Patents

Literature

34results about How to "Improve coordination and deformation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

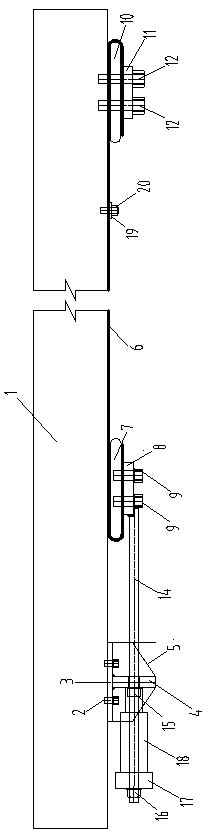

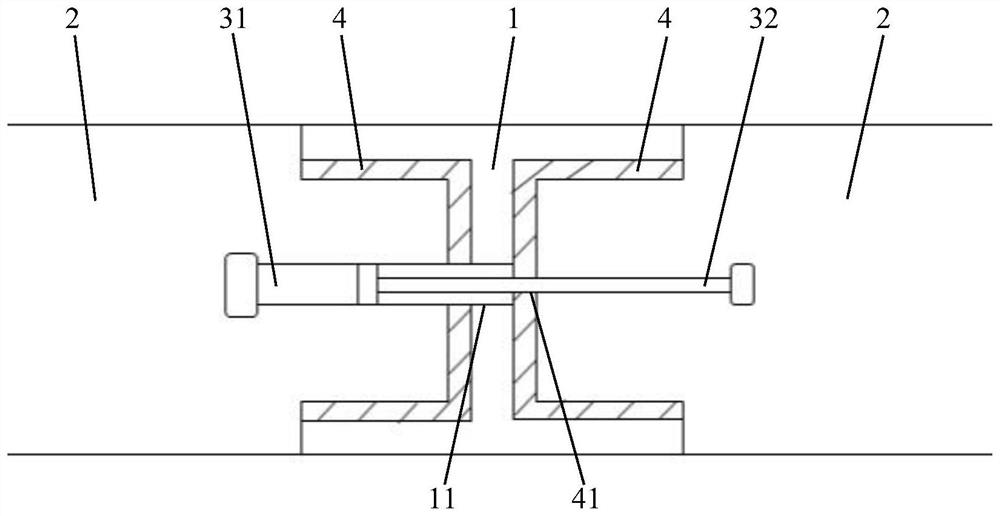

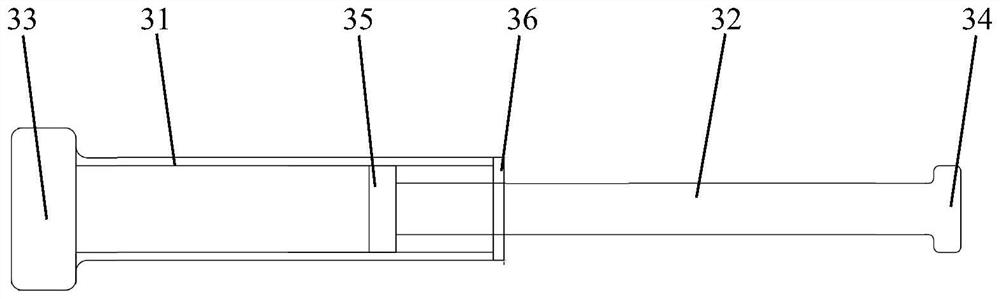

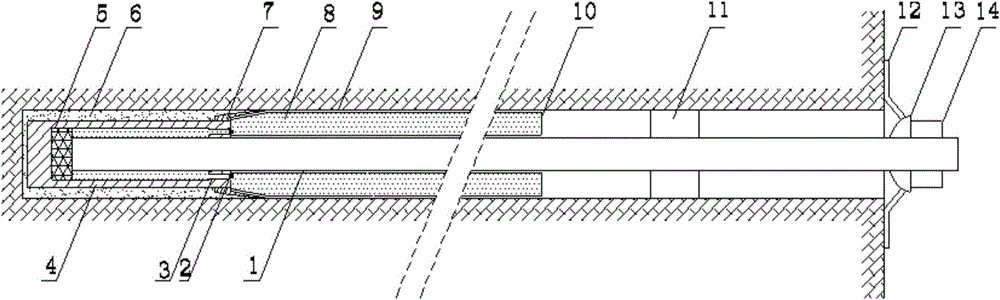

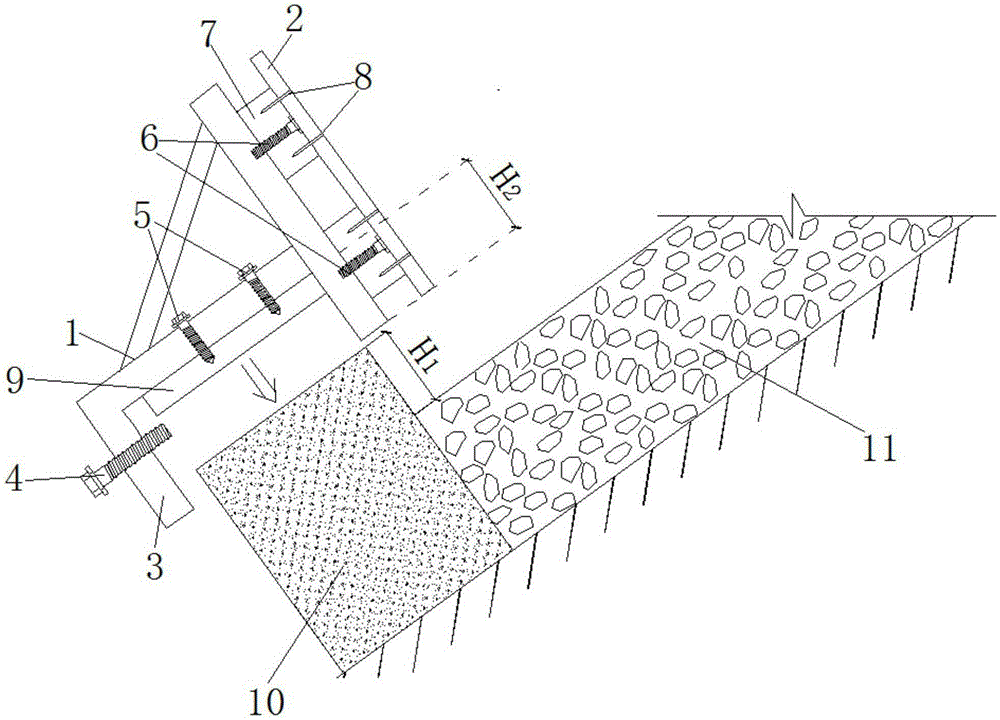

Construction method of reinforcing large-span concrete structure with prestressed carbon fiber sheet

InactiveCN103321430AWidely applicable reinforcementImprove mechanical performanceBridge erection/assemblyBuilding material handlingFiberCarbon fibers

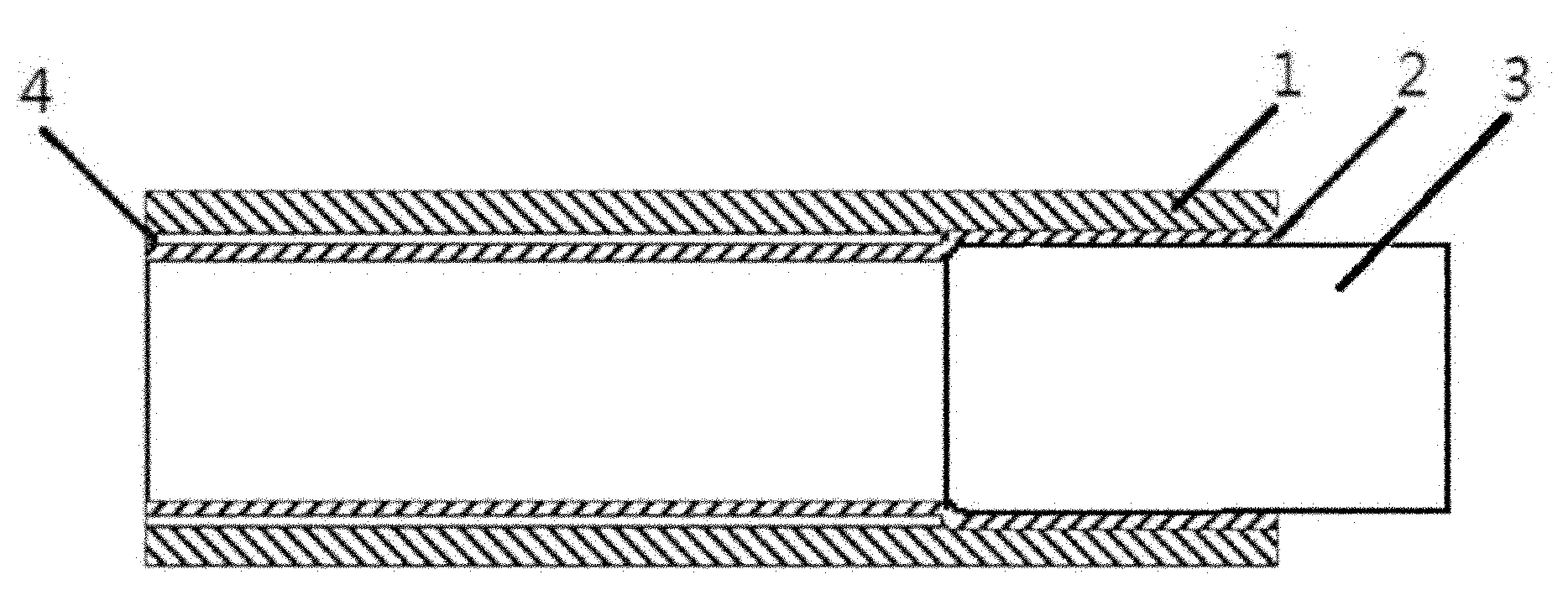

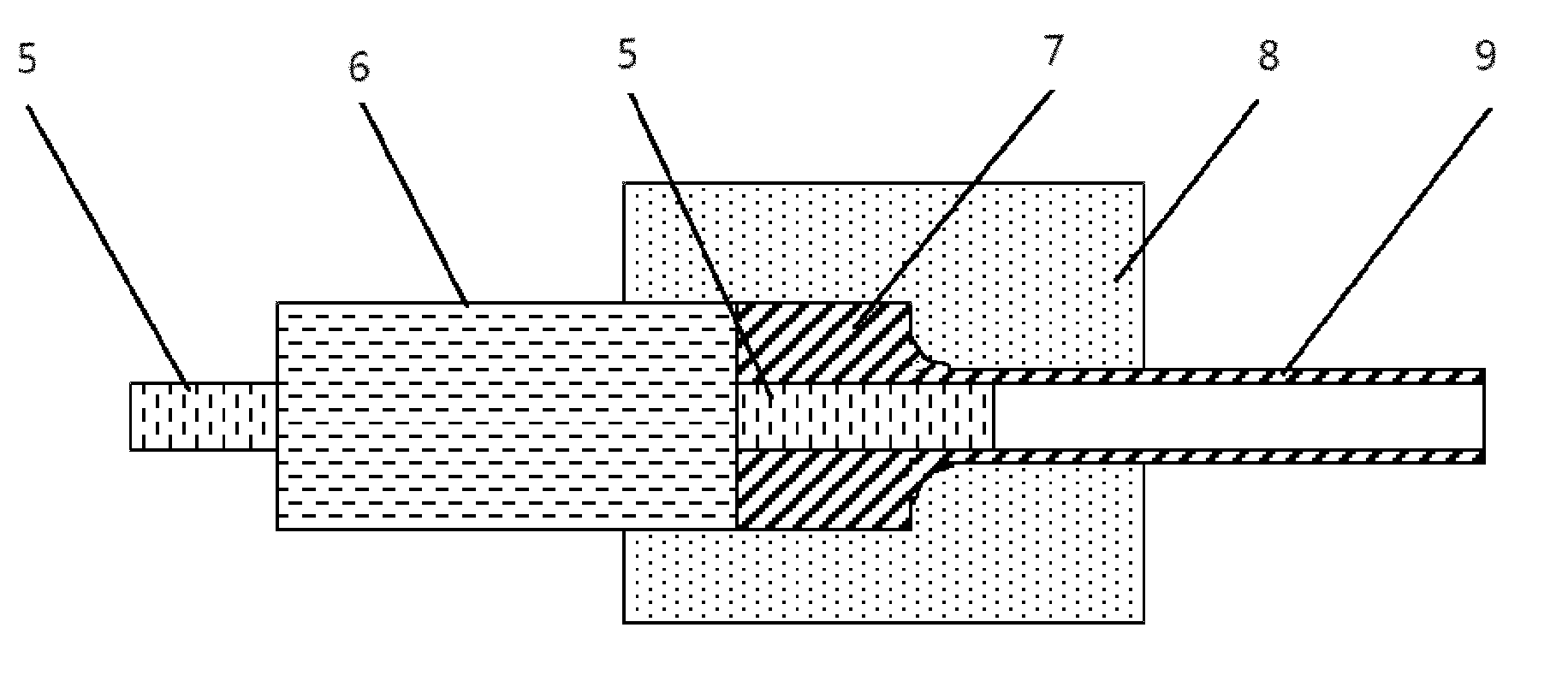

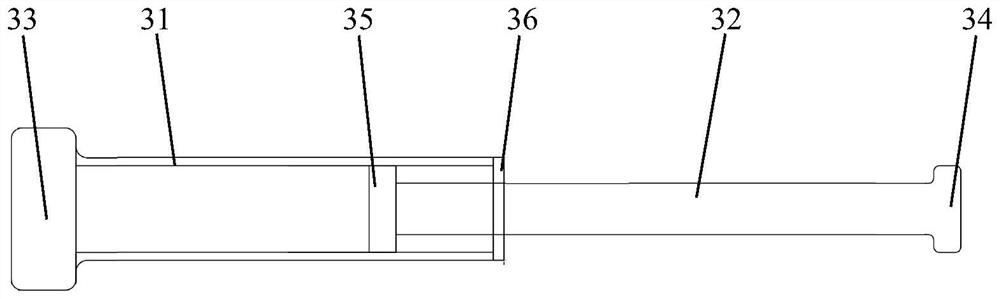

A construction method of reinforcing a large-span concrete structure with prestressed carbon fiber sheet comprises the following steps of forming bolt embedding holes on the side surface to be reinforced of the large-span concrete structure, and embedding high-strength bolts of different specifications into the bolt embedding holes through adhesive glue; fabricating stretch sheet fixing portions, stretch sheet moving portions and stretch power fixing portions; mounting the stretch sheet fixing portions, stretch sheet moving portions, stretch sheet assembling units, stretch power fixing portions and stretch power portions, wherein the stretch sheet assembling units, the stretch power fixing portions and the stretch power portions are made of carbon fiber materials; stretching stretch sheet; and removing stretching power and tightly pressing and adhering the stretch sheet onto the surface of the large-span concrete structure. The construction method of reinforcing the large-span concrete structure with the prestressed carbon fiber sheet can achieve the gapless adhesion between the prestressed stretch sheet and the concrete structure to be reinforced, facilitate the coordination of the uniform stress force of the same sections of the carbon fiber filaments of the stretch sheet, improve the integral stress performance of the prestressed carbon fiber sheet and the coordination deformation capability of the prestressed carbon fiber sheet and the concrete structure and give full play to the high-strength characters of the carbon fiber sheet.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

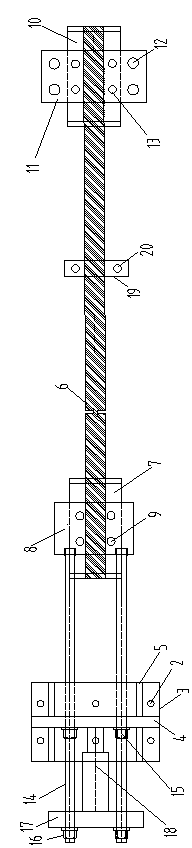

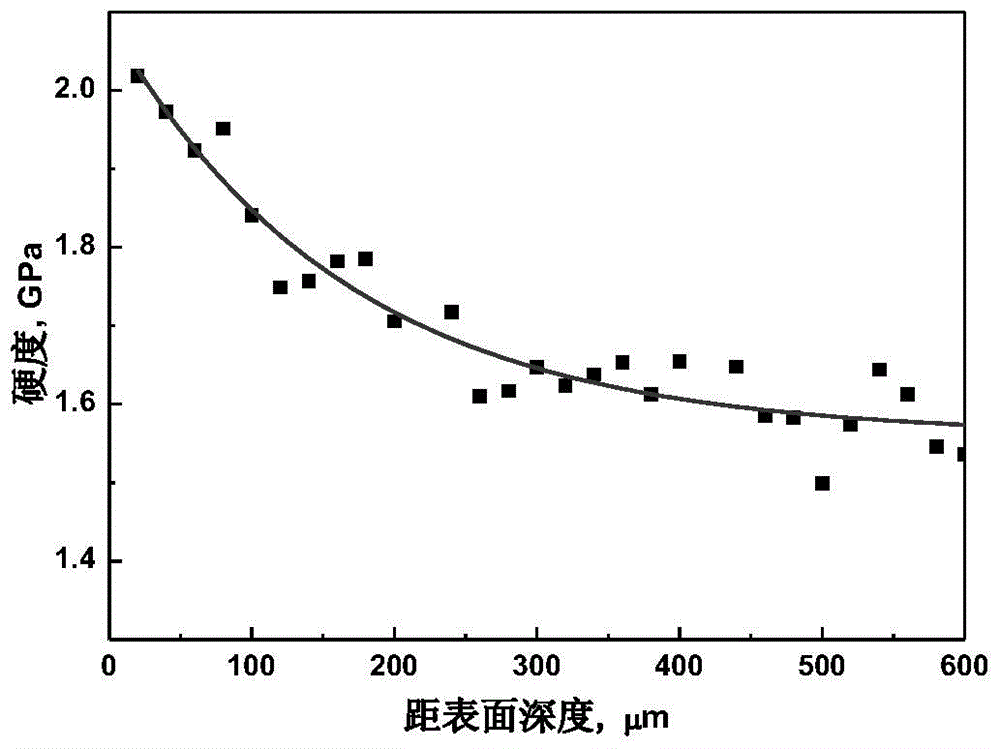

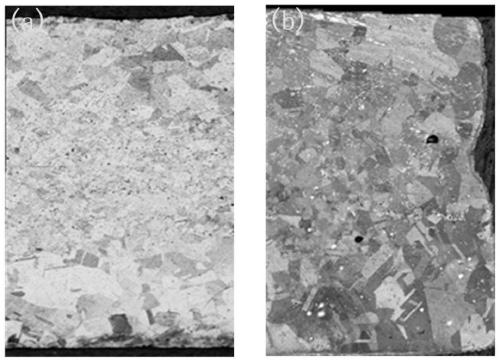

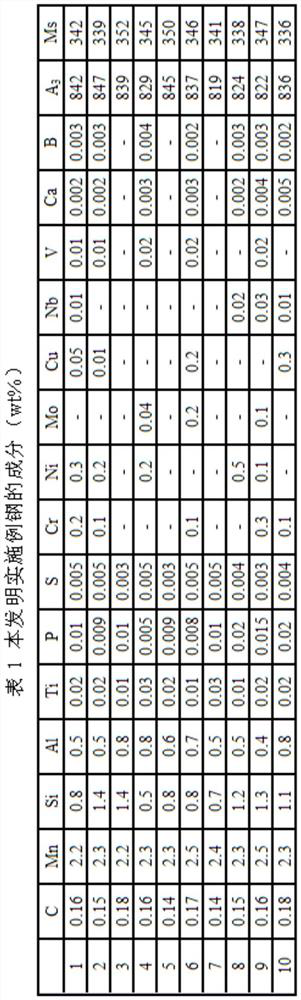

High-reaming high-plasticity 980MPa-grade dual-phase galvanized steel plate and preparation method thereof

ActiveCN113416888AControl carbon equivalentControl contentHot-dipping/immersion processesFurnace typesAlloyContinuous annealing

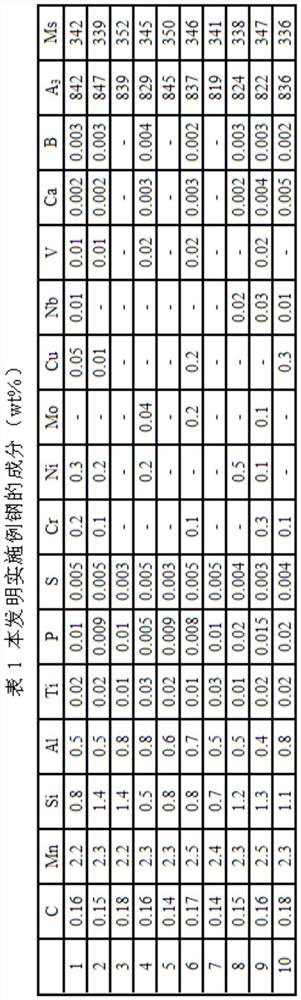

The invention provides a high-reaming high-plasticity 980MPa-grade dual-phase galvanized steel plate and a preparation method thereof. The steel plate comprises the following components in percentage by weight: 0.13-0.18% of C, 0.5-1.4% of Si, 2.2-2.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, less than or equal to 0.03% of Ti, 0.015-0.8% of Al and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps of smelting, hot rolling, acid pickling, cold rolling, continuous annealing galvanizing and finishing. By optimizing alloy design and ingenious process design, force energy indexes of high reaming and high plasticity are considered, and the technical difficulty that reaming and drawing performance of a traditional 980 MPa-grade steel plate are incompatible is broken through.

