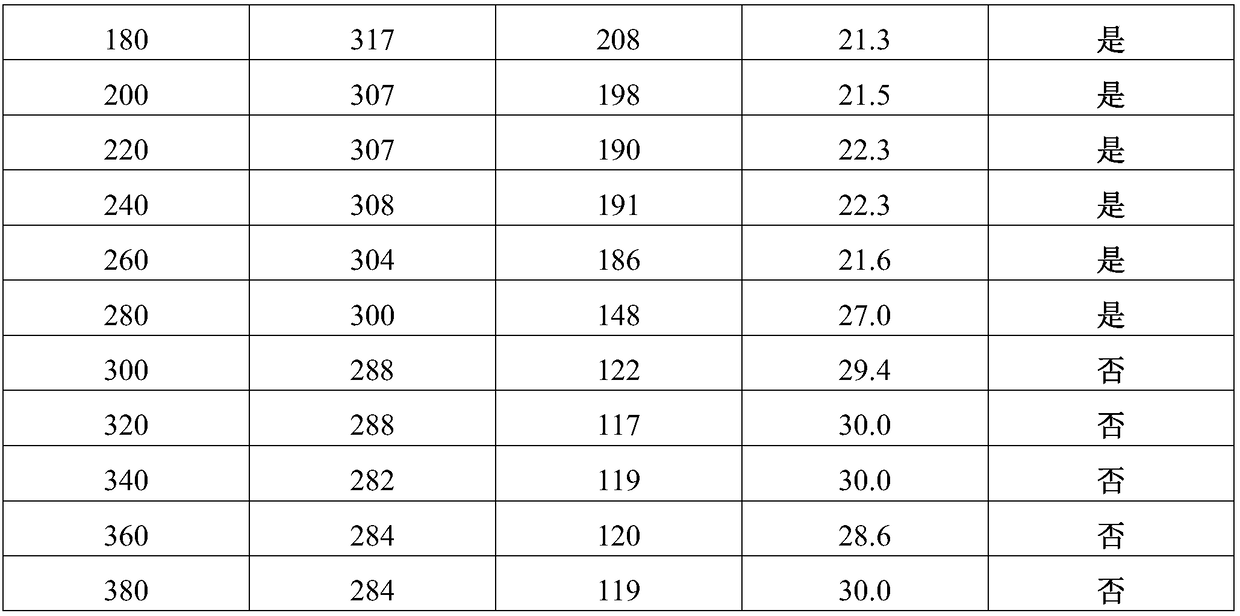

Arc added material manufacturing method of 5083 aluminum alloy/TC4 titanium alloy structures

InactiveCN109332860AAvoiding Difficulties in Structure PreparationReduce volume fractionWelding accessoriesManufacturing technologyTitanium

The invention discloses an arc added material manufacturing method of 5083 aluminum alloy / TC4 titanium alloy structures, and belongs to the technical field of arc added material manufacturing of dissimilar materials. The method is to realize connection between aluminum alloys and titanium alloys by using the arc added material manufacturing method on the surfaces of titanium alloy structures and to finish formation of aluminum alloy structures. According to the characteristics of large melting point difference between the aluminum alloys and the titanium alloys, tungsten electrode argon arcs are used as heat sources for heating aluminum alloy welding wires for fusion to connect with the titanium alloys; and then, the added material manufacturing method is used for preparing the aluminum alloy structures to finally form aluminum alloy / titanium alloy composite structures. The method realizes manufacturing of large or complicated aluminum alloy / titanium alloy structures, can improve the mechanical performances of joints, simplifies procedures, and realizes convenient, efficient and automatic connection of the aluminum alloys / titanium alloys. The method can effectively reduce the thickness of connecting interface intermetallic compound layers; the thickness of the aluminum alloy / titanium alloy connecting interface intermetallic compound layers is 2.25-3.5 microns; and the connecting strength of the joints can reach 171.6 MPa.

Owner:DALIAN UNIV OF TECH

Preparation process of aluminum alloy 5083 with high bending performance

InactiveCN109266881AReduce corrosionReduce riskFurnace typesHeat treatment furnacesRoom temperatureFree cooling

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a preparation process of aluminum alloy 5083 with high bending performance. The preparation process includes cutting and milling ingots of aluminum alloy 5083, sending the cut and milled ingots of aluminum alloy 5083 to a heating furnace, heating at the temperature of 54 DEG C for 6 hours, cooling to the temperature of 500 DEG C, holding the temperature for 2 hours, discharging and performing hot rolling until the thickness of the aluminum alloy sheets is 10.0mm under the finishing rolling temperatureof 320 DEG C, naturally cooling the hot-rolled aluminum alloy sheets to the room temperature, performing cold rolling until the thickness of the aluminum alloy sheets ranges from 3.0 to 8.0 mm with the cold rolling rate ranging from 20% to 70%, annealing at the temperature of 260-340 DEG C for 2 hours after cold rolling, straightening to obtain 5083-O type aluminum alloy sheets. The preparation method has the advantages simple processing and low energy consumption; the finished product has high bending processing performance and wide application range.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

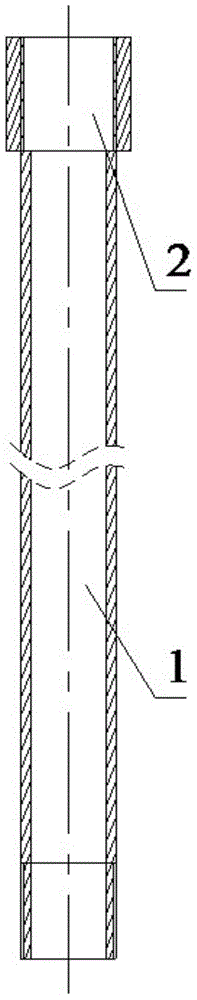

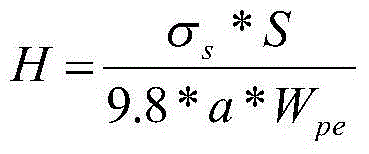

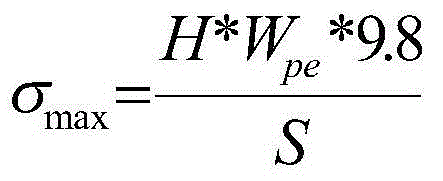

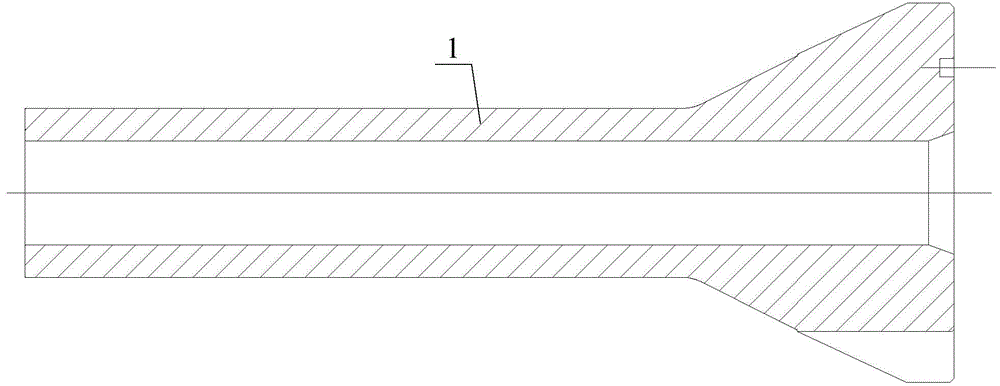

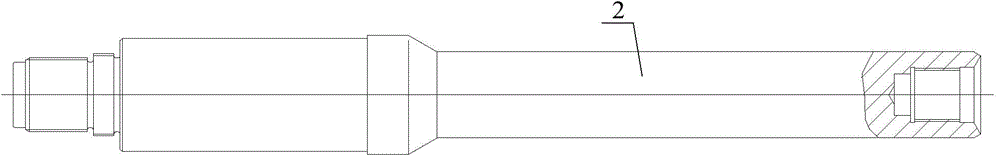

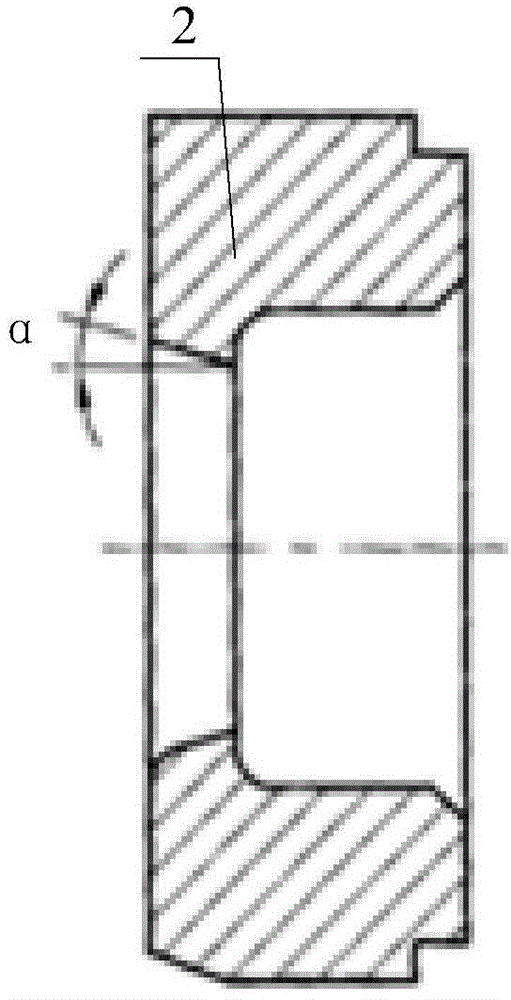

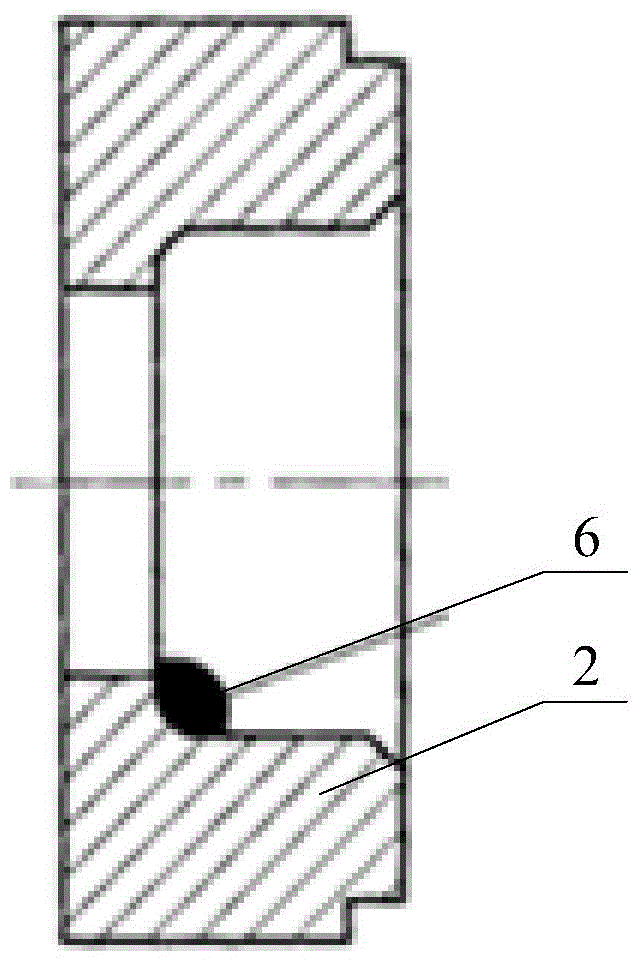

Minor-diameter water draining and gas producing pipeline column

ActiveCN104632091ALow costImprove liquid carrying capacityDrilling rodsDrilling casingsCarrying capacityCoiled tubing

