Processing technology for 5083 aluminum alloy plate for ship

A technology of aluminum alloy sheet and processing technology, applied in the field of metal materials, can solve the problems that the corrosion resistance of aluminum alloy sheet cannot be improved, and can not meet the production approval requirements of ABS marine aluminum alloy sheet, so as to increase mechanical properties and corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

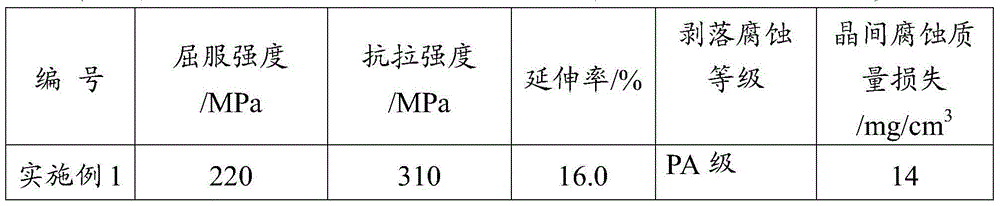

[0034] Mill the 5083 aluminum alloy plate with a thickness of 50 mm, heat the milled aluminum alloy plate at 450 degrees Celsius, and perform hot rough rolling and hot finish rolling on the heated plate to obtain an aluminum alloy with a thickness of 6.5 mm Plate, the plate is annealed, the annealing temperature is 350 ° C, after annealing and cooling, the first cold rolling is performed, the thickness of the plate after the first cold rolling is 3.25mm, and then intermediate annealing is performed, after annealing, The plate is subjected to the second cold rolling, and after the second cold rolling, the plate reaches a preset thickness of 3mm. After the second cold rolling, the plate is sheared and straightened, and then the plate is heated to 80° C., kept for 3 hours, and sawed to length to obtain a marine 5083 aluminum alloy plate.

[0035] The performance of the aluminum alloy plate under H321 is measured, wherein the corrosion resistance is tested for exfoliation corrosio...

Embodiment 2

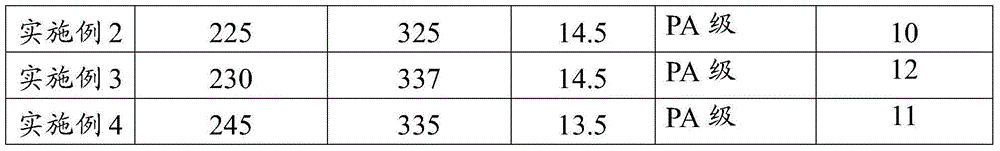

[0037] Mill the 15mm 5083 aluminum alloy plate, heat the milled aluminum alloy plate at 450 degrees Celsius, and perform hot rough rolling and hot finish rolling on the heated plate to obtain an aluminum alloy plate with a thickness of 6mm , the plate is annealed, the annealing temperature is 350 ° C, after annealing and cooling, the first cold rolling is carried out, the thickness of the plate after the first cold rolling is 3.3 mm, and then intermediate annealing is carried out. After annealing, the plate The second cold rolling is carried out, and after the second cold rolling, the plate reaches a preset thickness of 3mm. After the second cold rolling, the plate is sheared and straightened, and then the plate is heated to 80° C., kept for 3 hours, and sawed to length to obtain a marine 5083 aluminum alloy plate.

[0038]The performance of the aluminum alloy plate under H321 is measured, wherein the corrosion resistance is tested for exfoliation corrosion sensitivity accordi...

Embodiment 3

[0040] The 20mm 5083 aluminum alloy plate is milled, the milled aluminum alloy plate is heated at 450 degrees Celsius, and the heated plate is subjected to hot rough rolling and hot finish rolling to obtain an aluminum alloy plate with a thickness of 8mm , the plate is annealed, the annealing temperature is 350 ° C, after annealing and cooling, the first cold rolling is carried out, the thickness of the plate after the first cold rolling is 4.5mm, and then intermediate annealing is carried out. After annealing, the plate The second cold rolling is carried out, and after the second cold rolling, the plate reaches a preset thickness of 4 mm. After the second cold rolling, the plate is sheared and straightened, and then the plate is heated to 80° C., kept for 3 hours, and sawed to length to obtain a marine 5083 aluminum alloy plate.

[0041] The performance of the aluminum alloy plate under H321 is measured, wherein the corrosion resistance is tested for exfoliation corrosion sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com