Owner:ANGANG STEEL CO LTD

Ti-Al-Zr-Cr-series martensitic titanium alloy and preparation method thereof

ActiveCN111394616AHigh strengthGood mechanical properties at room temperatureTitanium alloyCr element

Owner:XI AN JIAOTONG UNIV

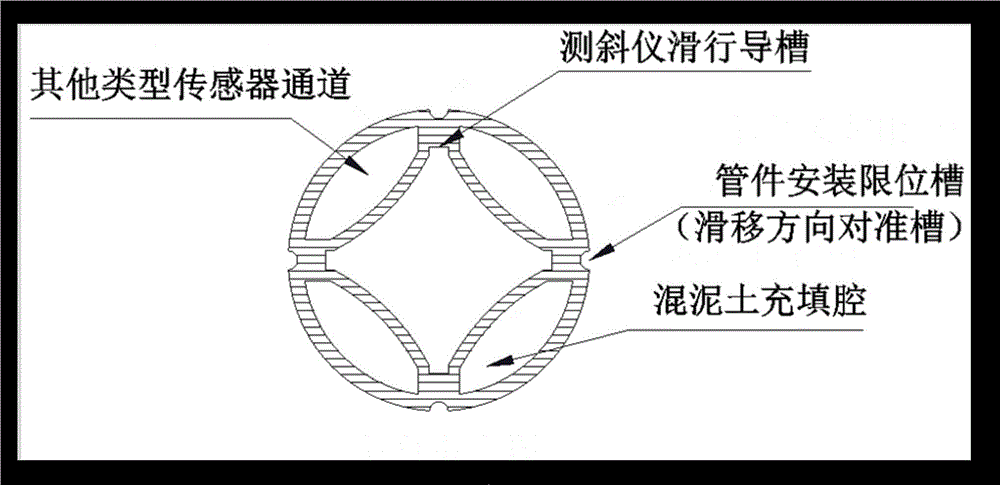

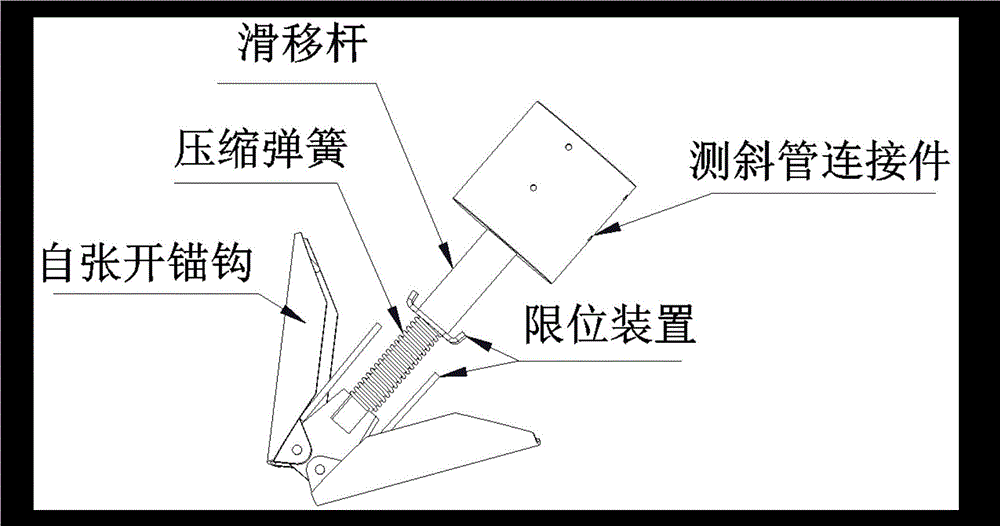

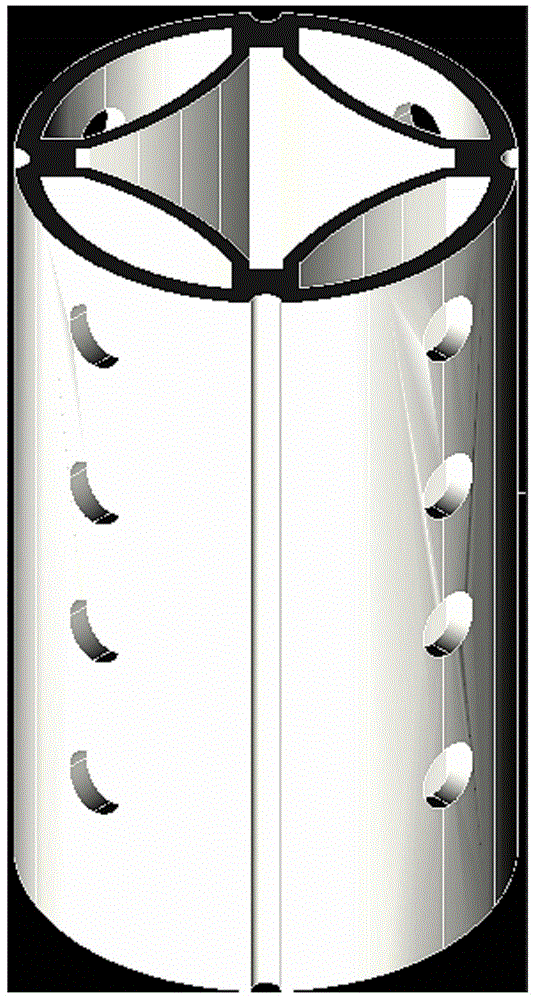

High-strength double-wall inclinometer casing for inclined displacement measurement

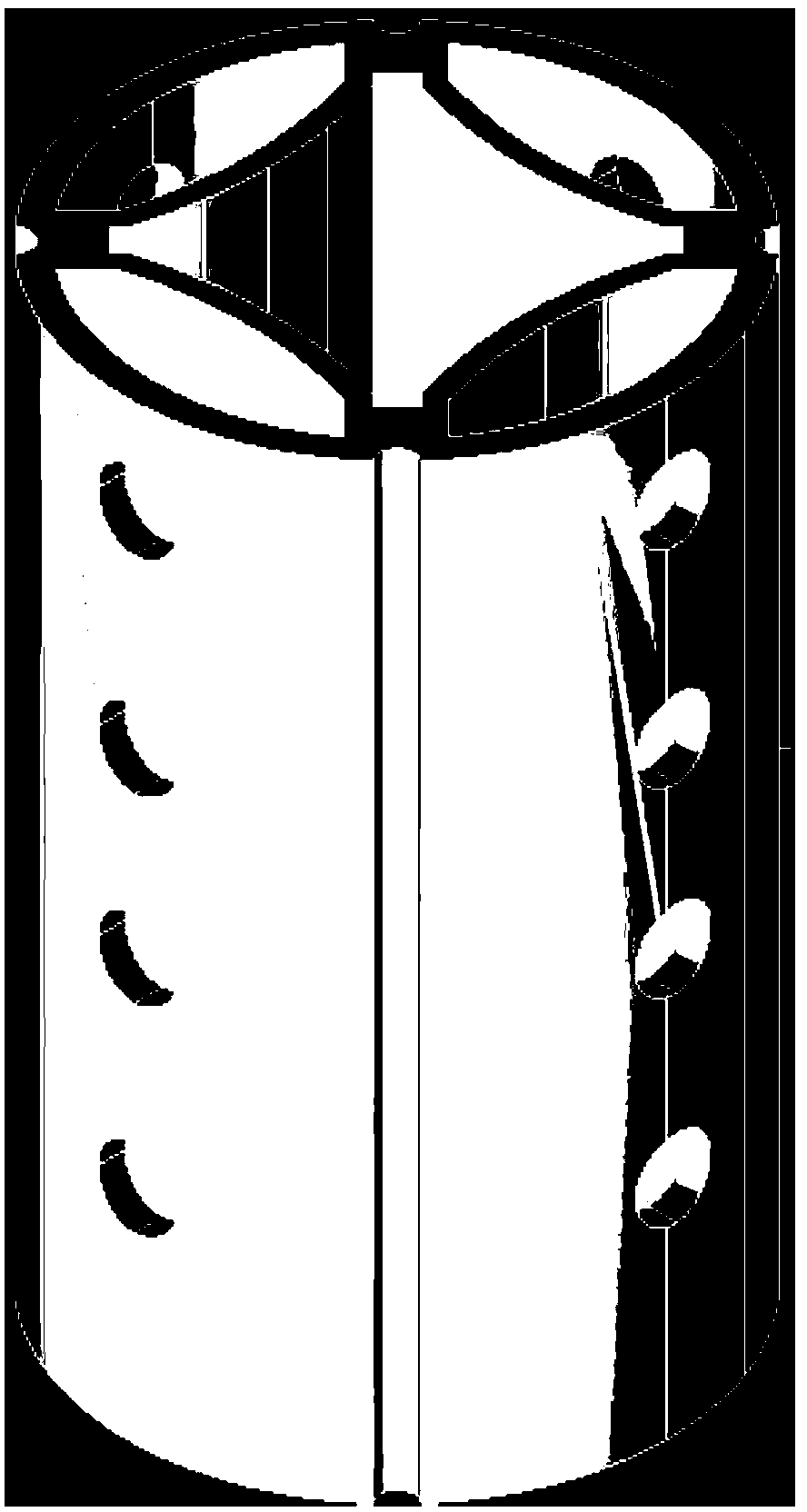

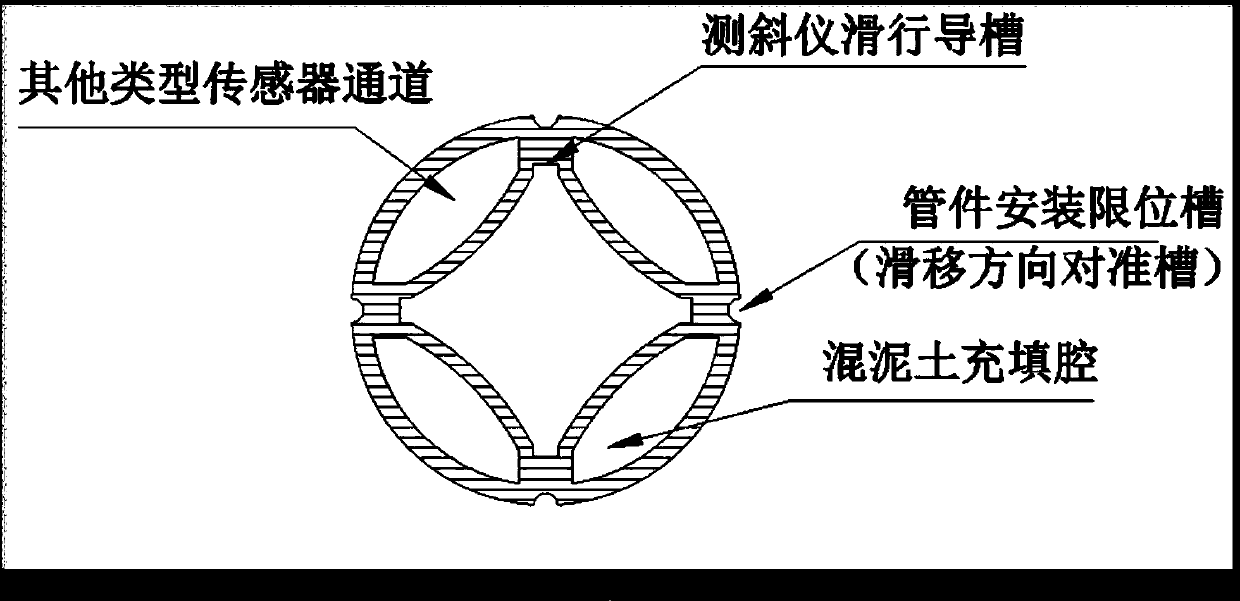

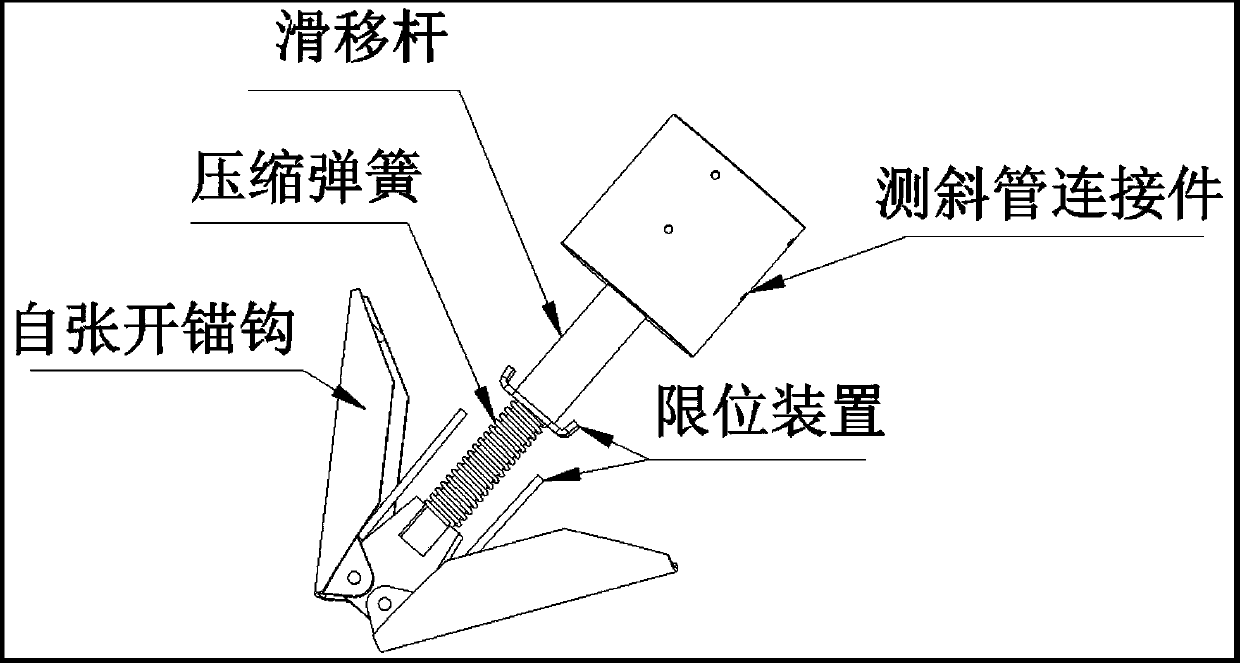

ActiveCN103882848AHigh mechanical strengthStrong bending resistanceFoundation testingIn situ soil foundationAxial pressurePipe fitting

The invention relates to a high-strength double-wall inclinometer casing for inclined displacement measurement. The high-strength double-wall inclinometer casing comprises a plurality of measuring pipe fittings, a plurality of pipe fitting connecting pieces and an axial pressure trigger self-opening type anchor hook base. The measuring pipe fittings are connected through the pipe fitting connecting pieces, the axial pressure trigger self-opening type anchor hook base is connected with the measuring pipe fitting which firstly conducts hole sinking, the measuring pipe fittings are provided with inner walls and outer walls, four concrete filling cavities of inner and outer pair arc structures are formed by the inner walls and the outer walls, a plurality of holes are formed in the outer walls, when the inclinometer casing is submerged in the bottom of drilled holes, pressure is exerted in the axial direction, the axial pressure trigger self-opening type anchor hook base is opened and is anchored to the pedestal rock, and when back filling is carried out on concrete, cement paste enters the concrete filling cavities through the holes. The inclinometer casing has the strong capability of resisting tension and pressure, resisting bending and resisting torsion, the compatible deformation capability of the inclinometer casing and the surrounding rock-soil layer is improved, the upward buoyancy of serous fluid on the inclinometer casing is reduced, and a base of the inclinometer casing and the bed rock are in the fixed connection state all the time.