The invention relates to a minor-diameter water draining and gas producing pipeline column. The pipeline column is composed of a seamless tube (1) and a connector (2). Materials used for the seamless tube (1) are divided into two kinds, one is 45 # carbon steel, and the other is 5083 aluminium alloy. When the well depth is equal or lesser than 3000 meters, the 45 # carbon steel seamless tube (1) and the connector (2) are adopted on the whole well section, and the mode of connecting a single rod is adopted; when the well depth is greater than 3000 meters, the compound mode is adopted by the pipeline column, the 45 # carbon steel seamless tube (1) and the connector (2) are adopted on the upper portion of a shaft; the 5083 aluminium alloy seamless tube (1) and the connector (2) are adopted on the lower portion of the shaft, the mode of connecting the single rod is adopted, an insulated joint is adopted on the transition part between the two kinds of oil pipes, and the galvanic corrosion is prevented from happening; the water draining and gas producing function of the pipeline column is equivalent to a coiled tubing, but the cost of the pipeline column is 40-50 percent of the coiled tubing. By narrowing the gas producing channel of a gas well, the liquid carrying capacity of the gas well is improved, so that water is timely discharged from the shaft, the gas well productivity is recovered, and the production period is prolonged.

Owner:PETROCHINA CO LTD

Machining process of 5083 aluminum alloy profile for ship

The invention belongs to the technical field of aluminum alloys and relates to a machining process of a 5083 aluminum alloy profile for a ship. By directly performing manual annealing treatment on thealuminum alloy profile after online extruding is completed, the annealing regime is (320-350)DEG Cx(3-5)h, a material is made to be converted into an annealing structure from an extruding deforming structure, the surface hardness of a product is decreased to 26 HRB or so from 30 HRB under the extruding state, by means of treatment of the early stage annealing process, the hardness of the materialis made lowered, the machinable or stretchable performance of the later period is made improved, and the material becomes softer; according to the stretching process after annealing, when the extruded profile length is 25000 mm, the displacement range of the stretching stroke of a stretching machine is set as 1250-2250 mm, the stretching speed range is set as 40-20 mm / s, the stretching deformingrate is 5-9%, after the extruded 5083 aluminum alloy profile is subjected to stretching machining, according to the mechanical performance of the 5083 aluminum alloy profile, the yielding strength islarger than and equal to 215 MPa, the tensile strength is larger than and equal to 300 MPa, the percentage elongation is larger than or equal to 10%, and the mechanical performance of the 5083 aluminum alloy profile completely meets the performance requirement under the 5083-H116 state.

Owner:CHINA ZHONGWANG

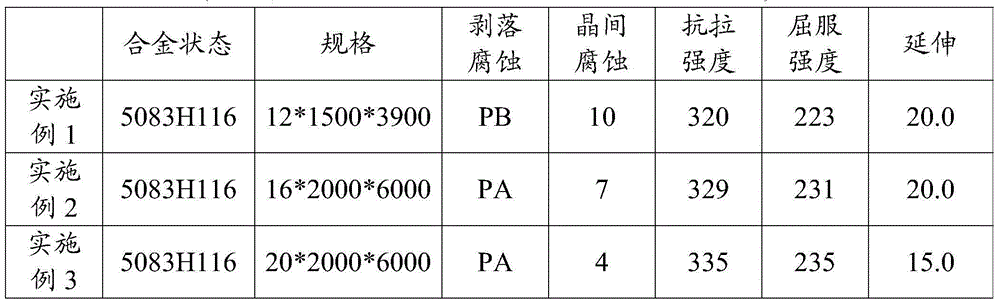

Processing technology for marine 5083 aluminum alloy sheet

The invention provides a processing technology for a marine 5083 aluminum alloy sheet. The processing technology comprises the following steps: sequentially performing surface milling, heating, hot rough rolling, hot finishing, pre-annealing, first cold rolling, intermediate annealing, second cooling, shearing and strengthening on 5083 aluminum alloy ingot, carrying out stabilizing thermal treatment, sawing-cutting and sizing, to obtain the marine 5083 aluminum alloy sheet. The mechanical performance and corrosion resistance capability of the aluminum alloy sheet can be enhanced by adding annealing between twice cold rolling and finally performing stabilizing thermal treatment operation.

Owner:SOUTHWEST ALUMINUM GRP

Machining process of thick 5083 aluminum alloy plate for ships

The invention provides a machining process of a thick 5083 aluminum alloy plate for ships. The machining process is characterized by comprising the following steps: sequentially milling, heating, rolling, shearing, drawing to straighten and sawing to fix the size of 5083 aluminum alloy cast ingots, thereby obtaining the 5083 aluminum alloy plate for ships. With the combination of procedures of hot rough rolling, heating, shearing, drawing to straighten and the like of the machining process of the thick aluminum alloy plate, the mechanical property and the anticorrosion property of the thick aluminum alloy plate in an H321 state are improved.

