Arc added material manufacturing method of 5083 aluminum alloy/TC4 titanium alloy structures

An additive manufacturing, titanium alloy technology, applied in the field of arc additive manufacturing, arc additive manufacturing of dissimilar materials, can solve the problems of huge differences in thermal physical properties and chemical properties, reducing joint performance, reducing joint strength, etc. Contradictions of welding heat input control, improving mechanical properties, and the effect of automatic connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

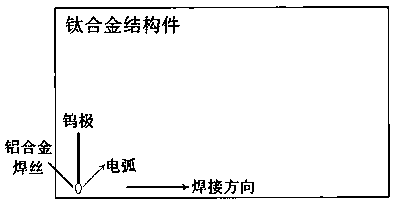

[0029] There are mainly three schemes for arc additive preparation of dissimilar materials of aluminum alloy and titanium alloy. The difference between the three schemes lies in the matching range of the direction of welding wire feeding, welding current, welding speed and wire feeding speed. The specific technical scheme is as follows:

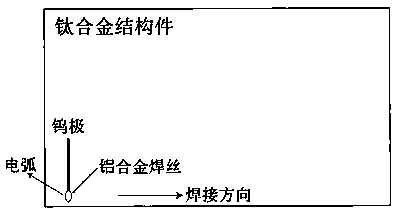

[0030] Scheme 1: (1) The surface of the titanium alloy structural parts to be connected is mechanically polished with sandpaper to remove surface pollutants, then cleaned with alcohol or acetone, then dried with a hair dryer, and fixed with a clamp; (2) along the welding direction, the aluminum alloy welding wire is in front of the tungsten electrode, such as figure 2 As shown, the wire feeding angle is 45°; (3) select a tungsten electrode with a diameter of 3.2mm and a tip angle of 45° as the electrode; (4) start the arc and use the arc to heat the welding wire to melt it and form a connection with the surface of the titanium alloy. The cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com