Owner:BEIJING ZHONGLI ZHIYAN INTERNET OF THINGS TECH CO LTD

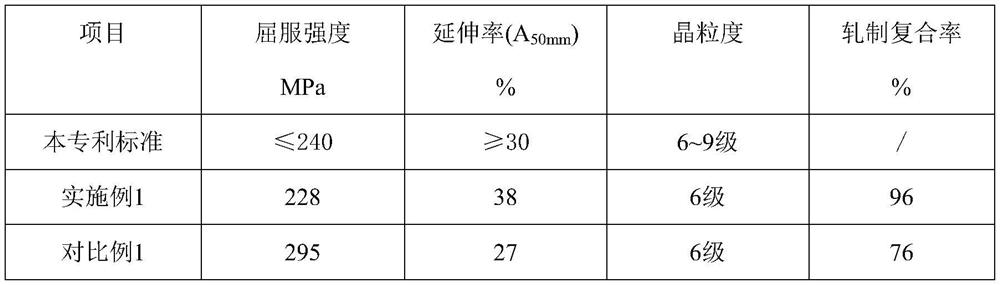

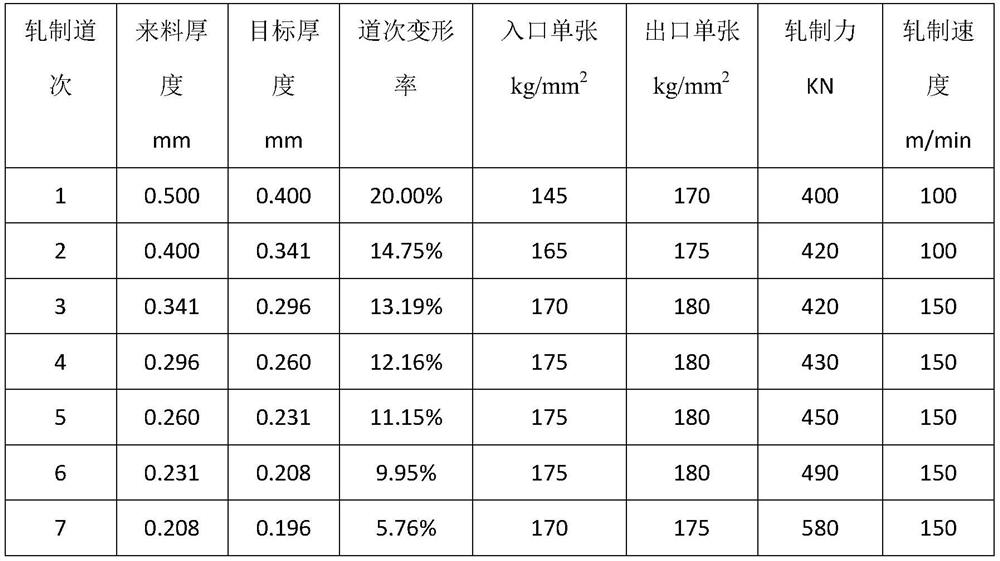

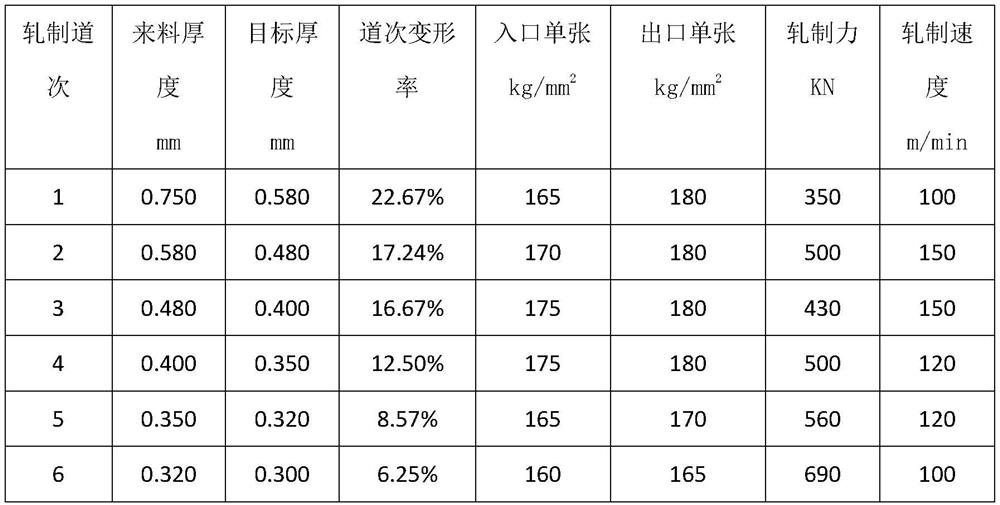

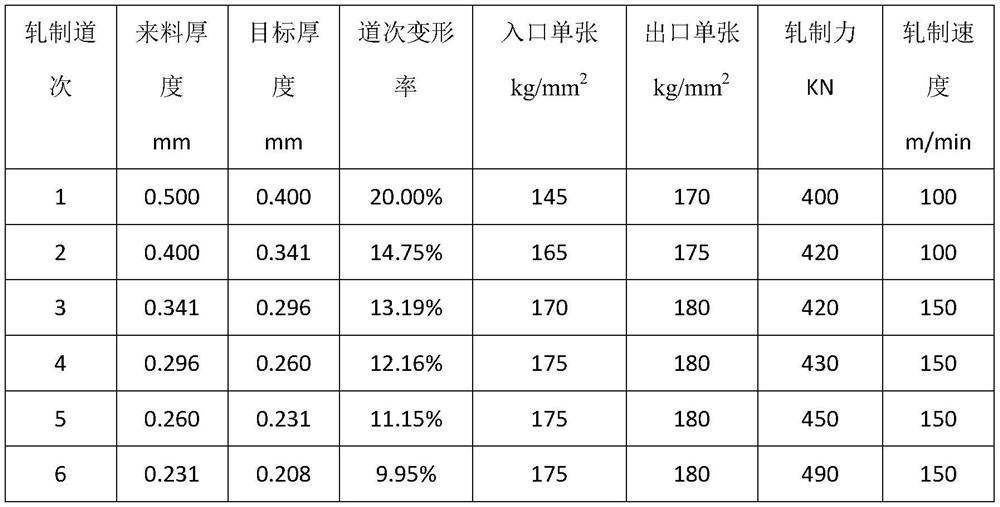

Preparation process method of wide ultrathin cold-rolled titanium strip coil for rolling bonding

ActiveCN112122382AExcellent overall performanceImprove compound rateMetal rolling arrangementsTitanium metalDissimilar metal

The invention relates to a preparation process method of a a wide ultrathin cold-rolled titanium strip coil for rolling bonding. The preparation process method comprises that a plate blank is preparedby adopting an EB furnace die casting slab ingot through process routes and parameters such as innovation, component design optimization, plate blank preparation, cold coiling rolling, heat treatment, leveling and shape correction and the like, the surface is machined by using a large integral cutterhead, a treatment method of first performing edge cutting and then performing annealing is adoptedafter cold rolling of a mother strip, a small-tension rolling control manner is adopted in the finished product rolling stage, finished product heat treatment is carried out in a long-time heat preservation and furnace cooling cover type annealing manner, and a rolling leveling method is selected to further improve the strip shape of the annealed strip coil; the width of the prepared cold-rolledtitanium strip coil can reach 1000 mm or above, the thickness can reach 0.1-0.3 mm, the strip shape is flat and straight, the comprehensive mechanical property is excellent, the rolling bonding rate with dissimilar metal is high, and meanwhile, the cost of the composite material titanium metal can be remarkably reduced.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Preparing method of stainless steel/copper multi-core composite wire

InactiveCN110788159AImprove coordination and deformation abilityHigh tensile strengthWire rodSS - Stainless steel

The invention discloses a preparing method of a stainless steel / copper multi-core composite wire. The method comprises the following steps that firstly, a copper bar is loaded in a stainless steel sheath, and two ends are subjected to sealing welding; secondly, through hot extrusion, a stainless steel / copper single-core composite bar is obtained; thirdly, multi-pass drawing is carried out to obtain a stainless steel / copper single-core composite wire; fourthly, straightening, sizing, cutting off, acid pickling and drying are carried out in sequence; and fifthly, bundling assembling is carried out to obtain a stainless steel / copper multi-core composite body, the sealing welding process, the hot extrusion process and the multi-pass drawing process are sequentially repeated, and through in-order putting, the a stainless steel / copper multi-core composite wire is obtained. Through the bundling assembling drawing method and in combination with hot extrusion, the excellent physical and chemical characteristics of the stainless steel are used, through design of the machining process and parameters, the synchronous coordinated deforming capacity of a stainless steel base body and a copper core wire can be greatly improved, the good stainless steel / copper interface combination effect can be formed, and the tensile strength and the conductive property of the stainless steel / copper multi-core composite wire can be improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High plasticity magnesium alloy and preparation method thereof

InactiveCN101392341AImprove coordination and deformation abilitySignificant increase in plasticityStress concentrationUltimate tensile strength

The invention discloses a magnesium alloy with high plasticity, which contains the following components by mass percent: 0.5 percent to 4 percent of Sn, 0.1 percent to 6 percent of Pb, 0.05 percent to 6 percent of Zr, and Mg as the rest. The preparation steps thereof are as follows: materials are proportioned according to the proportion of alloy components, metals proportioned are heated and melted in protective atmosphere of SF6, the mass percent of Zr in Mg-Zr hardener is 30 percent, and the magnesium alloy of high plasticity is obtained after the temperature reaches 700 DEG C to 730 DEG C and is maintained for 5 minutes to 10 minutes. Magnesium can form a compound with both tin and lead, coordinating with deformation and alleviating stress concentration, thus greatly improving the plastic deformation capacity of magnesium alloy, not only effectively enhancing the strength of the magnesium alloy but also increasing the plasticity of the alloy. Under the function of a certain amount of Zr, tin and lead can impose a more obvious effect on the increasing of the plasticity of magnesium. The magnesium alloy of high plasticity only uses general elements of common tin and lead, thereby avoiding the use of a large amount of rare and precious elements, and has simple production and preparation technique, quite low cost and high normal-temperature plasticity.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

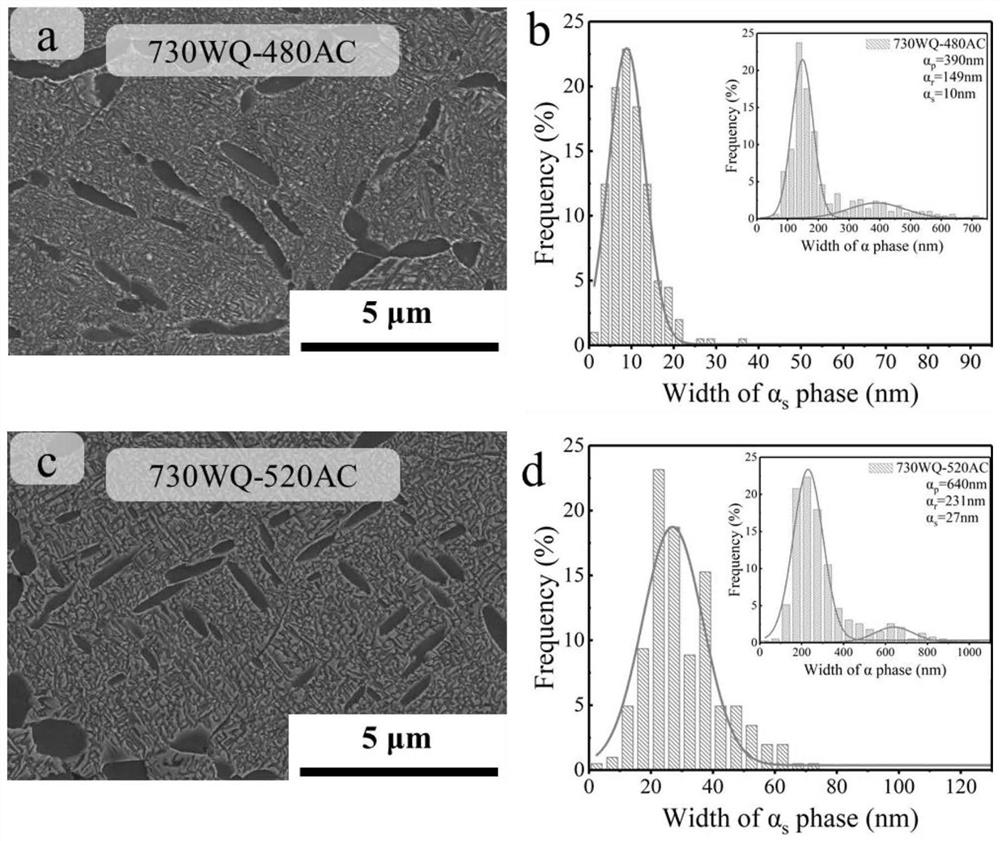

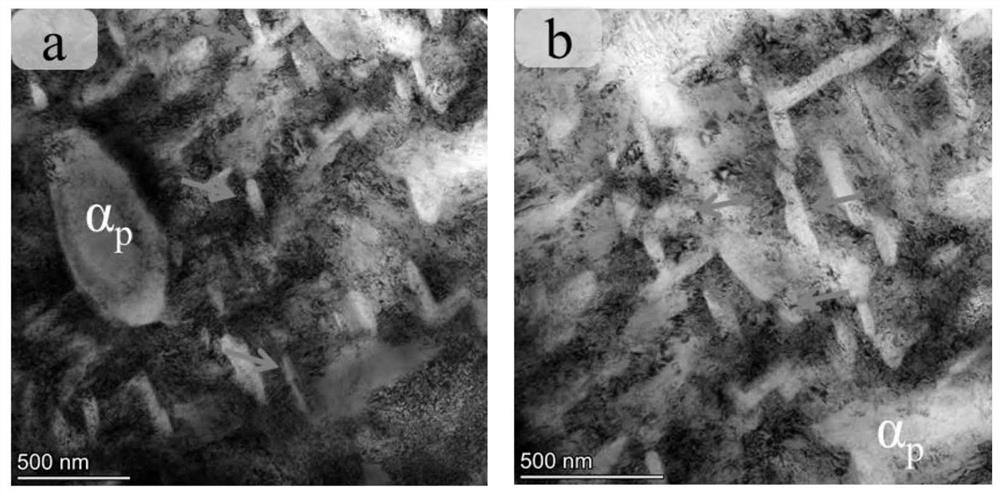

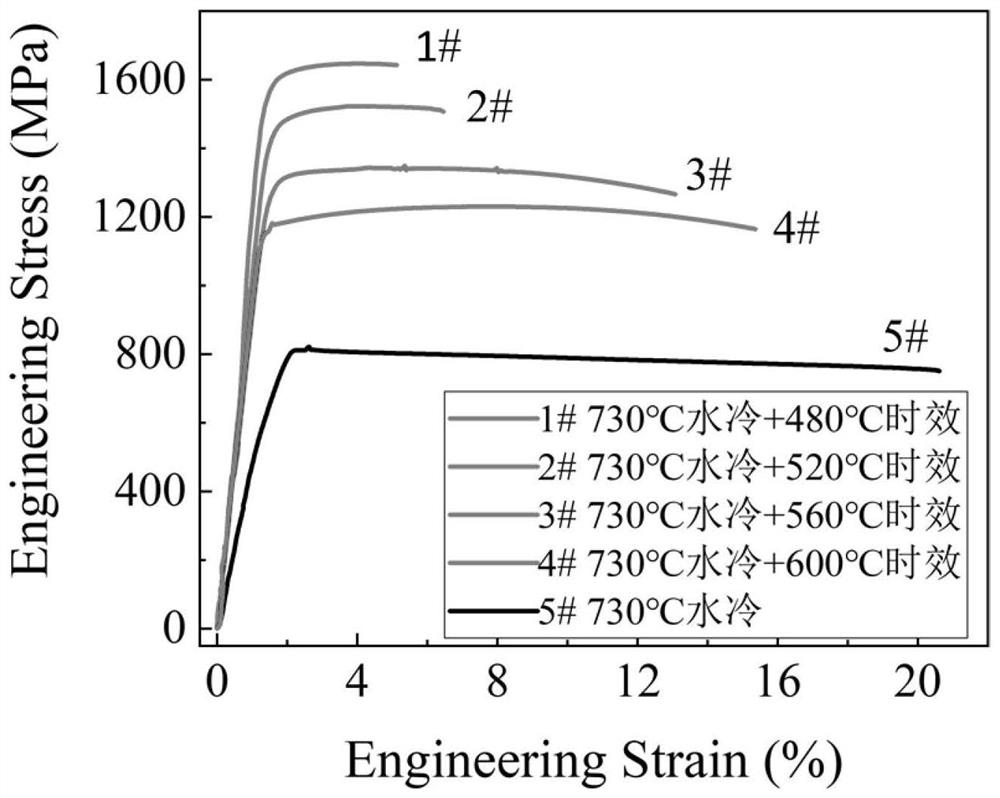

High-strength and high-plasticity metastable-state beta-type titanium alloy and preparation method thereof

ActiveCN113862514AHigh strengthPlastic reliefMetal-working apparatusIncreasing energy efficiencyTitaniumTitanium alloy

The invention discloses a high-strength and high-plasticity metastable-state beta-type titanium alloy and a preparation method thereof. The high-strength and high-plasticity metastable-state beta-type titanium alloy comprises the following components in percentage by weight: 11.0-12.0% of V, 5.0-6.0% of Al, 4.0-5.0% of Zr, 2.0-3.0% of Cr and the balance of Ti. After the alloy is subjected to conventional single-aging heat treatment, a secondary alpha s phase with the average size of about 10 nm can be obtained. In addition, a multi-level structure comprising a primary alpha phase and the secondary alpha s phase is constructed through two-phase region solid solution and aging heat treatment. Al and Zr elements are compounded to strengthen the alpha phase, and a V element is added to improve the plasticity of the alloy while a common beta strengthening element Cr is added to obtain extremely high strength. The yield strength of an existing metastable-state beta-type titanium alloy is improved to 1642 MPa which is unprecedented, the tensile strength is improved to 1726 MPa, and meanwhile, the ductility is 5%. Based on the characteristics, the alloy has great competitive advantages in high-strength and high-plasticity titanium alloys.