Owner:SOUTHWEST ALUMINUM GRP

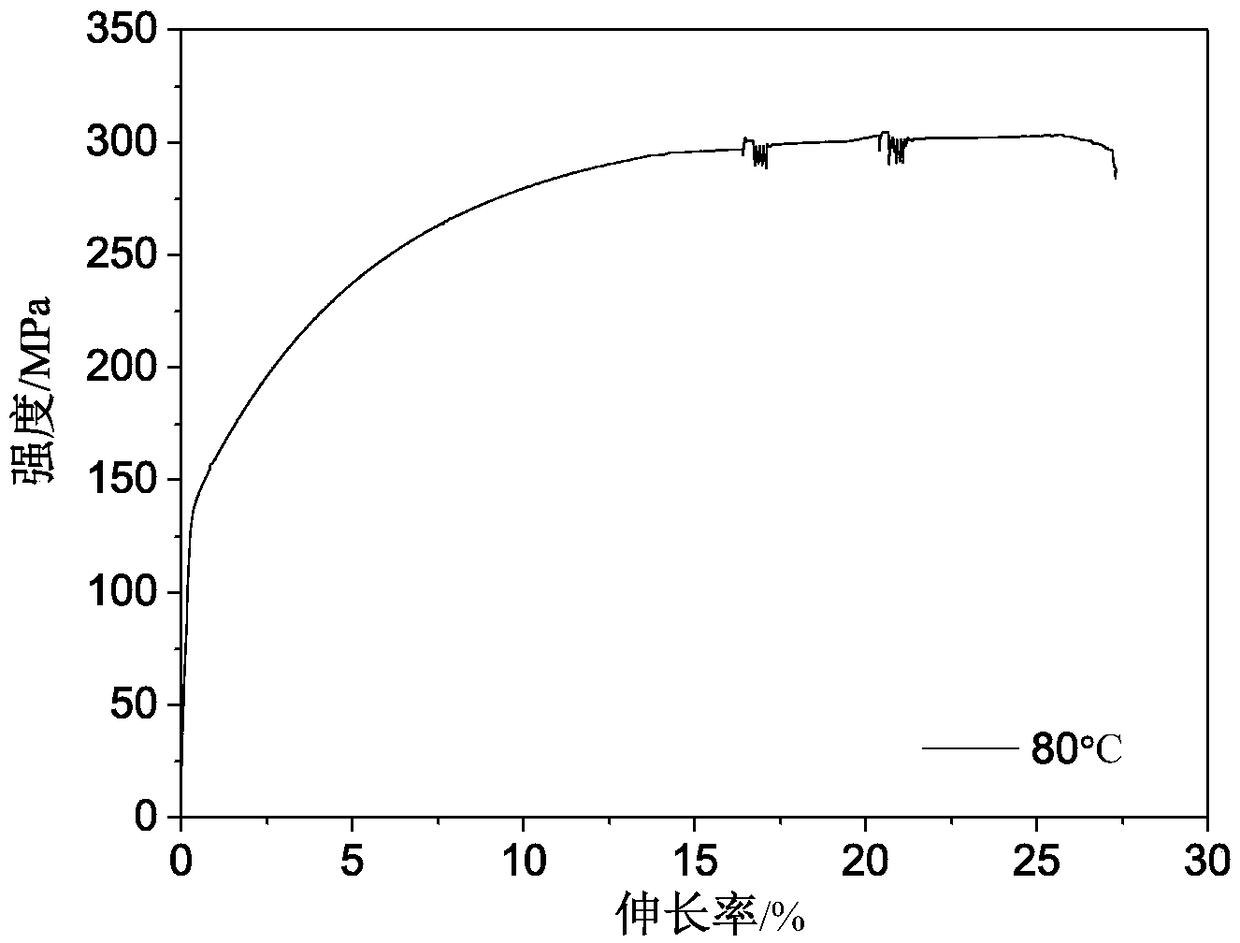

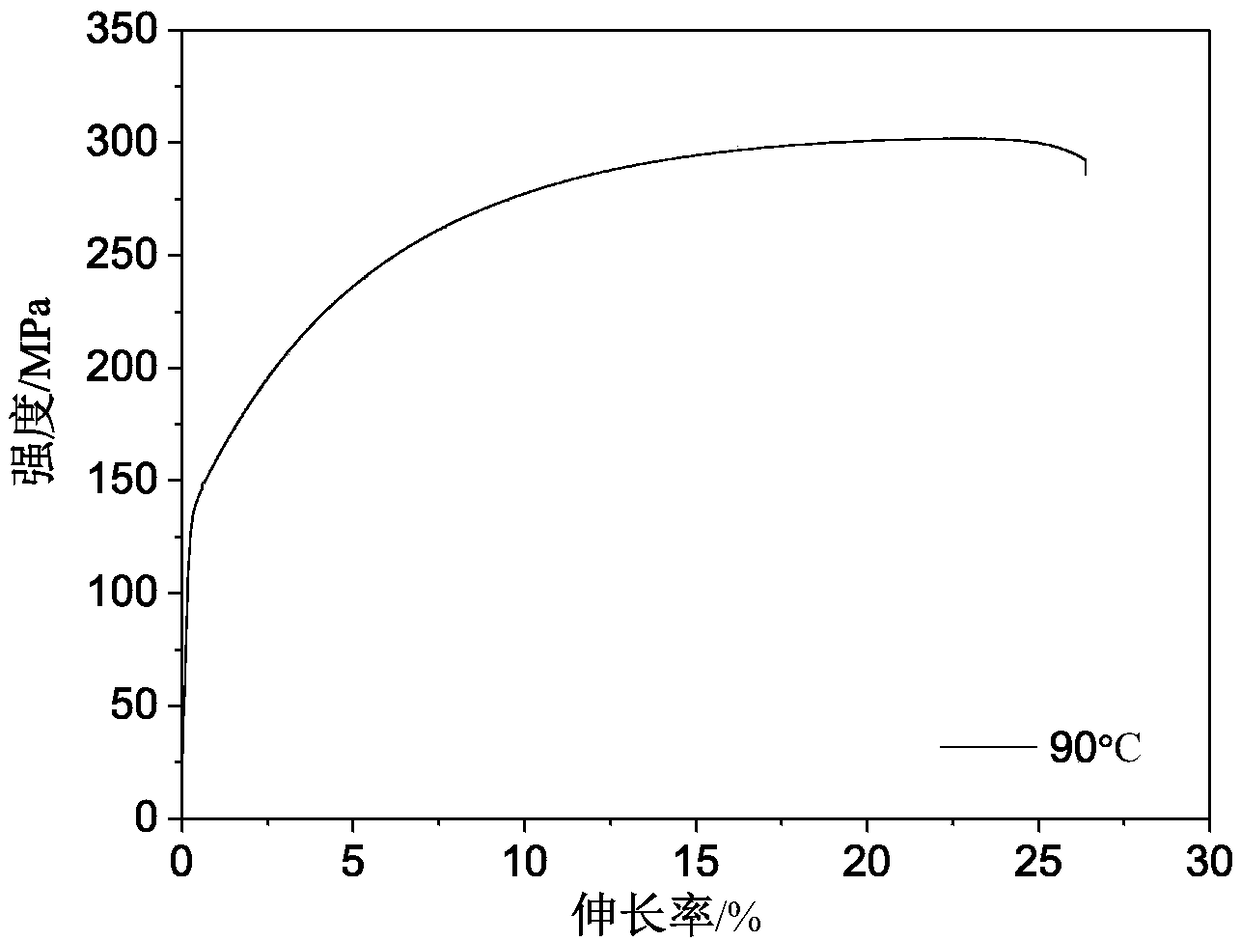

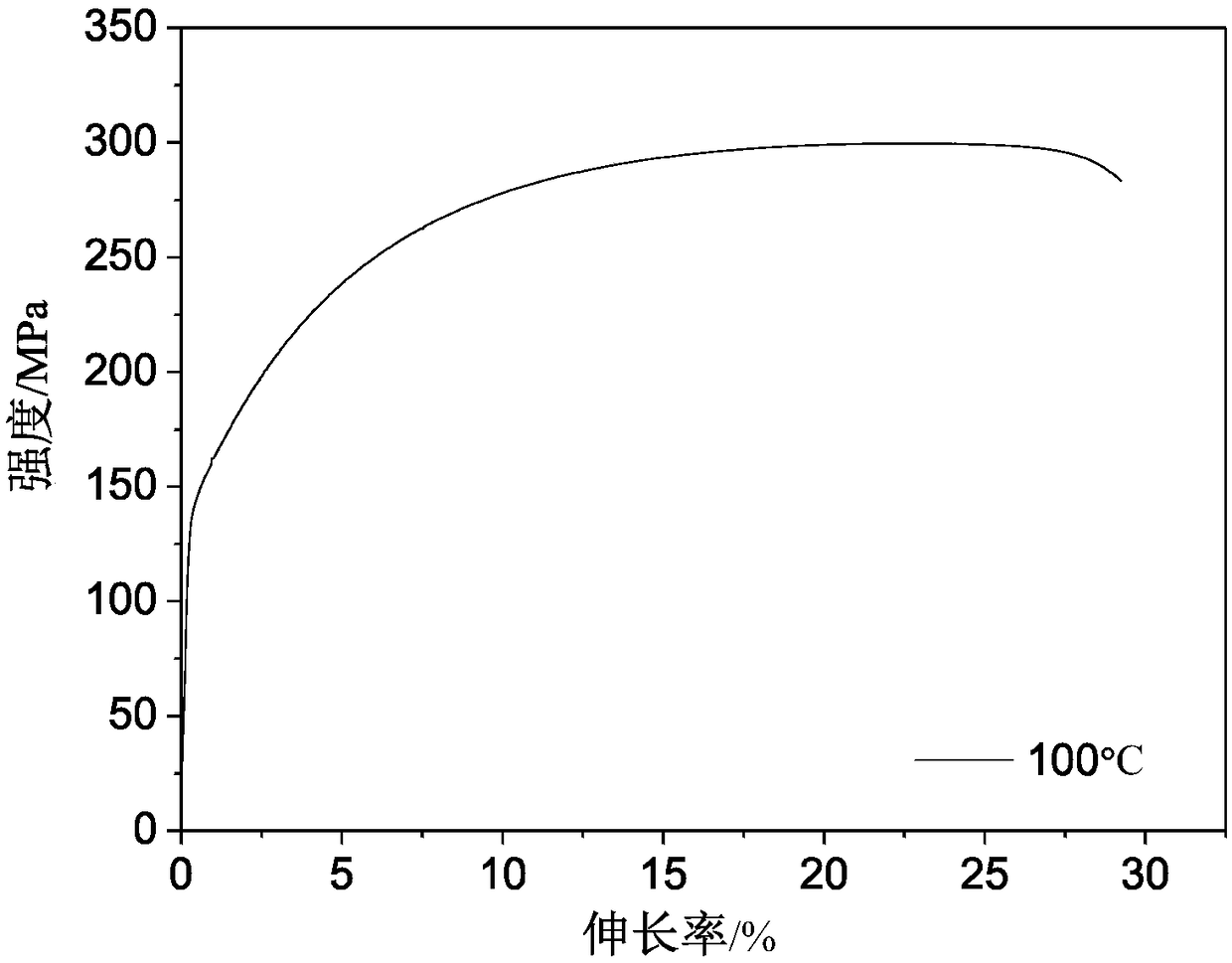

Preparation method of 5083 aluminum alloy plate

The invention belongs to the technical field of aluminum alloy manufacturing and relates to a preparation method of a 5083 aluminum alloy plate. The preparation method comprises the steps of conducting saw cutting and surface milling on a 5083 cast ingot, heating the 5083 cast ingot and then conducting hot rolling on the 5083 cast ingot; conducting annealing treatment at 85-105 DEG C after a plateis cooled to the indoor temperature; and then immediately conducting low-temperature prestretching to obtain the 5083 aluminum alloy plate. According to the preparation method, through low-temperature prestretching treatment on the 5083 aluminum alloy plate, the strain ageing effect during plate prestretching is effectively eliminated, and then slip lines on the surface of the prepared aluminum alloy plate are eliminated. The experimental result shows that a tensile strength and elongation curve of the 5083 aluminum alloy prepared through the method in the prestretching process has no obviousserrated waveforms. The surface of the prepared aluminum alloy plate has no slip lines, and the surface quality is improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Processing technology of 50mm thick aluminum alloy panel for ship

The invention provides a processing technology of a 50mm thick aluminum alloy panel for a ship. The processing technology is characterized by comprising the following step of sequentially carrying out face-milling, heating, rolling, shearing, stretch flattening and sawing and sizing on a 5083 aluminum alloy cast ingot to obtain the aluminum alloy panel for the ship. According to the processing technology of the aluminum alloy panel provided by the invention, a hot rough rolling step is combined with the heating, shearing and stretch flattening steps and the like, so that the mechanical performance and the resistance to corrosion of the aluminum alloy panel in an H116 state can be enhanced.

Owner:SOUTHWEST ALUMINUM GRP

Machining process of thick 5083 aluminum alloy plate for ships

The invention provides a machining process of a thick 5083 aluminum alloy plate for ships. The machining process is characterized by comprising the following steps: sequentially milling, heating, rolling, shearing, drawing to straighten and sawing to fix the size of 5083 aluminum alloy cast ingots, thereby obtaining the 5083 aluminum alloy plate for ships. With the combination of procedures of hot rough rolling, heating, shearing, drawing to straighten and the like of the machining process of the thick aluminum alloy plate, the mechanical property and the anticorrosion property of the thick aluminum alloy plate are improved.

Owner:SOUTHWEST ALUMINUM GRP

Processing technology of marine 5083-series aluminum alloy plate with thickness of 26 mm

InactiveCN104388856AImprove mechanical propertiesImprove corrosion resistanceIngotMechanical property

The invention provides a processing technology of a marine 5083-series aluminum alloy plate with a thickness of 26 mm. The processing technology is characterized by comprising the following steps: taking a 5083-series aluminum alloy cast ingot, sequentially milling the surface, heating, rolling, shearing, stretching, straightening, cutting with a saw, and sizing, and at last obtaining the marine 5083-series aluminum alloy plate. In the processing technology of the thick aluminum alloy plate provided by the invention, the hot rough rolling procedure is combined with the heating, shearing, stretching and straightening procedures, so as to increase the mechanical property and the corrosion resistance of the aluminum alloy plate under the H116 state.

Owner:SOUTHWEST ALUMINUM GRP

5 series aluminium alloy plate production method

InactiveCN104404411AImprove mechanical propertiesImprove corrosion resistance5005 aluminium alloyIngot

Owner:SOUTHWEST ALUMINUM GRP

Processing technology for 5083 aluminum alloy plate for ship

InactiveCN104404413AImprove mechanical propertiesImprove corrosion resistanceIngot castingMechanical property

The invention provides a processing technology for a 5083 aluminum alloy plate for a ship. The processing technology comprises the following steps: performing milling, heating, hot-coarse rolling, hot-fine rolling, pre-annealing, preliminary cold rolling, middle annealing, secondary cooling, shearing straightening, stabilized thermal treatment and sawing for size fixing on a 5083 aluminum alloy ingot casting in sequence. Annealing is carried out in twice cold rolling, and the stabilized thermal treatment operation is finally carried out, so that the mechanical property and the corrosion resistance property of the aluminum alloy plate can be enhanced.

