Anti-overflow device and construction method of plant-growing ecological concrete poured on inclined plane

An ecological concrete, plant-based technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of cumbersome erection and demolition, low recycling rate, affecting the construction progress, etc., to shorten the preparation time, the installation is simple and convenient, The effect of improving earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

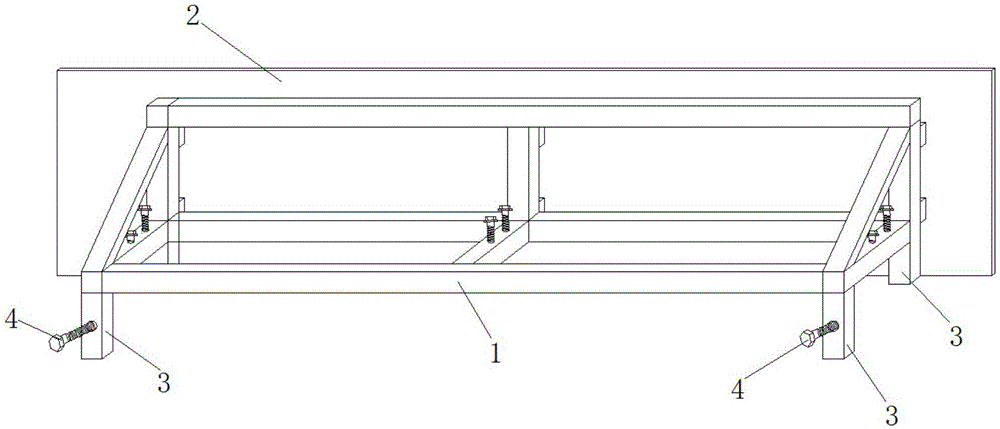

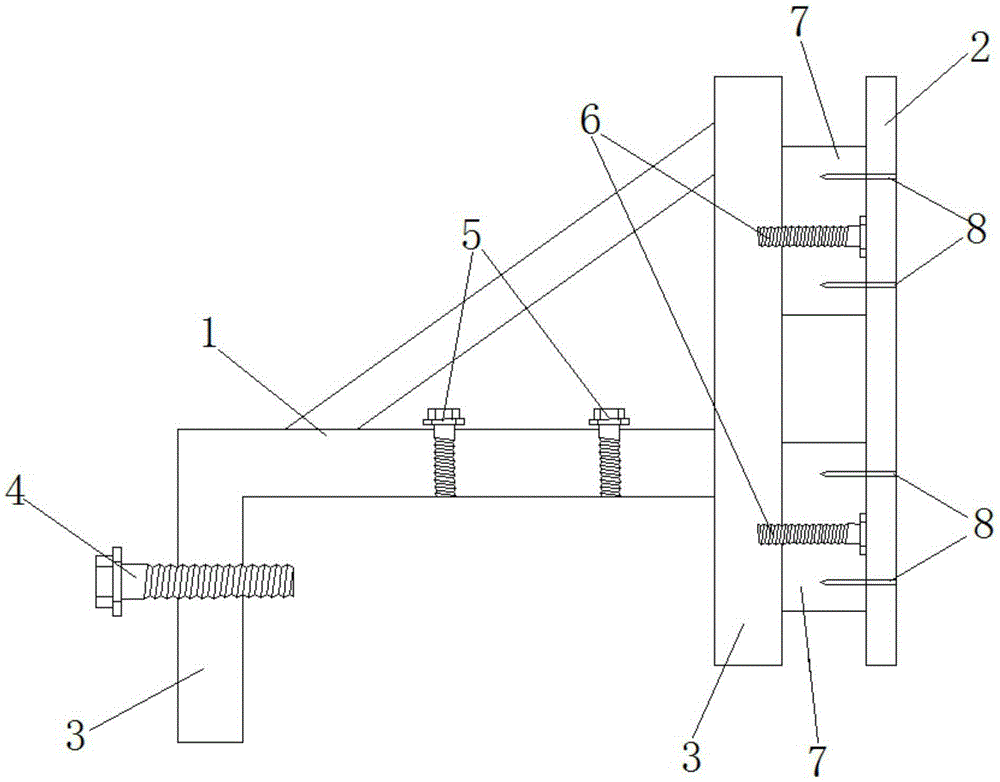

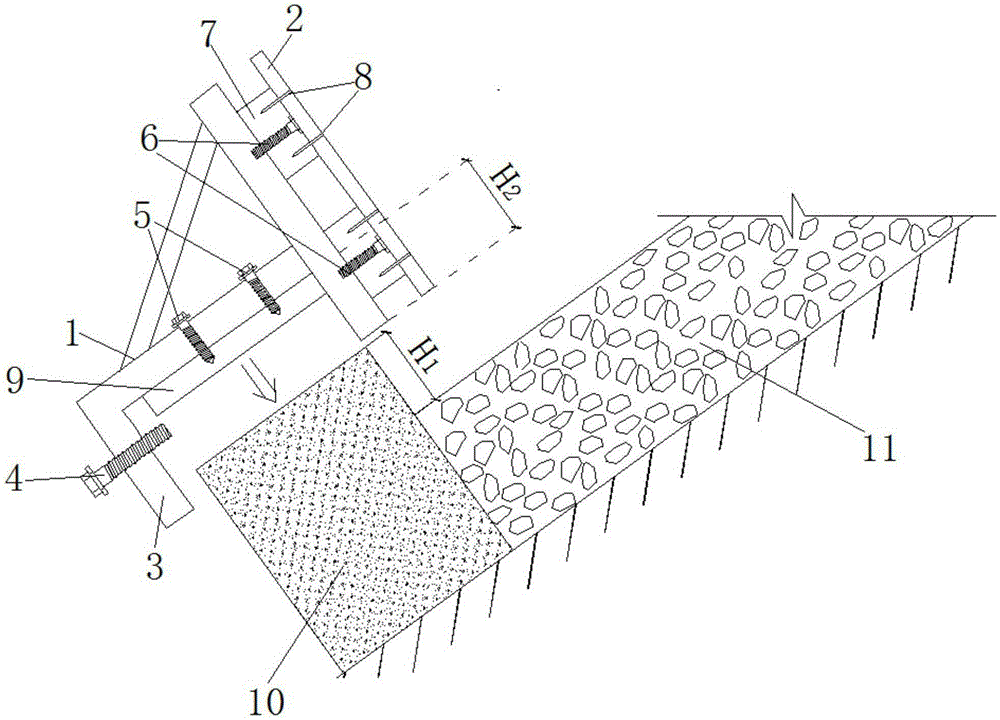

[0036] Such as Figure 1-3 As shown, a slope pouring planting type ecological concrete overflow prevention device includes a support frame 1, the support frame 1 is a skeleton structure, welded or bolted by steel square tubes with a side length of 80mm, and the whole is a right-angled triangular column Body shape (the support frame 1 is not limited to the shape of a right-angled triangular prism). Below the support frame 1, a fixed foot 3 is arranged, and the fixed foot 3 is located on both sides of the bottom of the support frame 1 (both sides at the bottom of the support frame 1 in the length direction of the frame beam), specifically the fixed foot 3 is arranged on a right-angled triangular column On a right-angled surface of the body-shaped support frame (this right-angled surface is used as the bottom surface of the support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com