Owner:XI AN JIAOTONG UNIV

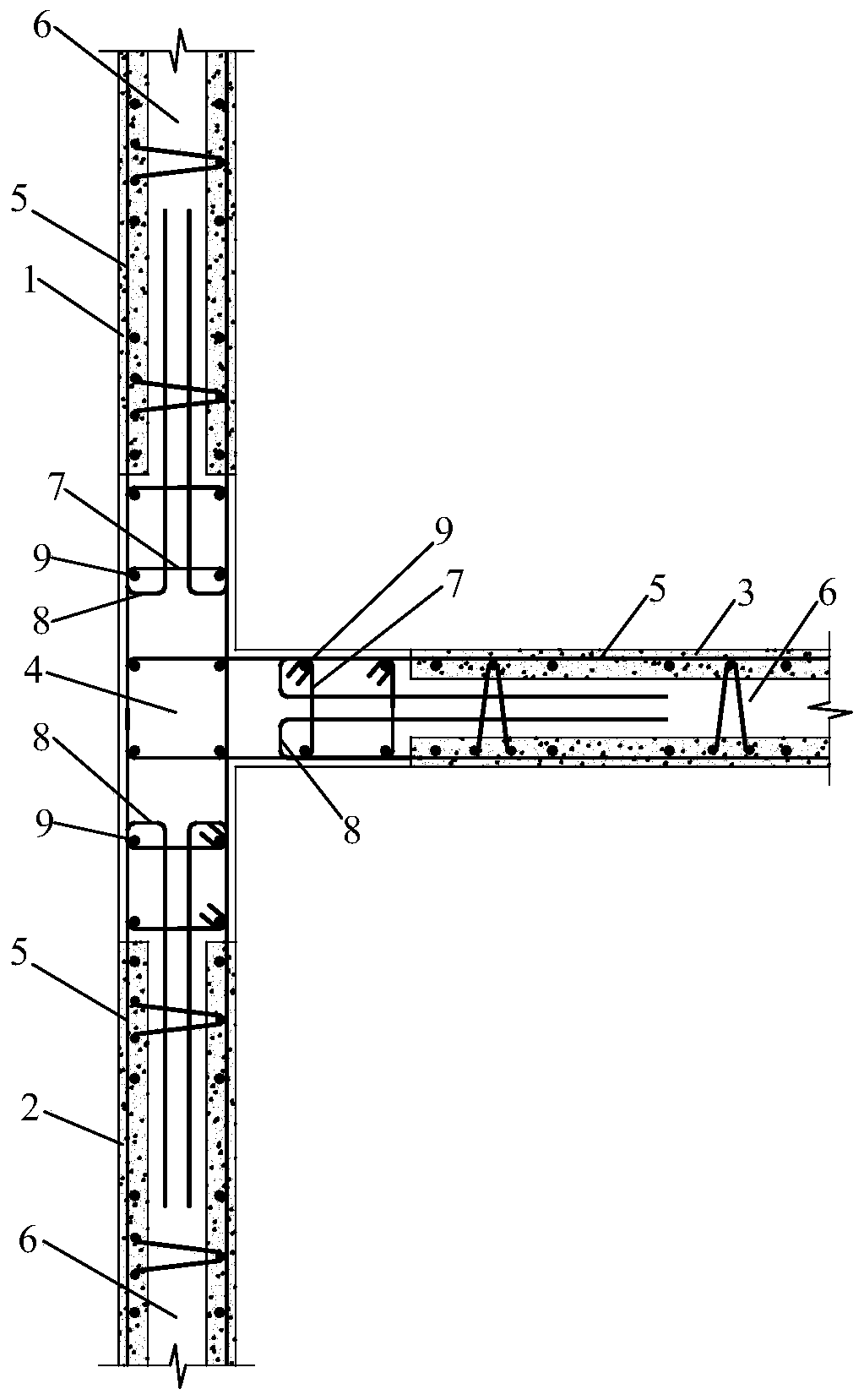

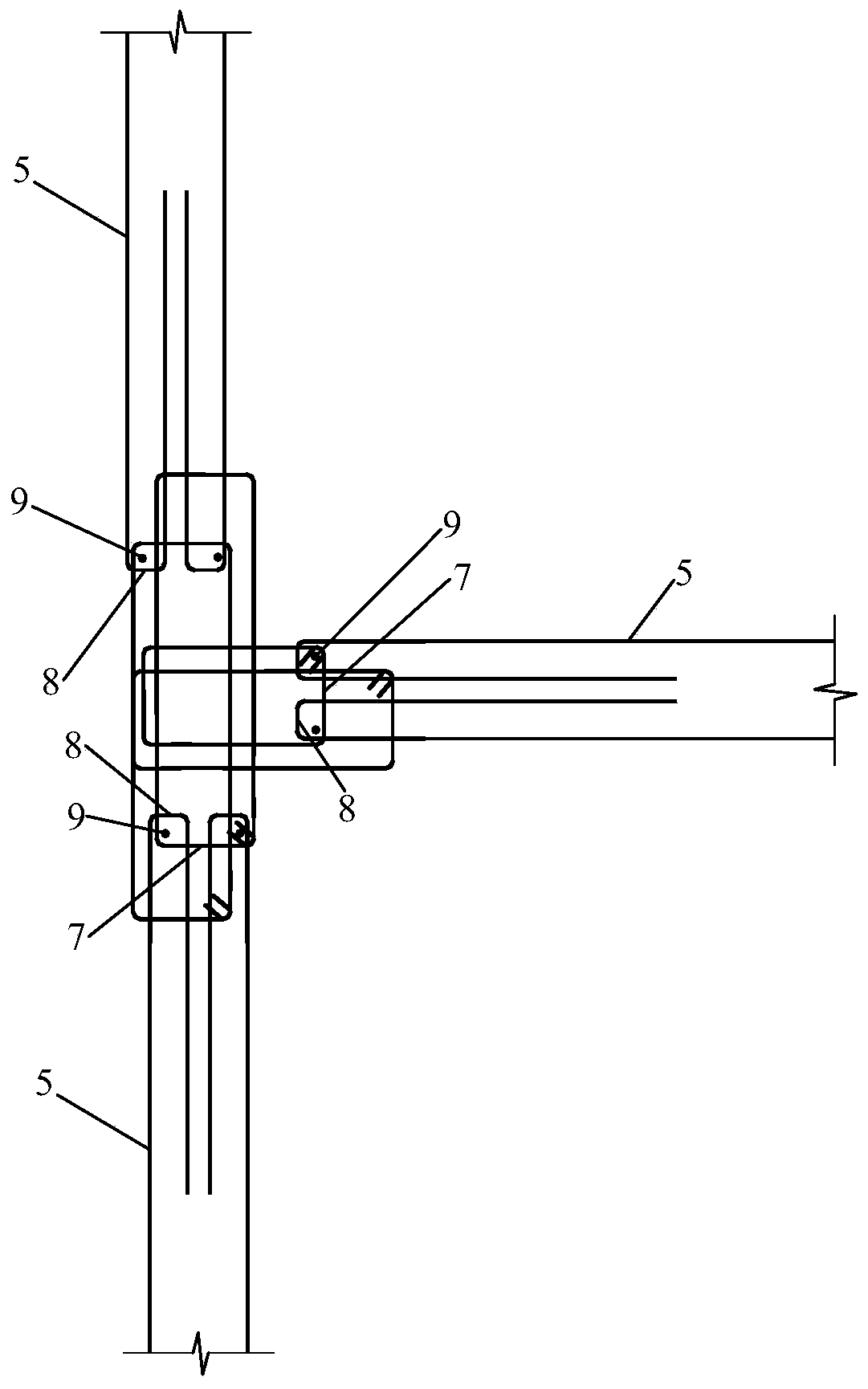

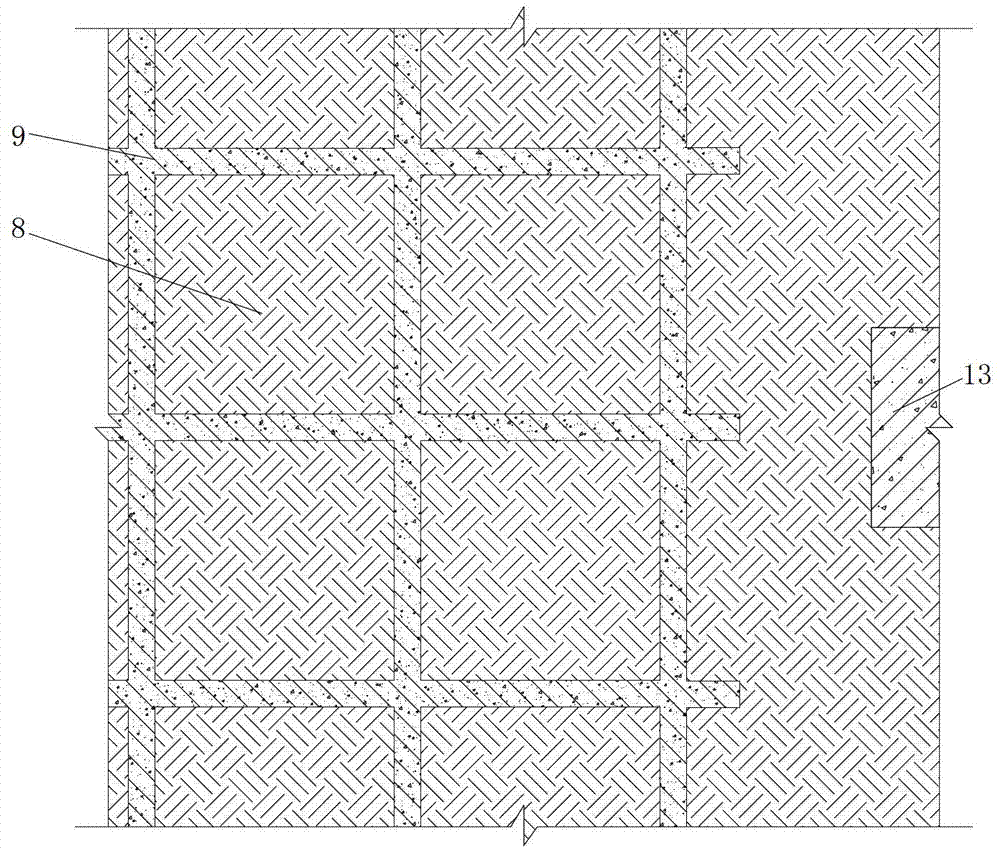

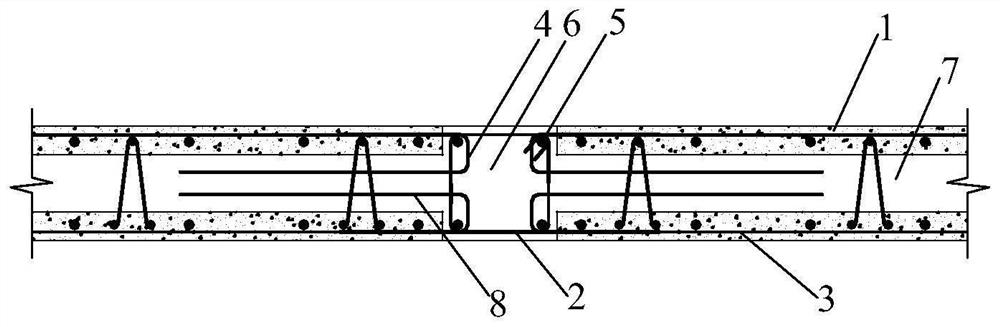

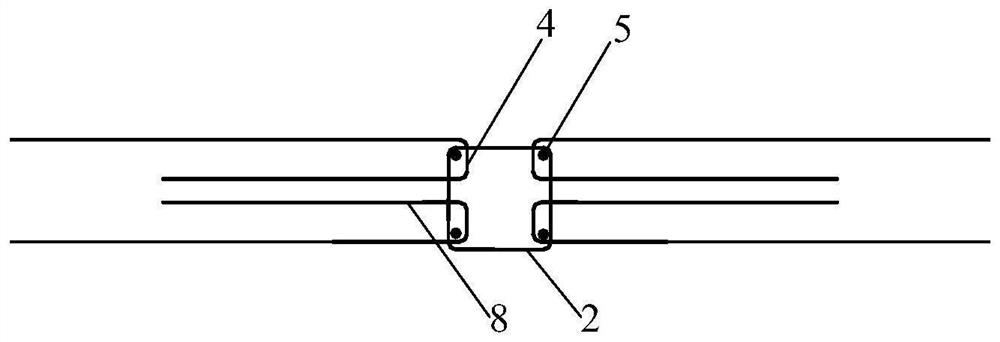

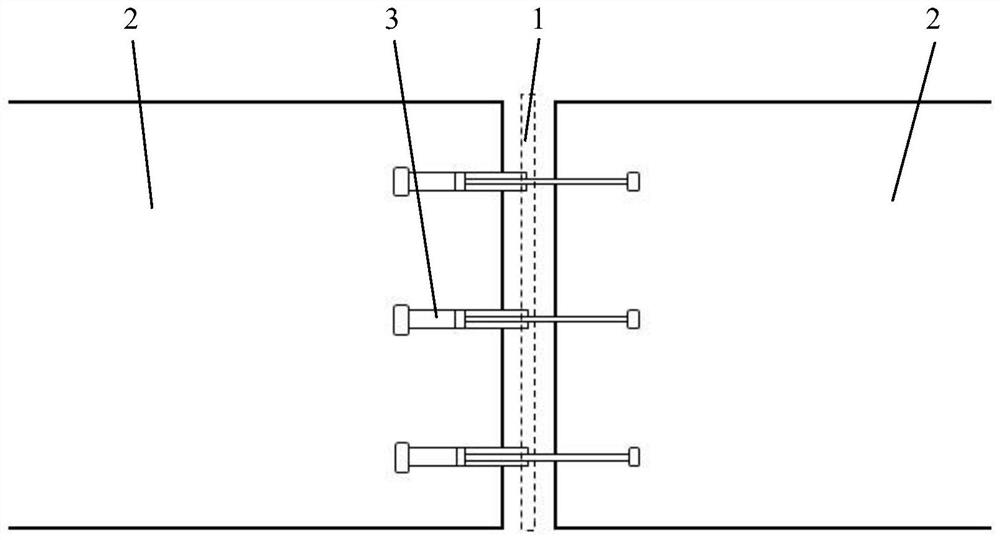

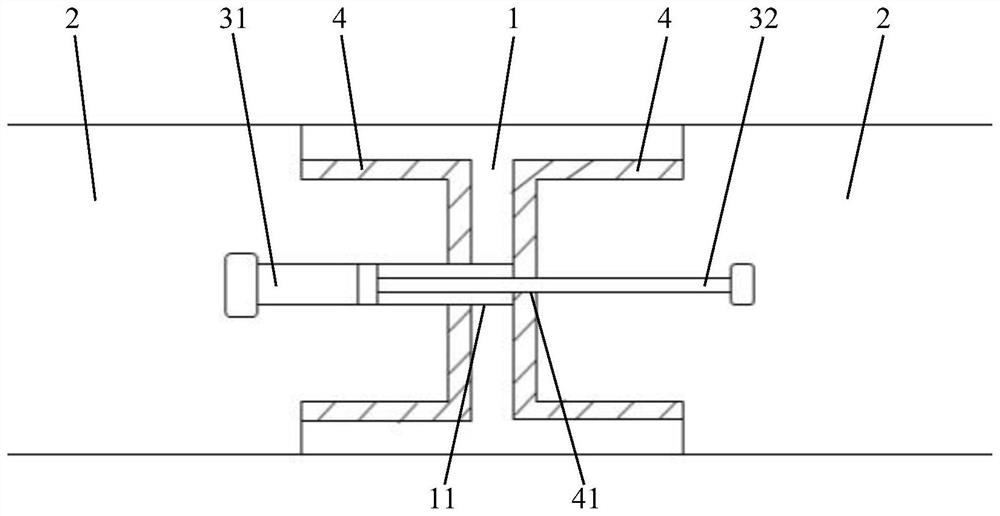

Connection structure of T-shaped superimposed shear wall edge member

ActiveCN109868920AFirmly connectedImprove coordination and deformation abilityWallsSemi openSteel bar

The invention relates to a connection structure of a T-shaped superimposed shear wall edge member. The connection structure of the T-shaped superimposed shear wall edge member includes first superimposed flange wallboards, second superimposed flange wallboards, superimposed webs and a post-pouring zone of the T-shaped edge member; horizontal reinforcing bars in inner superimposed layers and outersuperimposed layers of the first superimposed flange wallboards, the second superimposed flange wallboards and the superimposed webs extend into the post-pouring zone of the T-shaped edge member to acertain length, and are bended and turned to extend into cavity layers of the superimposed wallboards to form semi-open annular horizontal reinforcing bars; horizontal hooped reinforcing bars in the post-pouring zone of the T-shaped edge member are overlapped on the semi-open annular horizontal reinforcing bars at the ends of the superimposed flange wallboards and superimposed web wallboards and are bound to form a plurality of enclosed hoops; and vertical load-bearing reinforcing bars are inserted into the enclosed hoops, and concrete is poured into the cavity layers of the superimposed wallboards and the post-pouring zone of the T-shaped edge member to anchor the horizontal reinforcing bars. According to the connection structure of the T-shaped superimposed shear wall edge member, the post-pouring zone of the T-shaped edge member is reliably connected with the superimposed wallboards on the three sides of the T-shaped edge member by inserting the vertical load-bearing reinforcing bars into the enclosed hoops.

Owner:WUHAN UNIV OF TECH

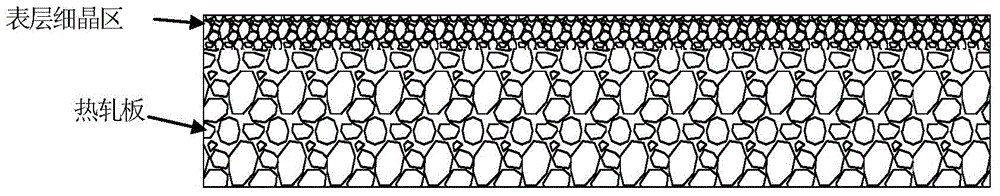

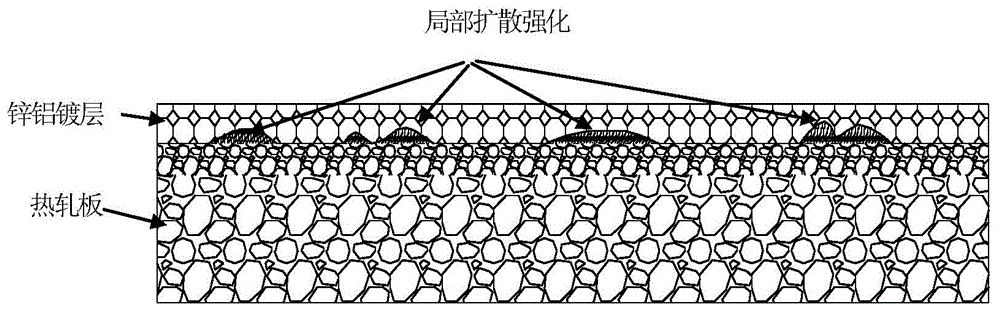

Locally reinforced hot-rolled zinc-aluminum plated steel plate and manufacturing method thereof

ActiveCN104943269AImprove coordination and deformation abilityImprove formation efficiencyPressure inorganic powder coatingMetal layered productsZinc compoundsSheet steel

The invention discloses a locally reinforced hot-rolled aluminum-zinc plated steel plate and a manufacturing method thereof. The locally reinforced hot-rolled aluminum-zinc plated steel plate comprises a matrix and a plating, wherein the interface between the plating and the matrix of the zinc-aluminum plated steel plate comprises a non-continuously distributed and locally diffused reinforced zone composed of an iron-zinc compound and an iron-aluminum compound. Compared with a normal hot-dipping zinc plated or zinc-aluminum plated plate, by controlling the formation and distribution of the metal compounds in the interface, the local interface reinforced zone is formed and has relative good adhesion strength and forming performance. The manufacturing method comprises the steps of pre-treatment of the hot-rolled steel plate, cold spraying of zinc-aluminum and post thermal treatment. By adopting the method, the effects of acidless descaling as well as fining and roughening of surface grains are synchronously realized; the method is high in efficiency, slight in pollution and environment-friendly; the plating is strong in adaptability and wide in product range.