Owner:SOUTHWEST ALUMINUM GRP

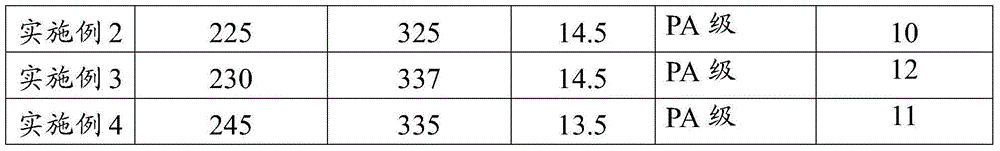

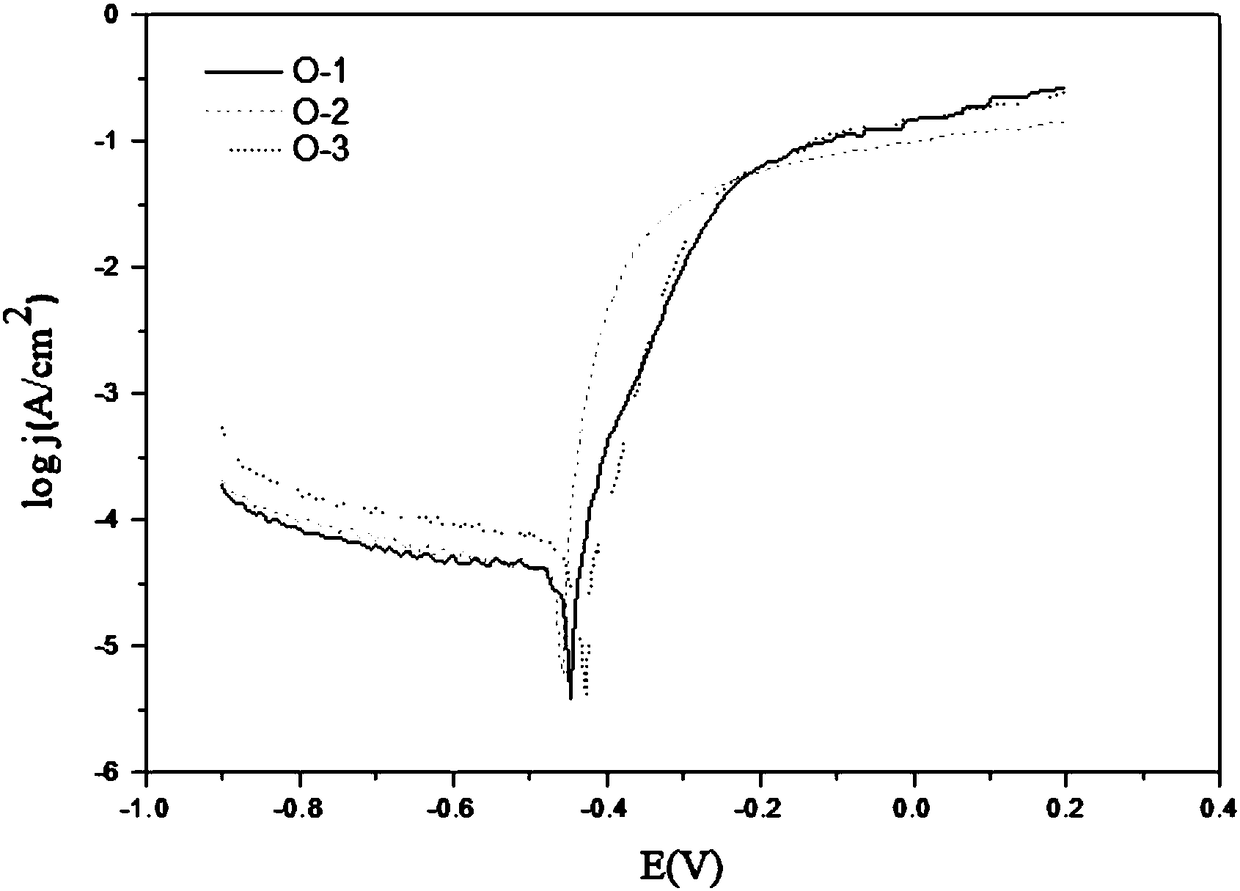

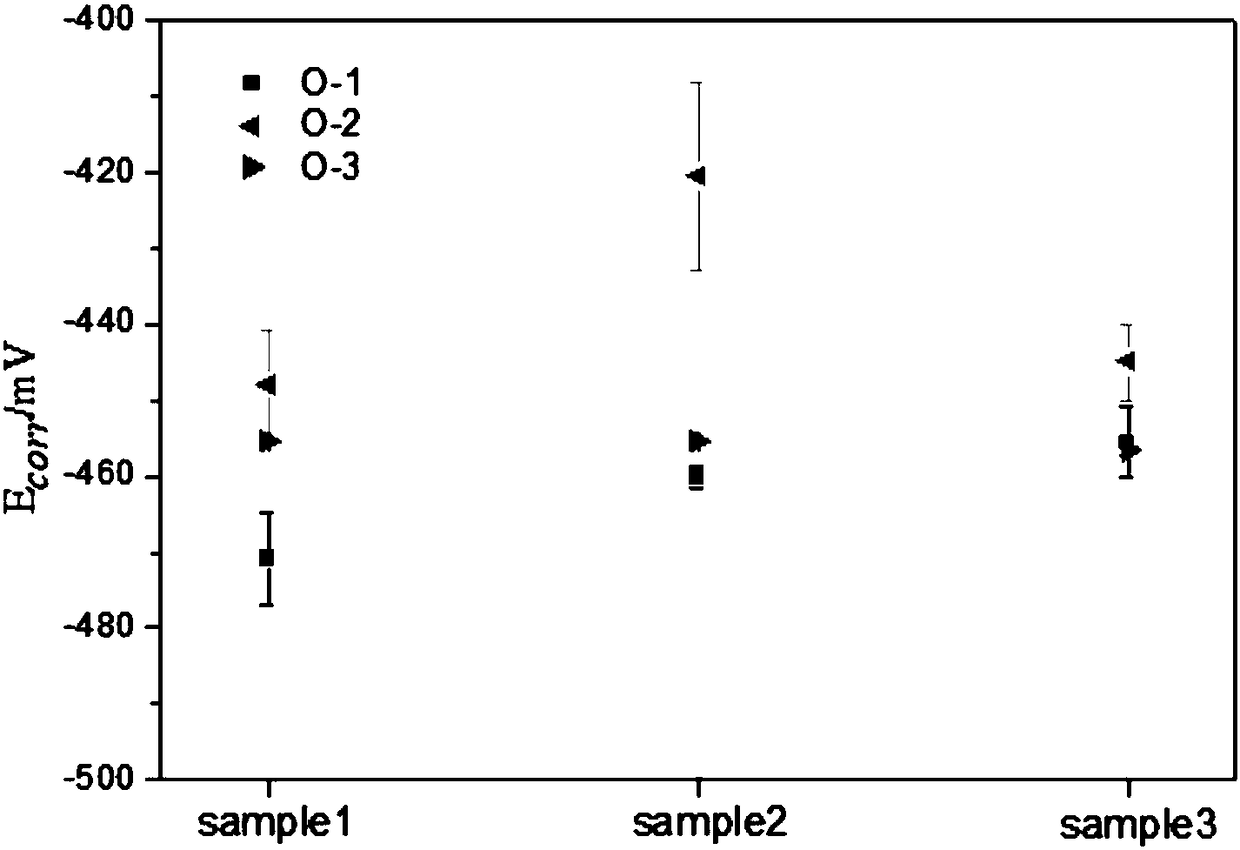

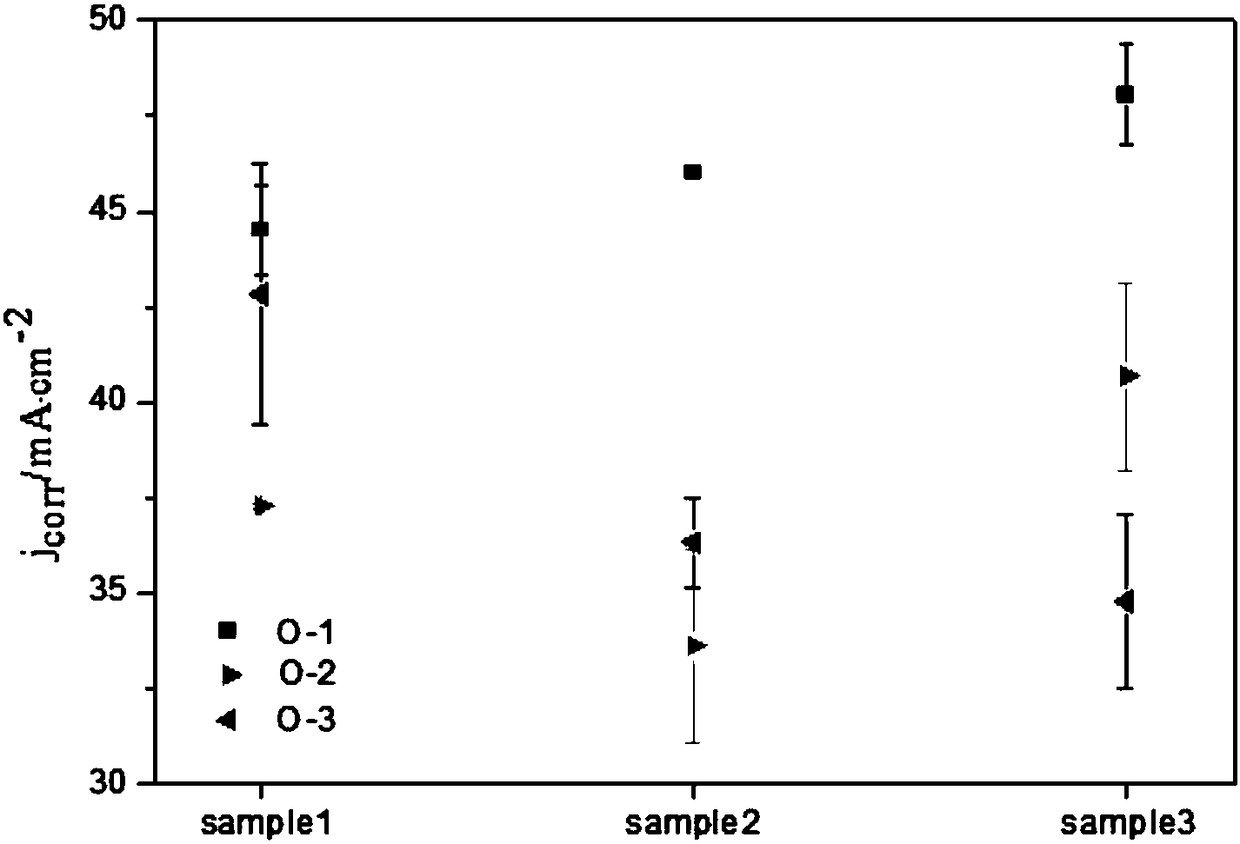

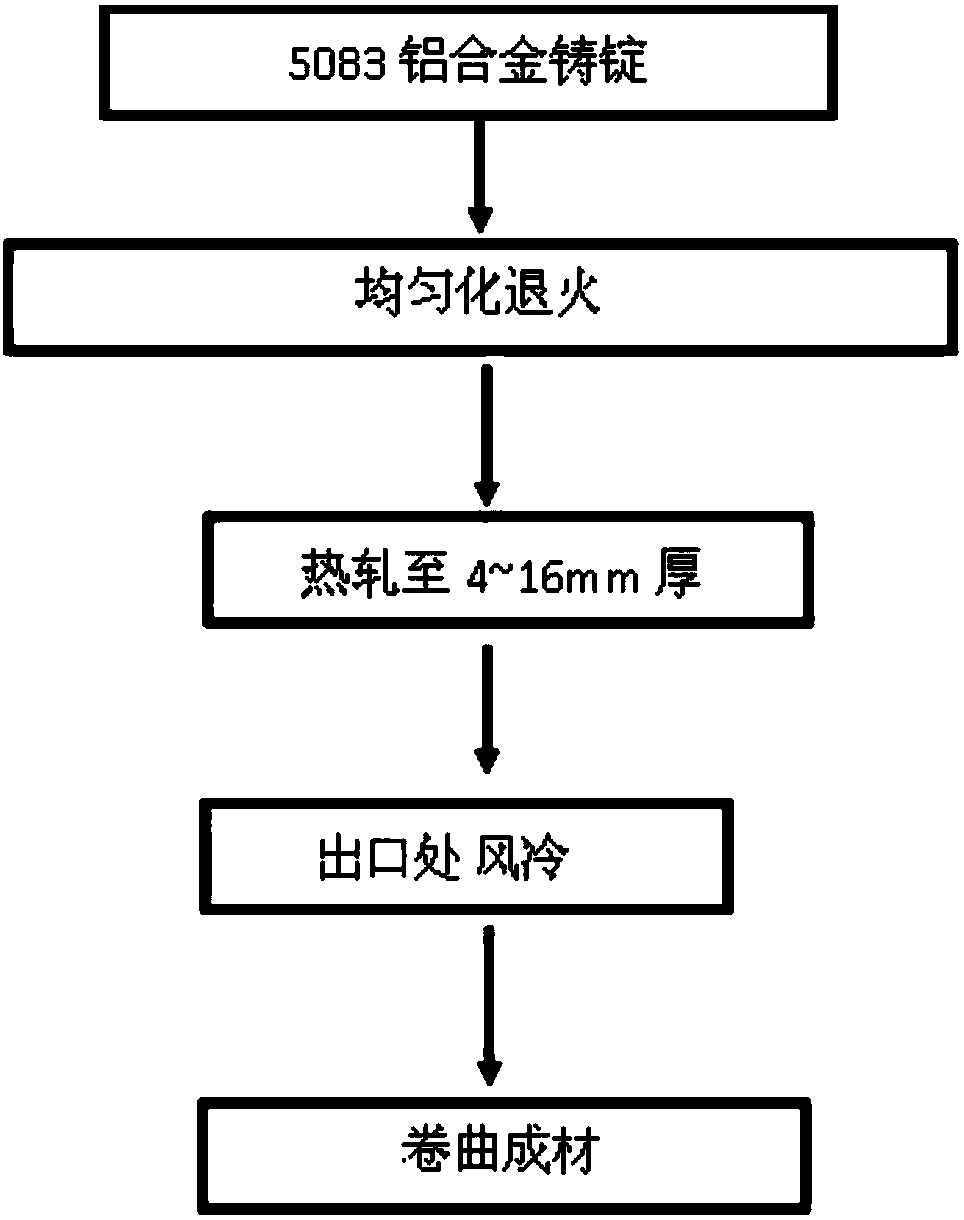

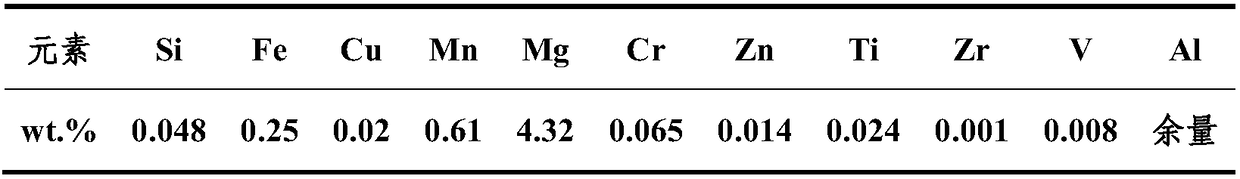

Method for improving corrosion resistance of 5083 aluminum alloy plate

The invention discloses a cast ingot uniformizing method for improving the corrosion resistance of a 5083 aluminum alloy plate. The cast ingot uniformizing method for improving the corrosion resistance of the 5083 aluminum alloy plate comprises the steps that a cast ingot is cut to be in a block shape; then the cast ingot is subjected to heat preservation at the temperature of 500-560 DEG C for 4-8 h for homogenizing treatment; the cast ingot is hot-rolled to 8-10 mm; low-deformation cold rolling is conducted for five passes till the thickness of the aluminum plate reaches 4 mm; and after coldrolling, the aluminum plate is annealed, and thus, an O-state 5083 aluminum alloy plate with high corrosion resistance is obtained. By the adoption of the cast ingot uniformizing method for improvingthe corrosion resistance of the 5083 aluminum alloy plate, the problems that during existing industrial production, energy consumption for uniformizing the 5083 aluminum alloy plate is high, the timefor uniformizing the 5083 aluminum alloy plate is long, and the metal oxidization loss is large are solved; and the corrosion resistance of the 5083 aluminum alloy plate treated through the cast ingot uniformizing method is very good.

Owner:CENT SOUTH UNIV

Manufacturing method of aluminum magnesium alloy

The invention relates to a manufacturing method of plates and particularly relates to a manufacturing method of an aluminum magnesium alloy thick plate, which can be used for solving the problems that a process for processing a plate made of aluminum alloy 5083 which is in the H321 state and is 12.5-75mm in thickness, and the aluminum alloy 5083 being in the H321 state and being 12.5-75mm in thickness, which is prepared by the existing casting method, is poor in strength and percentage elongation. The method comprises the steps of firstly, melting; secondly, casting; thirdly, evening fire; fourthly, rolling and fifthly, annealing. According to the method disclosed by the invention, the blank of the manufacturing method of an alloy thick plate 5083H321 being 12.5-75mm in thickness is filled; and according to the method, a reasonable technological process is selected, so that the yield strength of the plate is 275-293MPa, the tensile strength of the plate is 350-365MPa, and the percentage elongation of the plate is 10.8-11.9%. The aluminum magnesium alloy thick plate manufactured by the method can be used for the industrial fields of armored vehicles, ships, automobile industries, and canning.

