A High Strength and Corrosion Resistant al-mg Alloy

An alloy and corrosion-resistant technology, applied in the field of high-strength and corrosion-resistant Al-Mg alloys, can solve the problem that the corrosion resistance cannot fully meet the requirements, and achieve the effect of improving the strength of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

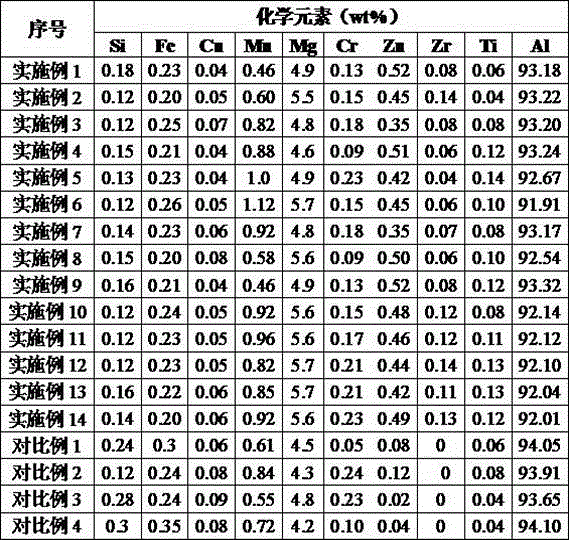

[0023] The present invention will be described in detail below in conjunction with examples and comparative examples.

[0024] Alloy chemical composition weight percent in each embodiment: Fe<0.25%; Si<0.2%; Cu<0.1%; Mn=0.4~1.2%; Mg=4.5~6.0%; Zn=0.25~0.55%; Cr=0.10~ 0.3%; Zr<0.15%; Ti<0.15%; single impurity ≤0.05%, total impurity ≤0.15%; the balance is Al.

[0025] Weight percentage of alloy chemical composition in each comparative example (5083 aluminum alloy): Fe<0.4%; Si<0.4%; Cu<0.1%; Mn=0.4~1.0%; Mg=4.0~4.9%; Zn<0.25%; Cr =0.05~0.25%;; Ti<0.15%; single impurity ≤0.05%, total impurity ≤0.15%; the balance is Al.

[0026] The high-strength corrosion-resistant Al-Mg alloy of the present invention can be prepared into materials of required specifications by means of rolling, extrusion, etc. Taking rolling and extrusion as examples, the preparation methods are as follows:

[0027] A. Plate preparation by rolling. Select the alloy components within the scope of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com