Owner:BAOSHAN IRON & STEEL CO LTD

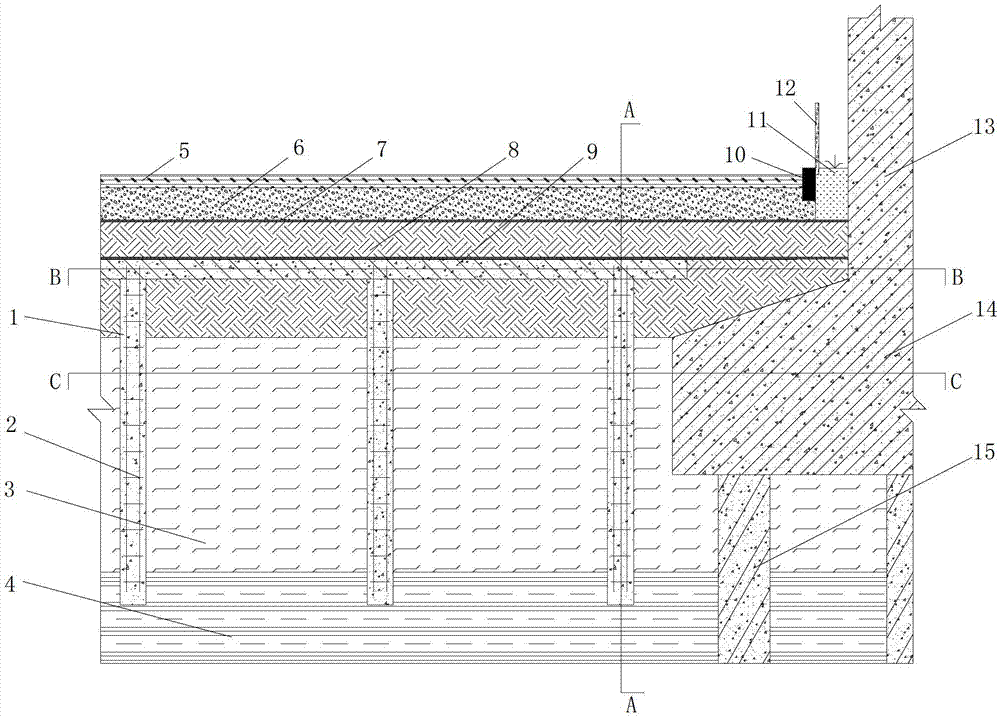

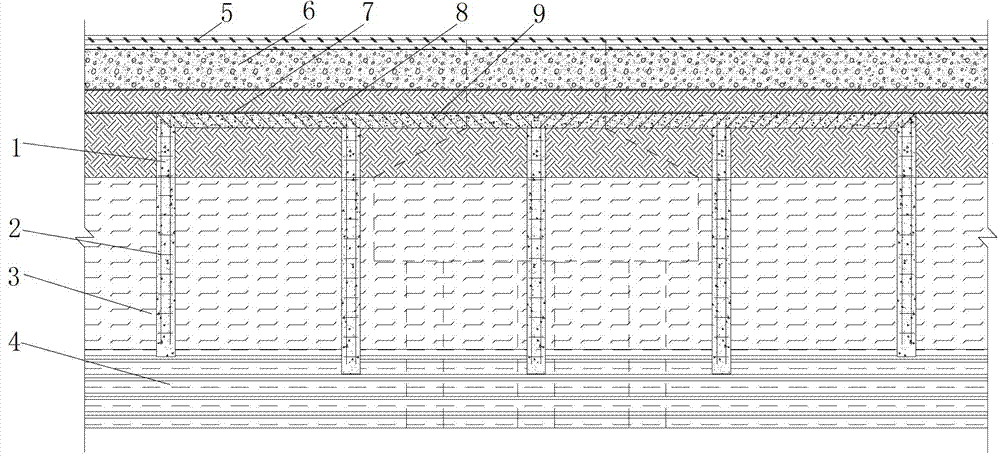

Viaduct road embankment structure with lower pile foundation bearing platform extending in roadbed, and construction method

InactiveCN103334357BMorph coordinationImprove integrityRoadwaysFoundation engineeringStructural engineeringRoad surface

The invention relates to a viaduct road embankment structure with a lower pile foundation bearing platform extending in a roadbed, which mainly comprises roadbed treatment piles, pile top vertical and horizontal connection cover beams, light filler layers, stabilized soil backfill layers and horizontal reinforcement layers, wherein roadbed treatment piles are arranged in the roadbed, and connecting rebars are connected on the pile tops in advance; the vertical and horizontal connection cover beams are poured on the pile tops of the roadbed treatment piles and are connected with pile bodies through the pile top connecting rebars; the roadbed is backfilled by stabilized soil and the light filler layers in a layered mode, and is internally provided with the horizontal reinforcement layers. According to the viaduct road embankment structure, the integrality of a viaduct road embankment can be greatly improved, the property of roadbed filler can be improved, the weight of the filler is reduced, the problem of pavement longitudinal cracks and waves due to differential settlement caused by that a pile foundation bearing platform extends in the roadbed is solved, and the god technical and economic benefits are gained. The invention also provides a construction method of the road embankment structure.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

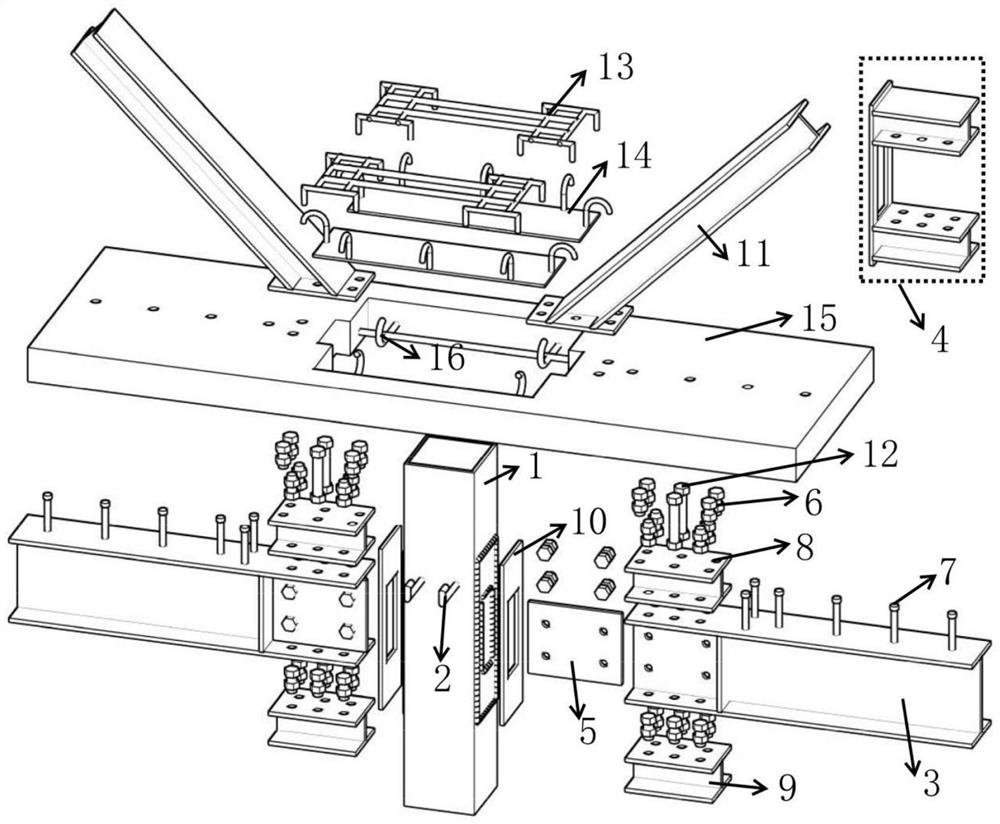

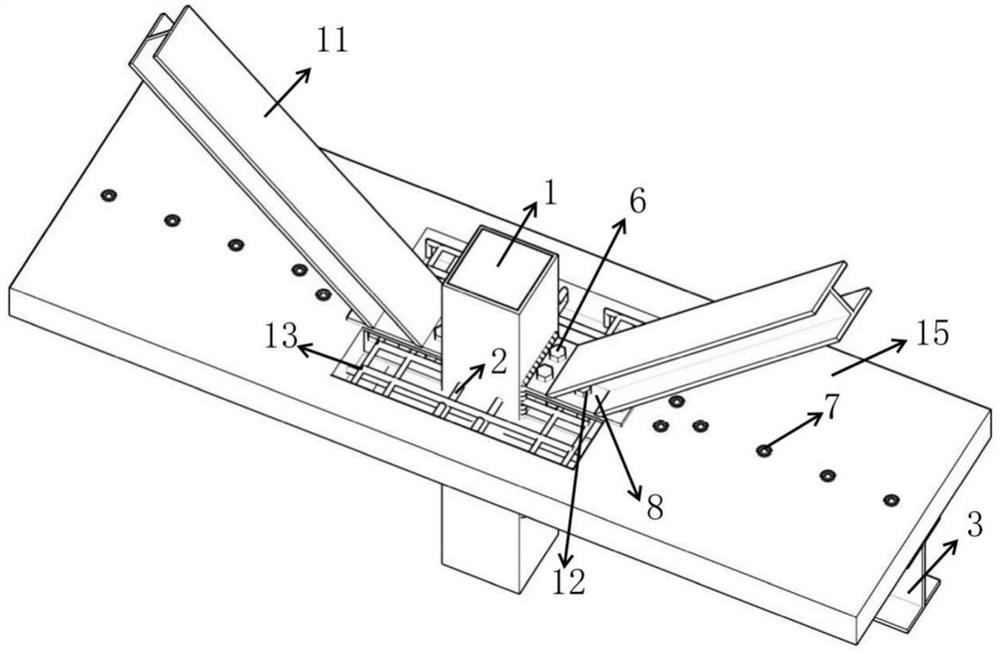

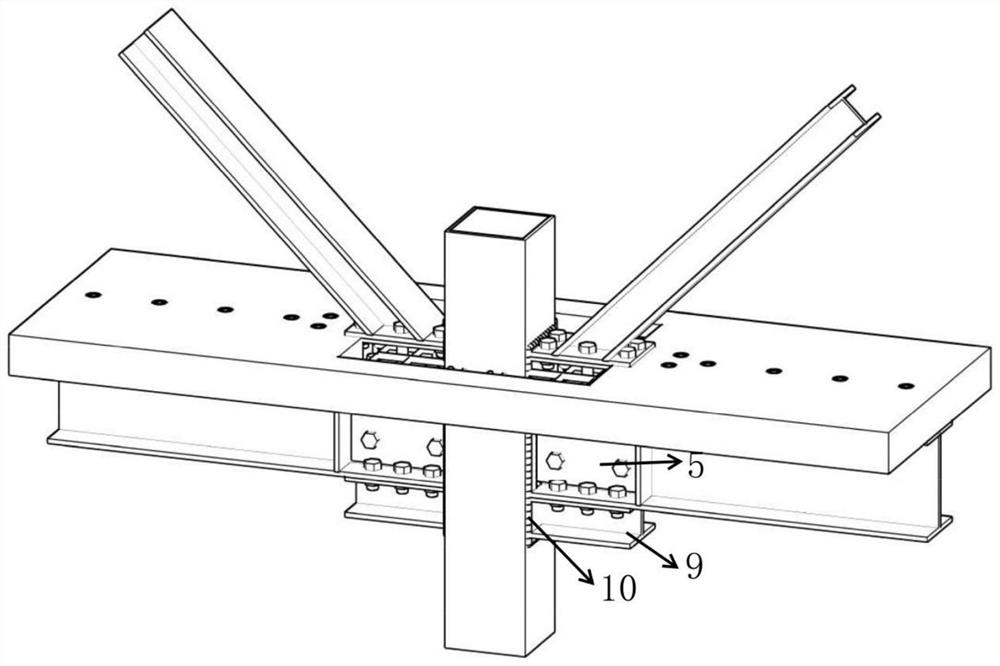

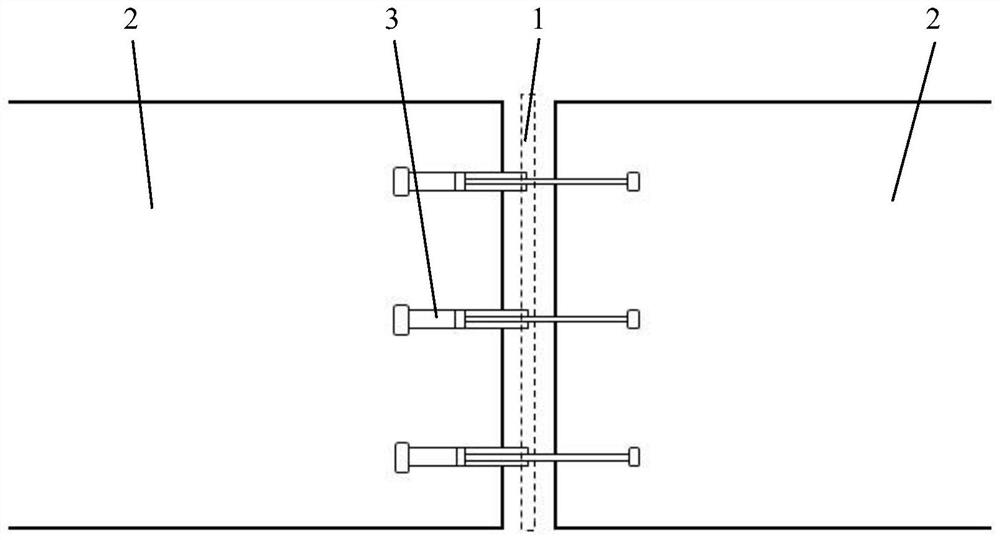

Concrete filled steel tubular column, H-shaped steel beam, steel support and pi type connecting piece combined center column bottom joint and making method

PendingCN111962952AIncreased shear capacityImprove corrosion resistanceFloorsHeat proofingEarthquake resistanceFloor slab

The invention discloses a concrete filled steel tubular column, H-shaped steel beam, steel support and pi type connecting piece combined center column bottom joint and a making method. The joint mainly comprises a light square steel tube recycled concrete column, H-shaped steel beams, a pi type connecting piece, web connecting plates, high-strength bolts, steel supports, I-shaped bench binding steel bars, slab column binding steel bars and a prefabricated recycled concrete floor. Compared with the prior art, the joint is simple in structure and convenient to construct, and has a clear force transferring route and two seismic fortification lines. The novel structures such as the pi type connecting piece, the bench binding steel bars and the slab column binding steel bars are creatively proposed, and integrality of slab-column-joint domain is enhanced; bending resistance, pressure resistance and stability of the joint are effectively improved; reliability of the steel support and the pitype joint connecting structure is further ensured; and the joint is firm in beam-column-support-floor connection, high in integrality and excellent in seismic performance and the key technological support is provided for engineering design of a prefabricated green housing light steel combined structure.

Owner:BEIJING UNIV OF TECH

Bearable and monitorable shearing-resistant non-pulling-resistant piston type expansion joint device

ActiveCN114016400AGuaranteed free scaling performanceReduce displacementBridge structural detailsExpansion jointPiston

The invention discloses a bearable and monitorable shearing-resistant non-pulling-resistant piston type expansion joint device which comprises I-shaped steel and telescopic components, wherein rubber layers are fixed on two sides of a web of the I-shaped steel and the inner side of a flange plate; the multiple telescopic components are arranged in the length direction of the I-shaped steel at equal intervals; the telescopic components pass through the web of the I-shaped steel, and the two ends of each telescopic component are fixedly connected with the connecting components on the two sides of the I-shaped steel respectively. According to the invention, the telescopic joint device with the telescopic function is composed of the I-shaped steel and the telescopic components, and the free telescopic performance between the adjacent connecting components is guaranteed; thus, the rubber is embedded in the gap between the I-shaped steel and the connecting component, so that the continuity of the whole structure and the durability of the telescopic device in use are improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