Owner:NORTHEAST LIGHT ALLOY CO LTD

5-series aluminum alloy panel, as well as preparation method and application thereof

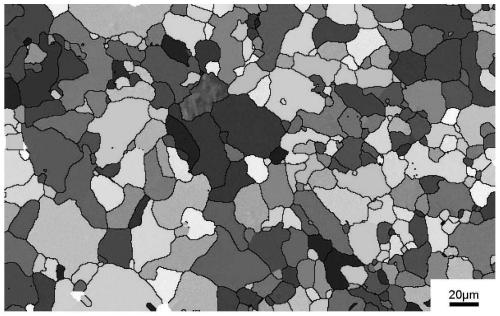

ActiveCN108531791AFine grain sizeImprove plasticityWork cooling devicesMetal rolling arrangementsUltimate tensile strengthFine grain

The invention relates to a 5-series aluminum alloy panel, as well as a preparation method and application thereof. The preparation method of the 5-series aluminum alloy panel is characterized by forced cooling a hot-rolled aluminum alloy panel to be below 200 DEG C at the cooling speed being 15 to 25 DEG C / s. By adopting the cooling method provided by the invention, a fine-grain panel with the grain size being smaller than 30mum can be prepared, so that the strength and the extensibility of the 5XXX-series, particularly 5083 aluminum alloy panel material are improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Corrosion-resistant aluminium alloy section and preparation method thereof

InactiveCN110819855AHigh strengthGood extrudabilityHot-dipping/immersion processesLiquid/solution decomposition chemical coatingGalvanic cellAlloy coating

The invention provides a preparation method of a corrosion-resistant aluminium alloy section. The proportion of Mn, Fe, Si, Cu, Zn, Bi, Ni and Al in aluminum alloys is preferentially selected and adjusted, so that the aluminum alloy section has higher strength and extrudability balance. The aluminum alloy section with double coatings is prepared by dip galvanizing treatment and chemical nickel-plating treatment, wherein the outer layer is an Ni coating, and the inner layer is an Al-Zn alloy coating. The inner Al-Zn alloy coating uses the primary battery principle to protect the aluminium alloysection wrapped in the inner Al-Zn alloy coating from corrosion by sacrificing chemically active Zn in the inner Al-Zn alloy coating, and the outer Ni coating protects the aluminium alloy section byusing corrosion resistance of Ni elements. The double coatings reduce the usage amount of Ni and improve the corrosion resistance of the aluminium alloy section. The tensile strength of the corrosion-resistant aluminium alloy section is 310-360MPa, and the elongation of the corrosion-resistant aluminium alloy section is 23-28. Compared with well-known 5083 aluminium alloy sections, the annual corrosion rate is decreased by 17%-38% at room temperature, and the annual corrosion rate is decreased by 23%-41% under the temperature of 300 DEG C.

Owner:WUXI SHIDA PRECISION WELDED TUBE MFG CO LTD

Manufacturing method of aluminum alloy for yacht hull

InactiveCN109022959ALower requirementReduce other production linksTechnological systemRoom temperature

