Carbon nano tube reinforced aluminum alloy composite material prepared through squeeze casting method

A technology of carbon nanotubes and squeeze casting, which is applied in the field of preparation of carbon nanotube-reinforced metal matrix composites, can solve problems such as uneven distribution of carbon nanotubes, poor bonding of carbon nanotubes and metal matrix interfaces, and achieve crystal grain Small size, low porosity, and the effect of eliminating oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

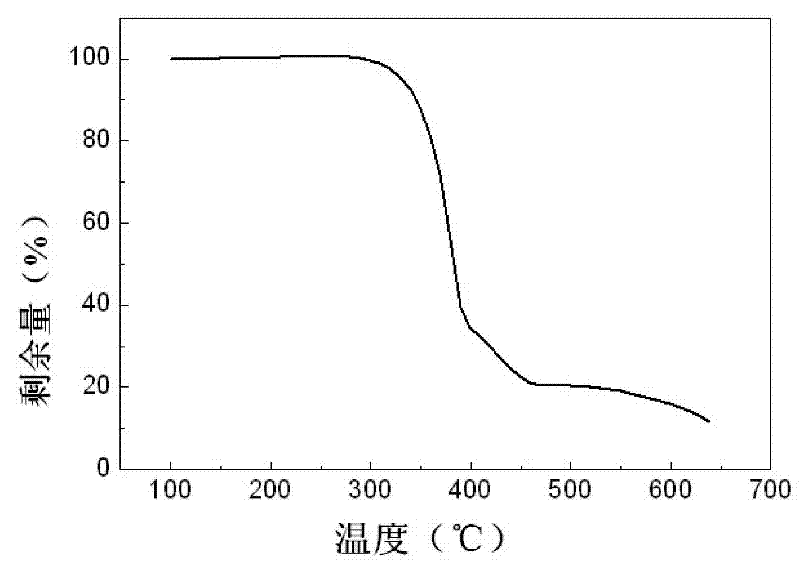

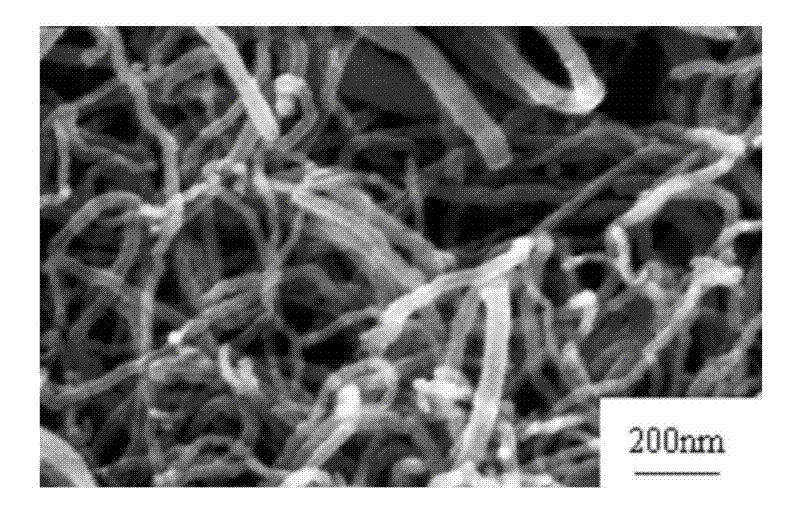

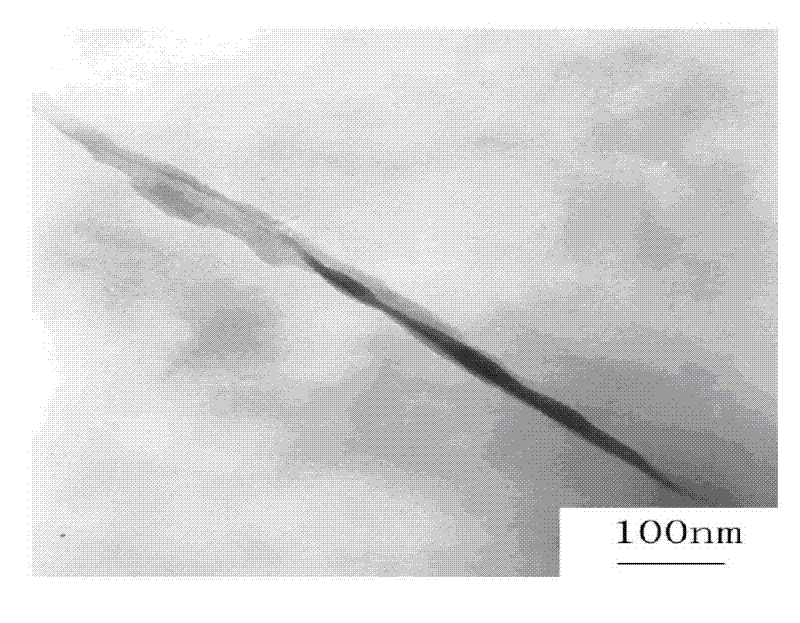

[0013] Specific embodiment 1: In this embodiment, the extrusion casting method is used to prepare carbon nanotube-reinforced aluminum alloy composite materials according to the following steps:

[0014] 1. Carbon nanotubes and nitric acid with a mass concentration of 65% to 69% are mixed according to a weight ratio of 0.8 to 1.2:100, refluxed at 100 to 120°C for 5 to 10 hours, and then filtered through a microporous filter with a pore size of 0.45 microns The membrane is subjected to negative pressure filtration, and distilled water is passed through at the same time until the pH value of the filtered solution is 6.0-7.0, and then the carbon nanotubes on the microporous filter membrane are washed down with distilled water to obtain an aqueous solution of carbon nanotubes, and then the aqueous solution of carbon nanotubes is added to the solution. Adding a sodium dodecyl sulfonate solution with a concentration of 18 to 22 mg / mL to obtain a mixed solution, wherein the weight rati...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, carbon nanotubes and nitric acid with a mass concentration of 67% are mixed in a weight ratio of 1:100. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Specific embodiment 3: This embodiment differs from specific embodiments 1 to 2 in that: in step 1, reflux at 110° C. for 8 hours. Other steps and parameters are the same as those in Embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com