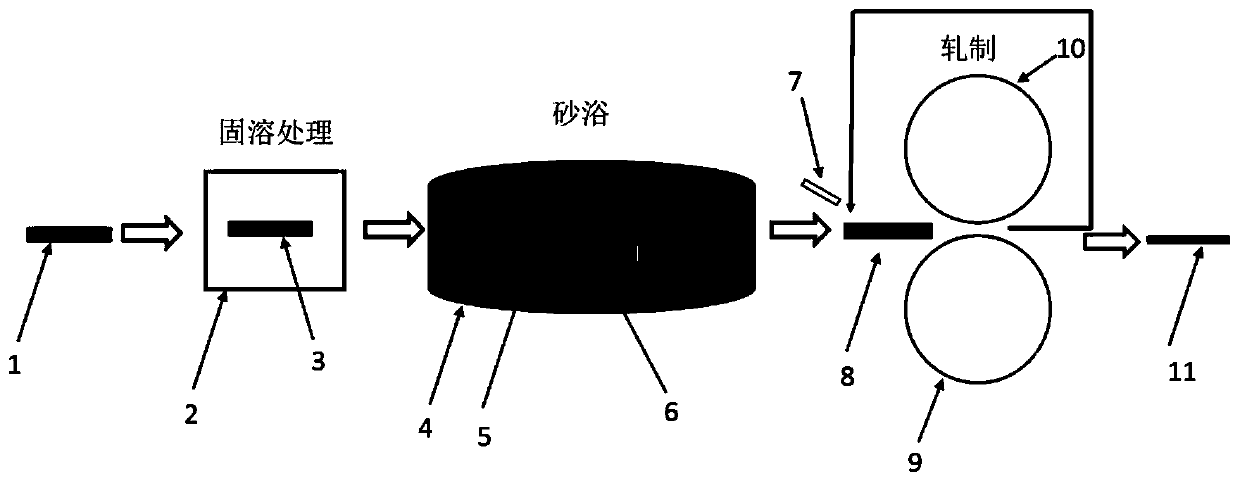

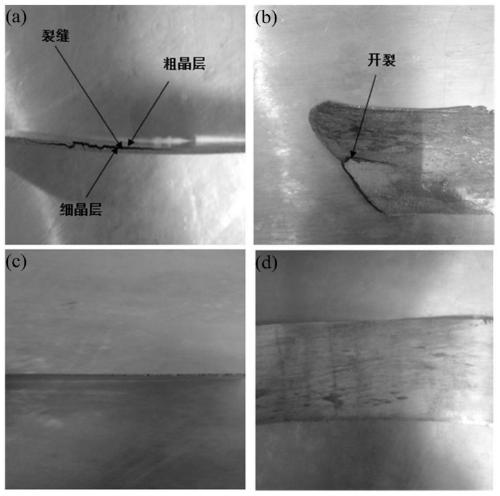

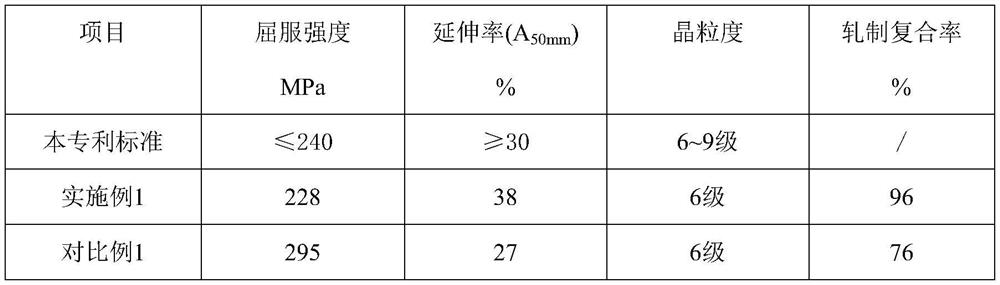

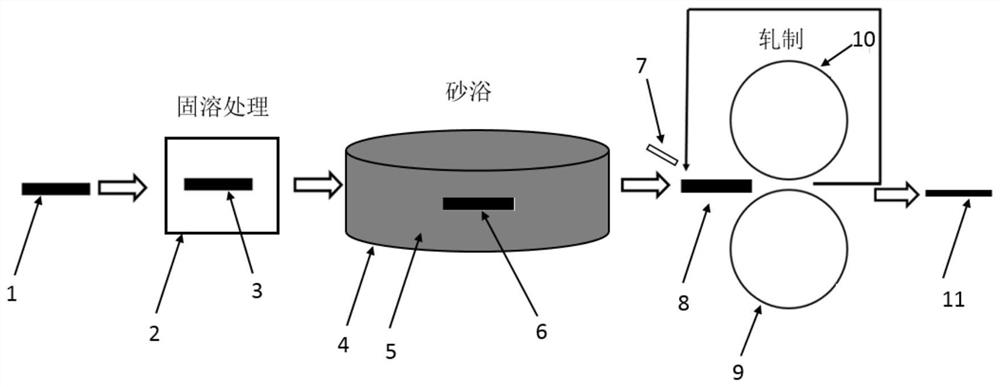

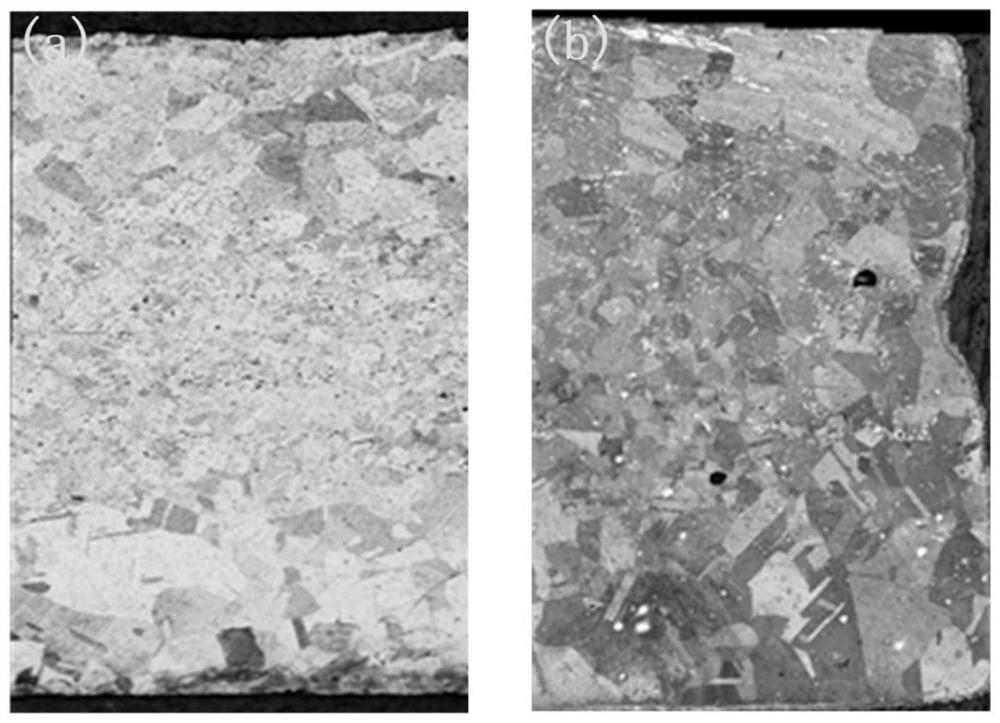

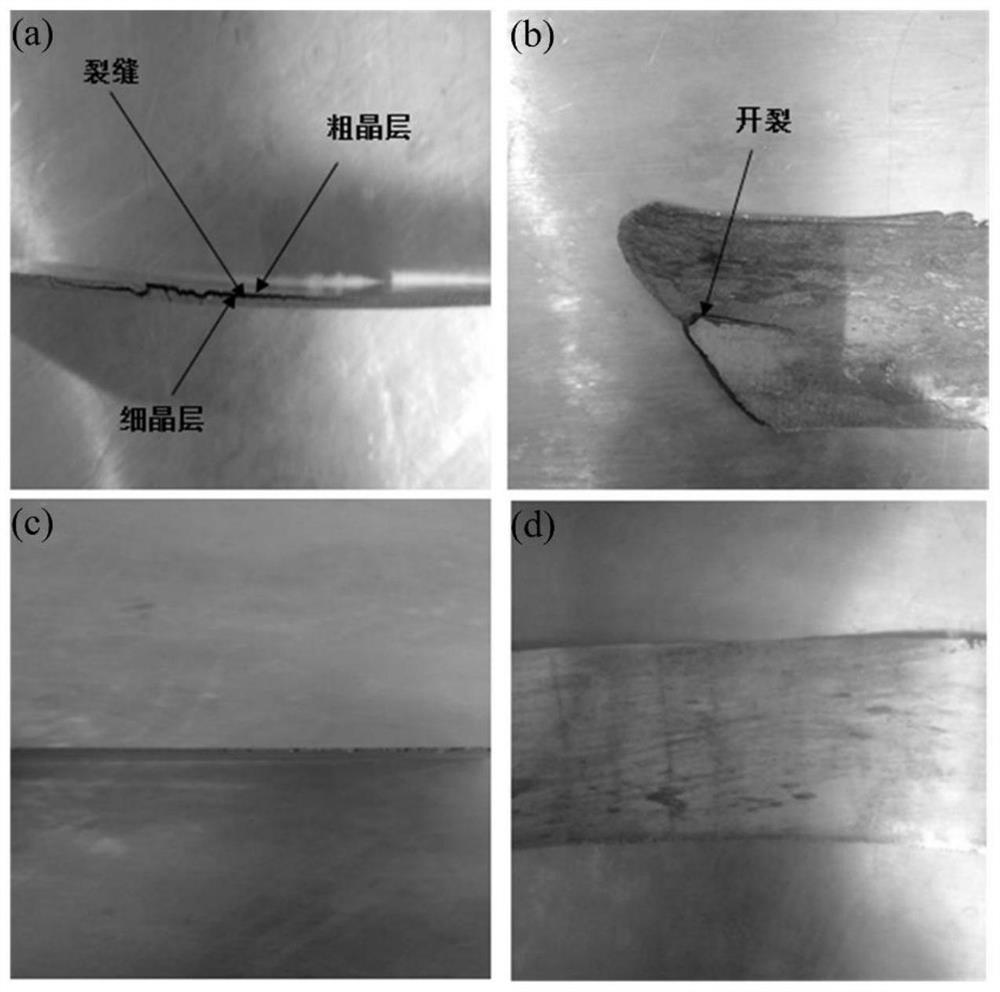

Preparation method capable of improving coordinated rheological capacity of fine grain layer and coarse grain layer of gradient structure copper alloy

ActiveCN110408870AGood formabilityImprove coordination and deformation abilityCold airStructure of the Earth

The invention discloses a preparation method capable of improving the coordinated rheological capacity of a fine grain layer and a coarse grain layer of a gradient structure copper alloy. A cast-rolled gradient structure copper alloy plate is subjected to solid-solution quenching; a solid-solution-quenched plate is stored in a container which is in the temperature of -80 DEG C to -105 DEG C and isfilled with fine sand, and the storing time is 15 minutes or above; the plate is taken out, and the surface sand particles are fast blown away completely through high-pressure cold air of -80 DEG C to -105 DEG C; the plate of which the surface is blown completely is rolled, and the rolling-pass reduction ratio is controlled to be 10%-15%; and repeated operation is performed in sequence till the whole rolling reduction ratio reaches 70%-95%. The coordinated rheological capacity of the fine grain layer and the coarse grain layer of a gradient structure copper alloy strip prepared through the method is improved remarkably, cracking does not occur any more, the machining forming property is better, and production is more efficient. The preparation method is suitable for all series of gradientstructure copper alloy materials at present, the forming effect of the gradient structure copper alloy materials can be improved to a great degree, and the technology can greatly promote wider application of the gradient structure copper alloy materials to all industries.

Owner:CENT SOUTH UNIV

Preparation method of in-situ synthesized titanium-aluminum composite material distributed in network shape

ActiveCN114734040AImprove coordination and deformation abilityImprove plastic toughnessAdditive manufacturing apparatusTransportation and packagingSelective laser meltingAl powder

A preparation method of an in-situ synthesis titanium-aluminum composite material distributed in a network shape comprises the following steps: adding graphene nanosheets and dodecylbenzene sulfonic acid into deionized water, and then carrying out ultrasonic dispersion treatment to obtain a graphene solution; the spherical Ti powder and the graphene solution are added into absolute ethyl alcohol, then heating ultrasonic stirring and drying treatment are conducted, and Ti / graphene composite powder with a graphene coating on the surface is obtained; and the spherical Al powder and the Ti / graphene composite powder are added into a ball mill to be subjected to ball milling, selective laser melting forming is conducted on the obtained Ti / Al / graphene composite powder, and the in-situ synthesis Ti2AlC / TiAl composite material distributed in a network shape is prepared. According to the method, heating ultrasonic stirring, ball milling and selective laser melting forming are matched with one another, so that an in-situ synthesized Ti2AlC reinforced phase is uniformly distributed in a TiAl matrix in a network shape, the overall deformation coordinating capacity of the material is improved due to the existence of a network structure, cracks are passivated, crack propagation is hindered, and the plasticity and toughness of the material are improved while the strength is improved.

Owner:HENAN UNIV OF SCI & TECH

A connection structure of vertical joints of superimposed shear walls

ActiveCN109868919BFirmly connectedImprove coordination and deformation abilityWallsClassical mechanicsEngineering

The invention relates to a connection structure of vertical joints of superimposed shear walls. In the present invention, horizontal stirrups are arranged along the wall height direction in the vertical joints of adjacent laminated shear walls, and the horizontal steel bars in the laminated layers of the inner and outer leaves in the laminated shear walls are extended to the vertical joints. After a certain length in the seam, it is bent and rotated to extend to the cavity layer of the laminated shear wall to form a semi-open annular horizontal reinforcement, and the horizontal stirrup in the vertical joint is placed on the semi-open annular horizontal The steel bars are bound and bound to form multiple closed hoops, and the vertical stressed steel bars are inserted into the closed hoops, and concrete is poured into the cavity layer and vertical joints of the laminated wall panels to anchor the semi-open circular horizontal steel bars . In the present invention, by inserting vertically stressed steel bars into the formed closed hoop, a reliable connection is formed between the post-cast concrete in the vertical joint and the superimposed shear walls on both sides, and the coordinated deformation of the two is improved The ability to ensure the overall mechanical performance of the two.

Owner:WUHAN UNIV OF TECH

A liquid-expanding yielding pressure, earthquake and high ground temperature bolt

ActiveCN103758550BReduce adverse effectsExtend the life cycleAnchoring boltsGround temperatureEngineering

The invention discloses a liquid-expansion type yielding anti-seismic high-ground-temperature-resistant anchor bolt which comprises a bolt body, a pressing-bearing one-way valve, oil passing holes, a sleeve, a sliding stopper, an anchoring agent layer, a slurry-blocking retainer, a hydraulic oil layer, a drill hole wall, an expansion pipe, centering devices, a bearing plate, a round-head-shaped spacer and a nut. The anchor bolt combines a yielding anchor bolt with a friction anchor bolt, and is large in ultimate elongation, strong and reliable in anchoring force, wide in application range, capable of realizing flexible yielding and well resisting impact load and excellent in anti-seismic property, and adverse impact of high ground temperature on the anchor bolt is reduced effectively; no interference and adverse impact are caused to secondary lining construction of underground engineering and sash grider construction of ground slope engineering; the anchor bolt is high in capacity of compatible deformation, good in yielding, anti-seismic and high in resistance to high ground temperature, service cycle of the anchor bolt is prolonged, and maintenance cost is lowered.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

A preparation method of wide-width ultra-thin cold-rolled titanium coil for rolling composite

ActiveCN112122382BStable productionUniform sizeMetal rolling arrangementsTitanium metalMachined surface

Owner:LUOYANG SUNRUI TI PRECISION CASTING

A preparation method for improving the coordination rheological ability of fine-grained layer and coarse-grained layer of copper alloy with gradient structure

A preparation method for improving the coordinated rheological ability of a gradient structure copper alloy fine-grained layer and a coarse-grained layer. The cast-rolled gradient-structured copper alloy sheet is subjected to solution quenching; the solution-quenched sheet is placed in fine sand ‑80℃~‑105℃ container, store for more than 15 minutes; take out the sheet, and quickly blow off the sand on the surface with high-pressure cold air at ‑80℃~‑105℃; roll the sheet with the surface blown clean , the rolling pass reduction rate is controlled at 10% to 15%; repeat in turn until the entire rolling reduction rate reaches 70% to 95%. The coordinated deformation ability of the coarse and fine grain layers of the gradient structure copper alloy strip prepared by the method of the invention is obviously improved, and no cracking occurs, so that the processing and forming performance is better, and the production is more efficient. The present invention is suitable for various series of gradient structure copper alloy materials, can greatly improve the forming effect of gradient structure copper alloy materials, and this technology can greatly promote the more extensive application of gradient structure copper alloy materials in various industries.

Owner:CENT SOUTH UNIV

A high-strength double-wall inclinometer tube for tilt displacement measurement

ActiveCN103882848BHigh mechanical strengthStrong bending resistanceFoundation testingIn situ soil foundationAxial pressurePipe fitting

The invention relates to a high-strength double-wall inclinometer casing for inclined displacement measurement. The high-strength double-wall inclinometer casing comprises a plurality of measuring pipe fittings, a plurality of pipe fitting connecting pieces and an axial pressure trigger self-opening type anchor hook base. The measuring pipe fittings are connected through the pipe fitting connecting pieces, the axial pressure trigger self-opening type anchor hook base is connected with the measuring pipe fitting which firstly conducts hole sinking, the measuring pipe fittings are provided with inner walls and outer walls, four concrete filling cavities of inner and outer pair arc structures are formed by the inner walls and the outer walls, a plurality of holes are formed in the outer walls, when the inclinometer casing is submerged in the bottom of drilled holes, pressure is exerted in the axial direction, the axial pressure trigger self-opening type anchor hook base is opened and is anchored to the pedestal rock, and when back filling is carried out on concrete, cement paste enters the concrete filling cavities through the holes. The inclinometer casing has the strong capability of resisting tension and pressure, resisting bending and resisting torsion, the compatible deformation capability of the inclinometer casing and the surrounding rock-soil layer is improved, the upward buoyancy of serous fluid on the inclinometer casing is reduced, and a base of the inclinometer casing and the bed rock are in the fixed connection state all the time.