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

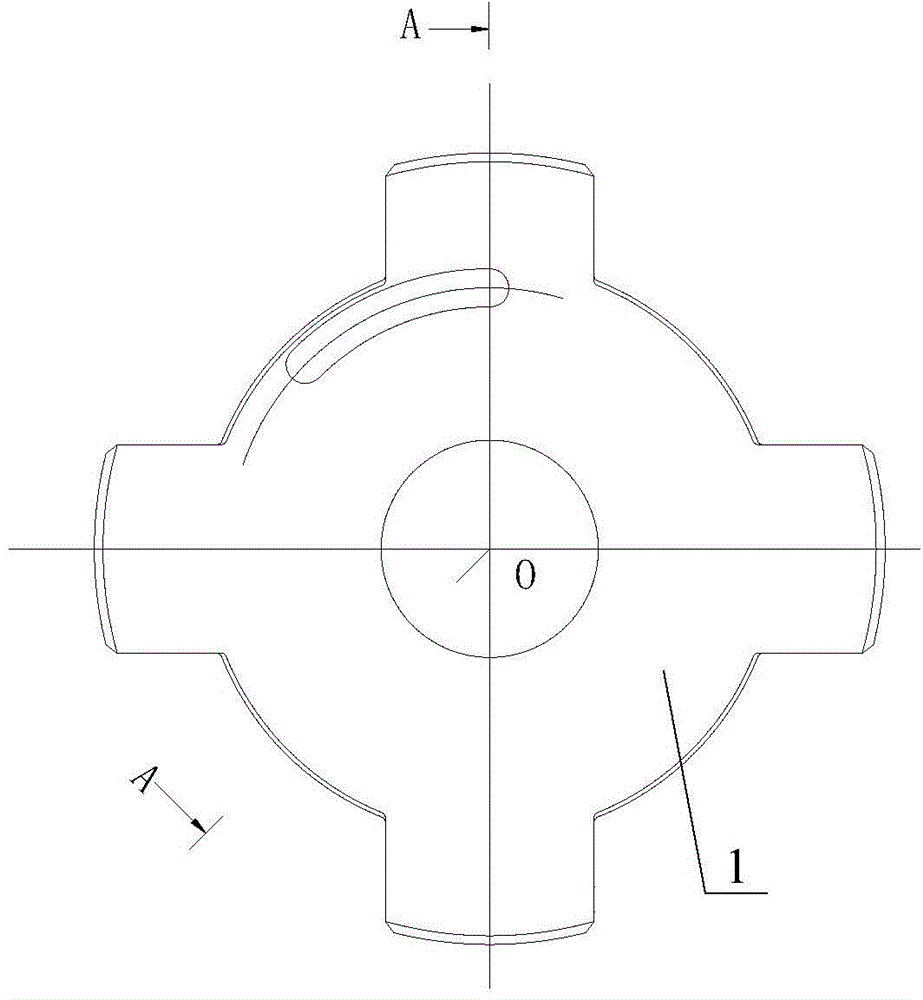

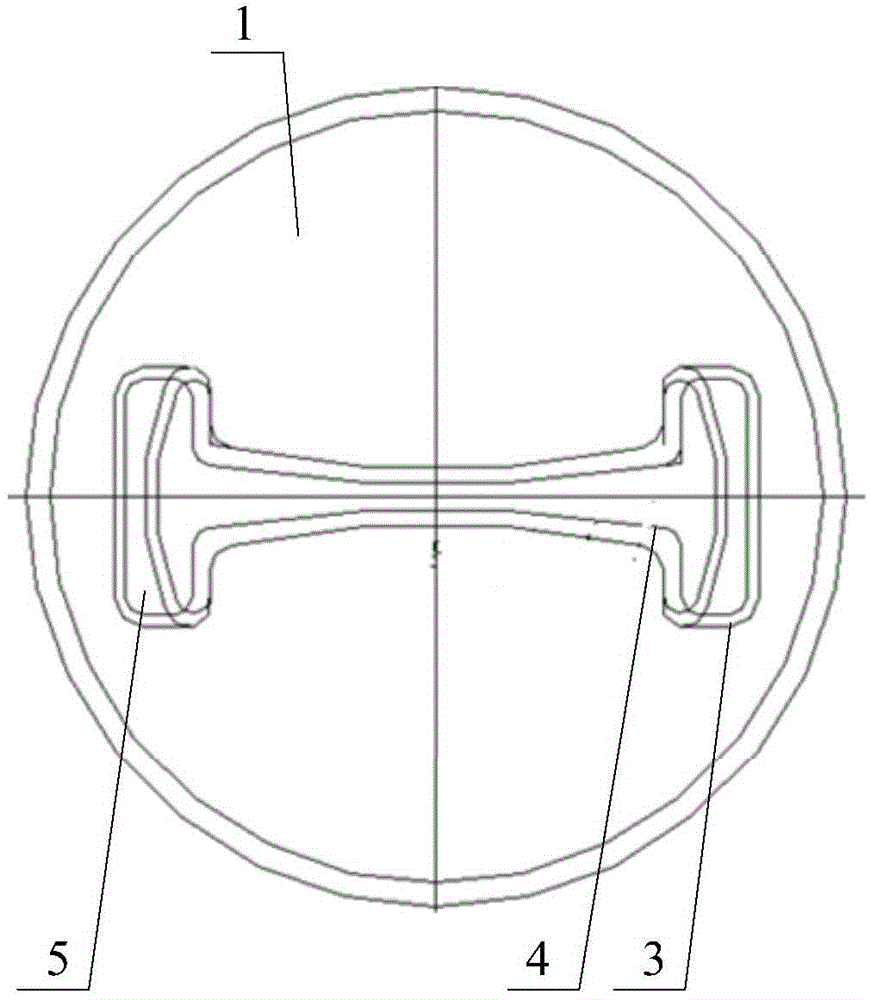

Processing equipment of 5083 aluminium-alloy thin-wall pipes

InactiveCN104525609AIncrease productivityReduce the cross-sectional areaRams/plungersBiomedical engineeringThin walled

The invention discloses processing equipment of 5083 aluminium-alloy thin-wall pipes. The processing equipment comprises an internal drum sleeve, a mold bearing, a hollow extruding shaft, an extruding needle and a needle bearing, wherein the inner diameters of the internal drum sleeve, the mold bearing and the hollow extruding shaft are respectively 420mm, and the diameters of the extruding needle and the needle bearing are respectively 210mm; the internal drum sleeve is arranged on the mold bearing; the extruding needle is arranged on the needle bearing; the hollow extruding shaft sleeves the extruding needle. The processing equipment disclosed by the invention has the advantages that since the inner diameters of the internal drum sleeve, the mold bearing and the hollow extruding shaft are respectively 420mm, and the diameter of the extruding needle is 210mm, the cross-section area of an extruding drum cavity formed by the internal drum sleeve and the extruding needle is effectively reduced, and the total cross-section area of an extruded product is not changed, so that the extruding coefficient is effectively reduced, and the blocking phenomenon in the extruding process is reduced; therefore, by the processing equipment provided by the application, the production efficiency of the 5083 aluminium-alloy thin-wall pipes can be improved.

Owner:SOUTHWEST ALUMINUM GRP

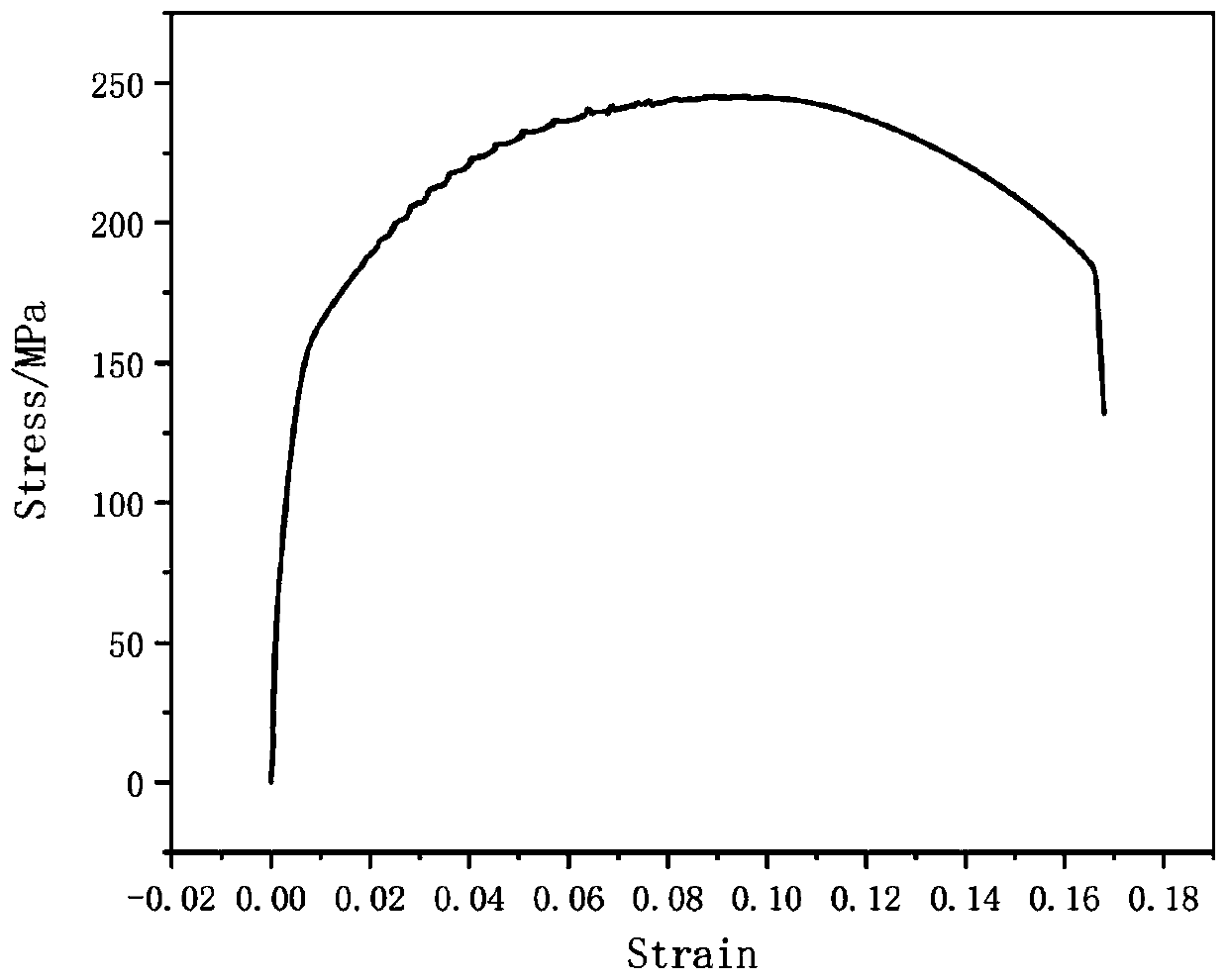

Zn-contained high-strength aluminum-based lightweight medium-entropy alloy and preparation method thereof

InactiveCN110106407AIncrease configuration entropyHigh strengthUltimate tensile strengthMachinability

The invention discloses a Zn-contained high-strength aluminum-based lightweight medium-entropy alloy and a preparation method thereof. The alloy composition of the medium-entropy alloy is aluminum alloy containing 5083 aluminum alloy-xZn, wherein x is the mass percentage of Zn in the total alloy composition, x is greater than 0 and no more than 6%, and the proportion error of each composition is within + / - 0.2%. The design idea of the alloy is from the point of view of the formation entropy, on the basis of the 5083 deformed aluminum alloy, the Zn element is added so as to improve the formation entropy of the alloy, and meanwhile, the alloy becomes the heat-treatable reinforced alloy; and then through the corresponding heat treatment process including vacuum induction smelting and the useof gravity casting, homogenization treatment, solidification and aging and the like, the strength of the alloy is improved accordingly, the machinable property is improved, and the application prospect of the alloy is expanded.

Owner:李扬德 +1

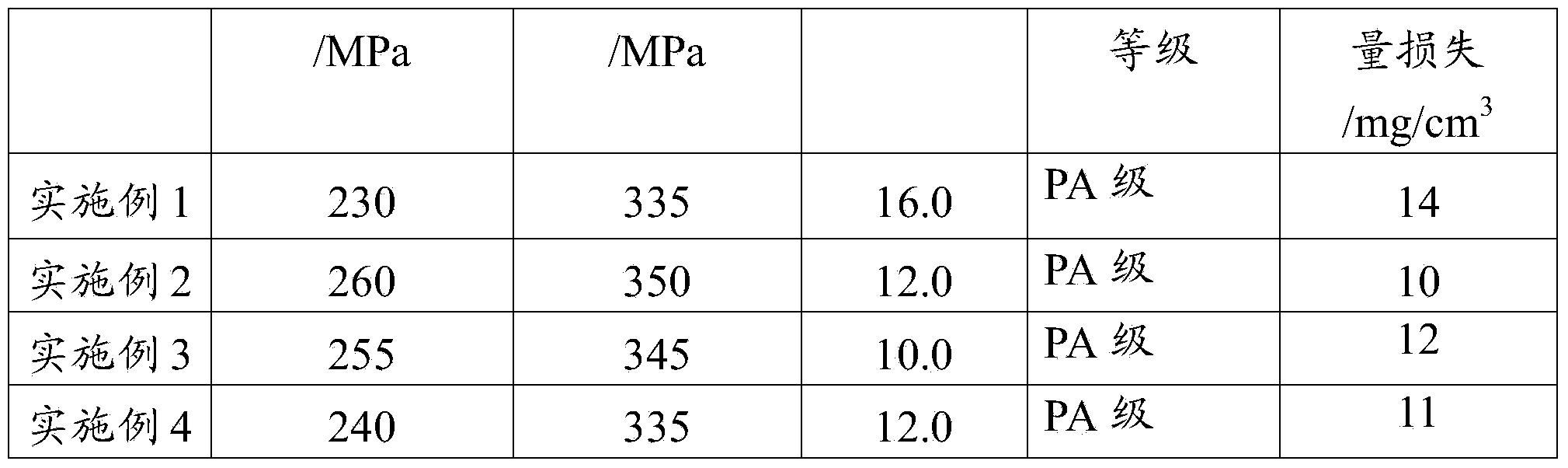

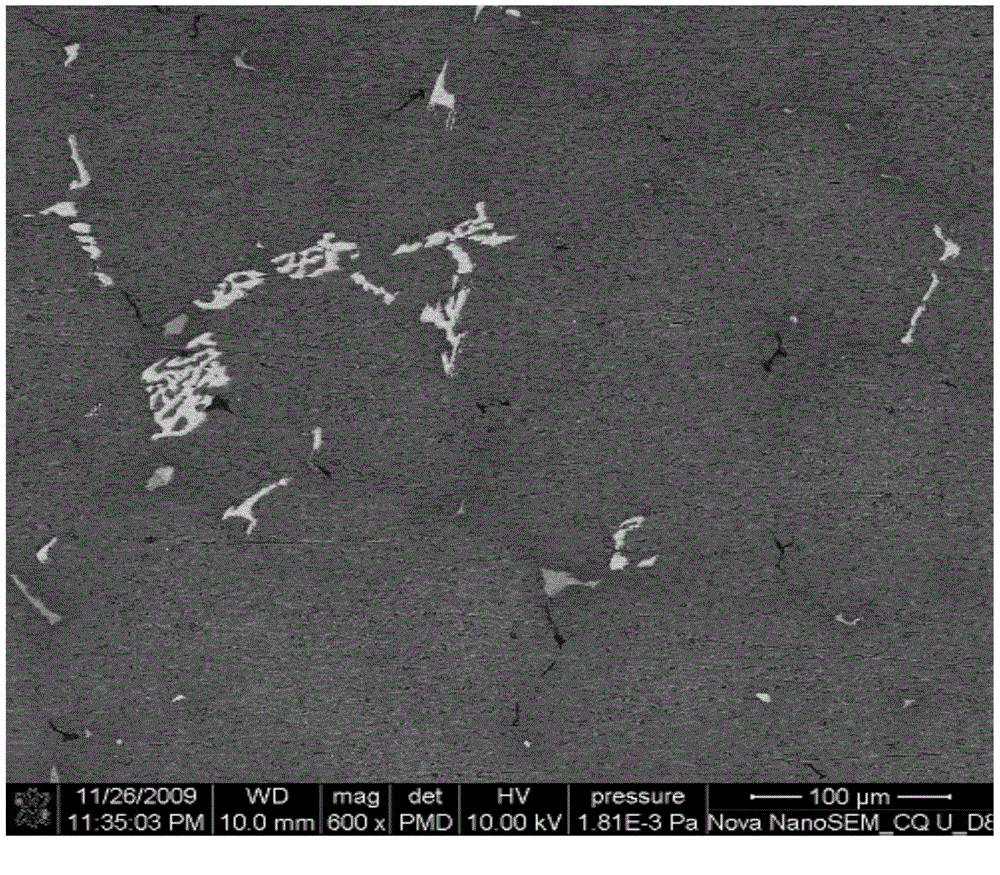

Judging method of exfoliation corrosion level of 5083 aluminum alloy

InactiveCN108107052AShorten the judgment cycleOptically investigating flaws/contaminationCorrosionExfoliation corrosion

The invention provides a judging method of exfoliation corrosion level of 5083 aluminum alloy. The judging method comprises the following steps: collecting 5083 aluminum alloy samples with different corrosion levels; performing microstructure test on the 5083 aluminum alloy samples; establishing the corresponding relationship between the corrosion levels of the 5083 aluminum alloy and microstructure characteristics according to microstructure test results; observing the microstructure of the to-be-tested 5083 alloy, and obtaining the corrosion level of the to-be-tested 5083 alloy according tothe corresponding relationship. Microstructure characteristic spectra corresponding to different exfoliation corrosion levels of the 5083 aluminum alloy are obtained by observation under an optical microscope, and microstructure characteristics of the to-be-tested 5083 aluminum alloy samples are observed and compared with the spectra, and accordingly, the exfoliation corrosion levels of the to-be-tested 5083 alloy samples are judged. With adoption of the provided method, the judging period of the exfoliation corrosion sensitivity levels of the 5083 aluminum alloy is shortened, and the method is quick and convenient.