Owner:BEIJING ZHONGLI ZHIYAN INTERNET OF THINGS TECH CO LTD

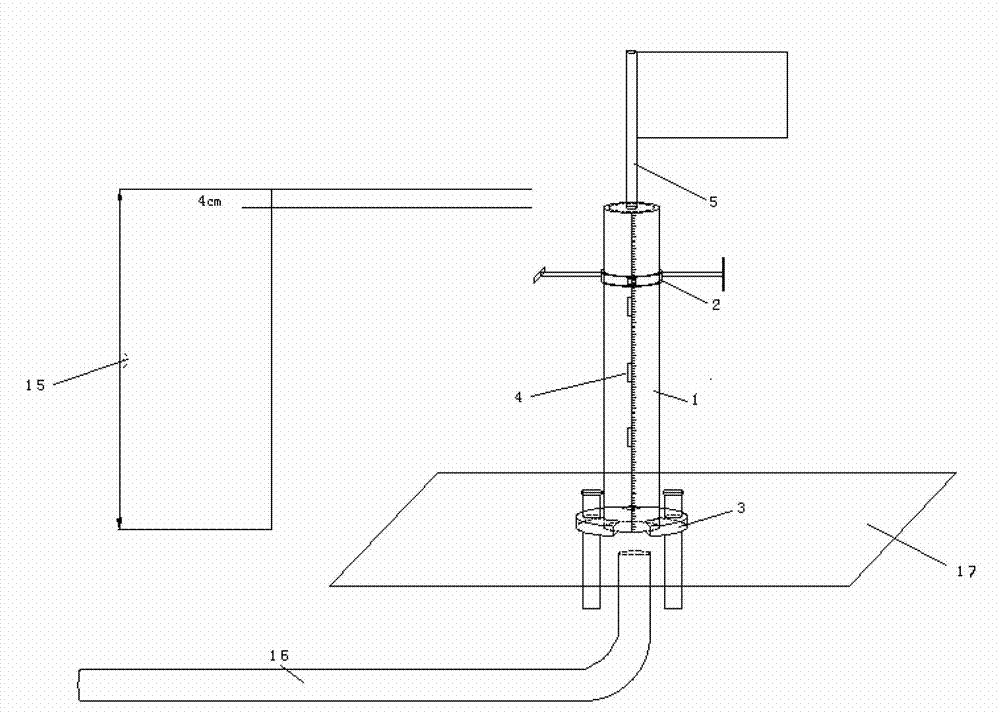

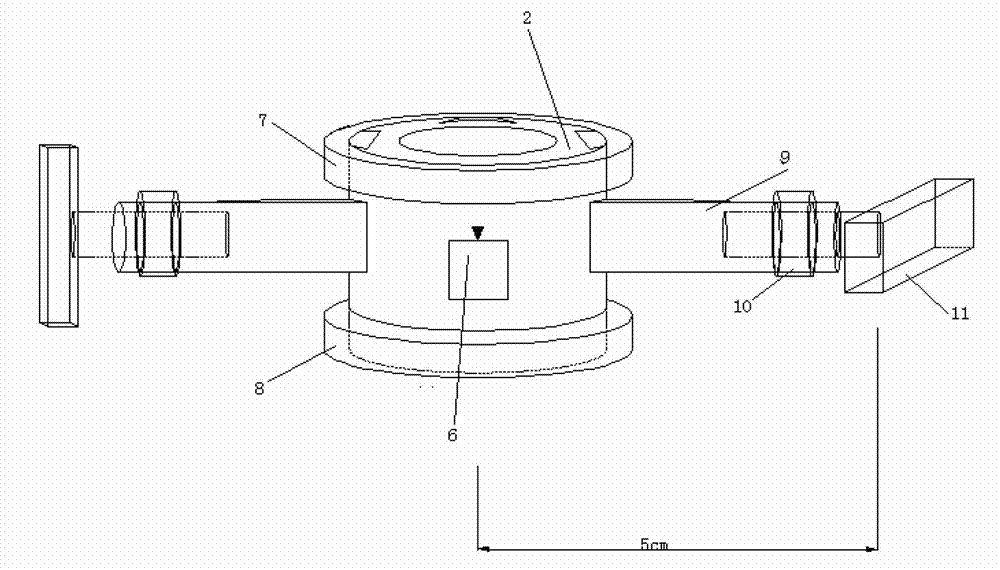

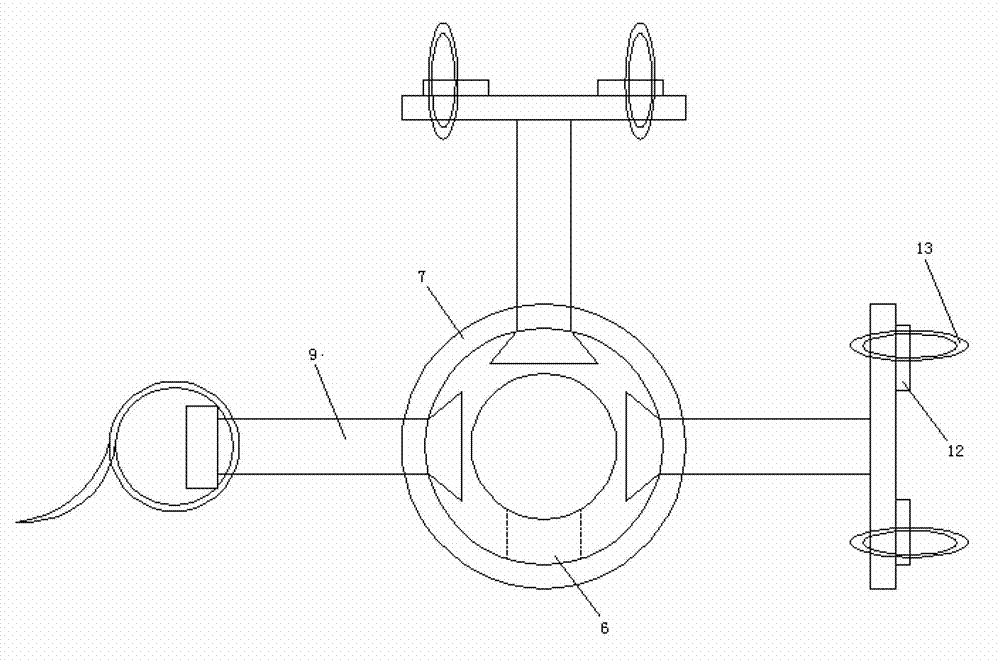

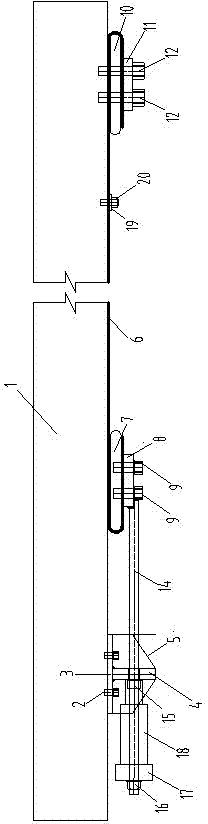

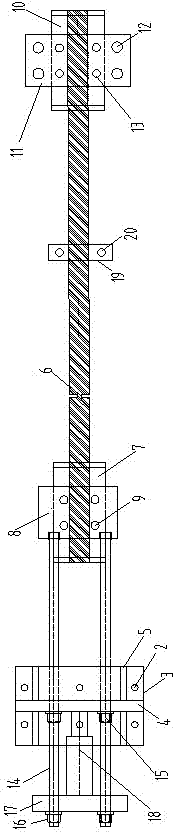

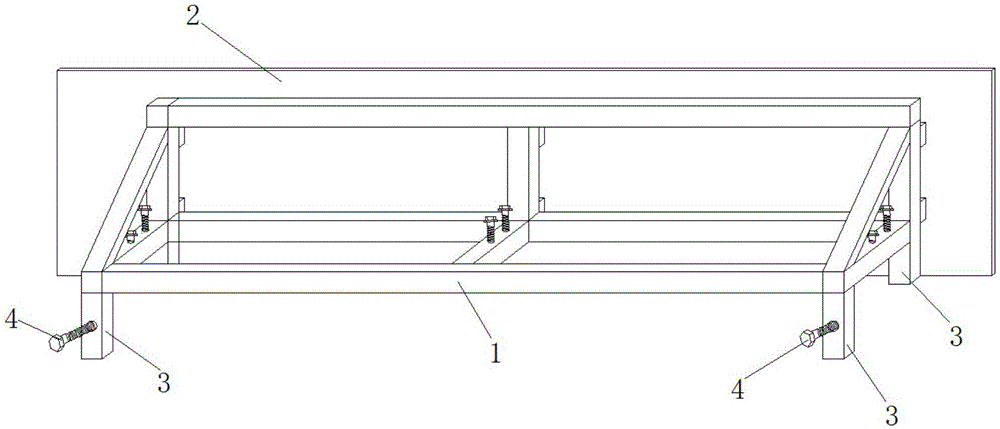

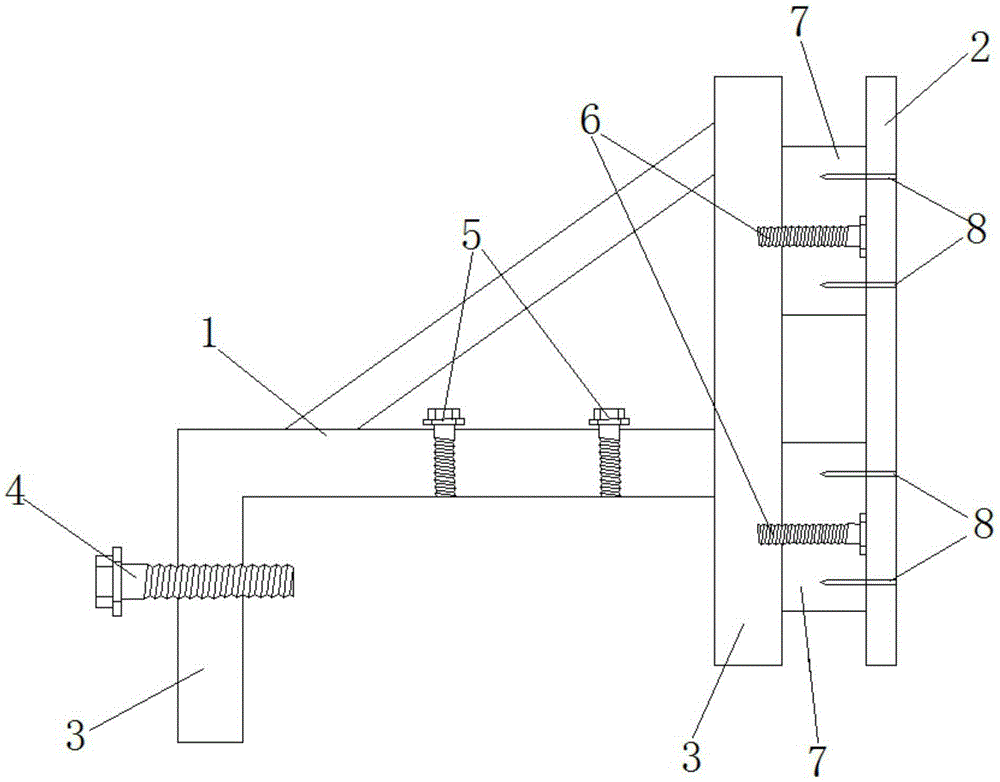

A cement concrete pavement health monitoring sensor fixing device

ActiveCN103266551BPrecise positioningEasy to fixRoads maintainenceStructure health monitoringUltimate tensile strength

The present invention relates to the field of concrete pavement structure health monitoring, particularly to a fixing device for cement concrete pavement health monitoring sensors, used for modular installation of the structure monitoring sensors rapidly and accurately. The present invention provides a fixing device for cement concrete pavement health monitoring sensors, comprising a base, a cylindrical tube and multifunctional rings. The cylindrical tube is located on the base vertically; the multifunctional rings are in lapped connection with the lateral outside the cylindrical tube; the multifunctional rings are equipped with a plurality of sensor installation beams. The sensor fixing device provided by present invention can position sensors precisely, with the advantages of easy and effective fixing way, simple fixing device structure, intensity meeting the standard, economical and reasonable materials, functional diversification, etc.

Owner:TONGJI UNIV

Compound pipe manufacturing technology for metallurgically bonding anti-corrosion special alloy lining with pipeline steel outer sleeve

InactiveCN102553961BImprove bindingImprove coordination and deformation abilityManufacturing technologySuperalloy

The invention relates to the field of processing of compound pipelines used for petroleum and natural gas, particularly relates to a compound pipe manufacturing technology for metallurgically bonding an anti-corrosion special alloy lining with a pipeline steel outer sleeve, solves the problems of poor comprehensive mechanical properties, low interface binding force and complexity in processing of a conventional compound pipe, and is applicable to compound pipelines with strong corrosion resistance and for conveying liquid or gas. The manufacturing technology comprises the steps as follows: preparing a compound pipe billet, putting an anti-corrosion special alloy inner pipe billet in a pipeline steel outer pipe billet, and tightly bonding the inner wall of the pipeline steel outer pipe billet of the compound pipe billet with the outer wall of an anti-corrosion and heat-resistant alloy inner pipe billet of the compound pipe billet through rotary extrusion of a roll expansion mandril; and heating the interface part of the inner and the outer pipe billets to the extrusion temperature under the protection of a protective coating, obtaining the finished compound pipe with the compound pipe billet through hot extrusion, and forming a diffusion layer at the interface part of the inner and the outer pipe billets under the conditions of high temperature and high pressure to realize favorable metallurgical bonding of the interface part of the inner and the outer pipe billets. The manufacturing technology is suitable for manufacturing compound pipes having anti-corrosion and heat-resistant alloy linings and having high requirements for bonding strength and mechanical property and used for oil and gas well drilling.

Owner:张皓

Construction method for strengthening long-span concrete structures with prestressed carbon fiber sheets

InactiveCN103321430BImprove mechanical performanceGive full play to high-strength characteristicsBridge erection/assemblyBuilding material handlingFiberCarbon fibers

A construction method of reinforcing a large-span concrete structure with prestressed carbon fiber sheet comprises the following steps of forming bolt embedding holes on the side surface to be reinforced of the large-span concrete structure, and embedding high-strength bolts of different specifications into the bolt embedding holes through adhesive glue; fabricating stretch sheet fixing portions, stretch sheet moving portions and stretch power fixing portions; mounting the stretch sheet fixing portions, stretch sheet moving portions, stretch sheet assembling units, stretch power fixing portions and stretch power portions, wherein the stretch sheet assembling units, the stretch power fixing portions and the stretch power portions are made of carbon fiber materials; stretching stretch sheet; and removing stretching power and tightly pressing and adhering the stretch sheet onto the surface of the large-span concrete structure. The construction method of reinforcing the large-span concrete structure with the prestressed carbon fiber sheet can achieve the gapless adhesion between the prestressed stretch sheet and the concrete structure to be reinforced, facilitate the coordination of the uniform stress force of the same sections of the carbon fiber filaments of the stretch sheet, improve the integral stress performance of the prestressed carbon fiber sheet and the coordination deformation capability of the prestressed carbon fiber sheet and the concrete structure and give full play to the high-strength characters of the carbon fiber sheet.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

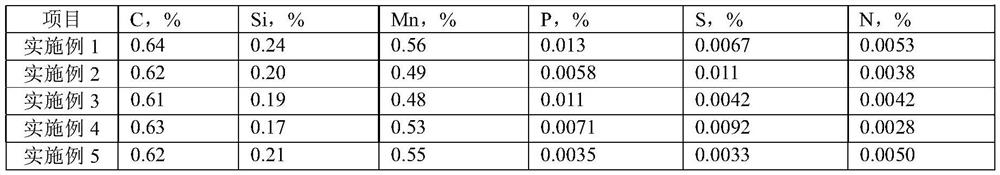

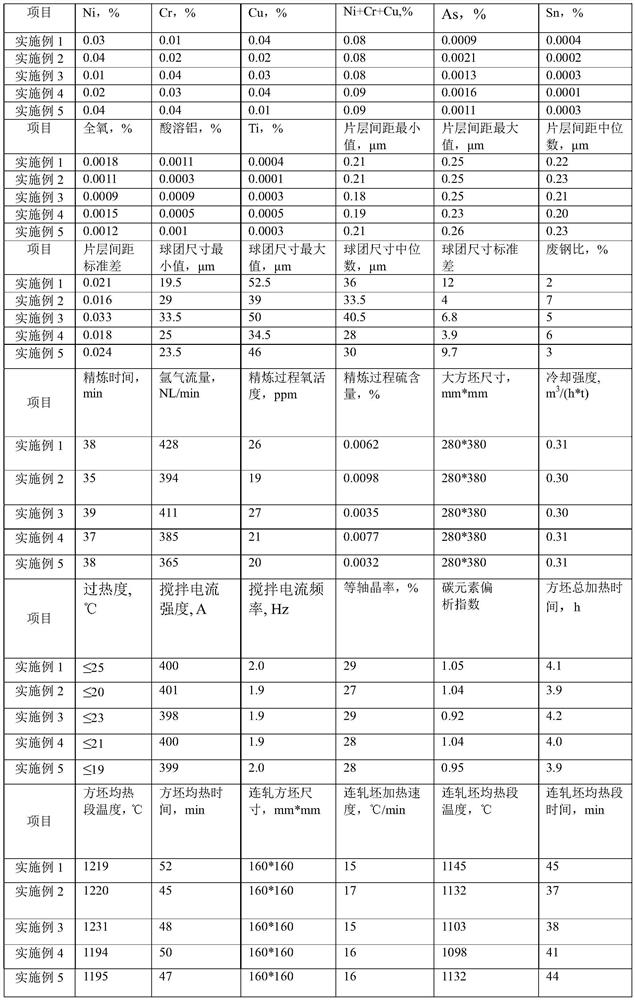

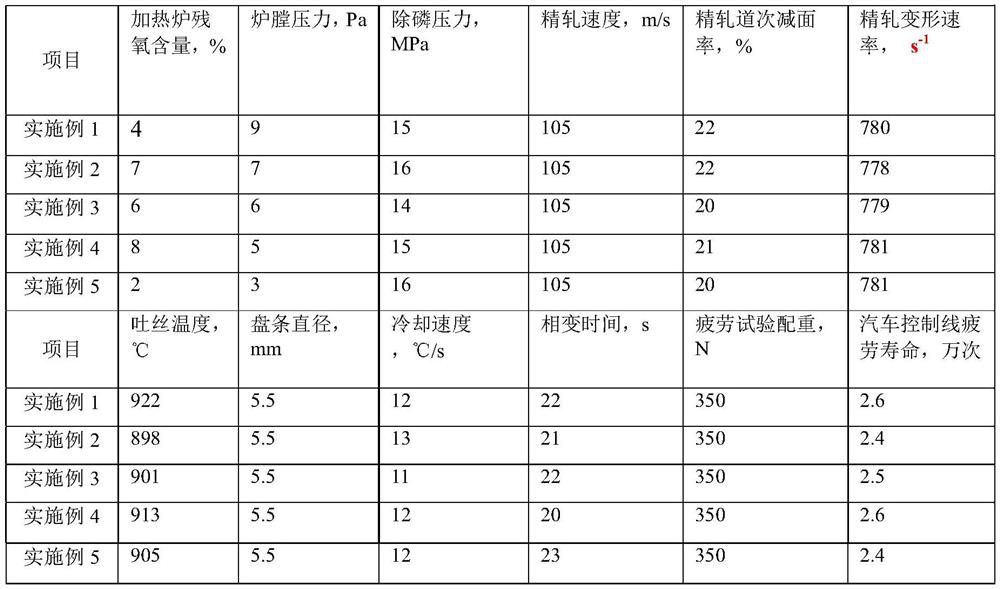

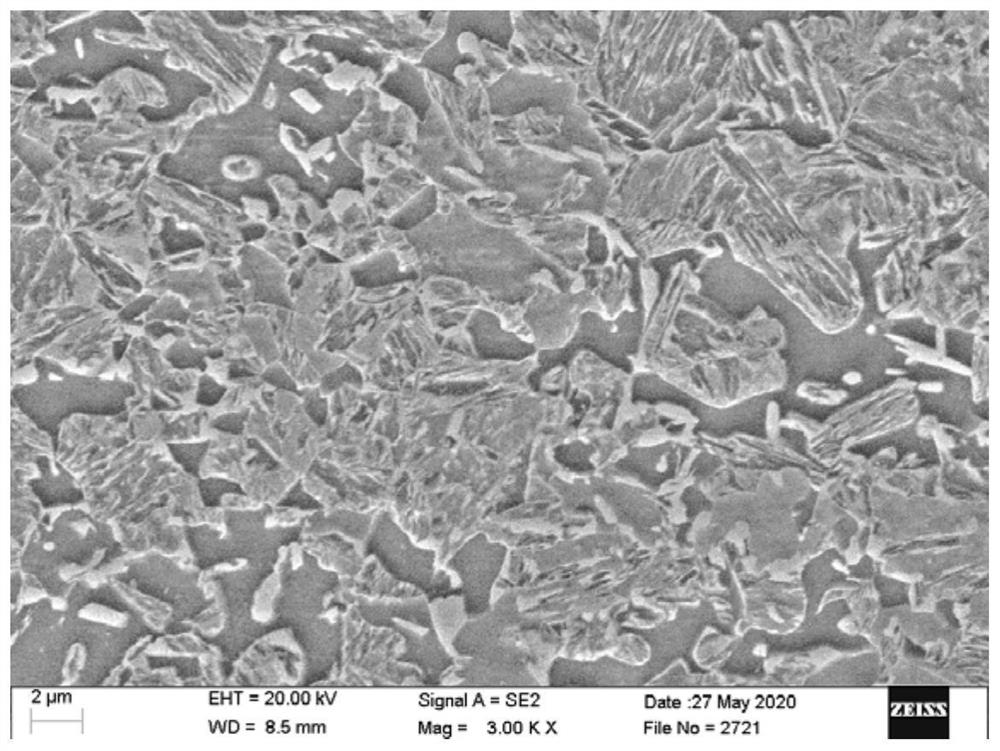

High-carbon steel wire rod with double repetitive phase structure and manufacturing method of high-carbon steel wire rod

ActiveCN114807767AReduce stress concentrationImprove pull performanceManufacturing convertersElectric furnaceWire rodPearlite

The invention provides a high-carbon steel wire rod with a double-repetition-phase structure and a manufacturing method of the high-carbon steel wire rod. The high-strength and high-toughness alloy steel comprises the following components in percentage by mass: 0.60 percent to 0.65 percent of C, 0.15 percent to 0.25 percent of Si, 0.47 percent to 0.58 percent of Mn, 0.0030 percent to 0.015 percent of P, 0.0020 percent to 0.015 percent of S, 0.0015 percent to 0.0060 percent of N, 0.01 percent to 0.04 percent of Cr, 0.01 percent to 0.04 percent of Ni, 0.01 percent to 0.04 percent of Cu, 0.0008 percent to 0.005 percent of As, 0.0001 percent to 0.0005 percent of Sn, 0.0001 percent to 0.0005 percent of Ti, 0.0008 percent to 0.0020 percent of total oxygen, 0.0001 percent to 0.0015 percent of acid-soluble aluminum and the balance of iron and inevitable impurities. The high-carbon steel wire rod provided by the invention is matched with a corresponding production process to form a double repetitive phase structure with a pearlite lamellar structure and a pellet structure, an automobile control wire with a monofilament diameter of 0.14 mm is prepared, the fatigue life reaches at least 20,000 times, and the quality of the wire rod meets the quality requirements of safety parts such as high-grade automobile control wires of users.

Owner:ANGANG STEEL CO LTD

High hole expansion and high plasticity 980mpa grade duplex galvanized steel sheet and preparation method thereof

ActiveCN113416888BControl carbon equivalentControl contentHot-dipping/immersion processesFurnace typesAlloyProcess design

The invention provides a 980MPa grade dual-phase steel galvanized steel sheet with high hole expansion and high plasticity and a preparation method thereof. The composition of the steel sheet in terms of weight percentage is as follows: C: 0.13%-0.18%, Si: 0.5%-1.4%, Mn: 2.2%~2.5%, P≤0.02%, S≤0.005%, Ti:≤0.03%, Al: 0.015%~0.8%, the balance is Fe and inevitable impurities. The manufacturing method includes the following steps: smelting, hot rolling, pickling, cold rolling, continuous galvanizing, and smoothing; the present invention realizes the force and energy index taking into account high hole expansion and high plasticity by optimizing alloy design and ingenious process design, Break through the technical difficulties that the traditional 980MPa grade steel plate is incompatible with hole reaming and drawing performance.

Owner:ANGANG STEEL CO LTD

A load-bearing and monitorable piston-type expansion joint device with resistance to shearing and non-pulling

ActiveCN114016400BGuaranteed free scaling performanceReduce displacementBridge structural detailsExpansion jointMechanical engineering

The invention discloses a load-bearing and monitorable shear and non-pull-resistant piston type expansion joint device, which comprises an I-beam and a telescopic member; rubber layers are fixed on both sides of the web plate of the I-beam and the inner side of the flange plate; The number of telescopic members is multiple, and they are arranged at equal intervals along the length of the I-beam; the retractable members pass through the web of the I-beam, and the two ends are respectively used for fixed connection with the connecting members on both sides of the I-beam. The invention adopts the I-beam and the telescopic member to form an expansion joint device with a telescopic function, which ensures the free expansion and contraction performance between the adjacent connecting members; the rubber is embedded in the gap between the I-beam and the connecting member to improve the The continuity of the overall structure and the durability of the telescopic device are improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

High plasticity magnesium alloy and preparation method thereof

InactiveCN100577837CImprove coordination and deformation abilitySignificant increase in plasticityStress concentrationUltimate tensile strength

The invention discloses a magnesium alloy with high plasticity, which contains the following components by mass percent: 0.5 percent to 4 percent of Sn, 0.1 percent to 6 percent of Pb, 0.05 percent to 6 percent of Zr, and Mg as the rest. The preparation steps thereof are as follows: materials are proportioned according to the proportion of alloy components, metals proportioned are heated and melted in protective atmosphere of SF6, the mass percent of Zr in Mg-Zr hardener is 30 percent, and the magnesium alloy of high plasticity is obtained after the temperature reaches 700 DEG C to 730 DEG C and is maintained for 5 minutes to 10 minutes. Magnesium can form a compound with both tin and lead, coordinating with deformation and alleviating stress concentration, thus greatly improving the plastic deformation capacity of magnesium alloy, not only effectively enhancing the strength of the magnesium alloy but also increasing the plasticity of the alloy. Under the function of a certain amount of Zr, tin and lead can impose a more obvious effect on the increasing of the plasticity of magnesium. The magnesium alloy of high plasticity only uses general elements of common tin and lead, thereby avoiding the use of a large amount of rare and precious elements, and has simple production and preparation technique, quite low cost and high normal-temperature plasticity.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Anti-overflow device and construction method of plant-growing ecological concrete poured on inclined plane

ActiveCN103953053BTroubleshoot overflow framing beamsSimple and fast operationExcavationsVegetationFrost

The invention discloses a spill-resistant device for vegetation form ecological concrete in bevel casting and a construction method. The device comprises a supporting frame, wherein a baffle for blocking concrete from spilling is arranged on the supporting frame, and fixing feet are arranged below the supporting frame; when the supporting frame is placed on a framework beam, the fixing feet are located on the two sides of the framework beam; fastening bolts are arranged on the fixing feet, and the supporting frame is fixed on the framework beam through the fastening bolts on the fixing feet. The construction method comprises the following steps: trimming a slope surface, constructing a slope protecting reinforced concrete framework beam, casting ecological concrete, processing the surface of the ecological concrete, grouting, and earthing for vegetation. The construction method provided by the invention makes up for a plurality of deficiencies of traditional slope protection, and effectively improves the shock resistance, the stability, the frost resistance and the durability of a slope body.