Owner:SOUTHWEST ALUMINUM GRP

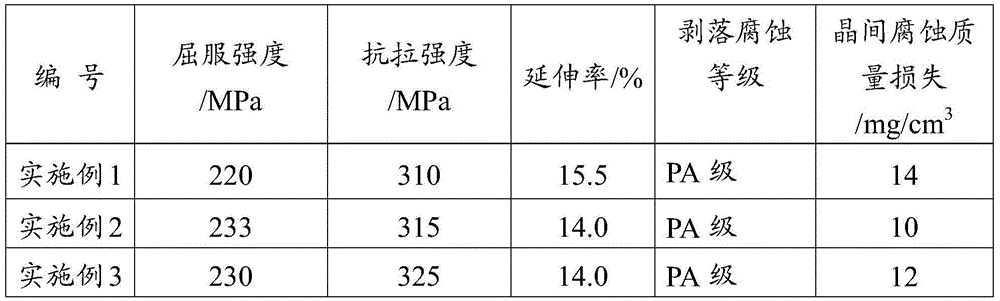

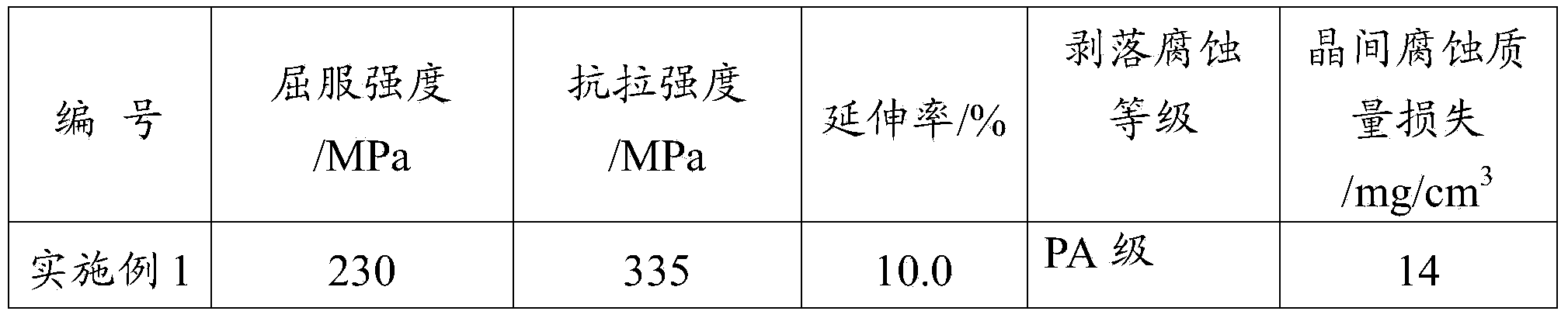

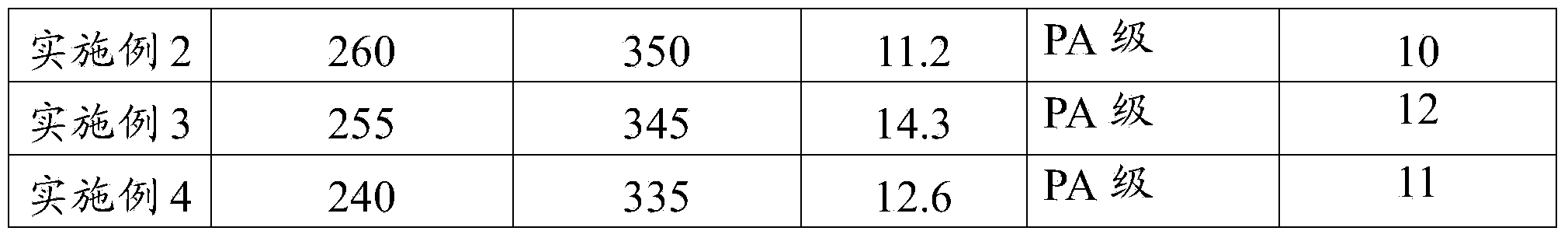

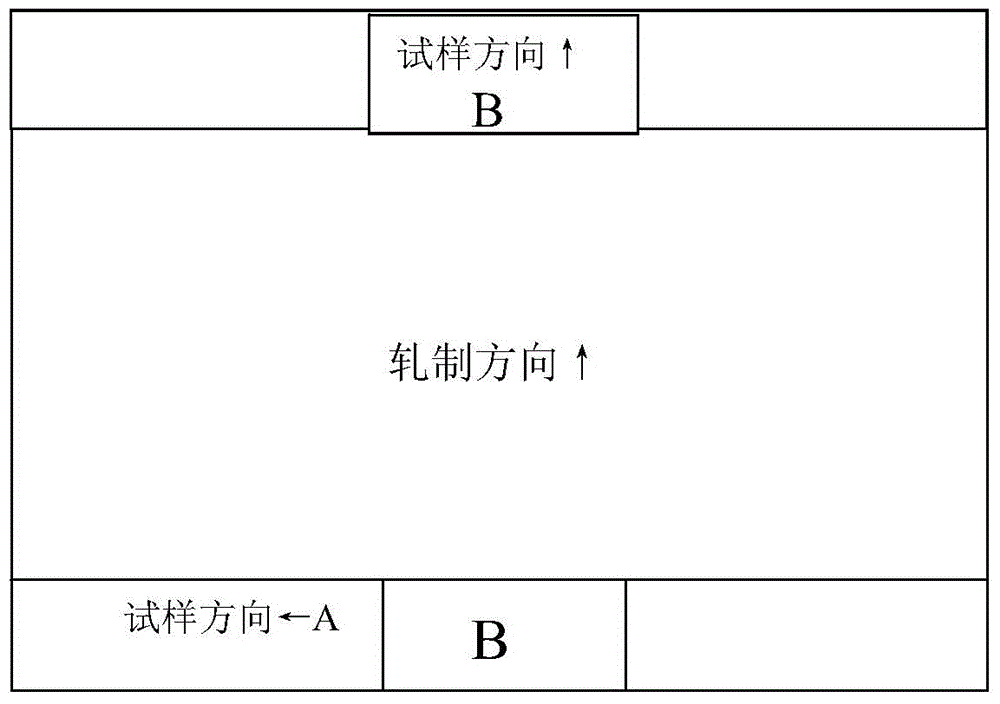

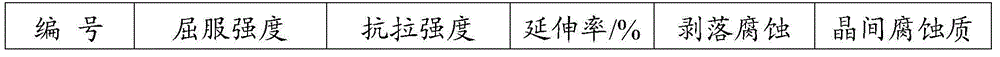

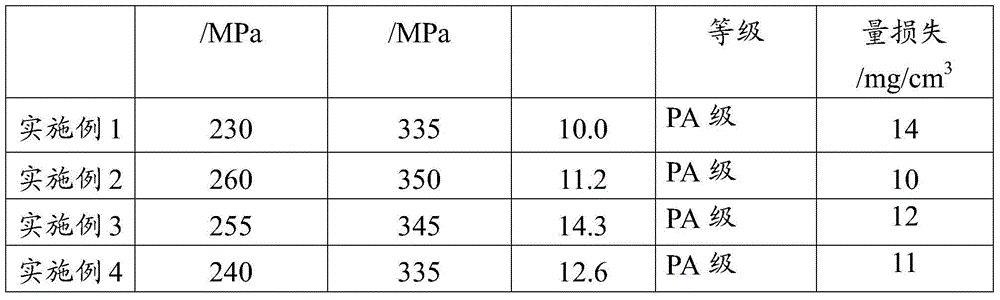

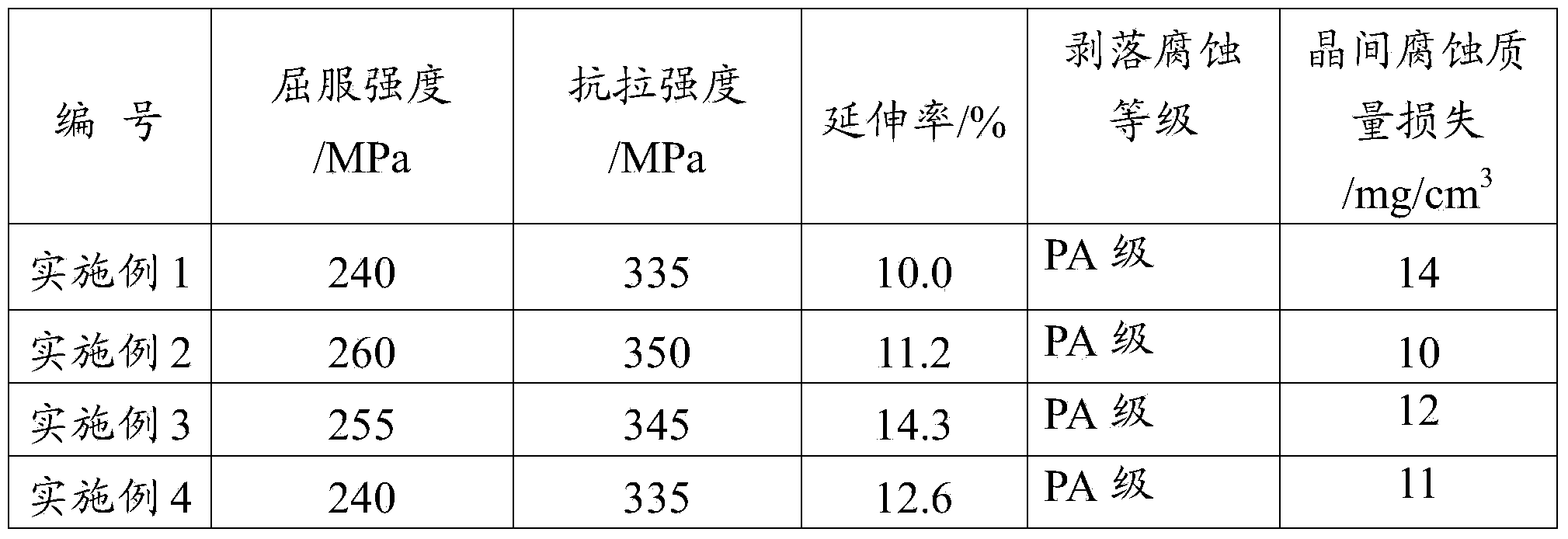

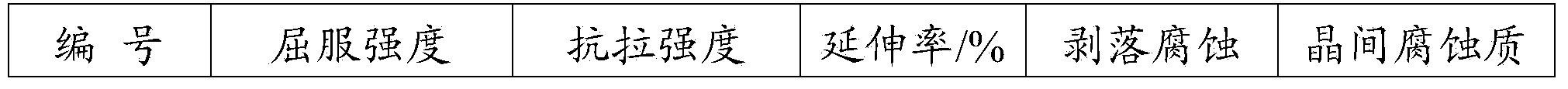

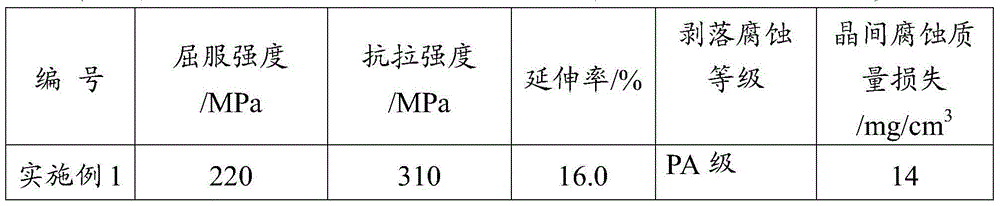

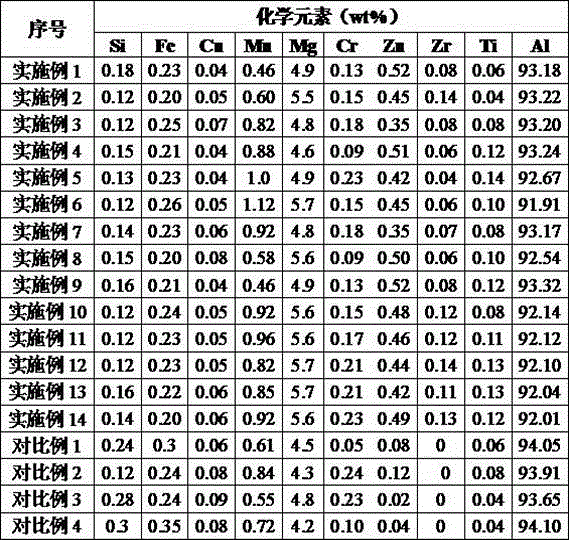

A High Strength and Corrosion Resistant al-mg Alloy

The invention discloses a high-strength corrosion-resistant Al-Mg alloy, the chemical composition weight percent is: Fe≤0.3%; Si≤0.25%; Cu≤0.1%; Mn=0.4-1.2%; Mg=4.5-6.0%; Zn =0.25~0.55%; Cr=0.10~0.3%; Zr≤0.15%; Ti≤0.15%; the balance is Al. The invention solves the problem of insufficient strength and corrosion resistance of the existing 5083 aluminum alloy in the manufacture of vehicles, and the obtained alloy has a tensile strength σb≥320 Mpa, a yield strength σ0.2≥160 Mpa, and an elongation δ≥23%. The exfoliation corrosion test grade reaches PA grade.

Owner:CENT SOUTH UNIV

Extruding device of 5083 aluminum alloy I beam

InactiveCN104475476AImprove molding qualityIncrease the supply of metalExtrusion dies5083 aluminium alloy

The invention discloses an extruding device of a 5083 aluminum alloy I beam. The extruding device comprises a mold body and a guide mold which is arranged on the mold body, wherein the guide mold is provided with a main guide cavity and auxiliary guide cavities which are arranged on two ends of the main guide cavity and communicated with the main guide cavity. A mold hole is formed in the mold body, and both the main guide cavity and auxiliary guide cavity are respectively communicated with the mold hole. In the extruding device of the 5083 aluminum alloy I beam, the flow area of the guide cavity on the guide mold is increased by arranging the auxiliary guide cavities, the auxiliary guide cavities are arranged on two ends of the main guide cavity, and inlets, in which a wing plate is formed, are formed in two ends of the main guide cavity, so that the metal supply amount of the position on which the wing plate is formed can be increased, the flow rate of metal of the position on which a shroud plate is arranged can be reduced, and the corrugation situation formed by the flow of the metal liquid on the position of the shroud plate can be reduced; therefore, the forming quality of the 5083 aluminum alloy I beam can be improved by the extruding device.

Owner:SOUTHWEST ALUMINUM GRP

A Processing Technology of Marine 5083 Aluminum Alloy Profile

The invention belongs to the technical field of aluminum alloys and relates to a machining process of a 5083 aluminum alloy profile for a ship. By directly performing manual annealing treatment on thealuminum alloy profile after online extruding is completed, the annealing regime is (320-350)DEG Cx(3-5)h, a material is made to be converted into an annealing structure from an extruding deforming structure, the surface hardness of a product is decreased to 26 HRB or so from 30 HRB under the extruding state, by means of treatment of the early stage annealing process, the hardness of the materialis made lowered, the machinable or stretchable performance of the later period is made improved, and the material becomes softer; according to the stretching process after annealing, when the extruded profile length is 25000 mm, the displacement range of the stretching stroke of a stretching machine is set as 1250-2250 mm, the stretching speed range is set as 40-20 mm / s, the stretching deformingrate is 5-9%, after the extruded 5083 aluminum alloy profile is subjected to stretching machining, according to the mechanical performance of the 5083 aluminum alloy profile, the yielding strength islarger than and equal to 215 MPa, the tensile strength is larger than and equal to 300 MPa, the percentage elongation is larger than or equal to 10%, and the mechanical performance of the 5083 aluminum alloy profile completely meets the performance requirement under the 5083-H116 state.

Owner:CHINA ZHONGWANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com