Owner:江苏金土木建设集团有限公司

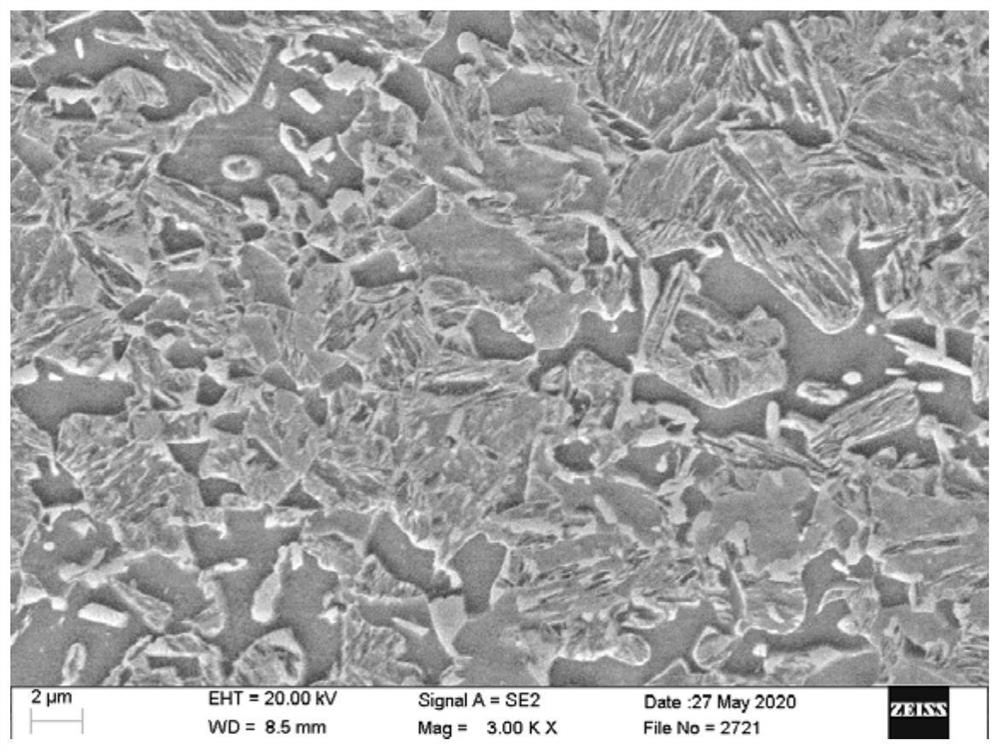

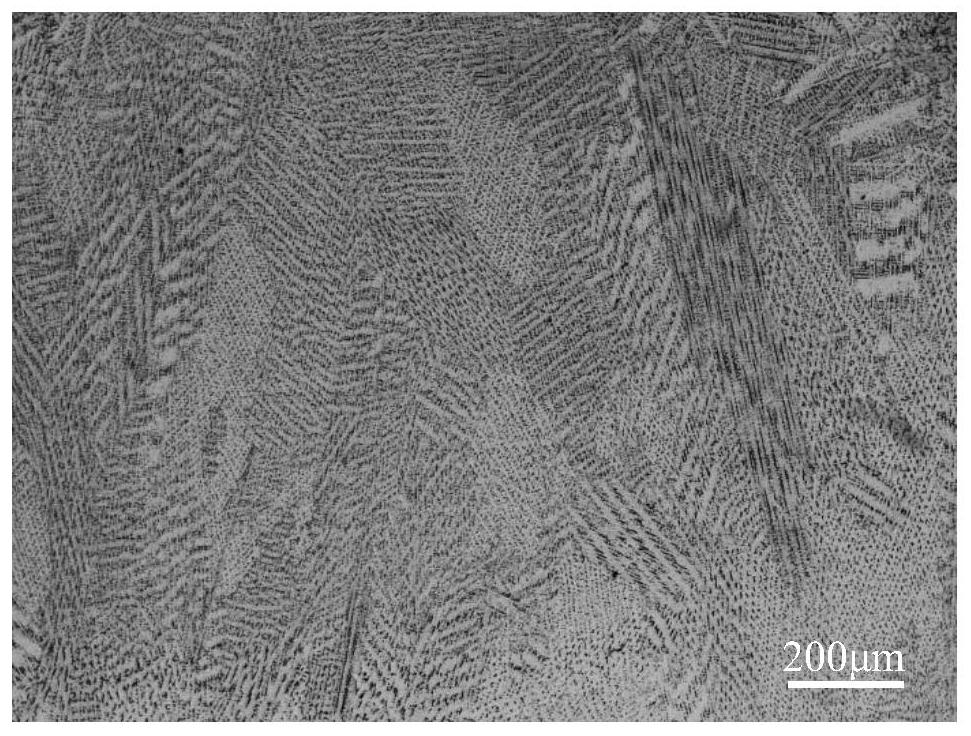

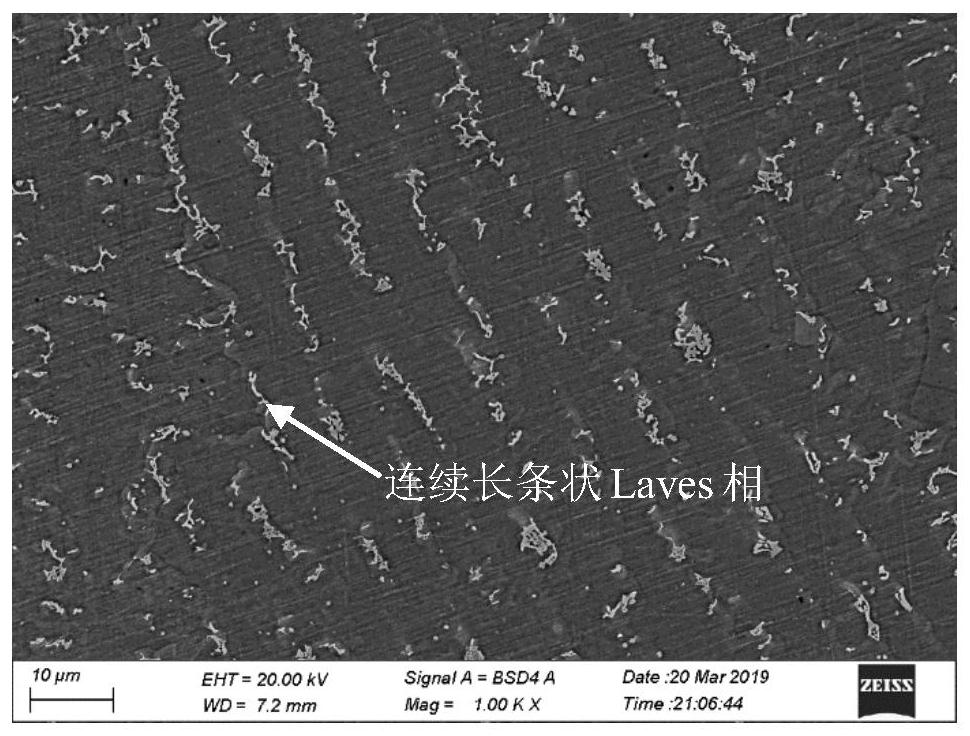

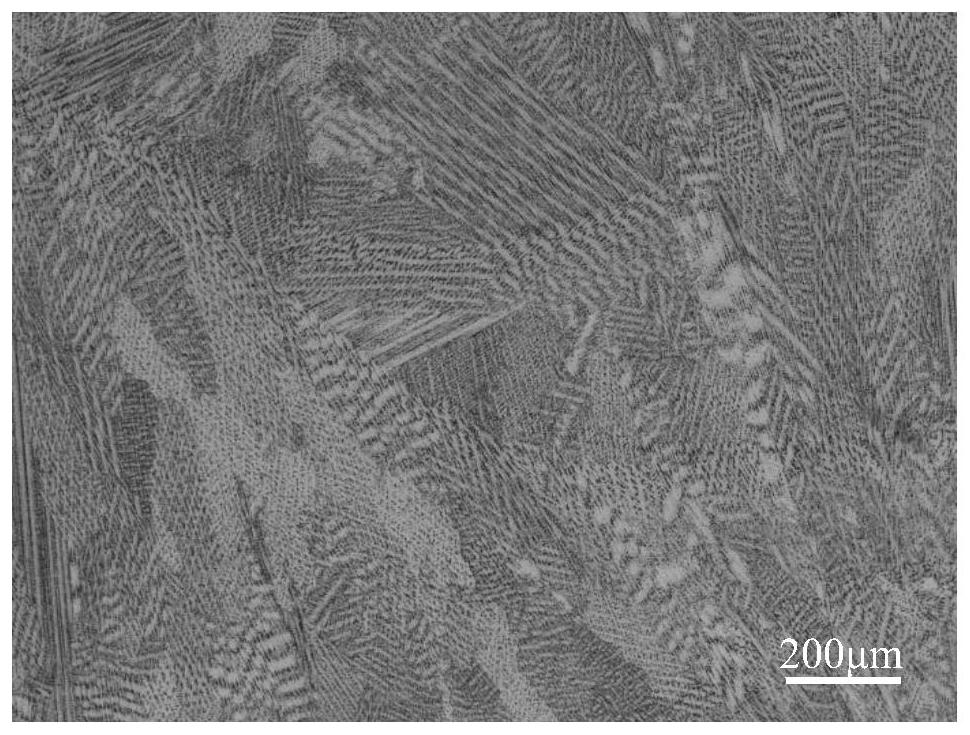

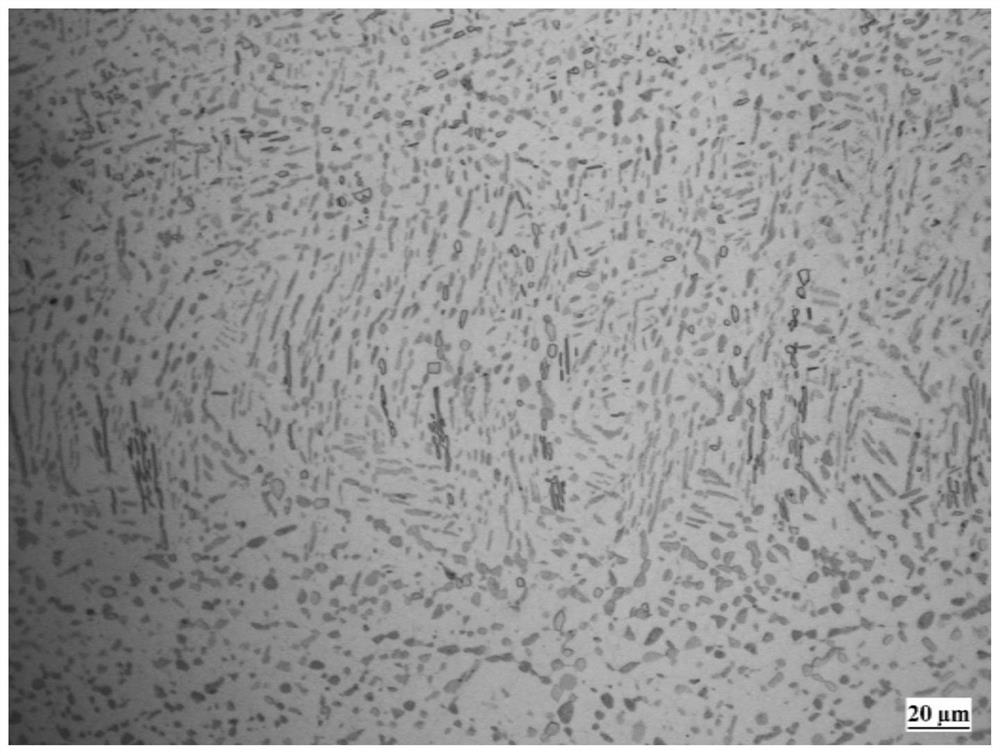

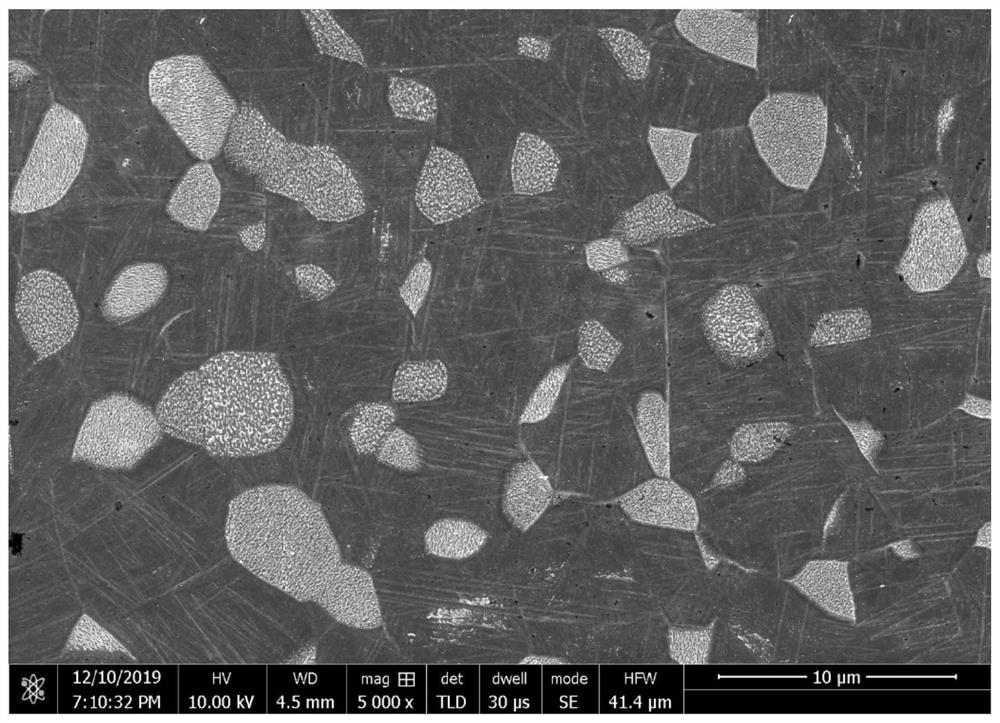

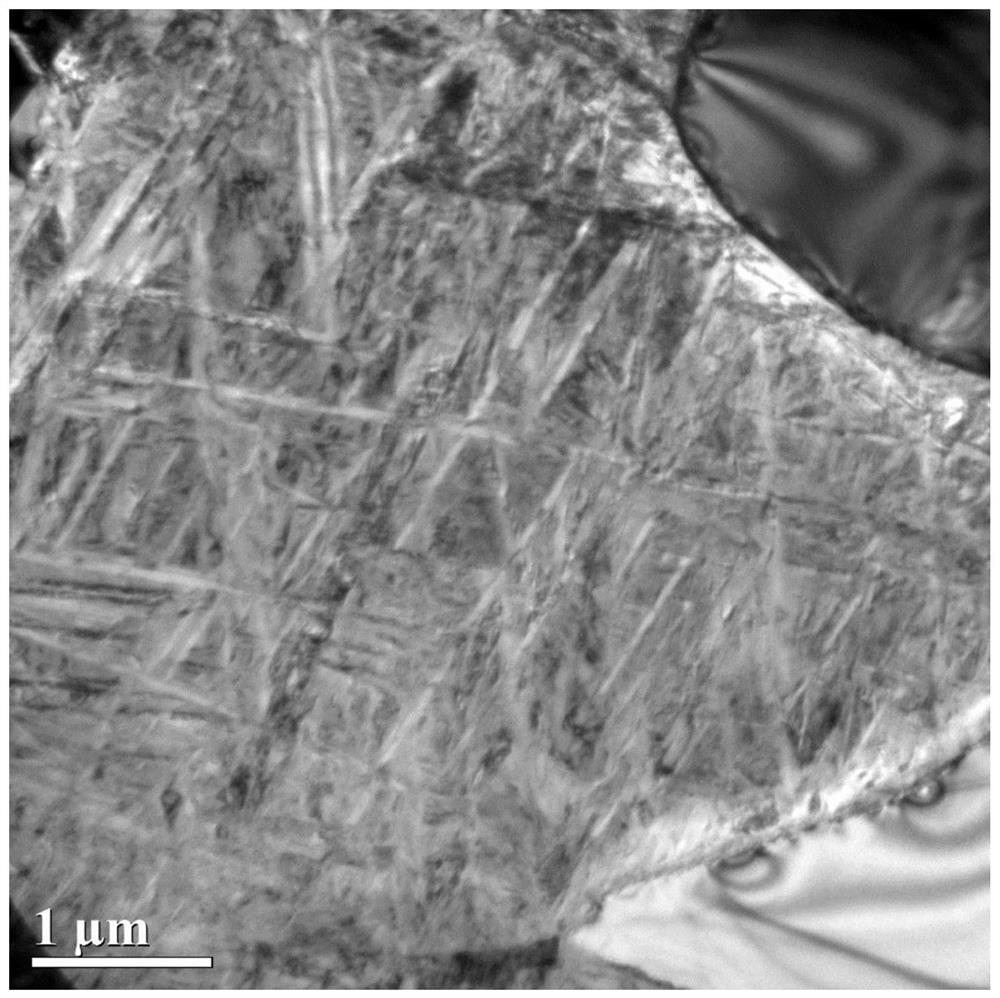

A simultaneous laser heat treatment method for laser additive manufacturing of nickel-based superalloys

ActiveCN110315075BImprove mechanical propertiesImprove coordination and deformation abilityAdditive manufacturing apparatusIncreasing energy efficiencySuperalloyLaser additive manufacturing

The invention discloses a synchronous laser heat treatment method for laser additive manufacturing of nickel-based superalloy. The method can effectively control the morphology, size and distribution of the Laves phase, and the Laves phase is transformed from a continuous long strip in a deposition state to a discrete granular shape. And its volume fraction decreased significantly with the prolongation of laser heat treatment time. The laser heat treatment method of the invention can realize the simultaneous heat treatment in the deposition and forming process, realize the regulation of the morphology and distribution of the Laves phase in the local area without affecting the tissue properties of the laser repaired substrate area, and obtain fine and dispersed granular Laves phase, thereby improving the overall mechanical properties of the parts, and can be effectively used in the repair and remanufacturing of superalloy structural parts. In addition, the invention can also be used in the fields of high-temperature alloy material preparation, rapid manufacturing of high-temperature alloy structural parts, and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of preparation method of ti-al-zr-cr series martensitic titanium alloy

ActiveCN111394616BHigh strengthGood mechanical properties at room temperatureTitanium alloyMartensite

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com